Description

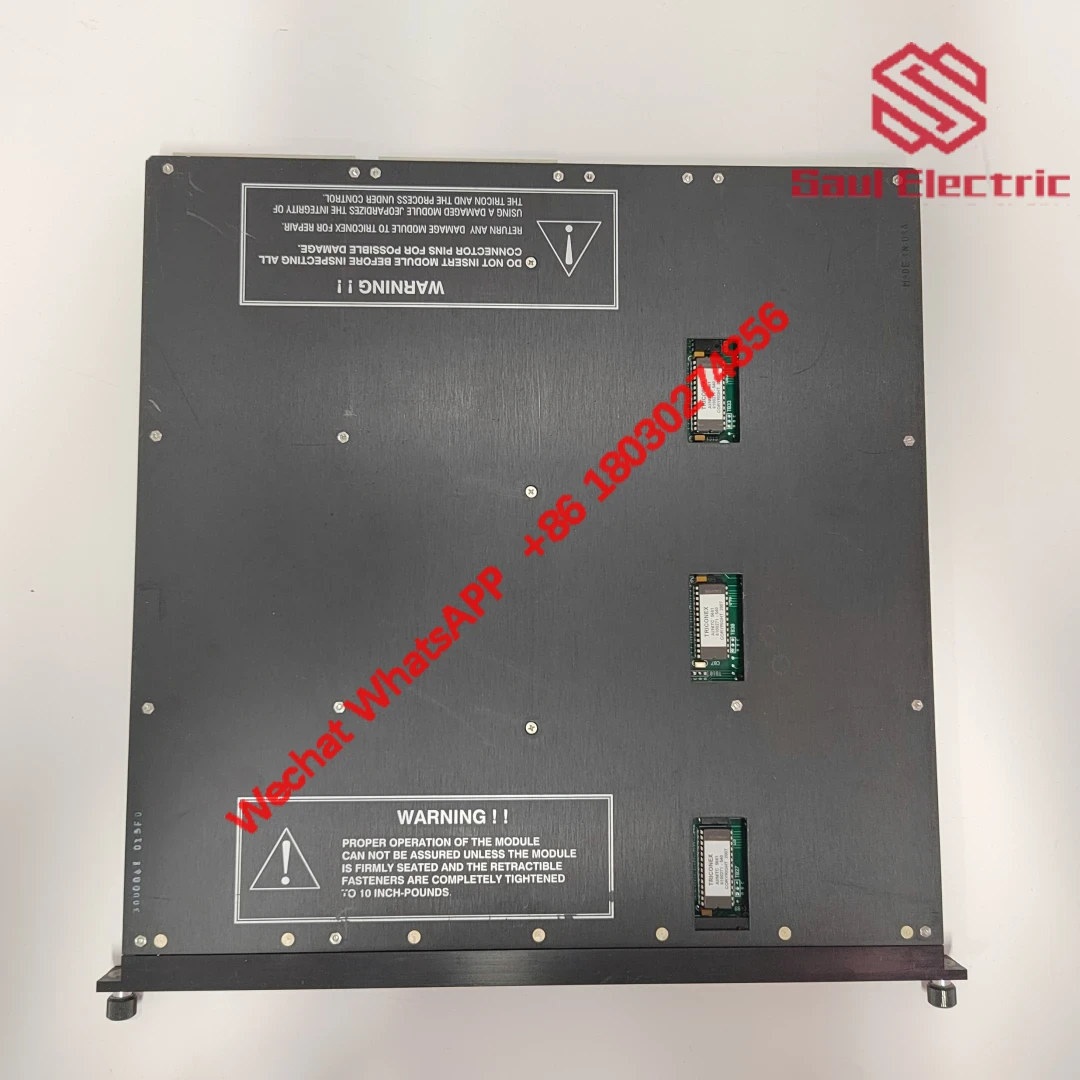

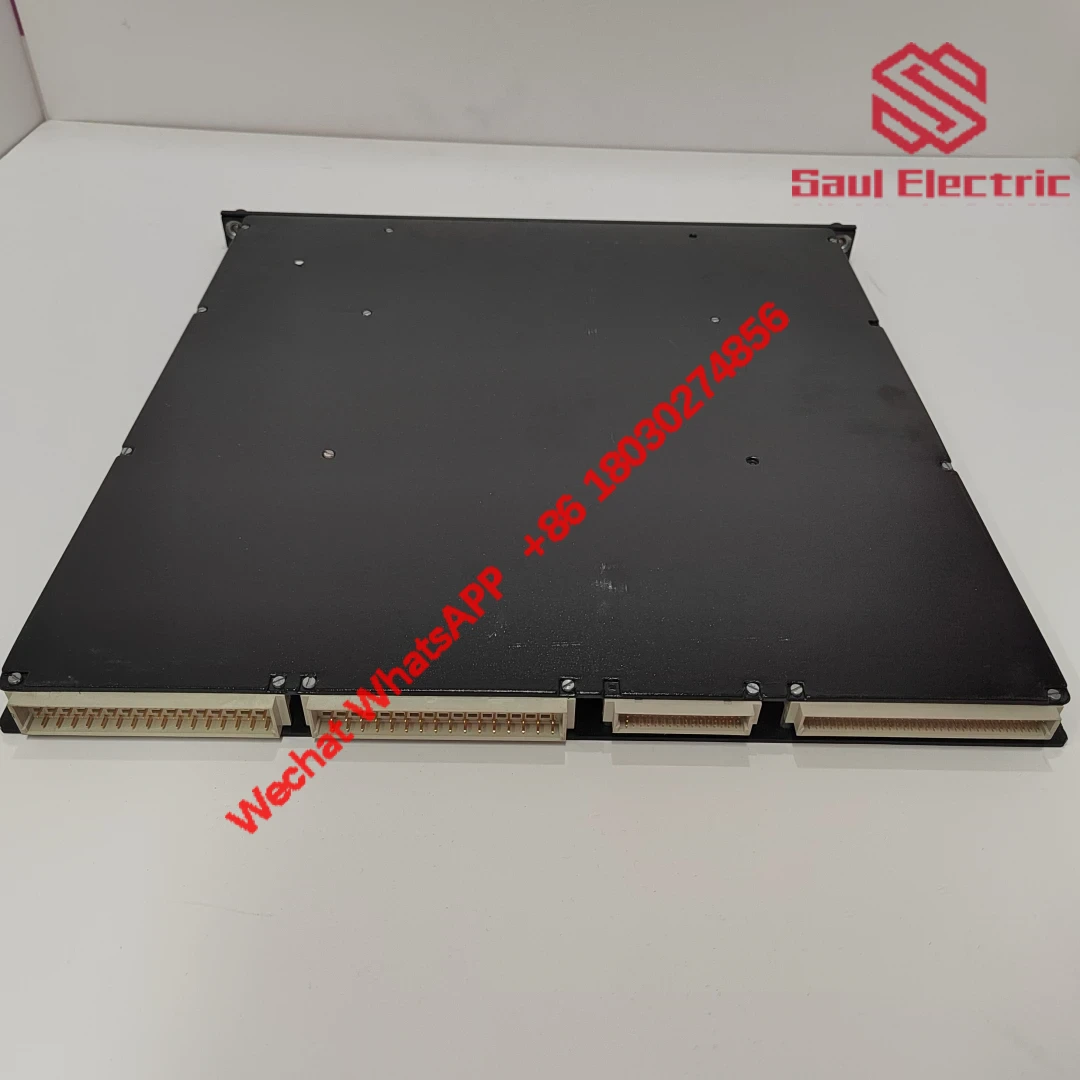

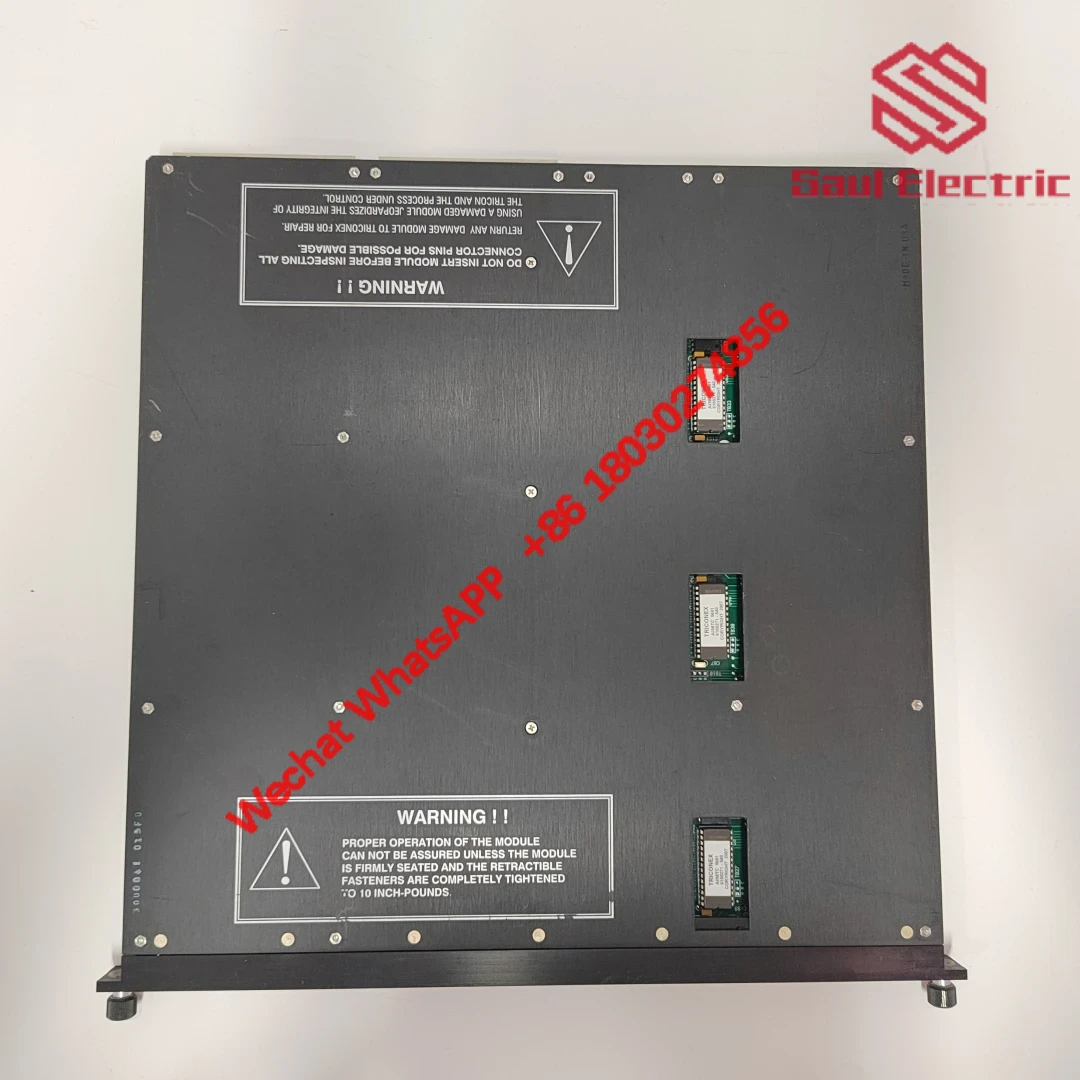

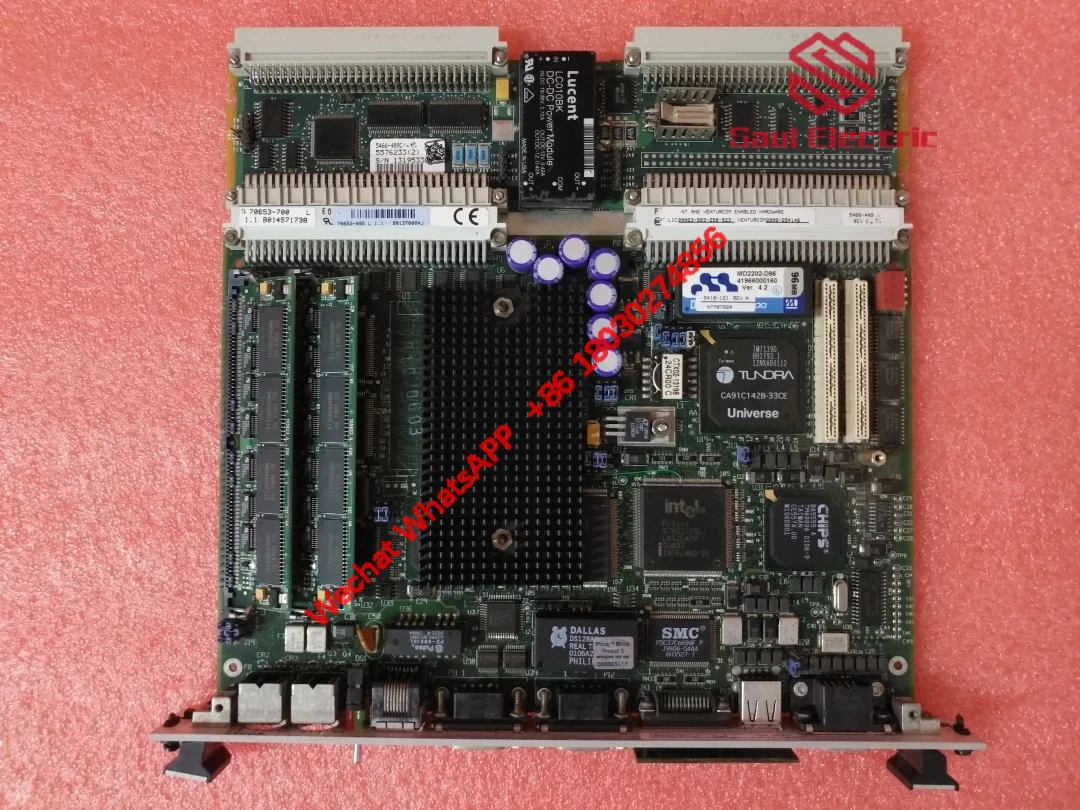

TRICONEX 3700A Process Control Module

Engineered for mission-critical industrial environments, the TRICONEX 3700A Process Control Module delivers rock-solid performance in complex control systems. This rugged module excels in maintaining operational continuity where reliability is non-negotiable – think oil & gas platforms, chemical plants, and power generation facilities that can’t afford downtime.

| Brand | TRICONEX |

|---|---|

