Description

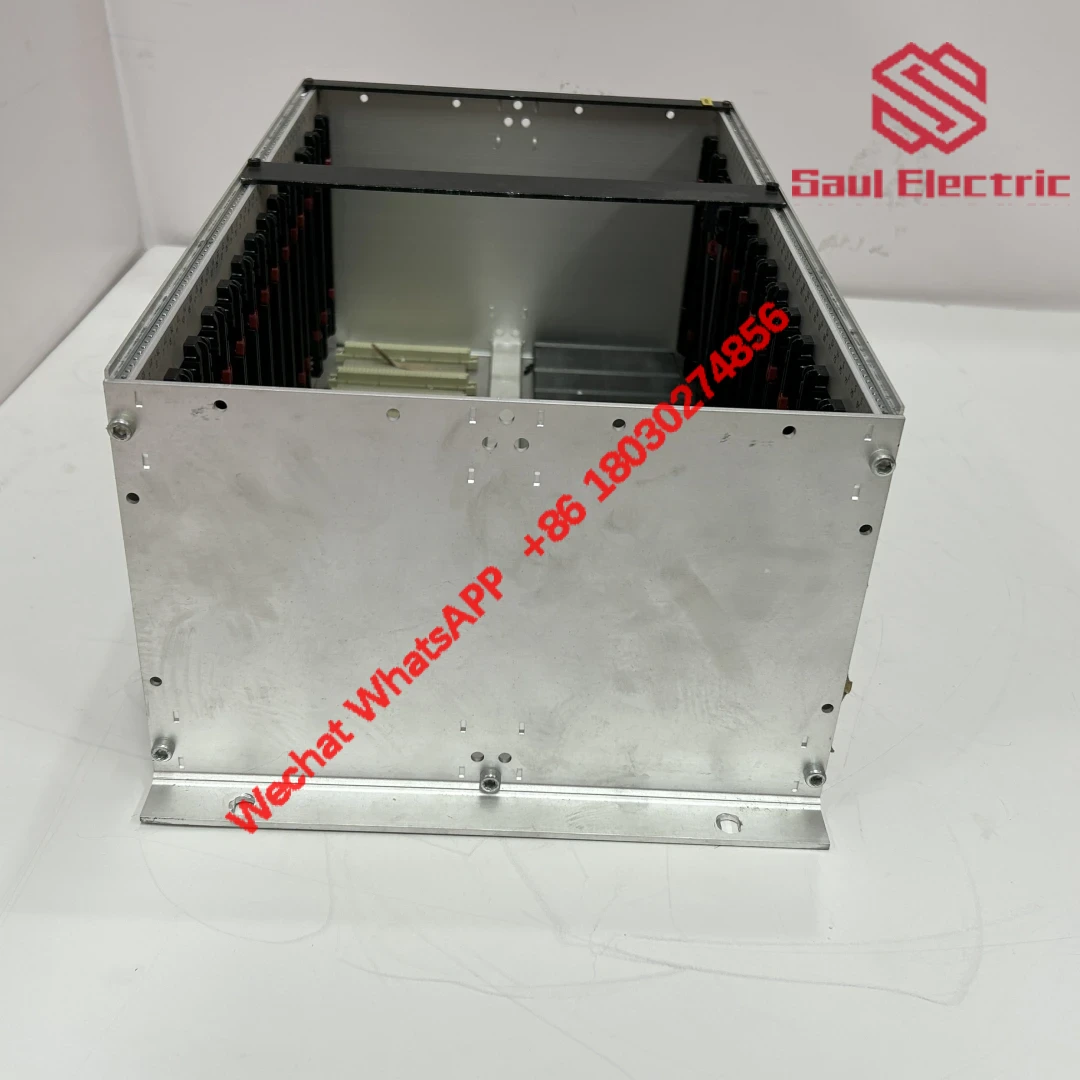

POWEC PMP10.48 SIC Industrial Control Module

Engineered for precision motor control and real-time automation tasks, the POWEC PMP10.48 SIC module delivers consistent performance in environments where reliability matters most. Its dual-interface design handles complex synchronization tasks across production lines, energy systems, and material handling equipment.

| Specification | Details |

|---|---|

| Brand | POWEC |

| Model | PMP10.48 SIC |

| Type | Industrial Control Module |

| Voltage | 24 VDC |

| Outputs | Analog/Digital |

| Protocols | CANopen/RS485 |

| Temp Range | -25°C to +70°C |

| Certifications | CE, UL, RoHS |

| Mounting | DIN Rail |

| Dimensions | 100×120×50 mm |

| Weight | 350g |

Commonly deployed in robotics and automated assembly systems, this module handles tasks like conveyor belt synchronization, servo motor positioning, and sensor data aggregation. We’ve seen it work particularly well with Allen Bradley PLCs in packaging machinery, and it’s a popular choice for retrofitting legacy systems requiring modern fieldbus connectivity. Related models we handle include the PMP10.48 SIC-RS485 variant and older PMP8.x series modules for backward compatibility scenarios.

What makes this module stand out is its dual-protocol capability – you can mix CANopen and RS485 devices on the same network without gateways. The 2500 VAC isolation between circuits isn’t just for show; we’ve had customers report reduced downtime in high-EMI environments like steel mills. While the DIN rail design saves panel space, don’t underestimate its thermal resilience – real-world tests show stable operation at 65°C ambient temps. For redundancy setups, pairing it with a backup module through the RS485 link creates a fail-safe architecture without needing proprietary hardware.

Reviews

There are no reviews yet.