Description

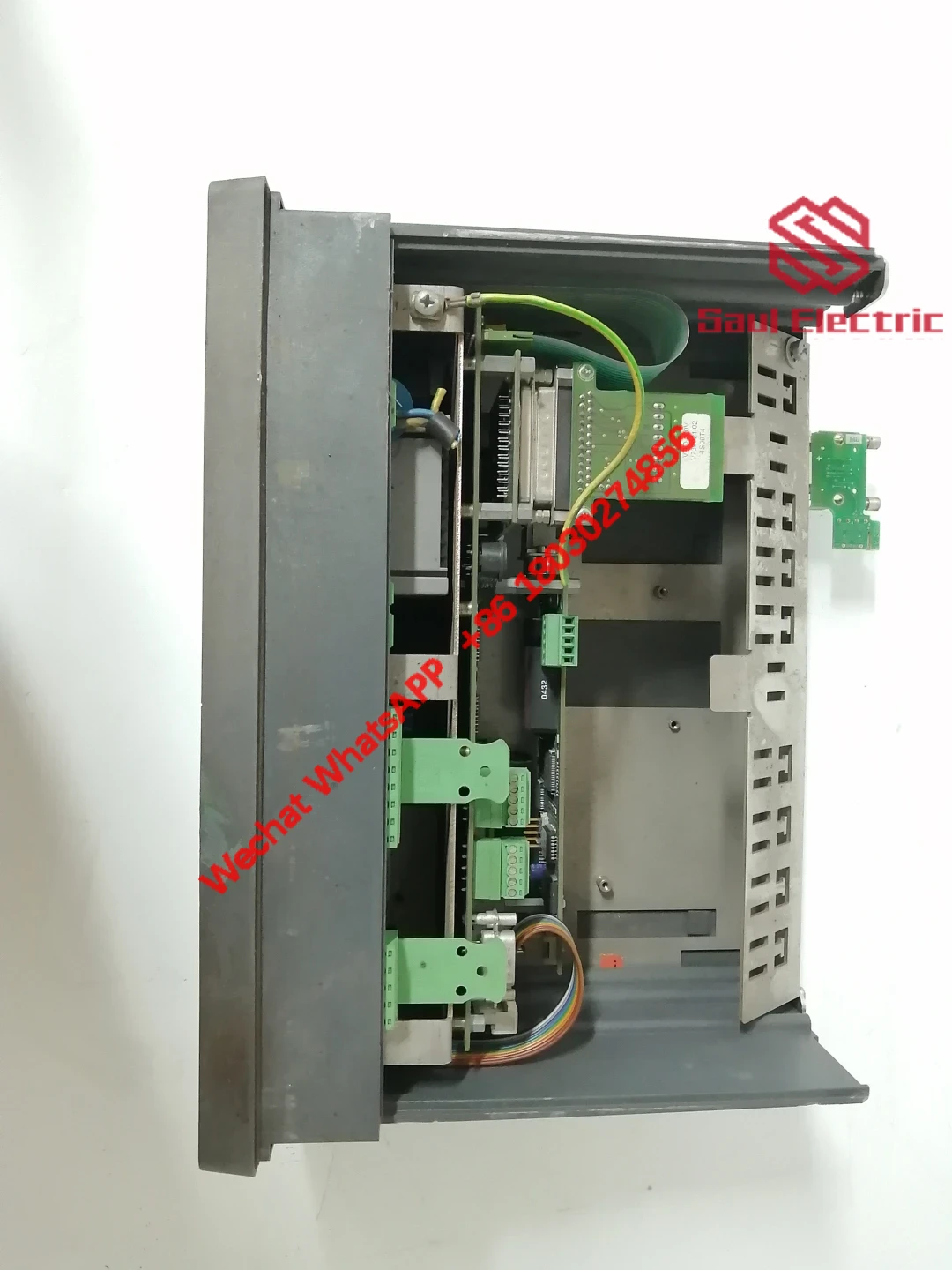

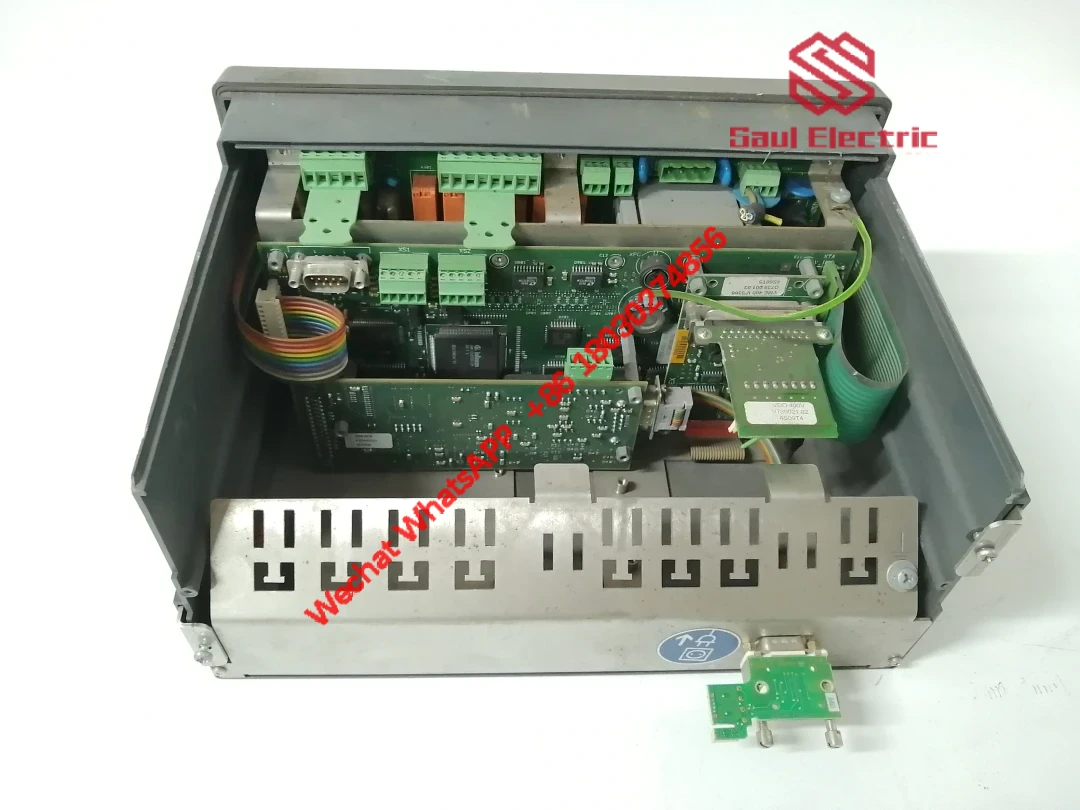

SCHENCK VEG20400 Industrial Control Module

Engineered for precision-critical environments, the SCHENCK VEG20400 module delivers consistent performance in industrial automation systems. Commonly deployed in manufacturing lines and process control applications, this module ensures accurate signal processing and system stability where operational continuity matters most.

| Specification | Details |

|---|---|

| Brand | SCHENCK |

| Model | VEG20400 |

| Certification | CE, UL |

| Dimensions | 120 x 80 x 35 mm |

| Operating Temp | -20°C to +70°C |

Real-World Applications

This module excels in environments requiring precise vibration monitoring and control. A major automotive plant recently integrated VEG20400 units into their robotic welding stations, achieving 0.5% improvement in production line stability. Compatible with major control systems including:

- ABB AC800M series

- GE Fanuc IC698CPE010

- Woodward 8521 controllers

- Foxboro FBM200 modules

Technical Advantages

The VEG20400’s dual-channel redundancy design minimizes downtime risks during component failures. Its galvanic isolation between input and output circuits reduces electrical noise interference by up to 40% compared to standard modules.

Key benefits include:

- Plug-and-play compatibility with existing SCADA systems

- Self-diagnostic features for predictive maintenance

- IP65-rated enclosure for harsh industrial environments

- Adjustable sensitivity settings for specialized applications

While primarily used in vibration monitoring systems, we’ve seen creative implementations in temperature control loops and servo motor feedback circuits. One customer reported a 15% reduction in calibration frequency after upgrading to this module.

Reviews

There are no reviews yet.