Description

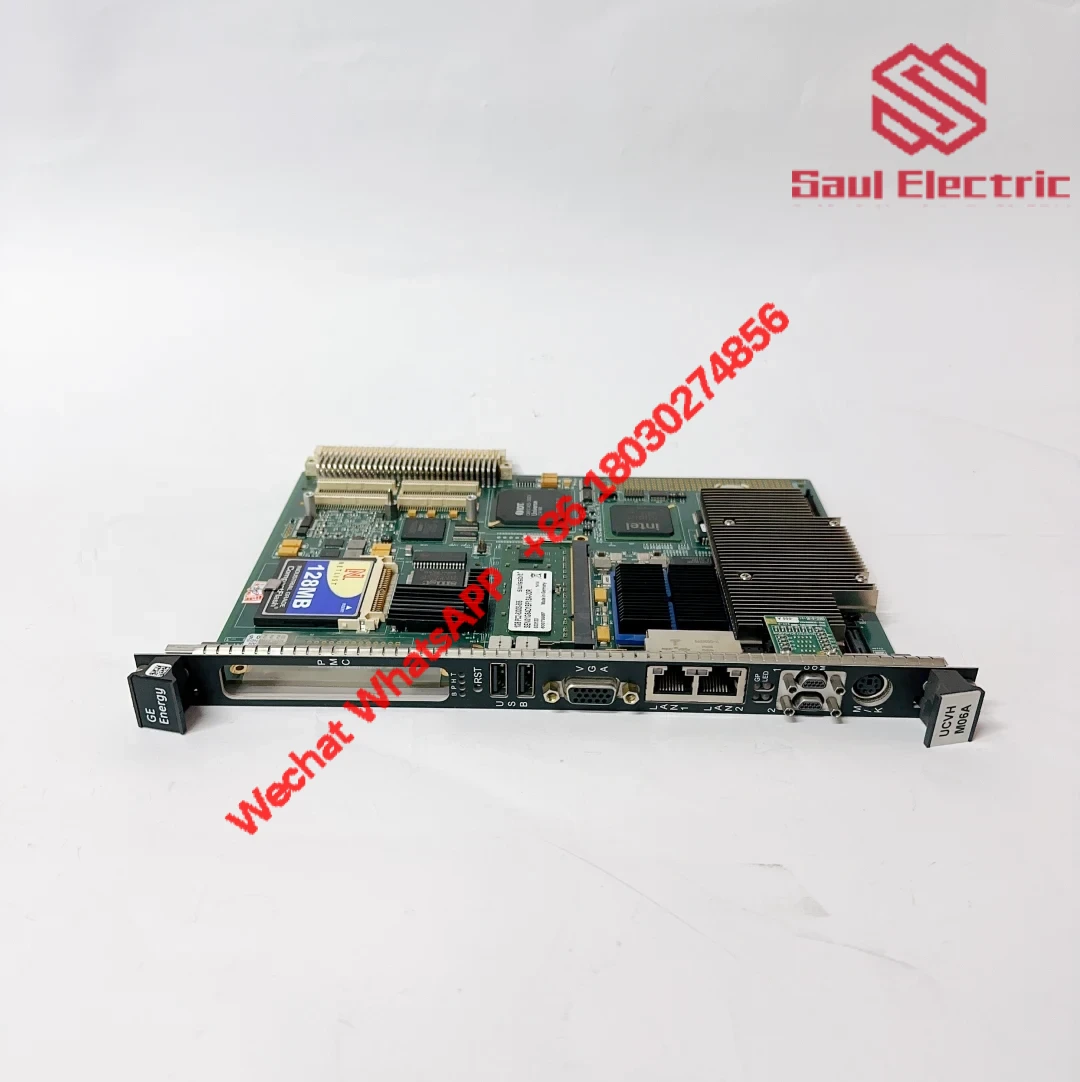

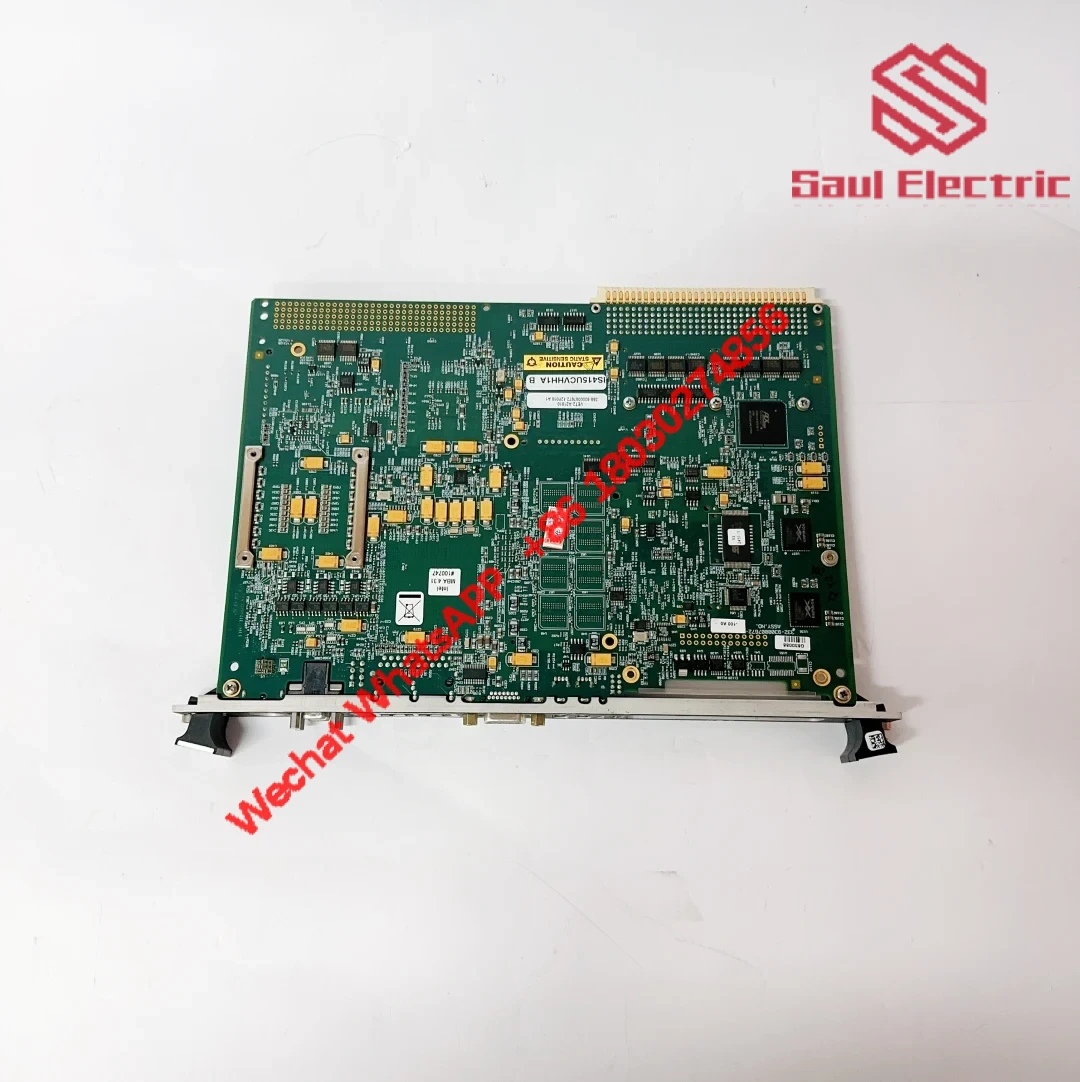

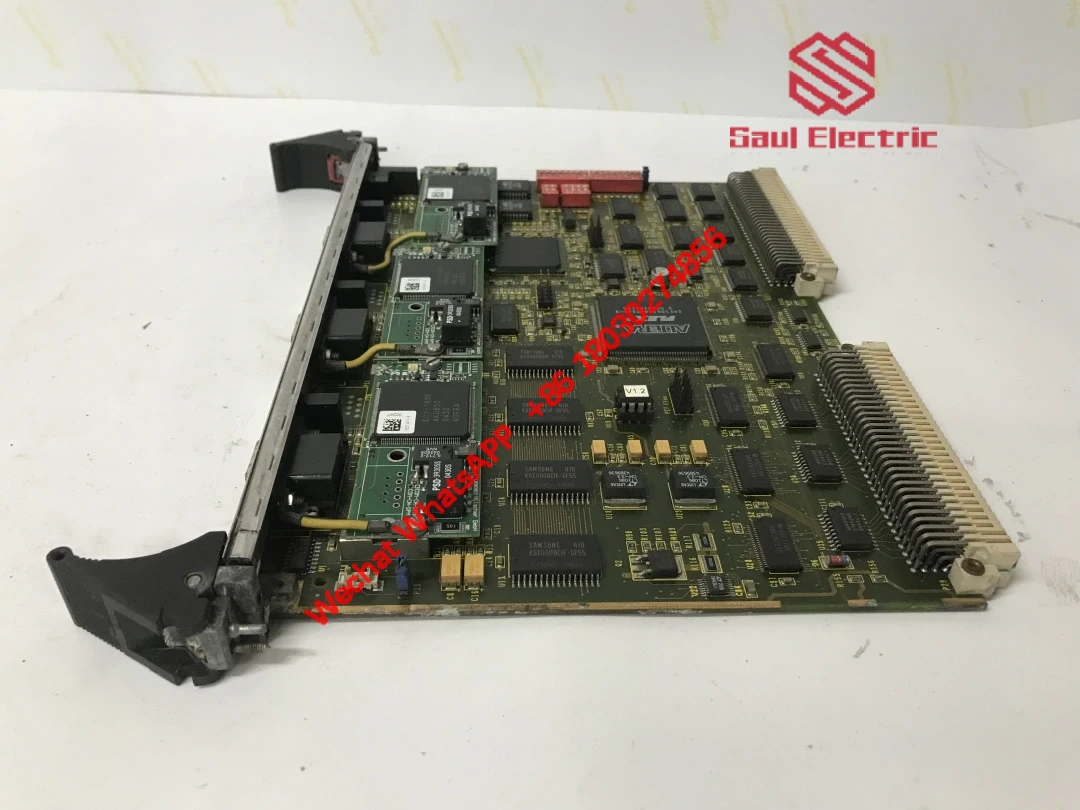

GE IS215UCVHM06A Control Module for Turbine Systems

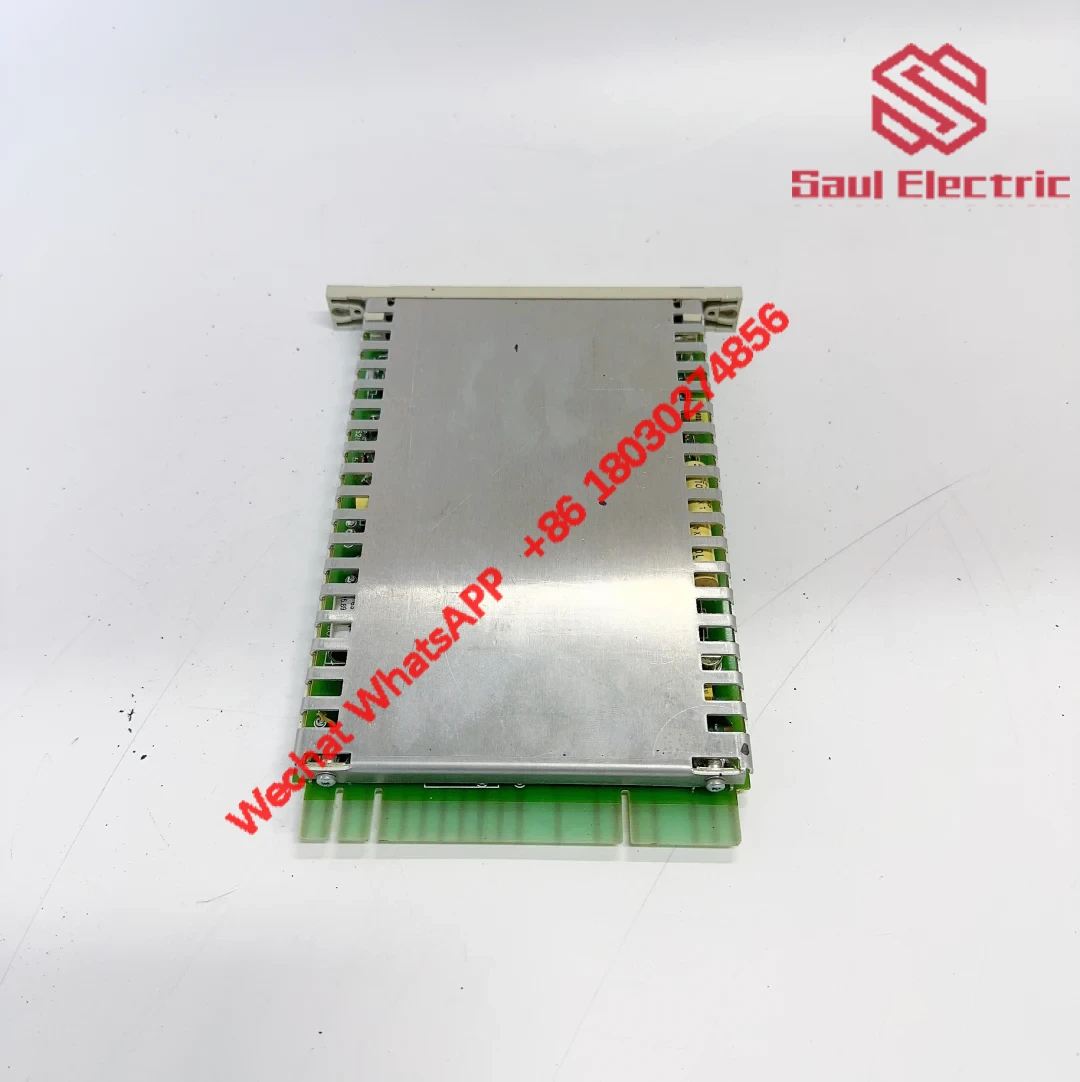

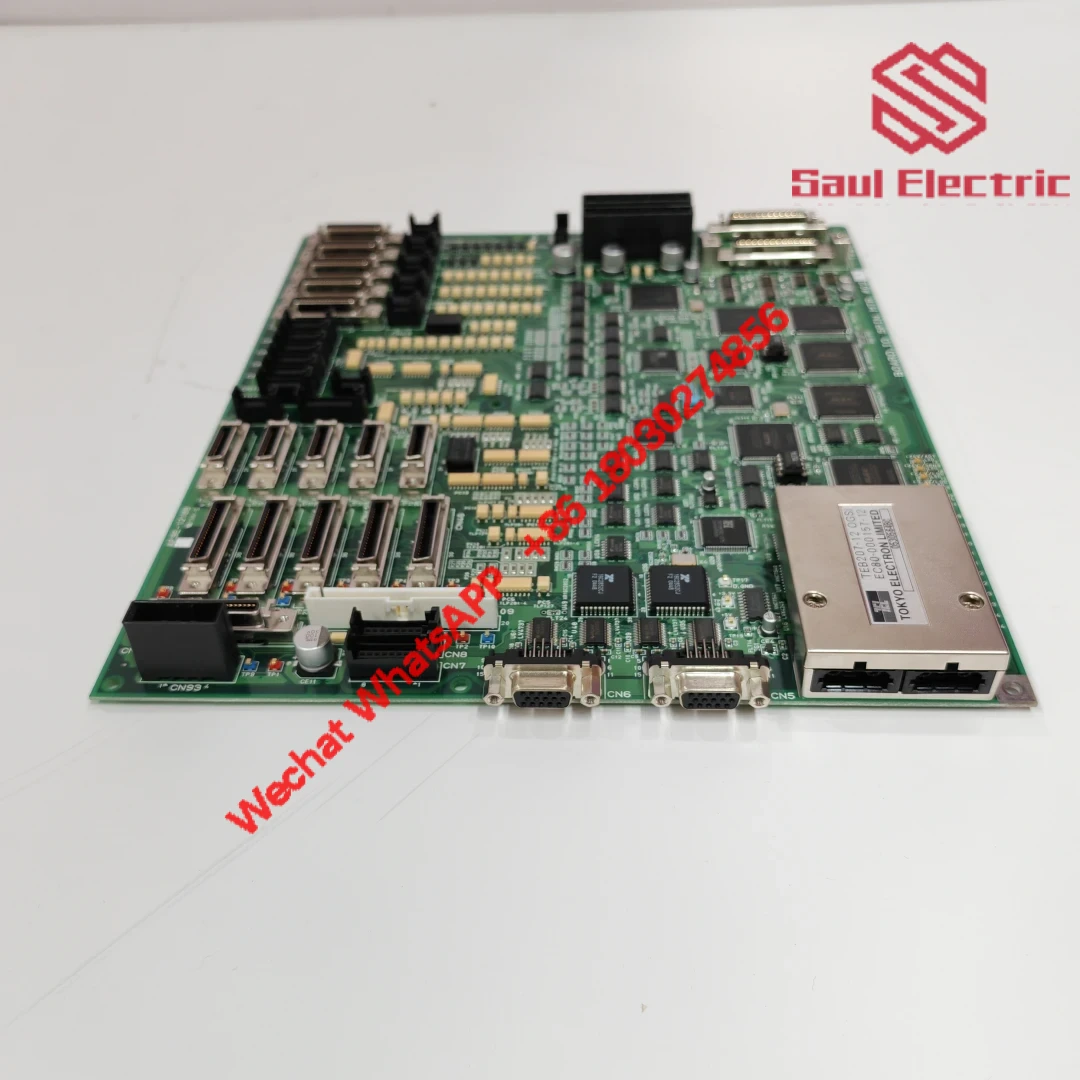

The GE IS215UCVHM06A IS415UCVHH1A B VET2-A21010 350-9300007672-12F010 A1 is a precision industrial control module engineered for high-stakes automation