Description

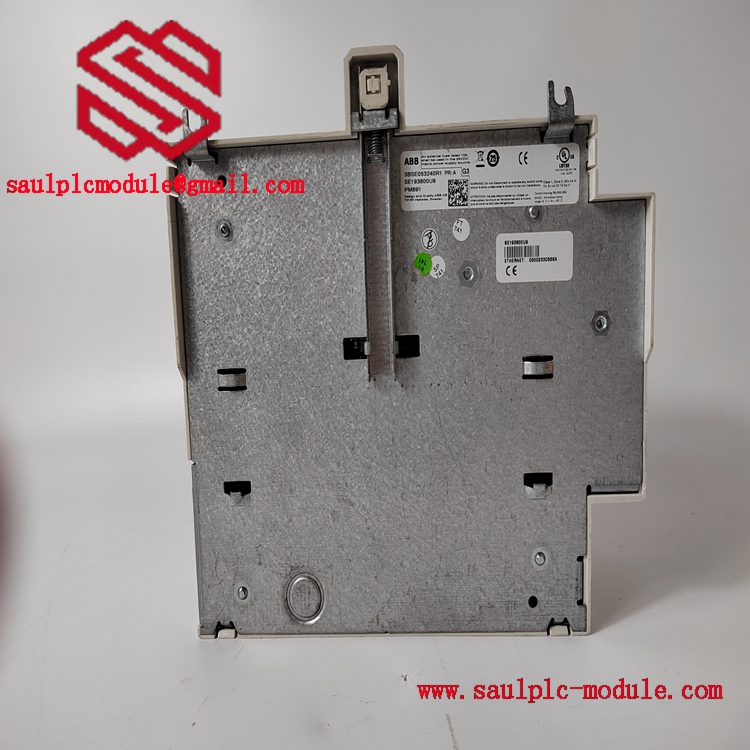

ABB PM891K01 3BSE053241R1: High-Performance CPU Module for Advanced Industrial Control

Product Overview

The ABB PM891K01 3BSE053241R1 is a powerful central processing unit (CPU) module, serving as the core of ABB’s AC800M distributed control system (DCS). Designed to handle complex industrial control tasks, this module integrates advanced processing capabilities with robust connectivity, making it a cornerstone of modern automation setups.

As a key component in the AC800M family, the PM891K01 3BSE053241R1 executes control logic, processes real-time data from field devices, and coordinates communication between various system components. It supports a wide range of industrial protocols, enabling seamless integration with sensors, actuators, and higher-level monitoring systems. In industries such as manufacturing, energy, and chemicals, the ABB PM891K01 3BSE053241R1 ensures precise control over production processes, enhances operational efficiency, and provides the reliability needed for continuous operation. Whether deployed in small-scale production lines or large-scale industrial complexes, this CPU module delivers the processing power and stability required to meet demanding automation challenges.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | PM891K01 3BSE053241R1 |

| Manufacturer | ABB |

| Product Type | CPU Module (AC800M DCS) |

| Processor | 32-bit RISC processor, 800 MHz |

| Memory | 256 MB RAM, 512 MB Flash |

| Operating System | Real-time operating system (RTOS) |

| Communication Interfaces | 2 x Ethernet (10/100/1000 Mbps), 1 x serial (RS-232) |

| I/O Capacity | Supports up to 4096 I/O points via remote modules |

| Cycle Time | Minimum 1 ms for control execution |

| Redundancy | Supports hot standby redundancy for high availability |

| Operating Temperature | -25°C to 70°C |

| Power Supply | 24 V DC (1.5 A typical) |

| Dimensions | 185 mm x 127 mm x 59 mm |

| Weight | Approximately 0.6 kg |

Main Features and Advantages

Superior processing power: The ABB PM891K01 3BSE053241R1 is equipped with an 800 MHz 32-bit RISC processor, enabling rapid execution of complex control algorithms. This high performance ensures that even large-scale industrial processes—with thousands of I/O points and intricate logic—are managed with minimal latency, critical for real-time decision-making.

Enhanced reliability through redundancy: Supporting hot standby redundancy, the module can seamlessly switch to a backup unit in case of a primary failure, eliminating downtime in mission-critical applications. This feature is particularly valuable in industries like power generation and chemical processing, where interruptions can lead to significant losses.

