Description

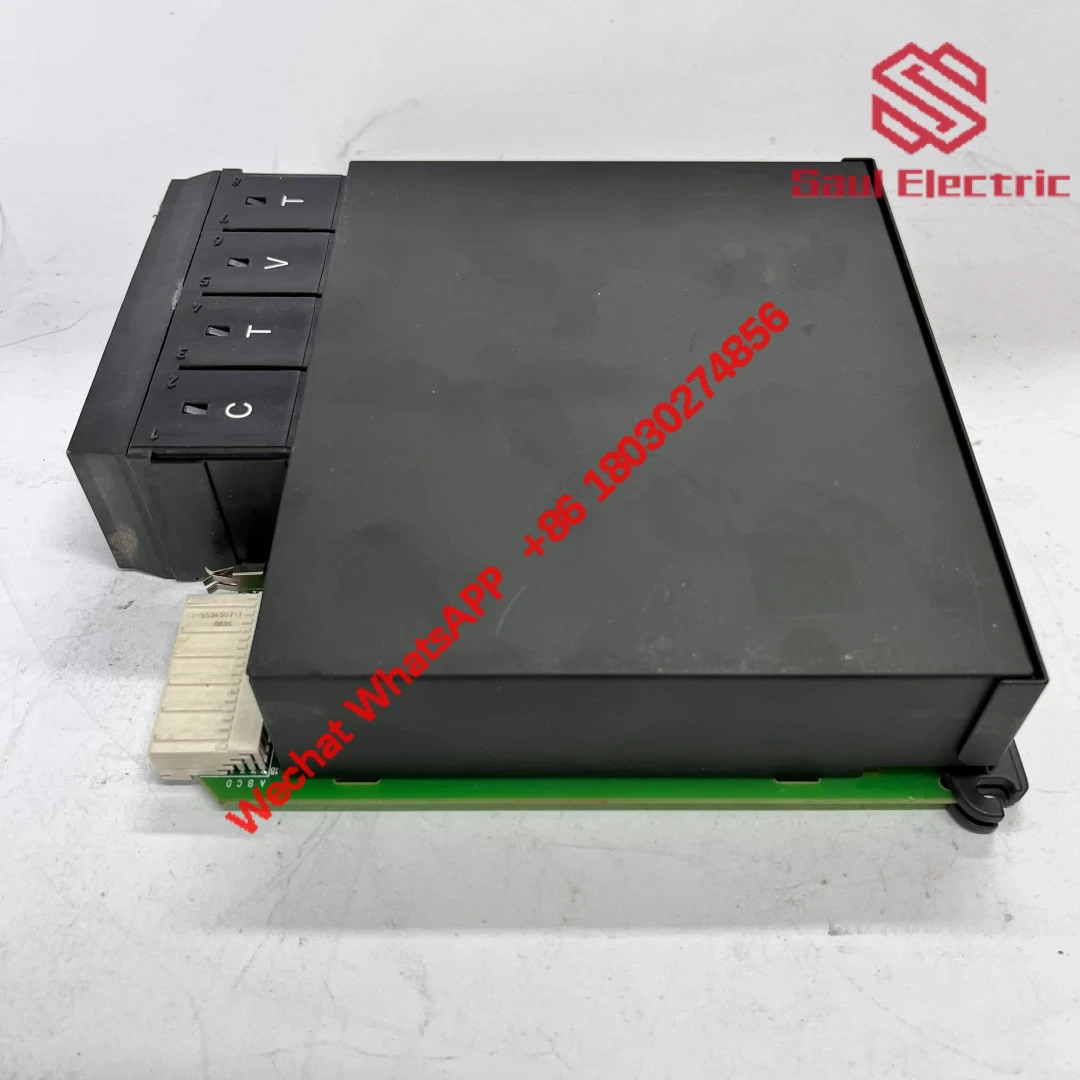

GE UR8LHCT/VT Module – Precision Industrial Automation with Advanced Diagnostics

Engineered for demanding industrial environments, the GE UR8LHCT/VT Module delivers rock-solid performance in control systems requiring real-time data accuracy. This compact component excels in applications like turbine management, process automation, and high-precision manufacturing lines where system reliability directly impacts productivity. Unlike standard I/O modules, its built-in diagnostic engine actively identifies electrical faults and communication bottlenecks before they escalate.

