Description

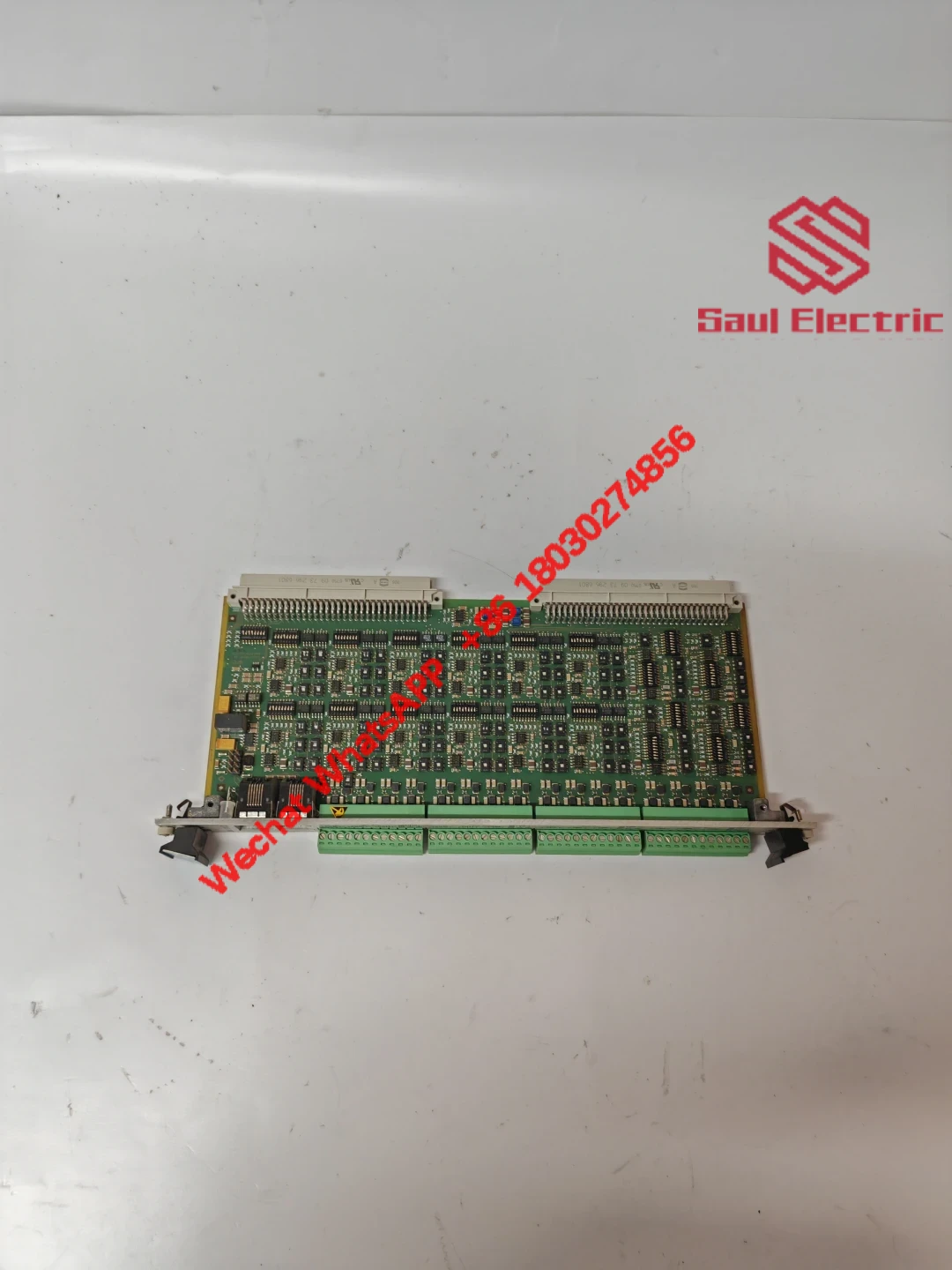

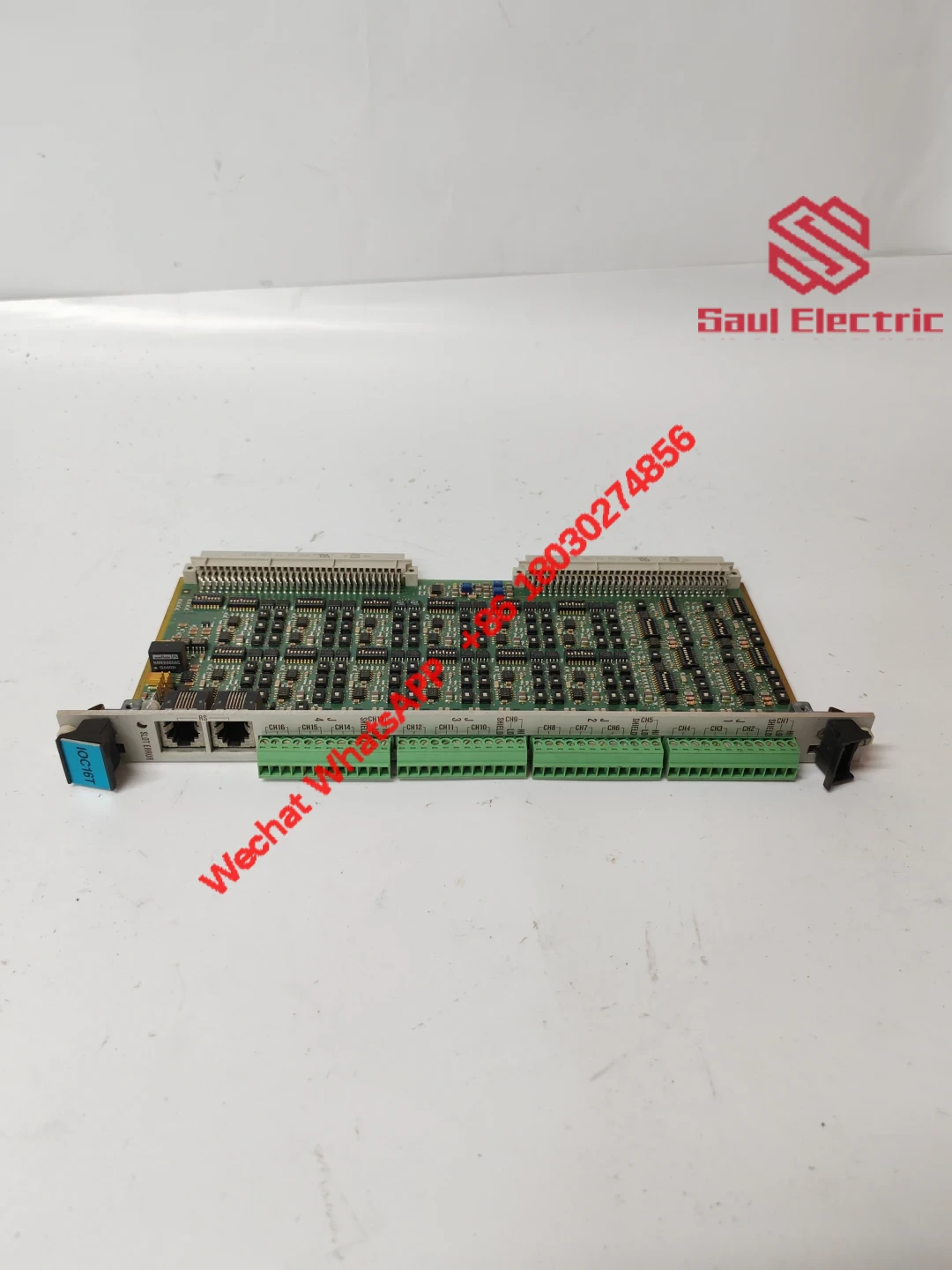

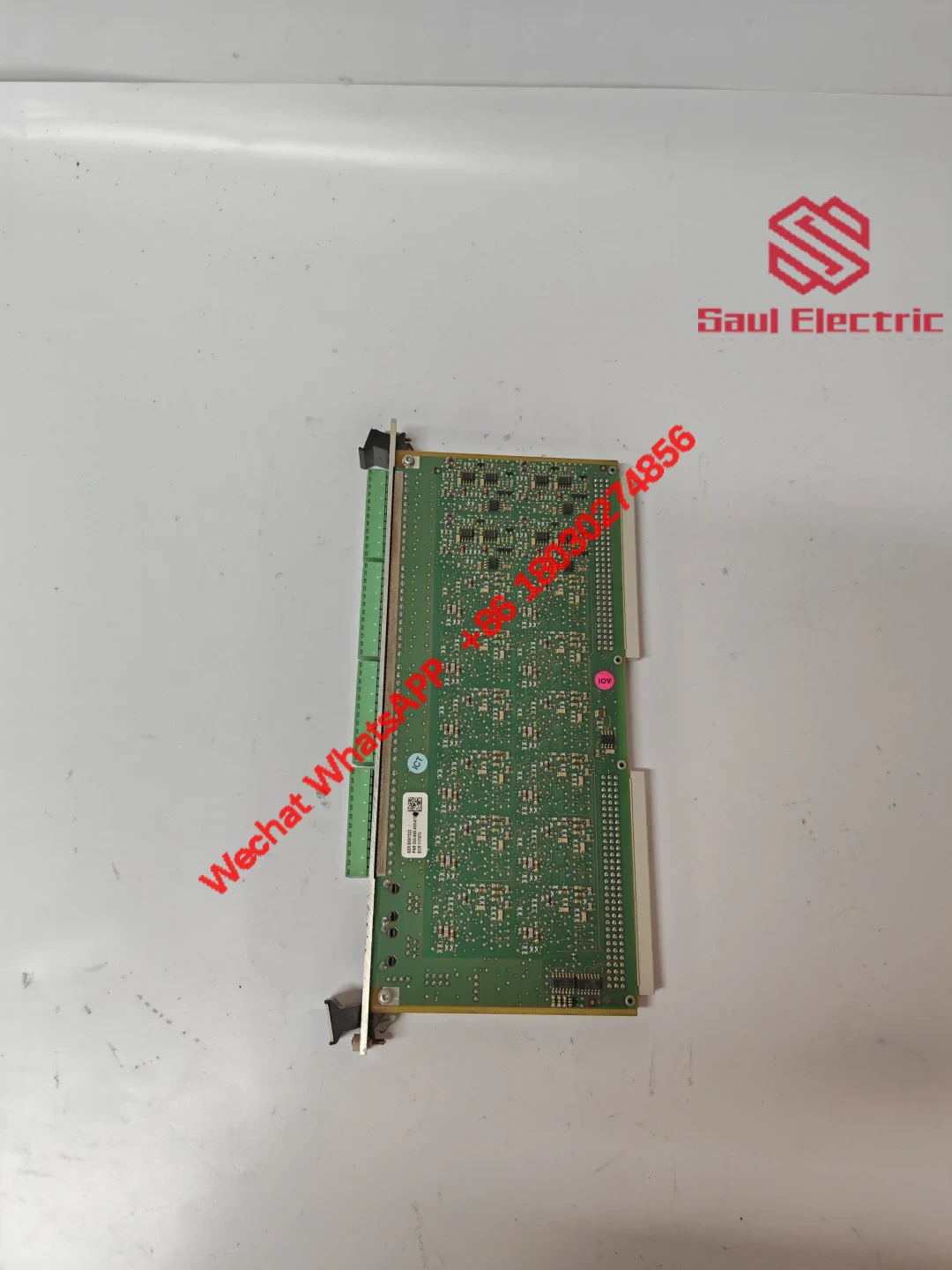

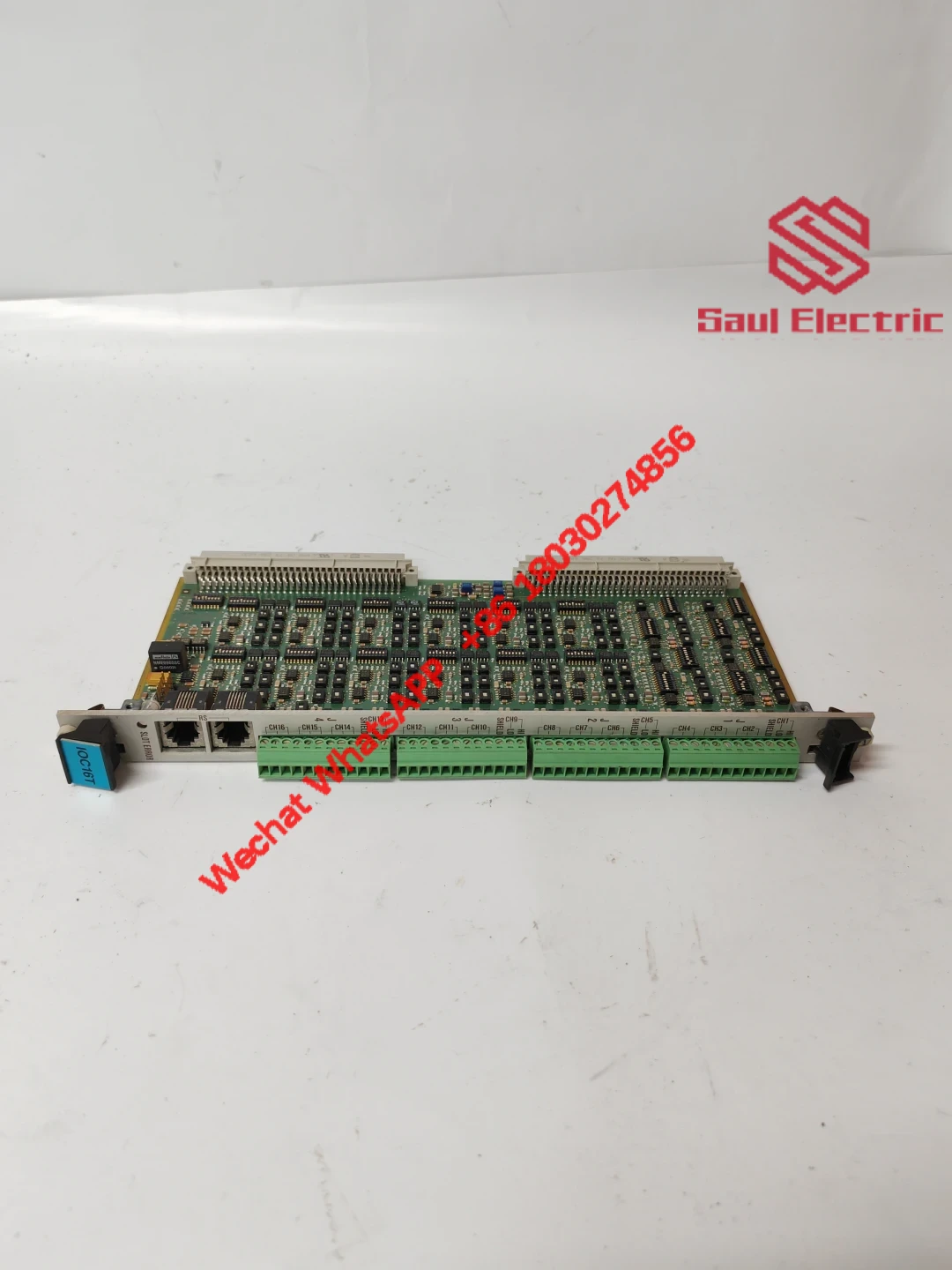

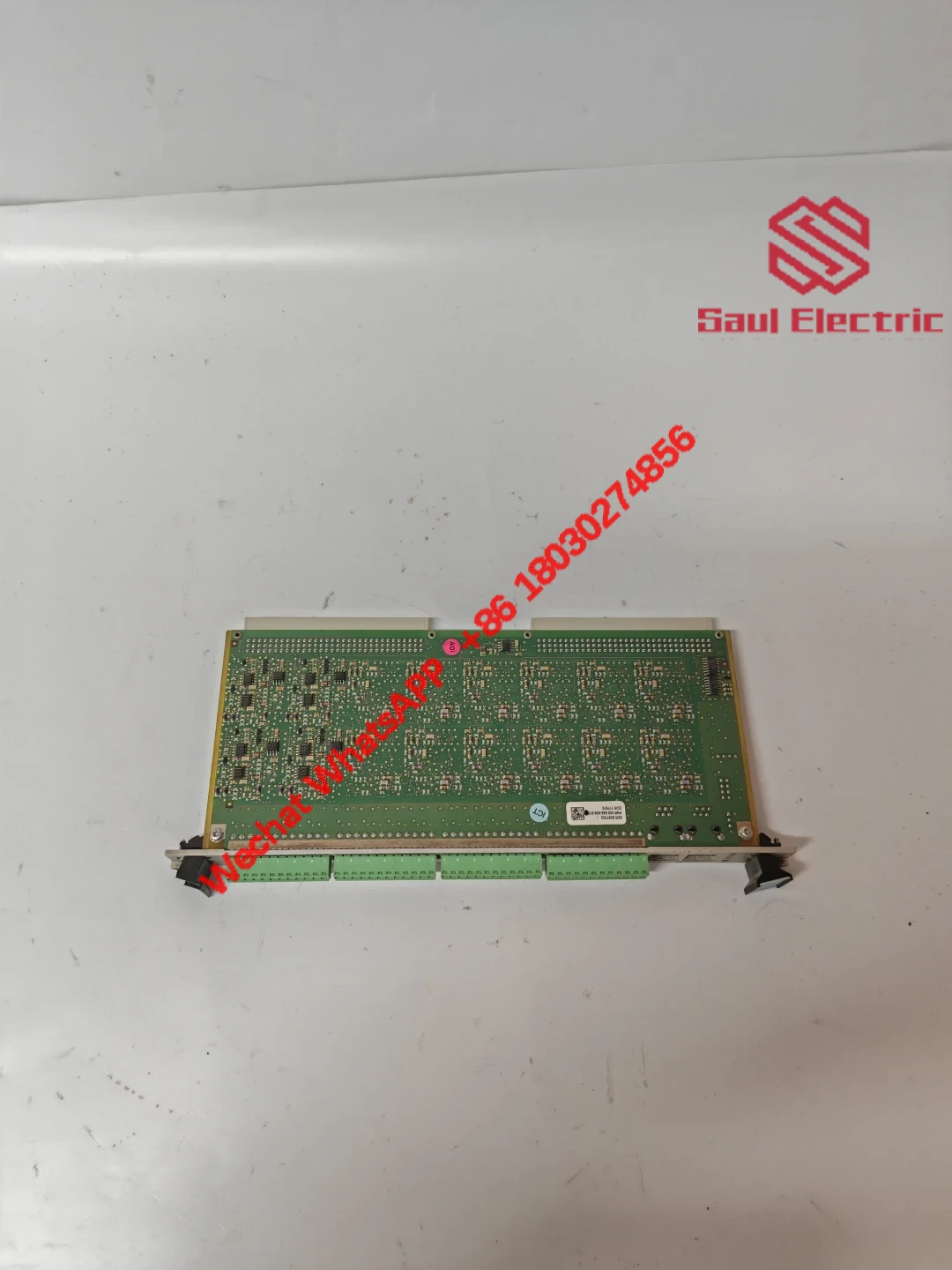

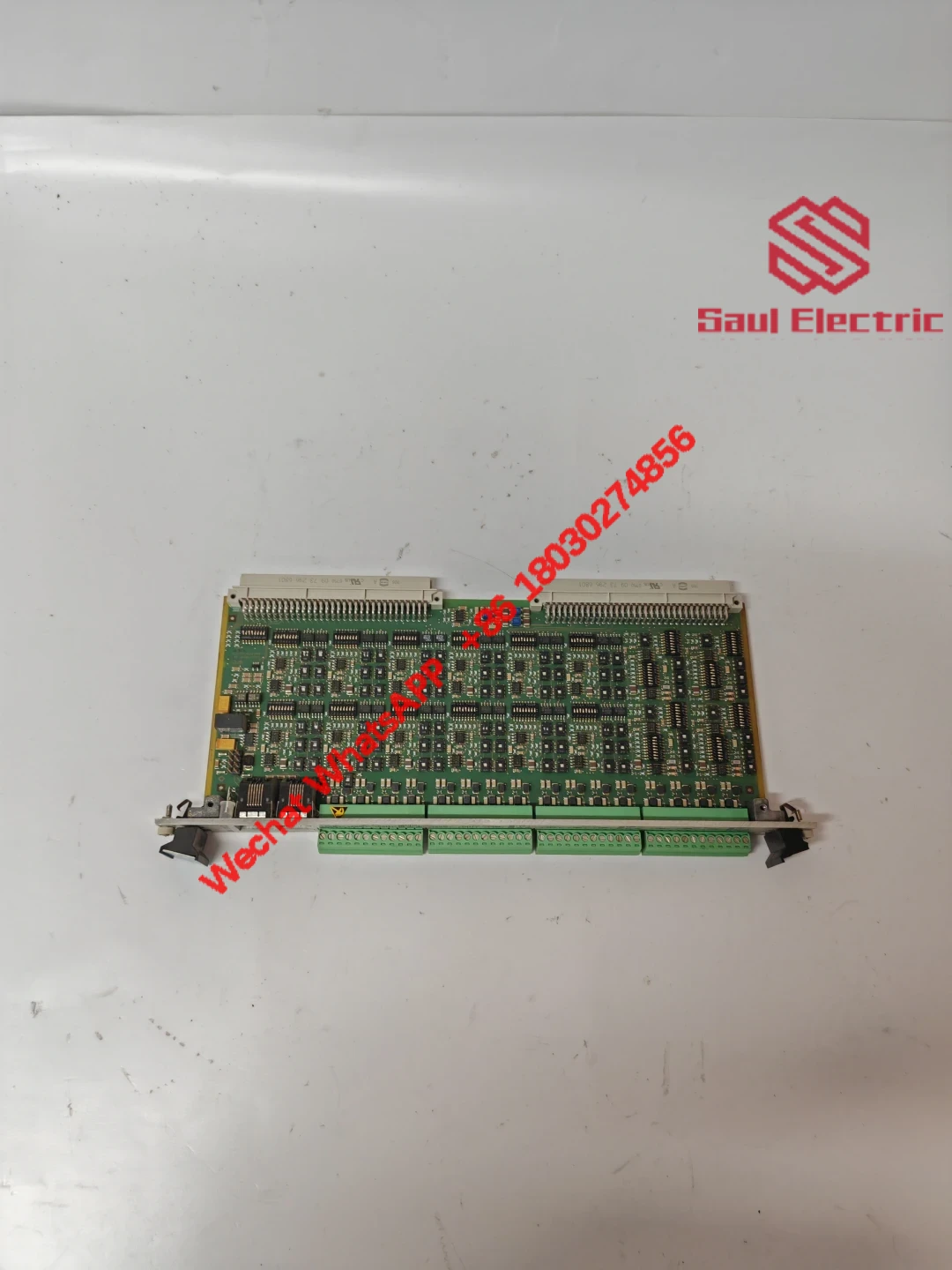

Vibro-meter VM600 IOC16T Industrial Control Module

This dual-variant control module (200-565-000-013 & 