| Model | 3700A |

| Dimensions | 150 x 100 x 30 mm |

| Weight | 0.45 kg |

| Operating Temp | -40°C to +85°C |

| Power | 12V/24V DC, <1W |

Industries from offshore drilling rigs to semiconductor fabrication plants rely on this module’s triple-redundant architecture. We’ve seen it deployed in tricky scenarios – like a Texas refinery that needed continuous operation during extreme weather conditions. The 32-channel capacity handles diverse sensor inputs simultaneously, from pressure transmitters to thermocouples, making it ideal for hybrid process control systems.

Common companion modules include the 3720 communication interface and 4351B I/O cards. Our engineers frequently integrate it with legacy Triconex systems while maintaining backward compatibility with older field devices – a lifesaver when upgrading aging infrastructure without full system overhauls.

What sets this module apart isn’t just the triple-modular redundancy (though that’s a big deal). It’s the seamless integration with MODBUS RTU, Ethernet/IP, and DeviceNet protocols that makes system architects’ lives easier. The hot-swappable design means maintenance crews can replace faulty modules mid-operation without shutting down critical processes – a feature that saved one pharmaceutical client $200k in potential downtime costs.

While the specs look impressive on paper, its real-world performance in vibration-prone environments (like offshore platforms with constant seismic activity) truly shines. The ruggedized circuit board coating resists corrosion from salt air, and the locking terminal blocks stay secure even when equipment shakes constantly. Just don’t forget to specify the conformal coating option if you’re deploying in high-humidity zones – learned that the hard way during a Southeast Asia project last year.

Reviews

There are no reviews yet.