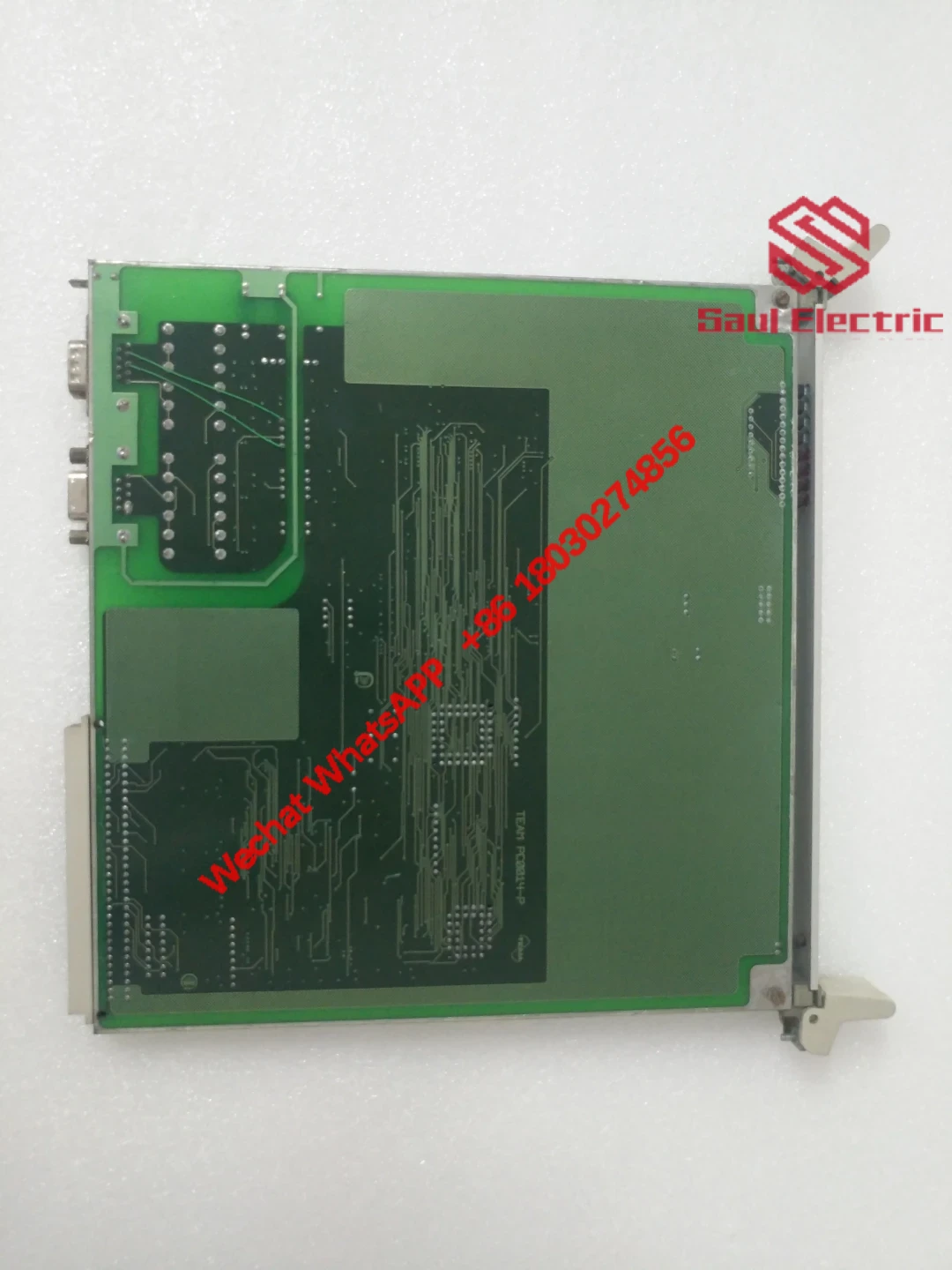

Description

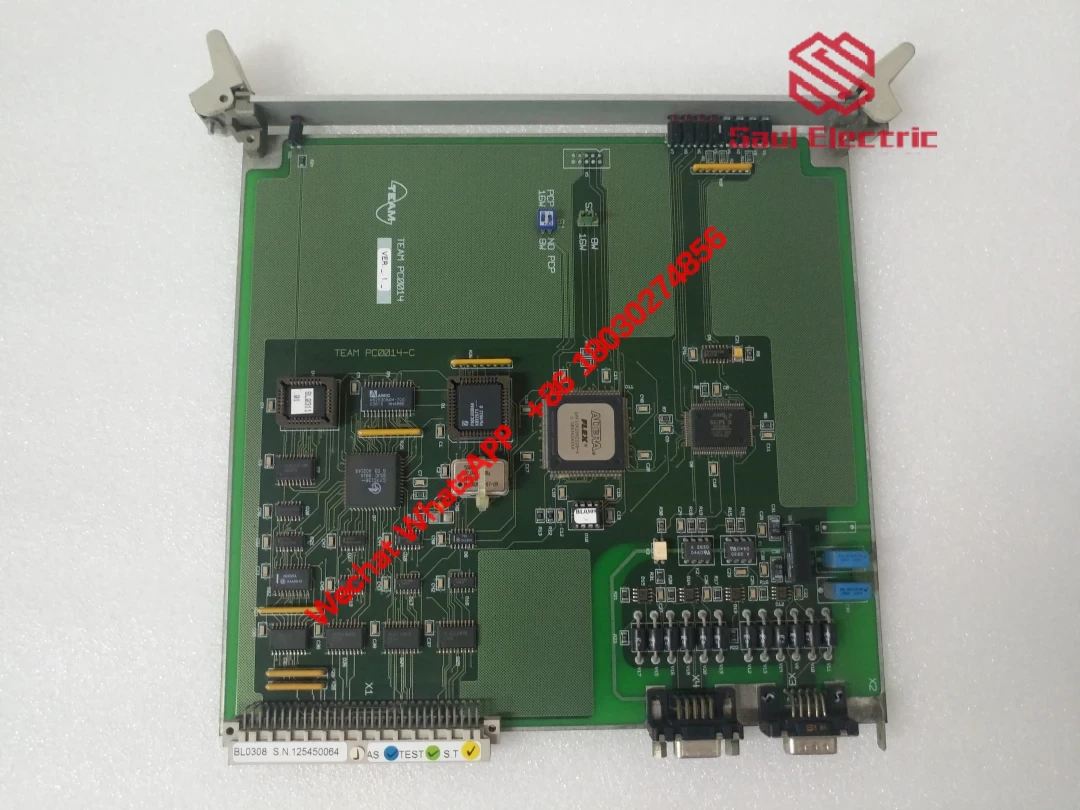

TEAM BL0308 Industrial Control Module

Engineers working in complex automation environments often turn to the TEAM BL0308 when they need rock-solid performance for motor control and process monitoring tasks. This module handles 220V operations while maintaining precision in challenging conditions, making it a go-to solution for critical systems in manufacturing plants and energy facilities. Unlike generic controllers, its design specifically addresses vibration resistance and electromagnetic interference issues common in industrial settings.

| Specification | Details |

|---|---|

| Brand | TEAM |

| Model | BL0308 |

| Voltage | 220V AC |

| Certifications | CE, UL, RoHS |

| Dimensions | 120 x 80 x 40 mm |

| Weight | 500g |

Factories running ABB’s INFI 90 systems or GE Fanuc’s VMIVME-7807 modules frequently pair them with BL0308 controllers for hybrid automation setups. We’ve seen this combination work exceptionally well in conveyor belt systems at automotive plants, where millisecond-level response times prevent production bottlenecks. One steel mill technician mentioned how the BL0308’s thermal management design outperformed alternatives in their 60°C control room environment.

The module’s terminal block design allows hot-swapping during maintenance cycles – a feature plant managers appreciate when minimizing downtime. While not a “smart” controller with built-in diagnostics, its compatibility with Bently Nevada’s 3500 monitoring systems gives engineers visibility into connected equipment health. Redundant signal paths ensure operation continues even when facing voltage spikes up to 20% above nominal levels.

Reviews

There are no reviews yet.