Description

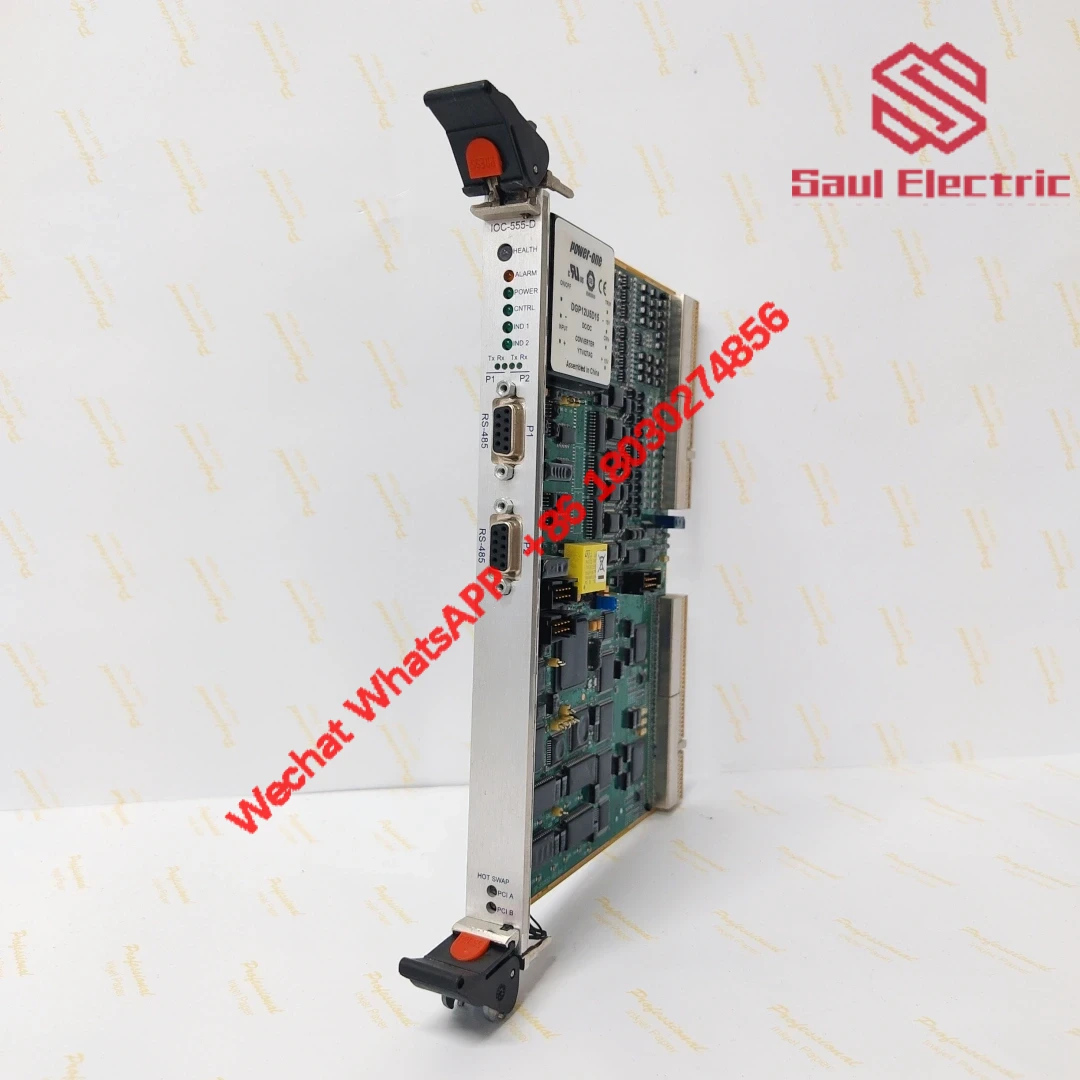

IOC-555-D Industrial Control Module for High-Precision Automation Systems

The IOC-555-D is a rugged industrial control module built for demanding automation environments. Designed to handle real-time process control and data communication, it’s commonly used in manufacturing lines, energy management systems, and logistics operations where reliability matters most. Its compact design and versatile I/O configuration make it a go-to solution for system integrators facing complex automation challenges.

| Brand | Industrial Optimal Controls |

|---|---|

| Key Attributes | 24 VDC, 16 digital inputs, 8 relay outputs, Modbus RTU/Ethernet/IP, -20°C to +70°C operating temp |

| Dimensions | 120mm x 80mm x 55mm |

Engineers often deploy this module in motor control cabinets for conveyor systems or HVAC automation setups. Its DIN rail mounting design saves panel space while maintaining accessibility – one technician mentioned how they retrofitted it into an aging bottling plant’s control system without rewiring existing sensors. The 16 programmable digital inputs handle everything from proximity sensors to temperature transmitters, while the 8 relay outputs manage actuators and motor starters. We’ve seen it integrated into pharmaceutical batch processing systems where precise timing and data logging are critical.

What stands out is its 32-bit RISC processor – even under heavy I/O load, response times stay consistent. The dual communication ports (RS485 + Ethernet) let technicians maintain legacy Modbus devices while connecting to modern SCADA systems. IP20-rated housing works fine for indoor industrial spaces, though we’ve seen customers add protective covers in high-humidity areas. One unexpected benefit? The non-volatile memory actually retained configuration during a 48-hour power outage at a wastewater treatment plant – saved them hours of reprogramming.

Reviews

There are no reviews yet.