Flexible connectivity: With dual Gigabit Ethernet ports and a serial interface, the PM891K01 3BSE053241R1 integrates effortlessly with ABB’s I/O modules, third-party devices, and enterprise-level systems. It supports standard protocols such as Modbus TCP/IP and PROFIBUS, simplifying integration into existing infrastructures.

Robust design for harsh environments: Operating reliably in temperatures ranging from -25°C to 70°C, the module withstands extreme industrial conditions, including vibration and electrical noise. Its rugged construction ensures consistent performance in factories, refineries, and outdoor installations.

Scalable architecture: The module’s ability to support up to 4096 I/O points allows systems to grow with evolving operational needs. Whether expanding production lines or adding new sensors, the PM891K01 3BSE053241R1 adapts without compromising performance, making it a cost-effective long-term solution.

Application Areas

The ABB PM891K01 3BSE053241R1 is widely used in process industries, where precise control over variables like temperature, pressure, and flow is essential. In chemical plants, it manages batch processing and continuous production lines, ensuring adherence to strict quality standards and safety protocols.

In power generation facilities—including thermal, hydro, and renewable energy plants—the module coordinates turbine control, boiler operations, and grid synchronization, optimizing efficiency and ensuring stable power output. Its redundancy feature is critical here, as any disruption could affect thousands of consumers.

In manufacturing, particularly automotive and semiconductor production, the PM891K01 3BSE053241R1 oversees automated assembly lines, robotic systems, and quality inspection processes. Its fast cycle time (as low as 1 ms) ensures that production steps are synchronized with minimal delay, improving throughput and reducing defects.

Water and wastewater treatment plants also benefit from the module, as it regulates pumps, valves, and chemical dosing systems, ensuring compliance with environmental regulations and efficient resource usage.

Related Products

- ABB AC800M I/O Modules (e.g., AI890, DI890): These modules connect to the PM891K01 3BSE053241R1 to collect field data (analog/digital signals) and execute control commands, forming a complete DCS ecosystem.

- ABB CI854AK01 3BSE030220R1: A PROFIBUS-DP interface module that extends the PM891K01’s connectivity to field devices using the PROFIBUS protocol, ideal for legacy systems.

- ABB 800xA HMI: A human-machine interface that pairs with the PM891K01 3BSE053241R1 to visualize process data, allowing operators to monitor and adjust systems in real time.

- ABB PM864K01: A lower-power sibling in the AC800M series, suitable for smaller applications but compatible with the PM891K01 in mixed-scale systems.

- ABB Power Supply Modules (e.g., PS802): Provide stable 24 V DC power to the PM891K01 3BSE053241R1, ensuring uninterrupted operation even during voltage fluctuations.

- ABB Communication Switches (e.g., ES824): Enhance network reliability by managing Ethernet traffic between the PM891K01 and other system components, supporting redundancy configurations.

Installation and Maintenance

Installation preparation: Before installing the ABB PM891K01 3BSE053241R1, ensure the mounting rail (DIN rail) is securely fastened and level, with adequate ventilation to dissipate heat. Verify that the 24 V DC power supply is properly grounded and meets voltage requirements. Review the wiring diagram to connect Ethernet cables (for communication) and power leads, taking care to avoid electrostatic discharge by using grounded tools and ESD wristbands. Confirm that the ambient temperature is within the -25°C to 70°C range to prevent thermal issues.

Maintenance suggestions: Regularly inspect the PM891K01 3BSE053241R1 for dust accumulation, cleaning vents with compressed air to maintain cooling efficiency. Check Ethernet and power connections for tightness, as loose links can cause communication errors. Monitor system logs via ABB’s Control Builder software to track processor load and memory usage, addressing anomalies promptly. Update firmware periodically using ABB-approved tools to access new features and security patches. In redundant setups, test failover functionality quarterly to ensure seamless 切换 during primary unit failures.

Product Warranty

Hong Kong Saul Electric Co., Ltd., a leading industrial control supplier since 2007, offers a 1-year warranty for the ABB PM891K01 3BSE053241R1. As an import-export trading company, we maintain extensive stock—including hard-to-find and discontinued models—ensuring rapid delivery for urgent requirements. Our robust supply chain guarantees access to genuine ABB components. During the warranty period, if the PM891K01 3BSE053241R1 experiences quality issues, our professional after-sales team provides prompt technical support, troubleshooting, and replacement services, ensuring your industrial control systems operate with maximum reliability.

Reviews

There are no reviews yet.