Description

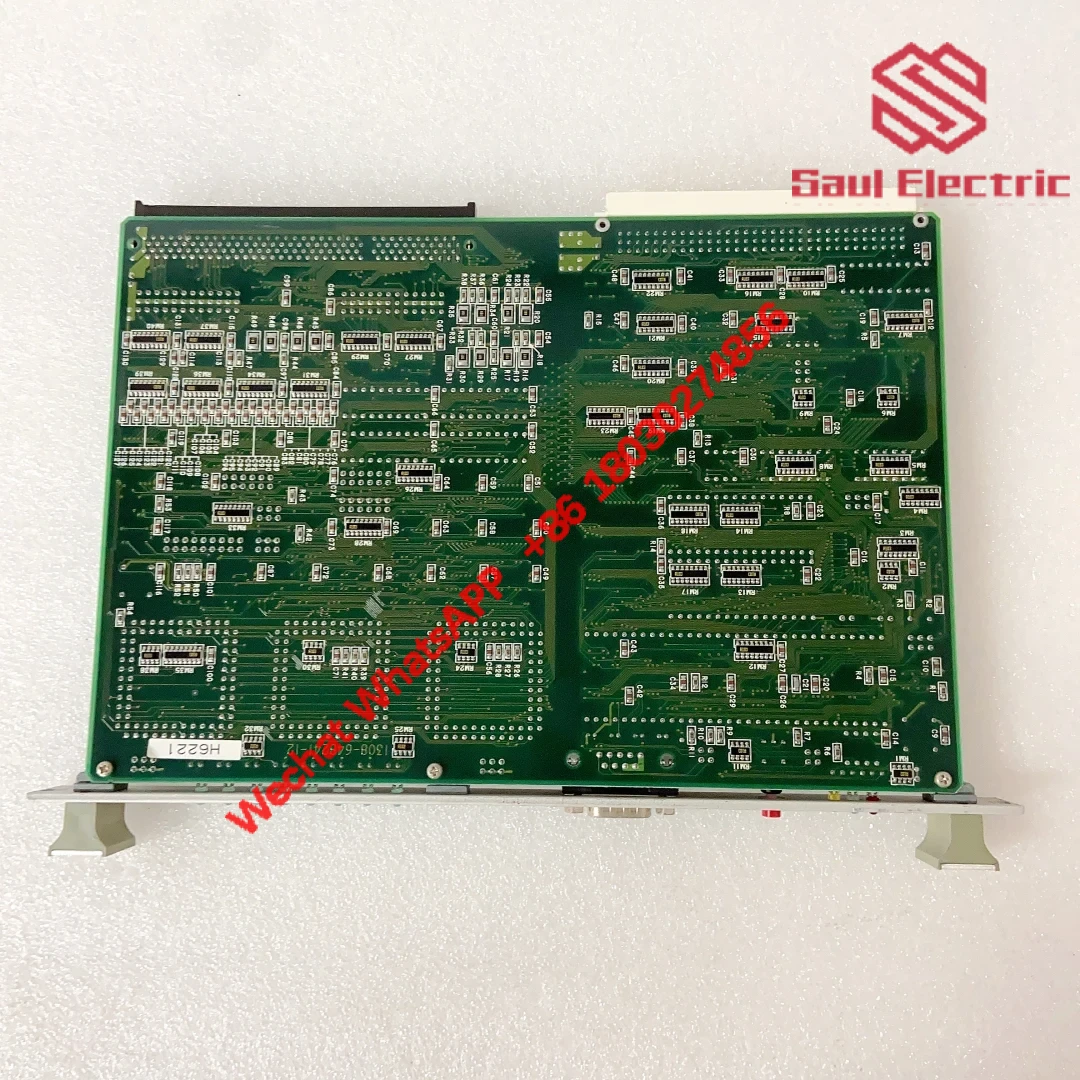

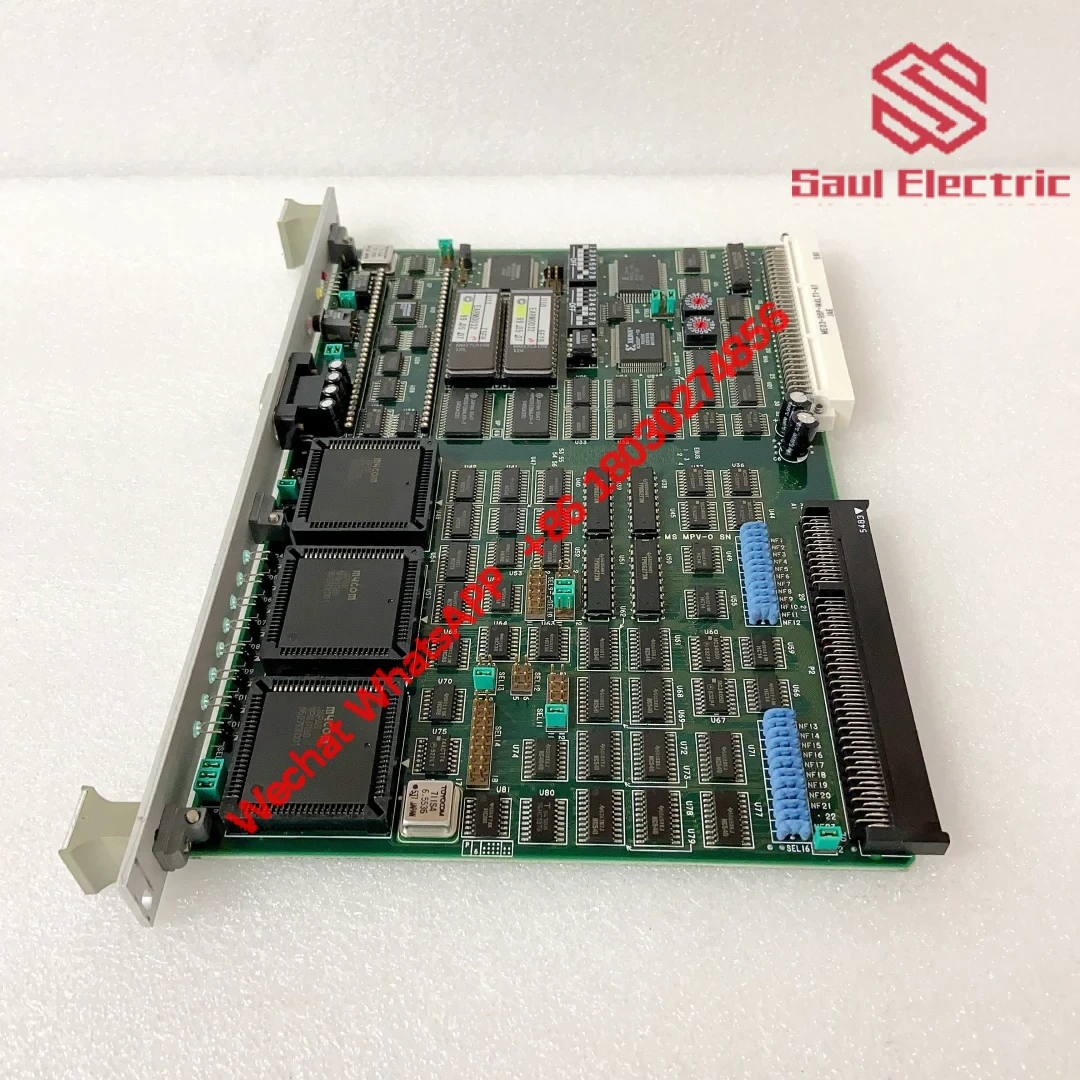

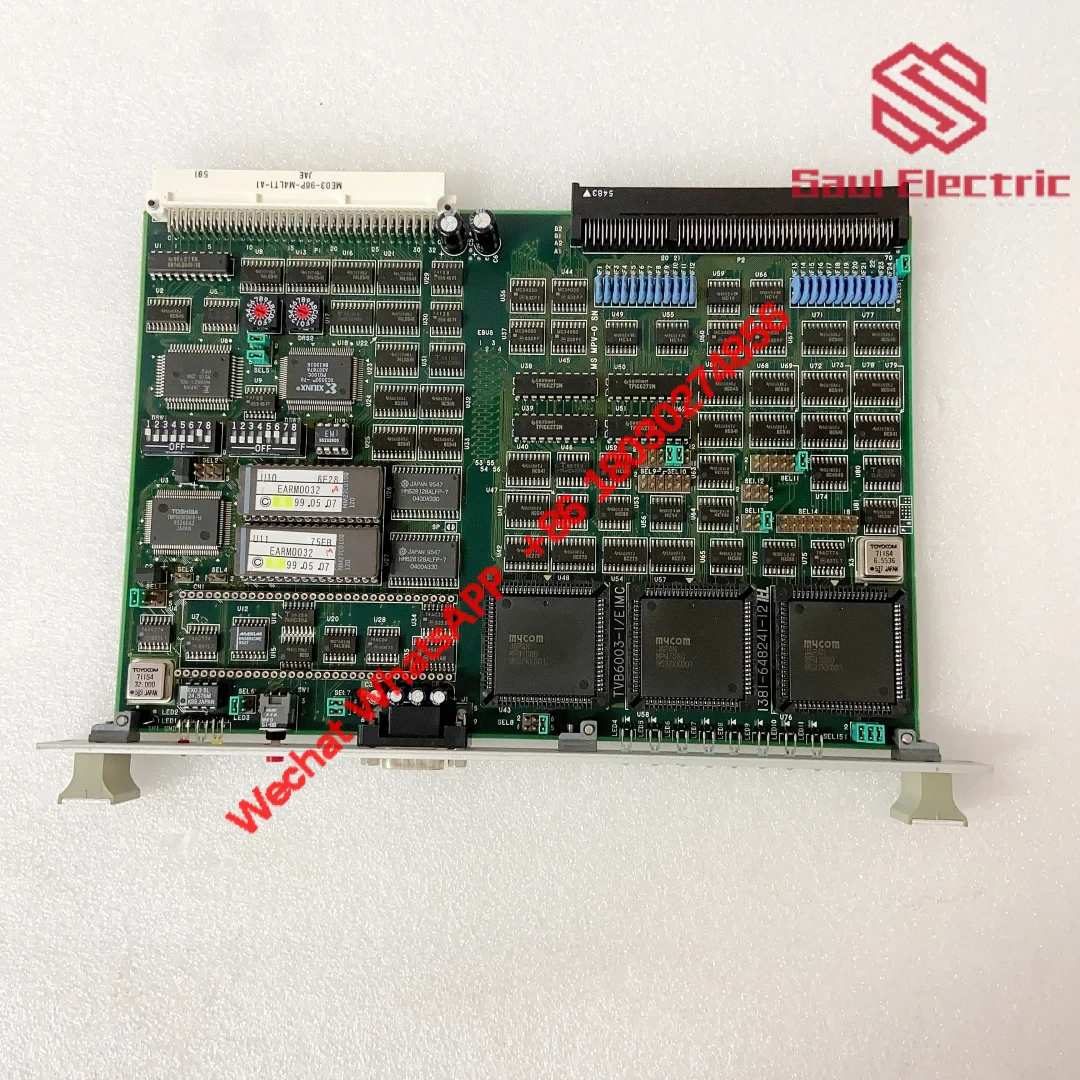

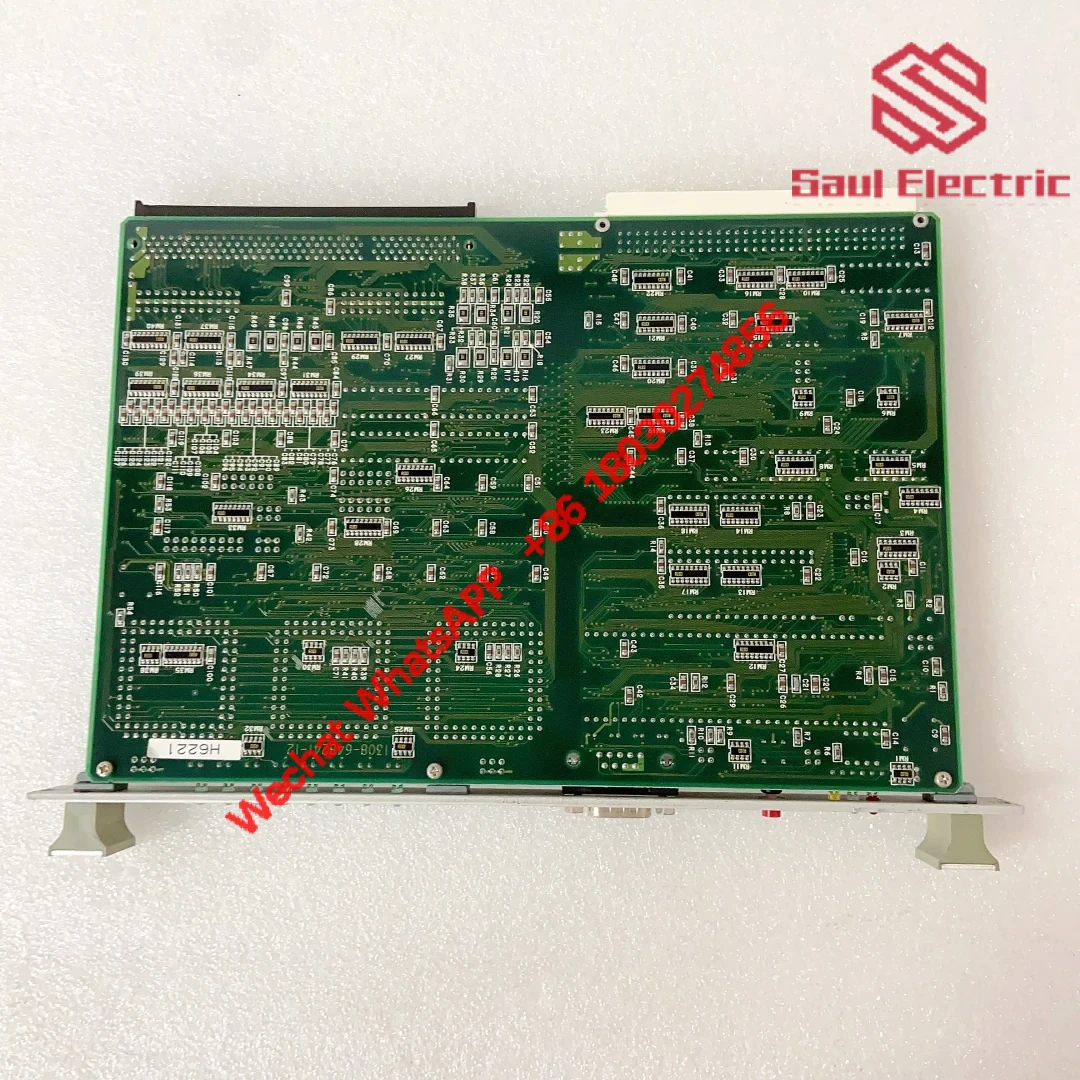

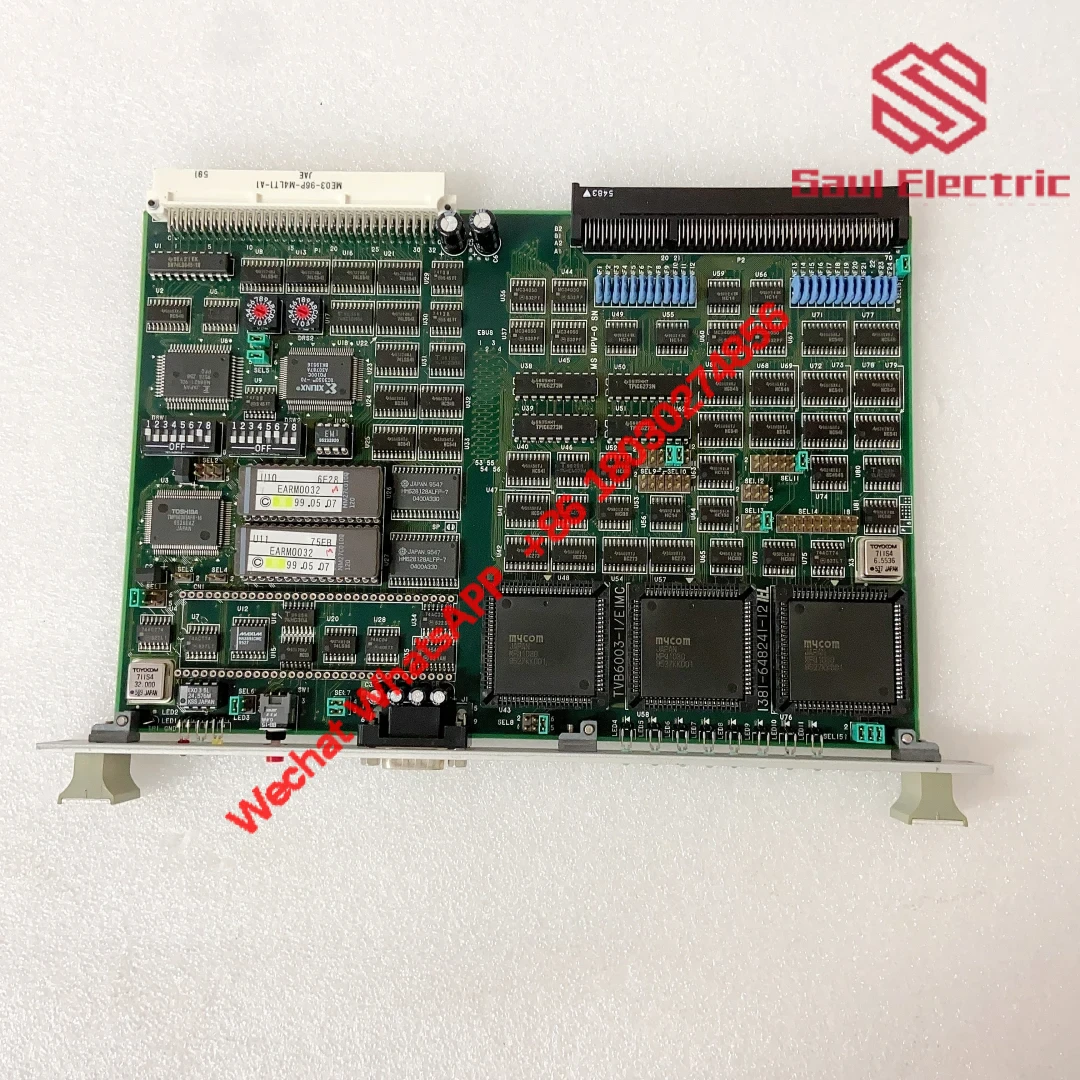

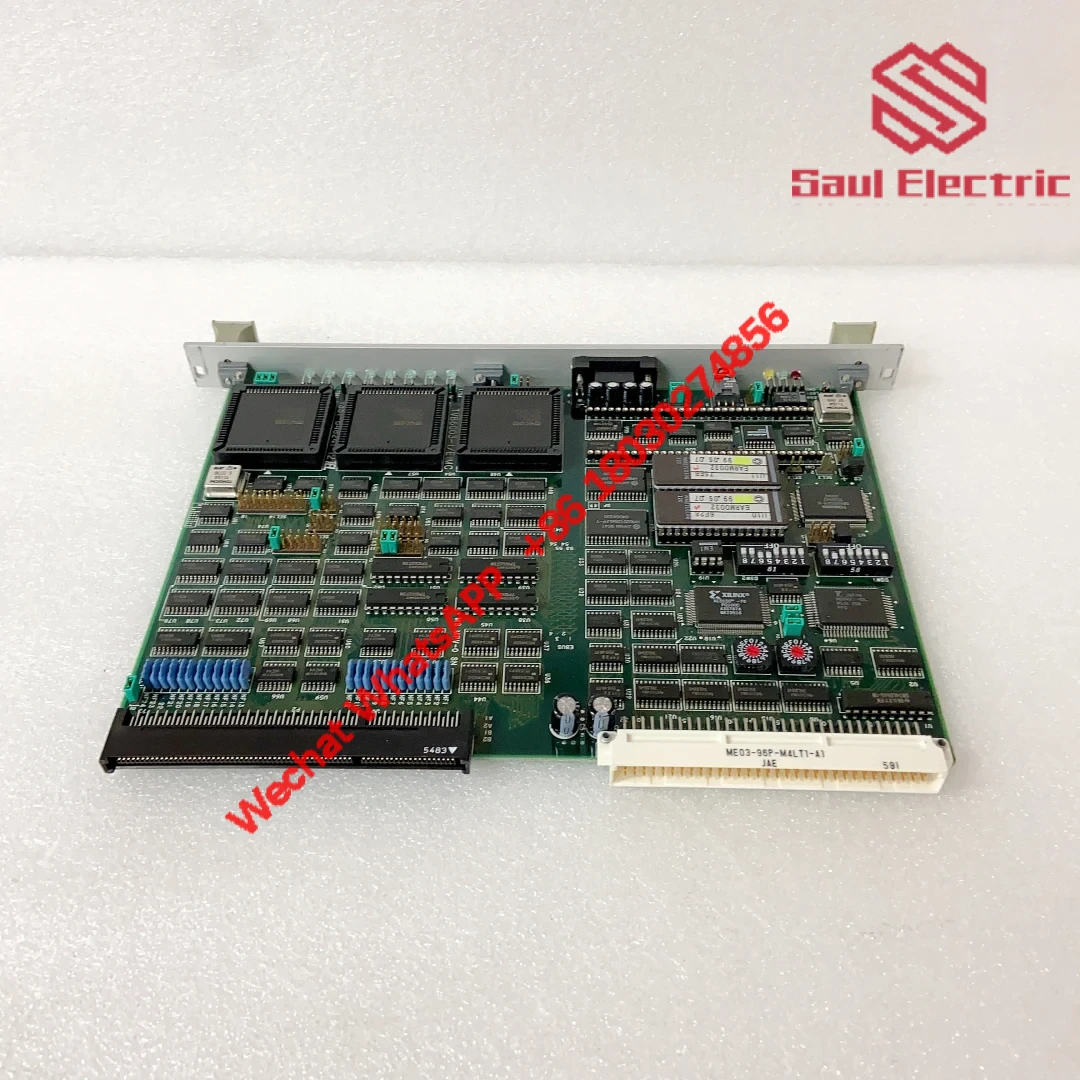

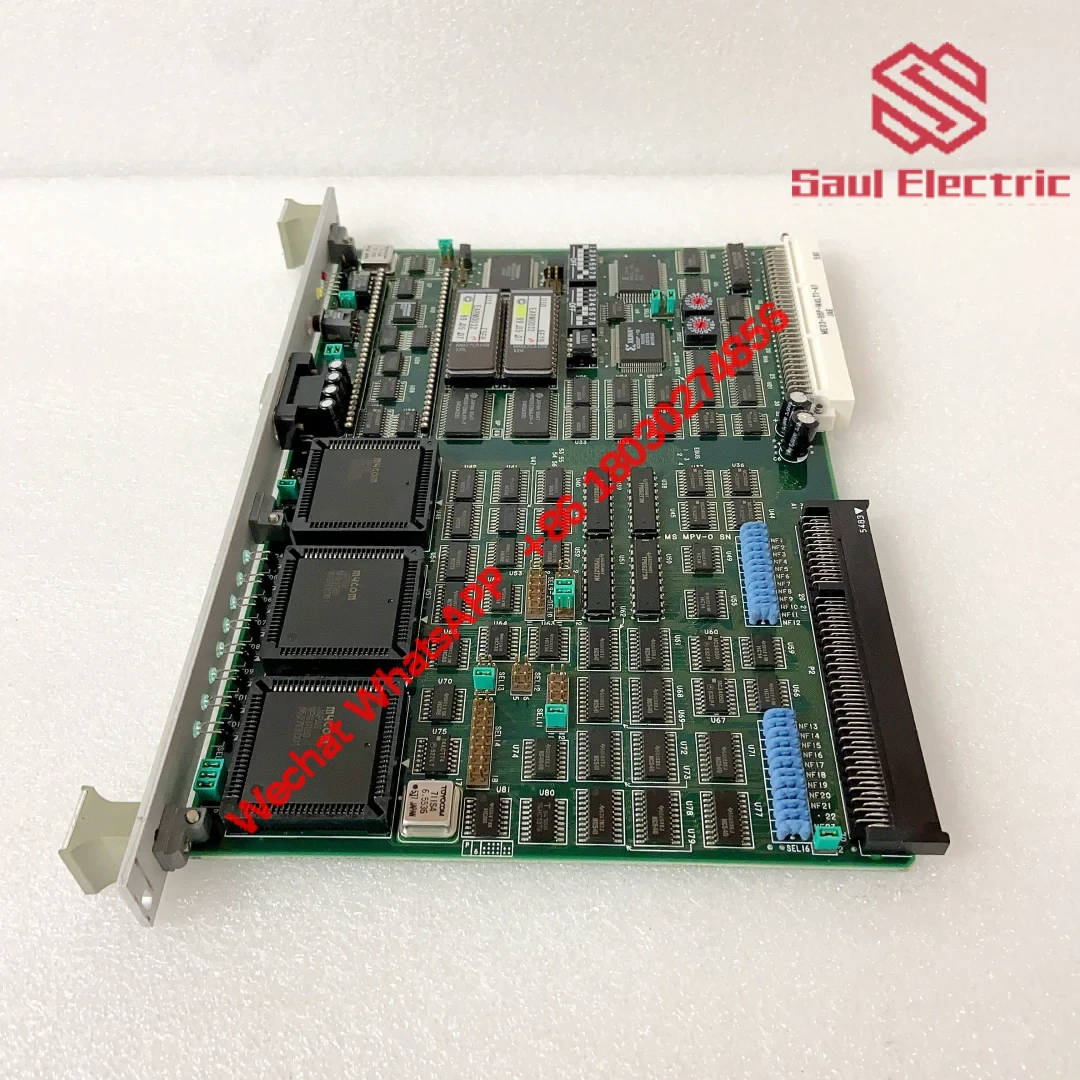

TVB6003-1/EIMC 1381-648241-12 Electronic Temperature Control Module