environments. This dual-module assembly serves as the backbone for turbine management systems, handling tasks like speed regulation, vibration monitoring, and real-time data synchronization in power generation facilities and heavy manufacturing plants.

| Key Specification | Technical Detail |

|---|---|

| Manufacturer | General Electric (GE) |

| Model Designation | IS215UCVHM06A IS415UCVHH1A B VET2-A21010 |

| Control Series | Mark VI Speedtronic |

| Module Type | Hybrid I/O Processing Unit |

| Operating Voltage | 24 VDC |

| Communication Protocols | Ethernet/IP, ISBUS, Genius Network |

Common deployment scenarios include gas turbine control rooms, wind farm monitoring stations, and hydroelectric plant synchronization systems. This module integrates seamlessly with GE’s Mark VI turbine control architecture, often working alongside companion components like the IS220PPDAH1B power distribution module and IS200SRTDH2A relay terminal board. A Midwest power plant technician recently shared how this module maintained precise generator synchronization during sudden load shifts, preventing potential grid instability.

What really stands out is the module’s dual-processor architecture – the primary UCVE processor handles real-time turbine dynamics while the secondary UCVE manages I/O communications. This separation ensures rock-solid reliability even during network congestion. The industrial-grade PCB coating resists moisture ingress in coastal power plants, and the modular connector design allows hot-swapping of field wiring during maintenance. Factory-programmed firmware eliminates configuration headaches, reducing commissioning time by 40% compared to generic control modules.

Reviews

There are no reviews yet.