Description

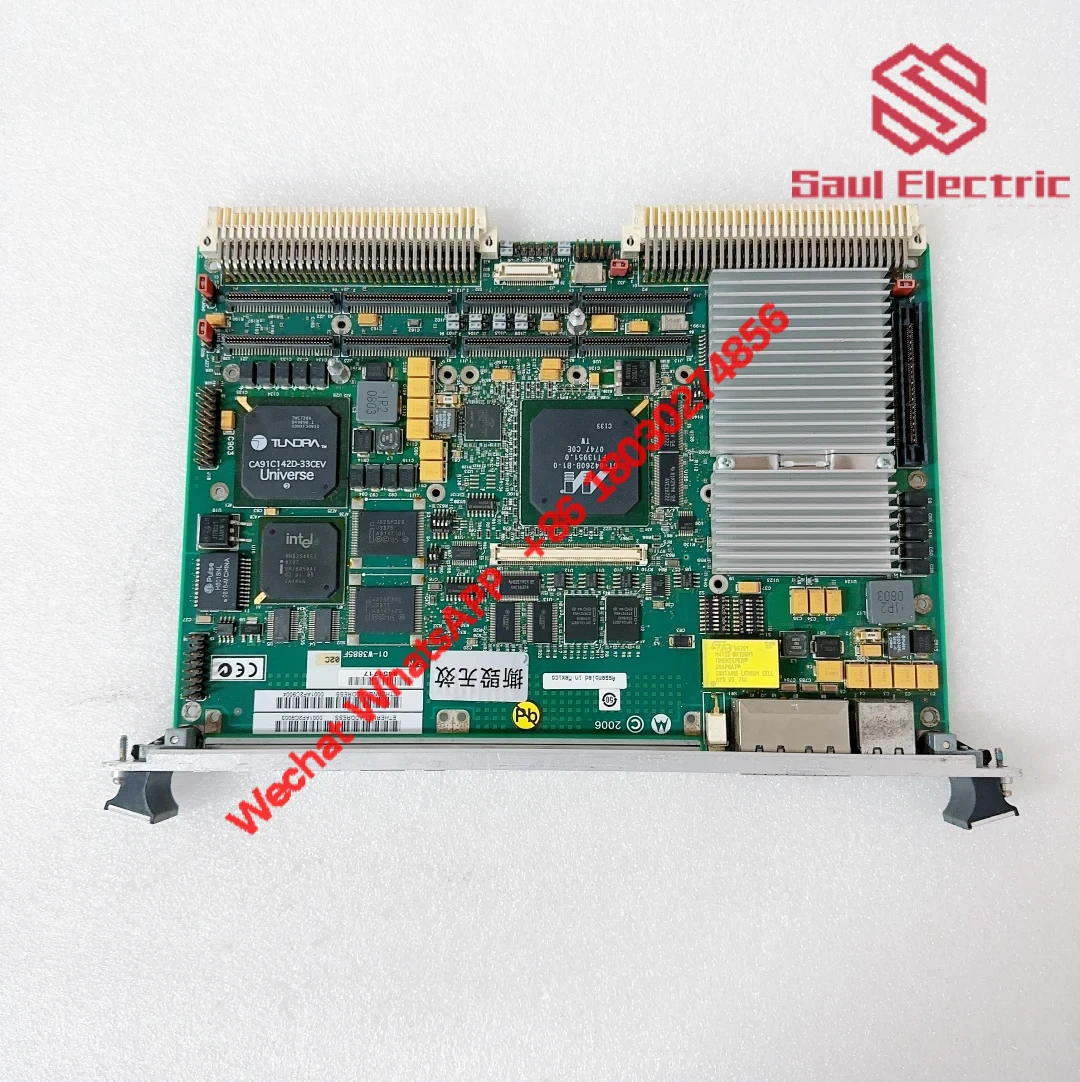

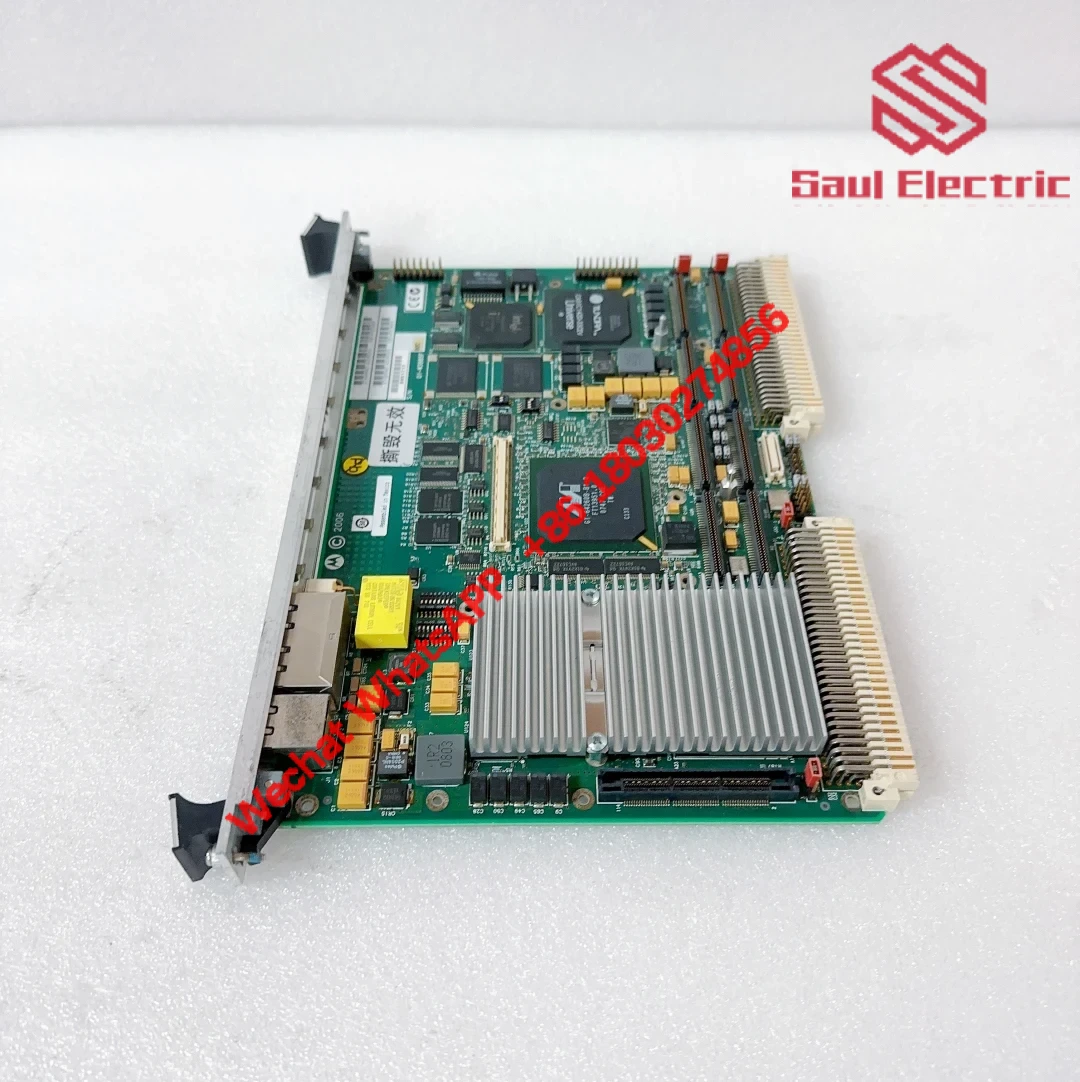

EMERSON MVME5500 Motor Control Module

The EMERSON MVME5500 Motor Control Module serves as a backbone for precision motor management in heavy-duty industrial settings. I’ve seen this module excel in applications like conveyor systems and automated assembly lines, where maintaining consistent torque and energy efficiency matters most. Its design prioritizes seamless integration with existing automation frameworks, making it a go-to choice for upgrading legacy systems without compromising performance.

