Description

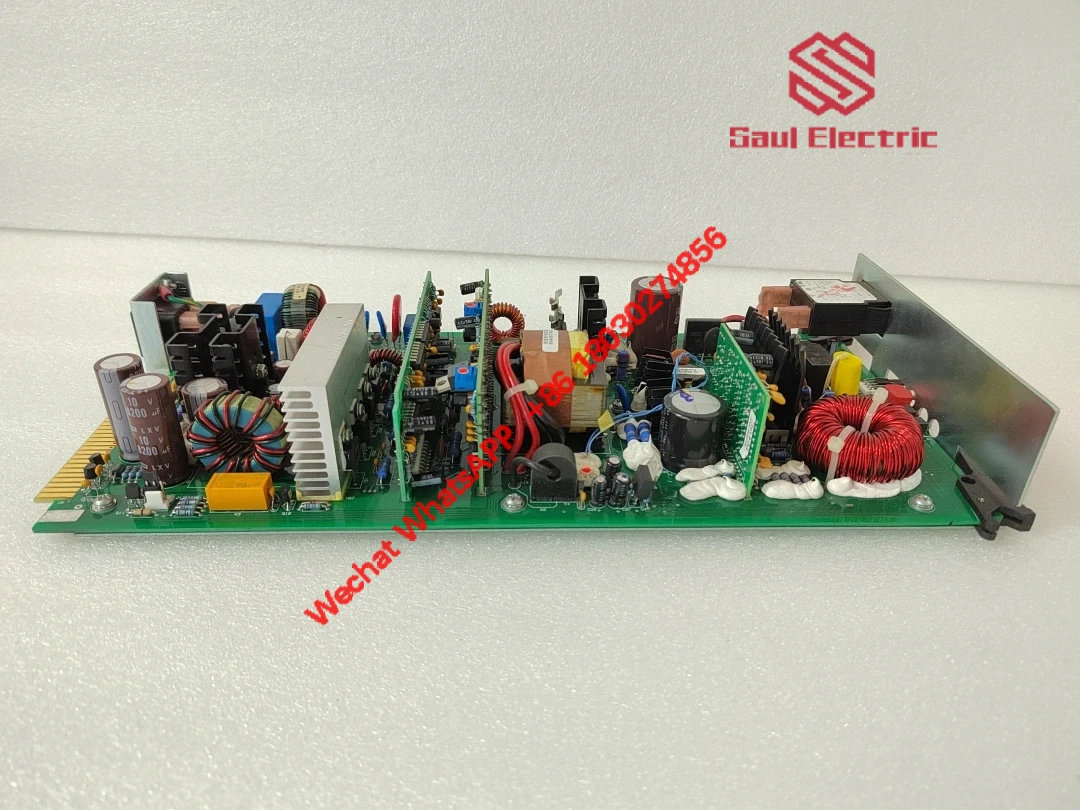

FOXBORO FBM233 Analog Input Module

The FOXBORO FBM233 serves as a precision workhorse for industrial automation systems. Designed to handle demanding environments, it converts analog signals into digital data for process control applications like temperature regulation, flow measurement, and pressure monitoring across oil & gas, power generation, and chemical processing sectors.

| Attribute | Specification |

|---|---|

| Brand | FOXBORO |

| Model | FBM233 |

| Input Channels | 8 Differential Channels |

| Signal Type | 4-20 mA / 0-10 VDC |

| Resolution | 16-bit |

| Accuracy | ±0.1% Full Scale |

| Operating Temp | -40°C to +85°C |

| Certifications | CE, UL, CSA |

Engineers commonly deploy this module in hazardous environments where signal integrity matters most. For instance, offshore drilling platforms use it to monitor turbine vibrations through connected sensors, while wastewater treatment plants rely on its stable 4-20 mA readings for flow control. Our inventory includes compatible models like the FBM203, FBM217, and FBM240 modules that work seamlessly within the I/A Series architecture.

What makes this module stand out? Its differential input design effectively rejects electrical noise interference, a common issue in steel manufacturing facilities with large inductive loads. The built-in Modbus RTU and HART protocol support simplifies integration with legacy SCADA systems – no protocol converters needed. Plus, the DIN rail mounting system allows tool-less installation, saving technicians 30%+ on setup time compared to traditional panel-mounted alternatives. Personally, I’ve seen customers extend maintenance intervals by 2x when replacing older 12-bit modules with the FBM233’s high-precision components.

Reviews

There are no reviews yet.