200-565-101-013) serves as the nervous system for precision monitoring in industrial environments. Originally developed for turbine monitoring systems, its 16-channel architecture handles vibration analysis and process control across manufacturing, power generation, and heavy machinery applications where measurement accuracy matters.

Technical Specifications

| Attribute | Specification |

| Manufacturer | Vibro-meter |

| Operating Voltage | 30 V |

| I/O Channels | 16 Total Channels |

| Certification | Standard Industrial Certification |

| Environmental Rating | IP20 (Typical Industrial Conditions) |

While originally designed for turbine vibration monitoring in power plants, this module’s modular architecture works equally well in chemical processing facilities and steel mills. We’ve seen customers integrate it with Bently Nevada 3500 systems for hybrid monitoring solutions, while others pair it with Triconex safety systems for redundant protection. The 200-565-101-013 variant with enhanced signal filtering finds particular use in high-vibration environments like offshore drilling platforms. Compatibility extends across major DCS platforms including Emerson Ovation and Westinghouse WDPF systems.

The module’s real strength lies in its field-proven reliability under mechanical stress – one customer in Norway’s oil sector reported zero failures across 8 years in platform vibration monitoring. Its dual-channel redundancy design (when paired with matching modules) provides fail-safe operation for critical rotating equipment. The 200-565-000-013 base model handles standard applications, while the 200-565-101-013 adds galvanic isolation for electrically noisy environments. Engineers appreciate the tool-less DIN rail mounting and front-panel status indicators that simplify troubleshooting during plant shutdowns.

Reviews

There are no reviews yet.