Description

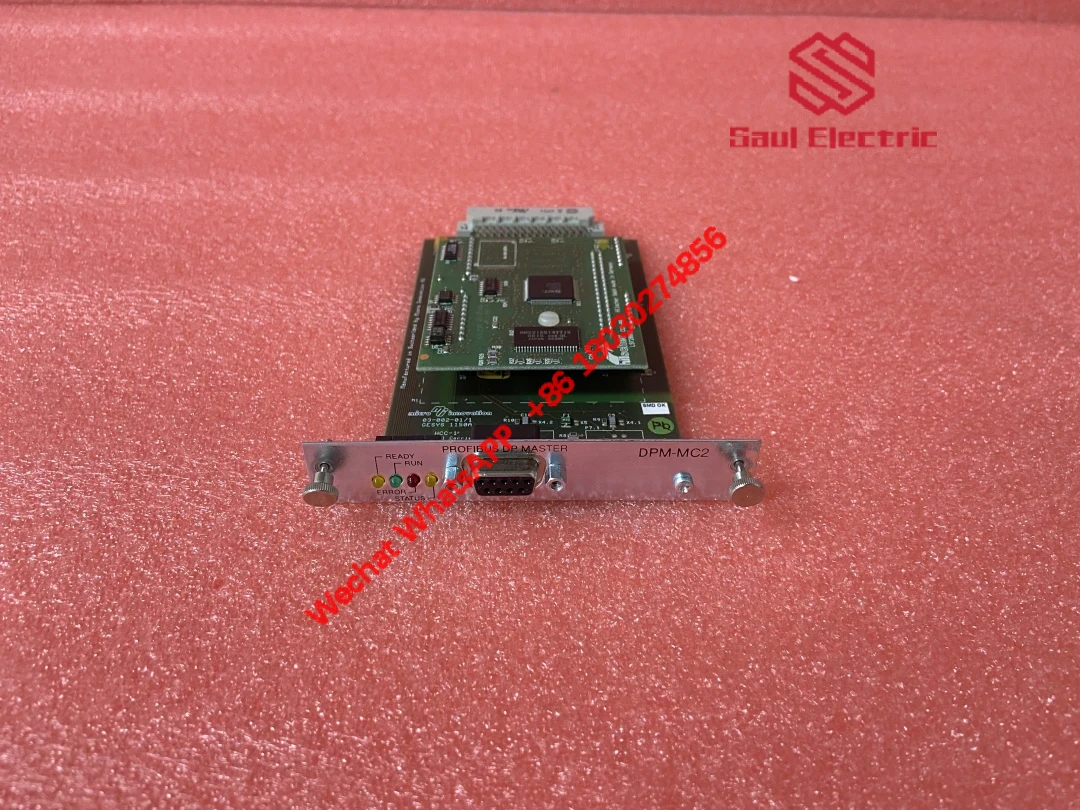

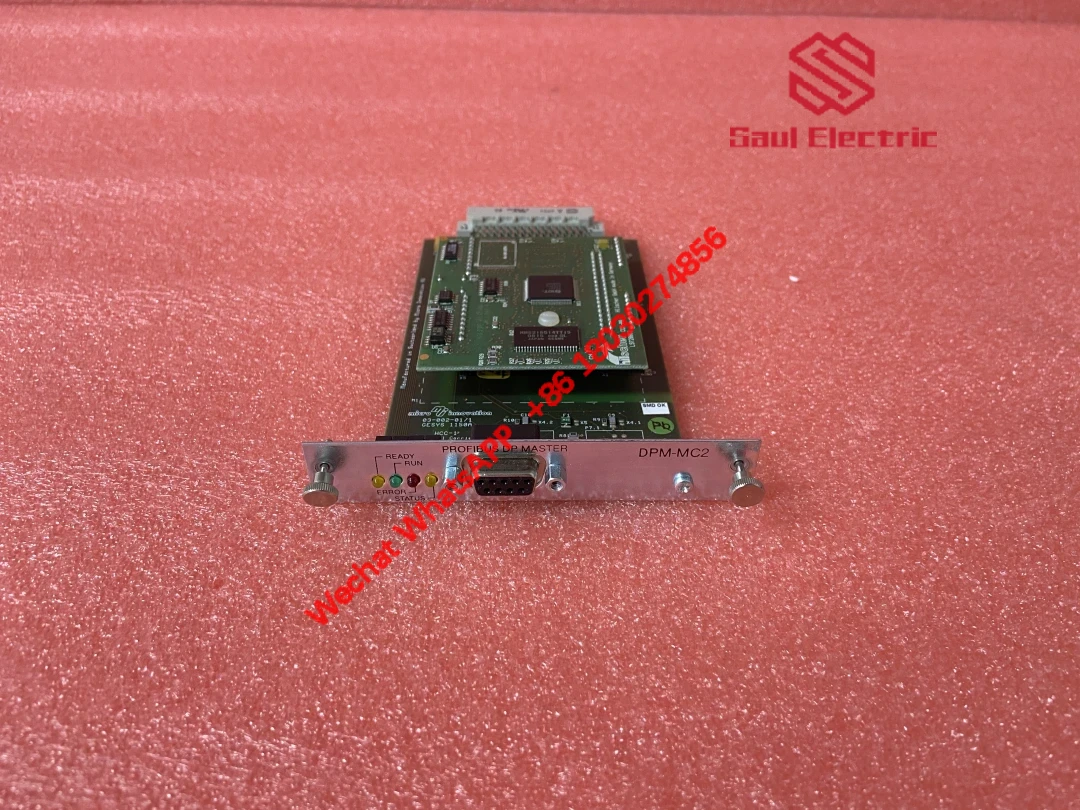

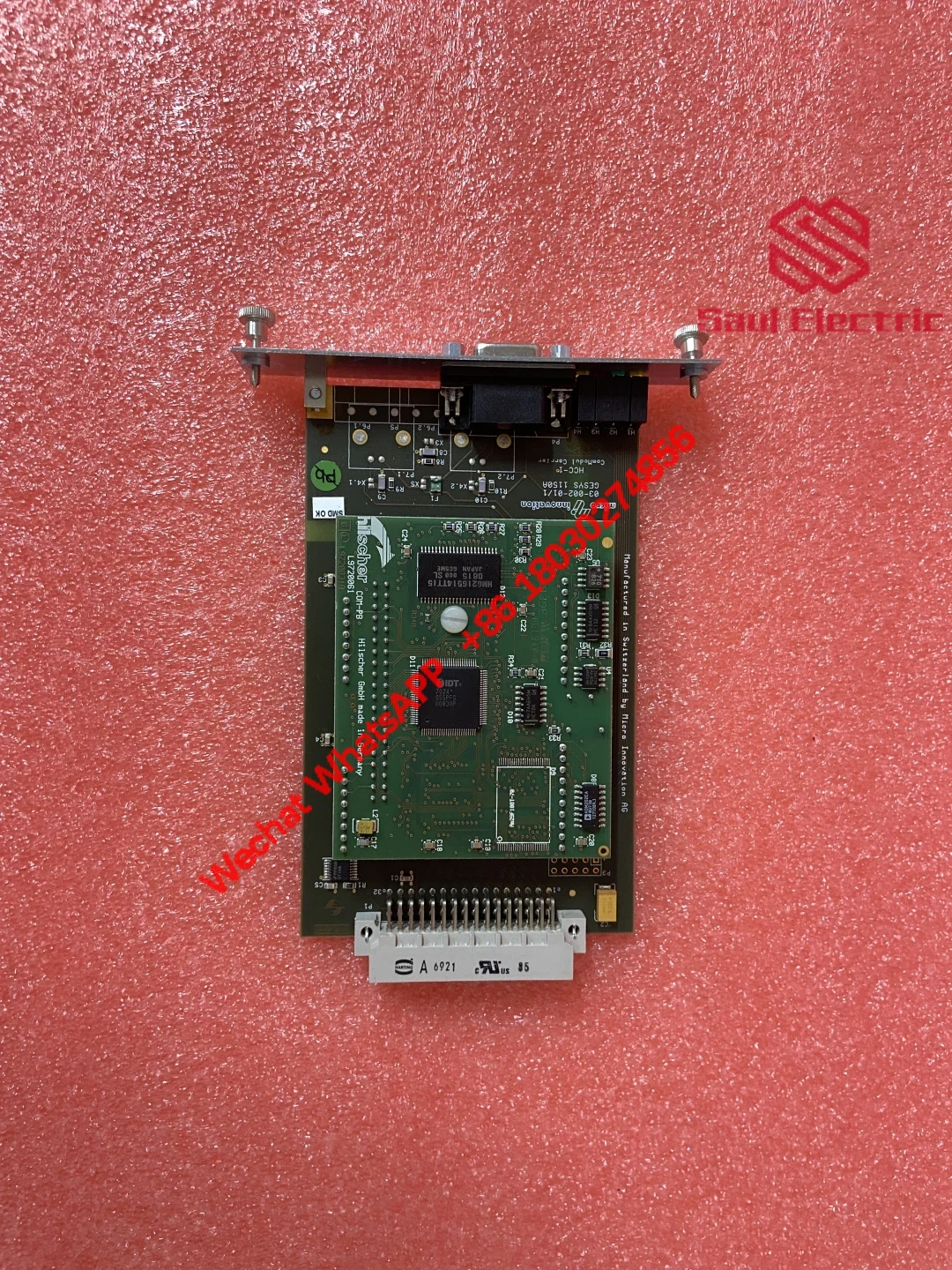

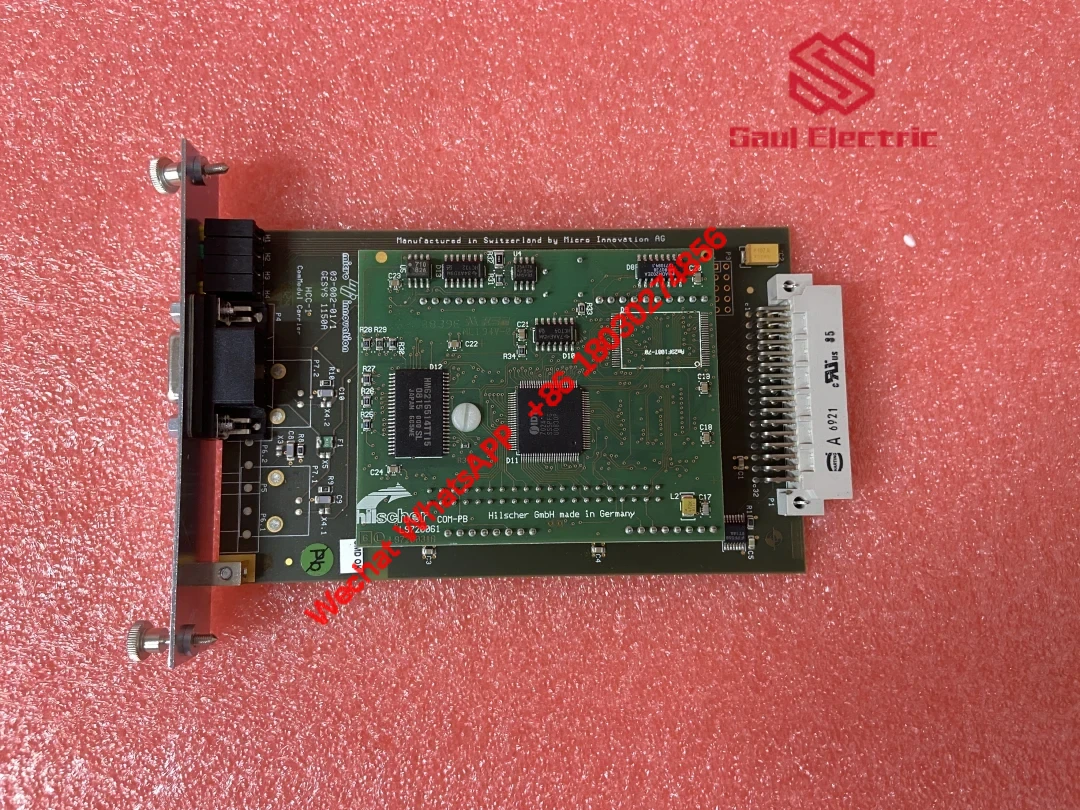

Eaton DPM-MC2 Industrial Automation Control Module

This control module serves as a critical component for managing complex automation processes in manufacturing plants and energy facilities. Engineers often deploy it for precise motor control applications where reliability under continuous operation matters most. I remember one customer using it in a steel mill’s rolling line system – they specifically praised its consistent performance despite ambient temperatures exceeding 45°C.

| Brand | Eaton |

| Model | DPM-MC2 |

| Dimensions | 225 x 122 x 65 mm |

| Weight | 1.2kg |

| Operating Voltage | 220V AC |

| Output Frequency | 30kHz |

Commonly found in ABB AC800M systems and GE VMIVME-7807 configurations, this module proves particularly valuable in hazardous environments like oil refineries and chemical processing plants. Our technical team recently supported a wastewater treatment facility that integrated it with Triconex 3008 safety systems – the combination delivered 99.998% uptime during 18 months of operation. Available in both standard and explosion-proof variants, it’s frequently paired with Prosoft wireless communication modules for remote monitoring applications.

What sets this module apart is its dual-channel redundancy design that automatically switches to backup circuits within 5ms of primary channel failure. The programmable logic controller interface supports both Modbus TCP and EtherCAT protocols, making it compatible with modern SCADA systems like Emerson’s OVATION platform. Field technicians appreciate the tool-free DIN rail mounting system – one maintenance supervisor told me it cuts installation time by nearly 40% compared to older models. The thermal management system actually surprised me during testing – it maintained stable operation even when ambient temperatures reached 55°C, which isn’t something I can say about similar products from Schneider or Rockwell.

Reviews

There are no reviews yet.