The TVB6003-1/EIMC 1381-648241-12 serves as a precision temperature management solution for industrial automation systems. Its primary role involves maintaining tight thermal control in machinery and processes where temperature deviations could impact product quality or operational safety. Common deployments include plastics molding equipment, chemical processing plants, and semiconductor manufacturing lines where stability matters.

| Specification | Details |

|---|---|

| Manufacturer | Various Industrial Equipment Suppliers |

| Accuracy | ±0.1°C |

| Control Method | Programmable PID |

| Response Time | ≤100ms |

| Output Types | PWM, Analog, Digital |

| Power Requirements | 24V DC (12-30V range) |

| Environmental Rating | IP20, -20°C to +70°C operating |

Industrial environments like food processing facilities and automated test benches frequently pair this module with complementary control hardware. For instance, Foxboro FBM203/217 I/O modules often interface with TVB6003-1/EIMC units through shared RS485 networks in packaging line temperature monitoring systems. Similarly, GE’s VMIVME-7750 motion controllers have been successfully integrated in plastics extrusion setups where maintaining 0.5°C process stability directly impacts material quality.

What sets this module apart is its combination of adaptive control algorithms and ruggedized construction. The programmable PID parameters allow fine-tuning for specific thermal dynamics – for example, slower response curves in large chemical reactor vessels versus aggressive correction in rapid-cycle injection molding machines. Built-in hysteresis management prevents unnecessary cycling in HVAC applications, while the DIN rail mounting system simplifies retrofitting into legacy control cabinets.

Redundancy options through mirrored module configurations ensure continuous operation in critical processes. Multiple communication channels (I2C/SPI/RS485) provide flexibility for integrating with both modern PLC systems like ABB AC800PEC and older DCS architectures. The thermal shutdown circuitry has proven particularly valuable in preventing catastrophic failures during sensor disconnection incidents – a common issue in mobile equipment applications.

Reviews

There are no reviews yet.