Description

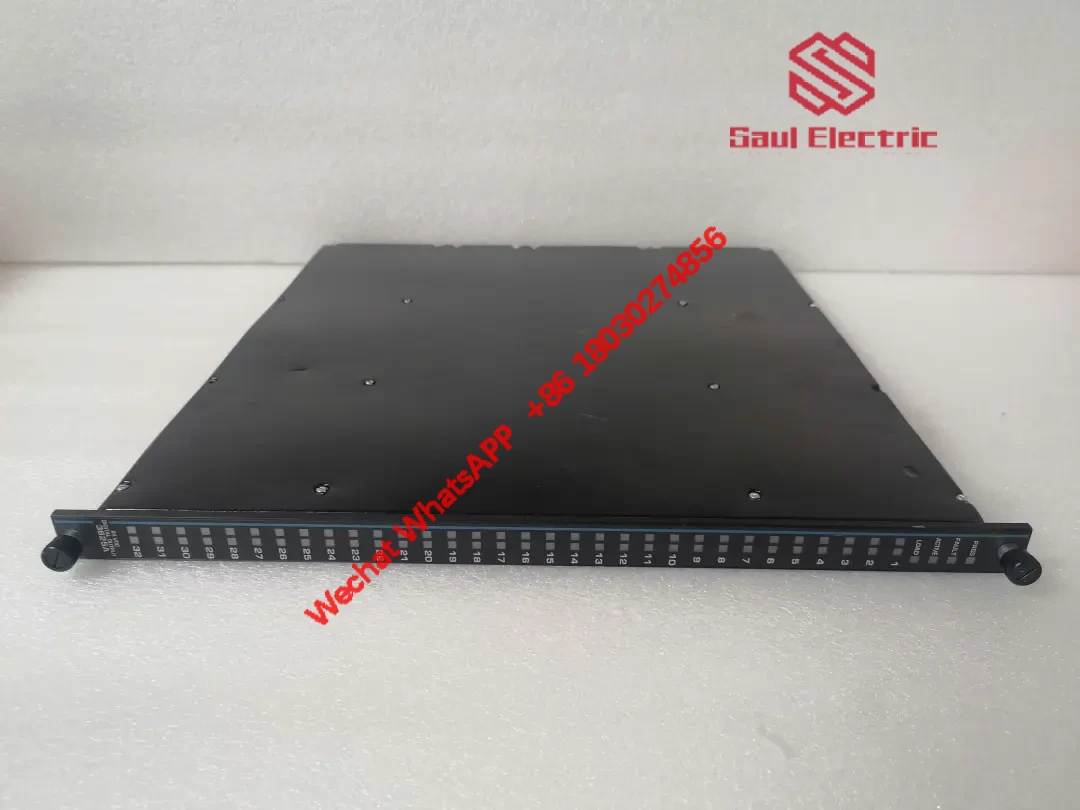

TRICONEX 3625A – Precision Control for Demanding Industrial Applications

Engineered for mission-critical environments, the TRICONEX 3625A industrial control module delivers rock-solid performance in sectors like oil & gas, power generation, and chemical processing. Its dual-role capability as both a controller and safety integrator makes it a workhorse for complex automation tasks where failure isn’t an option.

| Specification | Detail |

|---|---|

| Operating Voltage | 24 VDC |

| Temperature Range | -40°C to +85°C |

| I/O Channels | 8 Analog Inputs / 8 Digital Outputs |

| Communication | Modbus RTU, DeviceNet |

| Processing Speed | 0.5 μs per instruction |

| Certifications | CE, UL, CSA |

![]()

Deployed extensively in hazardous locations like offshore drilling platforms and petrochemical plants, this module thrives where others falter. We’ve supplied units for vibration monitoring systems in gas turbines, emergency shutdown circuits in refineries, and reactor control loops in specialty chemical facilities. Common companion models include the TRICONEX 3008 power module, 3703X communication interface, and 4351B analog input card.

![]()

What sets this module apart is its triple modular redundancy architecture – the core of TRICONEX’s fail-safe design. Unlike conventional PLCs, it maintains operation even with single-point failures through its hot-standby configuration. The ruggedized enclosure handles extreme vibration and temperature swings without performance degradation. I’ve personally seen units pulled from desert installations at +55°C ambient still functioning perfectly after three years straight runtime.

![]()

Reviews

There are no reviews yet.