Description

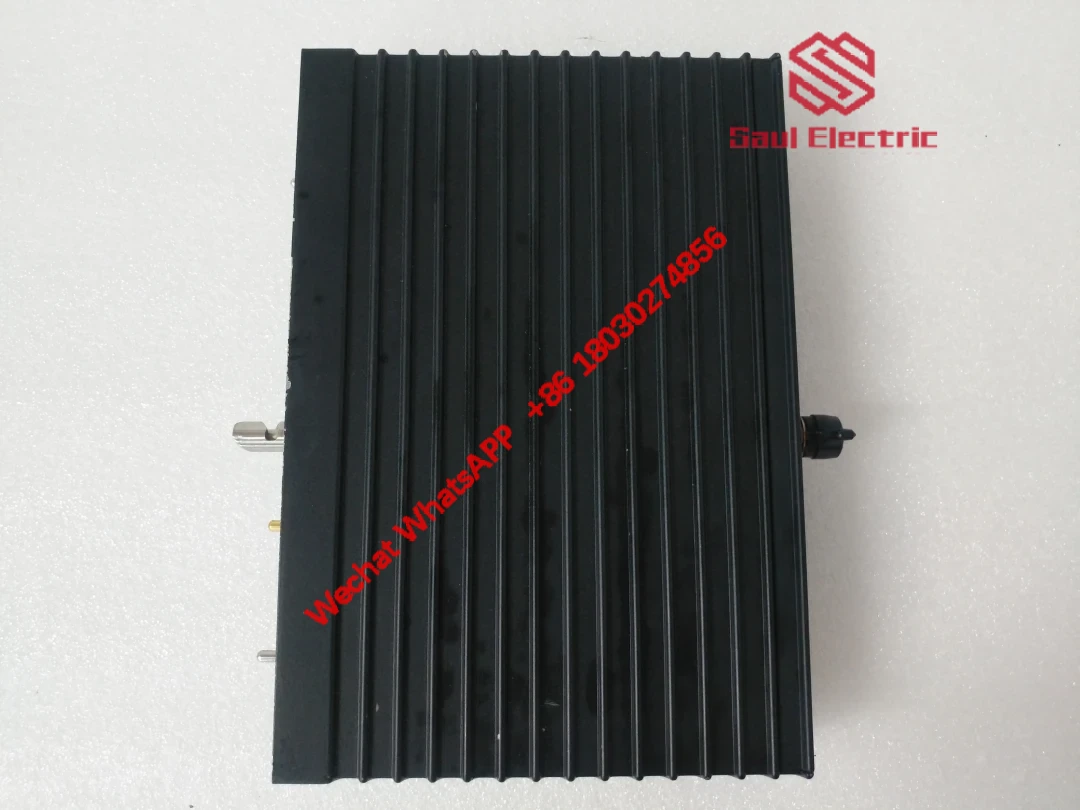

TRICONEX 3351 Control Module

Engineered for mission-critical industrial environments, the TRICONEX 3351 Control Module delivers rock-solid reliability in automation systems where failure isn’t an option. This triple-redundant controller has become a go-to solution for sectors like offshore drilling platforms, chemical processing plants, and power generation facilities that demand 99.999% uptime. Its self-diagnosing architecture and hot-swappable components make it particularly valuable in continuous-process industries where unplanned downtime costs millions.

| Brand | TRICONEX (Schneider Electric) | Form Factor | 19″ rack mount |

|---|---|---|---|

| Certifications | FM, CSA, IEC 61508 SIL 3 | Weight | Approx. 4.2kg |

| Power Supply | 24V DC (dual redundant) | Operating Temp | 0°C to 60°C |

![]()

When a Gulf Coast refinery needed to upgrade their emergency shutdown system, the 3351’s ability to handle 128 input/output points while maintaining full redundancy made it the obvious choice. We’ve also seen it deployed in unconventional settings – like a geothermal plant in Iceland where vibration resistance and thermal stability proved crucial. Common companion models in our inventory include the 3511 discrete I/O module and 4355 analog interface, often integrated with legacy Tricon systems during phased modernization projects.

![]()

What sets the 3351 apart is its native support for PROFIBUS DP and Modbus TCP protocols right out of the box – no gateway required. The three independent processor cores vote on every action in real-time, while the self-purging watchdog timer catches errors before they propagate. Maintenance crews appreciate the color-coded status LEDs that visible indicate channel synchronization states. For environments with extreme EMI concerns, the built-in galvanic isolation on all I/O channels has proven invaluable during field upgrades at steel manufacturing facilities.

Reviews

There are no reviews yet.