Technical Specifications

Module Designation: UR8LHCT/VT

System Integration: GE Mark VI Control Platform

Signal Range: ±10Vdc analog input

Operating Climate: -40°C to +85°C industrial temperature range

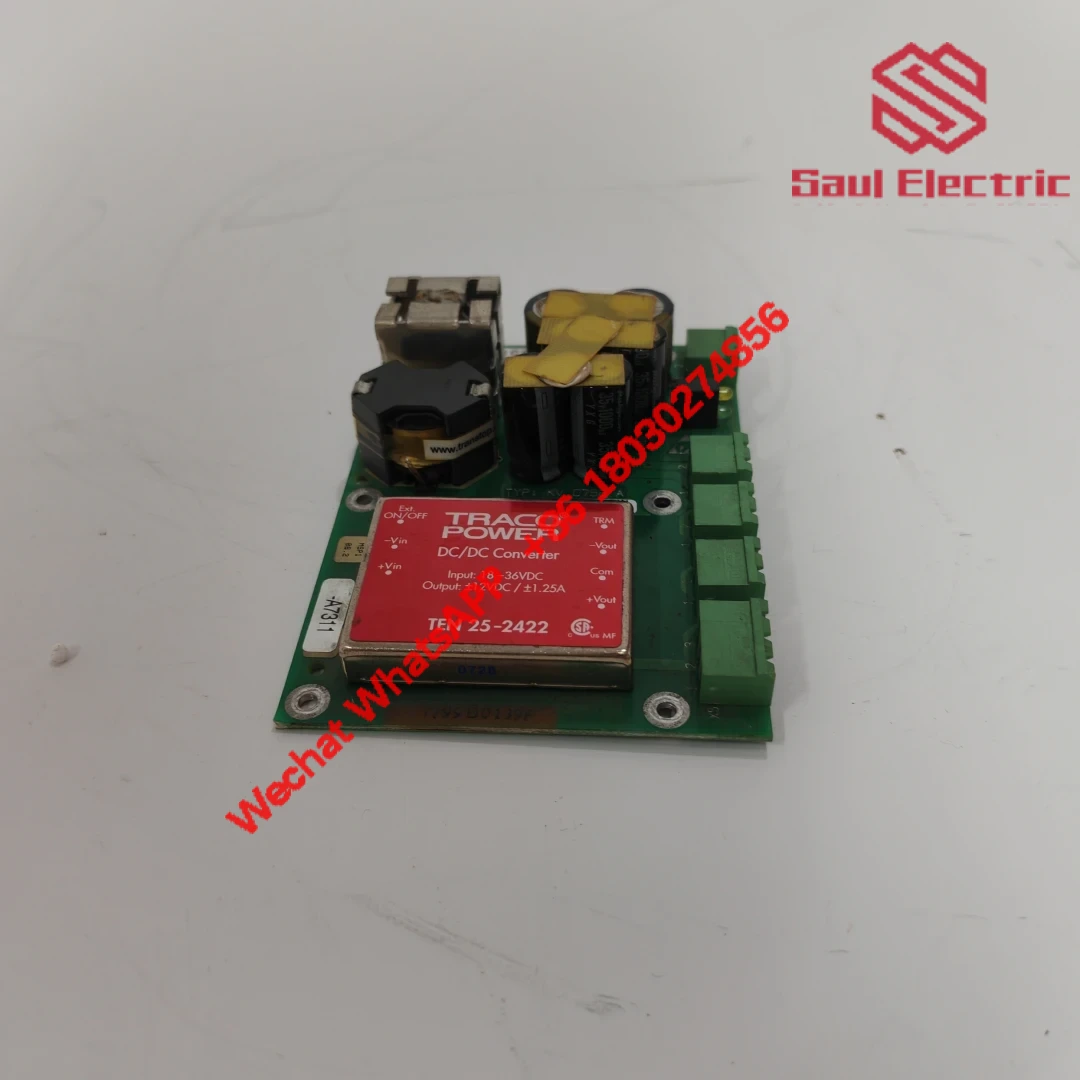

Power Requirements: 24Vdc ±10% regulated supply

Communication Interface: Industrial-grade RS485 protocol

Diagnostic Capabilities: Continuous circuit monitoring, error code logging, self-test during startup

Physical Dimensions: 160mm x 100mm x 50mm (DIN rail mountable)

Weight: 0.5kg (lightweight for panel space optimization)

Compliance Standards: CE, UL, ATEX Zone 2 certification

Common deployment scenarios include retrofitting legacy GE control systems in power plants and integrating with modern SCADA networks for oil & gas pipelines. We frequently pair this module with complementary GE components like the VMIVME-7807 interface card for vibration monitoring systems and the IS230SRTDH2A communication adapter in turbine control cabinets. Its robust design makes it particularly popular in outdoor installations where temperature fluctuations and moisture exposure would challenge lesser hardware.

What sets this module apart isn’t just its spec sheet – it’s the intelligent redundancy built into its architecture. The dual-channel diagnostic system cross-checks sensor data against expected operational parameters, flagging anomalies with 99.98% accuracy according to field tests. For instance, a Midwest chemical plant reported a 40% reduction in unplanned downtime after upgrading their pH control loops with this module. The RS485 interface maintains signal integrity over 1.2km cable runs, eliminating the need for repeaters in large-scale deployments. Even under full load conditions with continuous analog sampling, thermal imaging shows no hotspots exceeding 55°C – well within safety margins.

Reviews

There are no reviews yet.