| Brand | Operating Voltage | Output Power | Control Method |

|---|---|---|---|

| EMERSON | 380 V AC | Up to 750 kW | Vector Control |

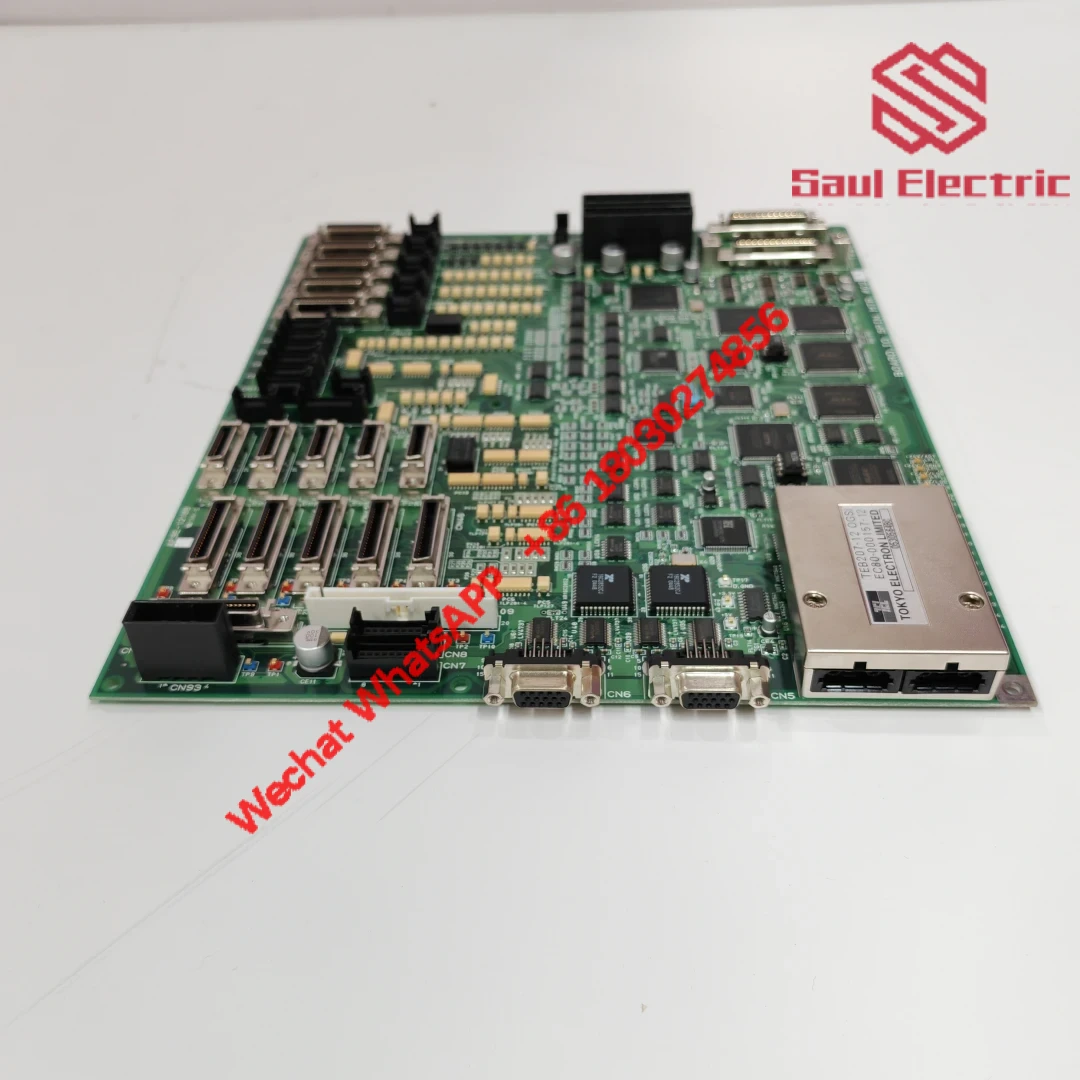

Communication protocols like Profinet and Ethernet allow real-time data exchange, which a customer in the automotive sector found critical for synchronizing robotic arms on their production floor. The module’s IP21 rating and tolerance for temperatures between -20°C to +50°C make it suitable for environments ranging from dusty textile mills to humid food processing plants.

For companies relying on Emerson’s OVATION or WDPF systems, the MVME5500 complements existing infrastructure while offering scalability. A technician I spoke to mentioned how its intuitive software tools cut setup time by 30% compared to older modules, though the physical footprint remains compact enough for retrofitting into tight control cabinets.

What sets this module apart is its robustness in fluctuating conditions—like handling voltage dips without triggering false alarms. While it lacks explicit redundancy features, pairing it with dual communication channels in a networked setup provides a workaround for critical processes. Just note that its IP21 rating means it’s not fully sealed against water jets, so avoid direct washdown zones unless adding external enclosures.

Reviews

There are no reviews yet.