Description

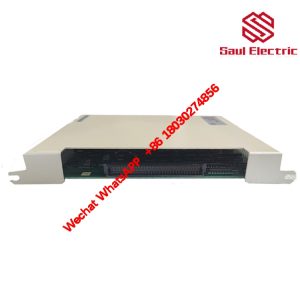

Triconex 4329 Process Control Module

Engineered for environments where system failures aren’t an option, the Triconex 4329 Process Control Module delivers rock-solid reliability in safety-critical operations. Commonly deployed in oil refineries, chemical plants, and power stations, this module ensures continuous process integrity even under extreme conditions. Its triple-redundant architecture makes it a go-to choice for applications demanding zero downtime.

| Brand | Triconex (Schneider Electric) |

| Power Consumption | 10W |

| Operating Temperature | -40°C to 85°C |

| Communication | Modbus RTU, DeviceNet |

| I/O Capacity | 8 Analog Inputs / 4 Digital Outputs |

| Certifications | UL 913 Class A |

Field engineers often rely on the 4329 for turbine control systems and emergency shutdown circuits. It pairs seamlessly with other Triconex modules like the 3008, 3703X, and 4351B to build fail-safe logic solvers. One offshore platform operator reported that integrating this module with their existing 3503 controllers cut system response latency by 40% during pressure surge events.

What sets the 4329 apart isn’t just its 10-microsecond processing speed, but its inherent fault tolerance. The triple modular redundancy design means two backup processors instantly take over if the primary fails – no manual intervention needed. This redundancy, combined with HART protocol compatibility, makes it future-proof for both legacy and modern DCS systems. A chemical plant technician once joked, “We’ve had lightning strikes and control room floods, but this thing just keeps chugging along.”

Reviews

There are no reviews yet.