Description

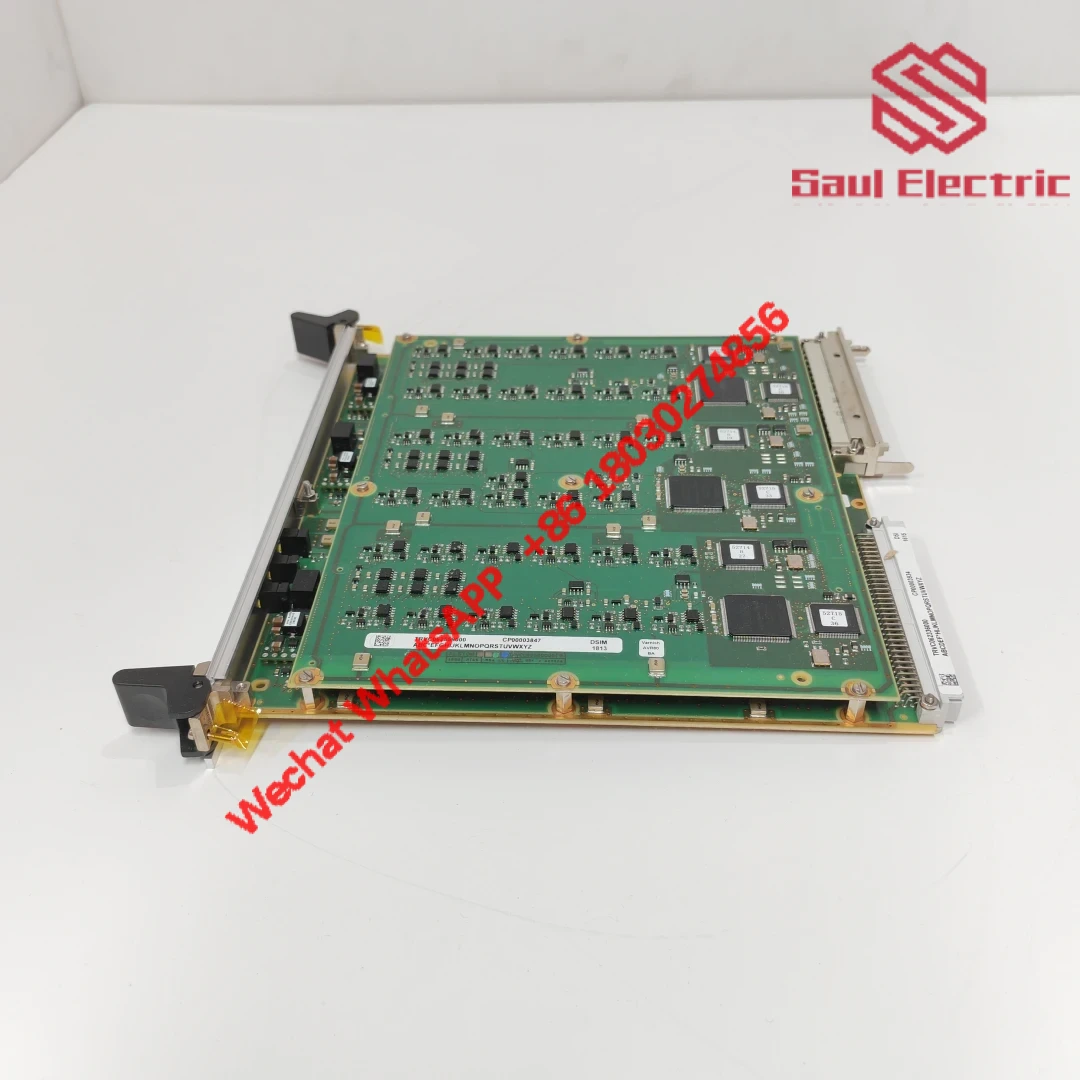

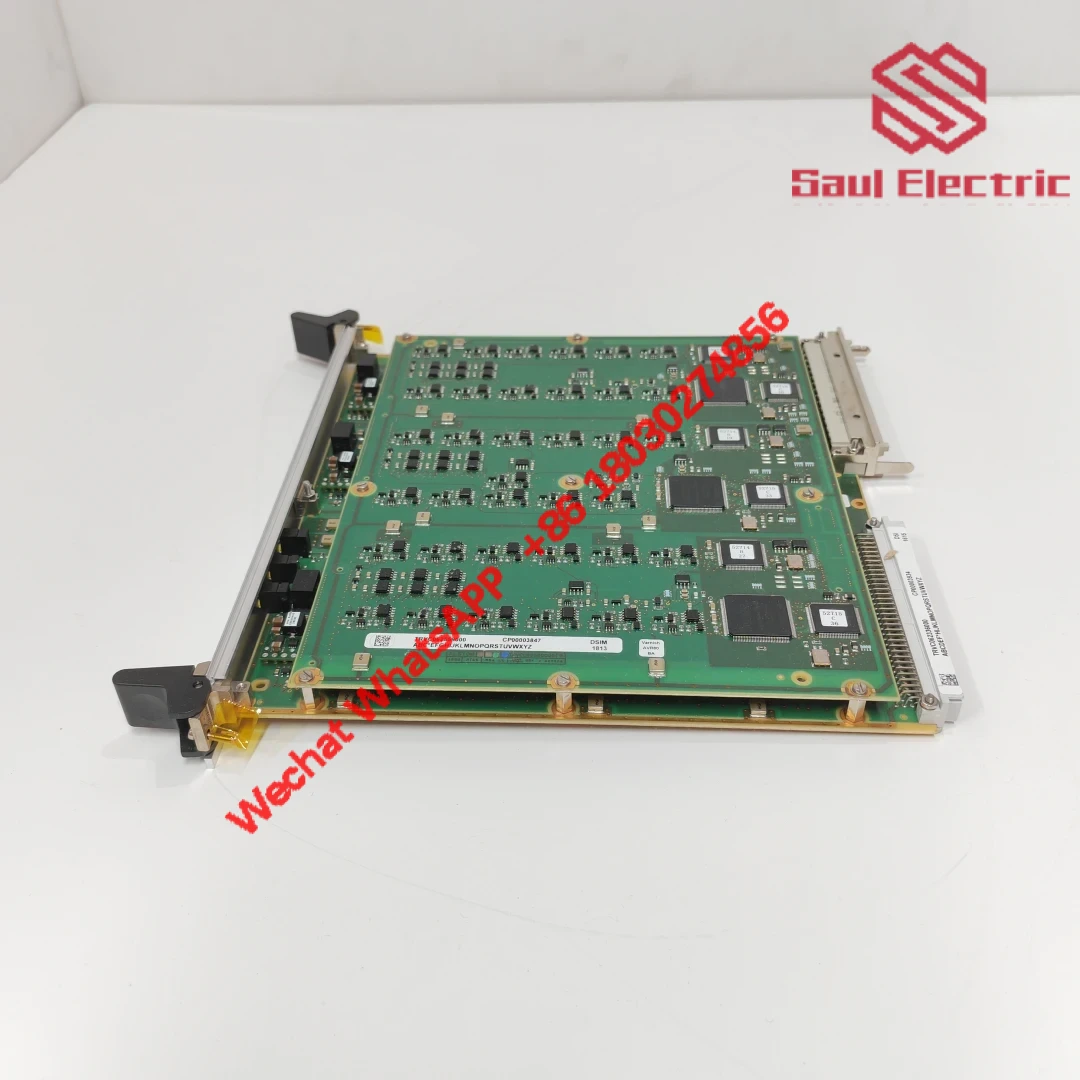

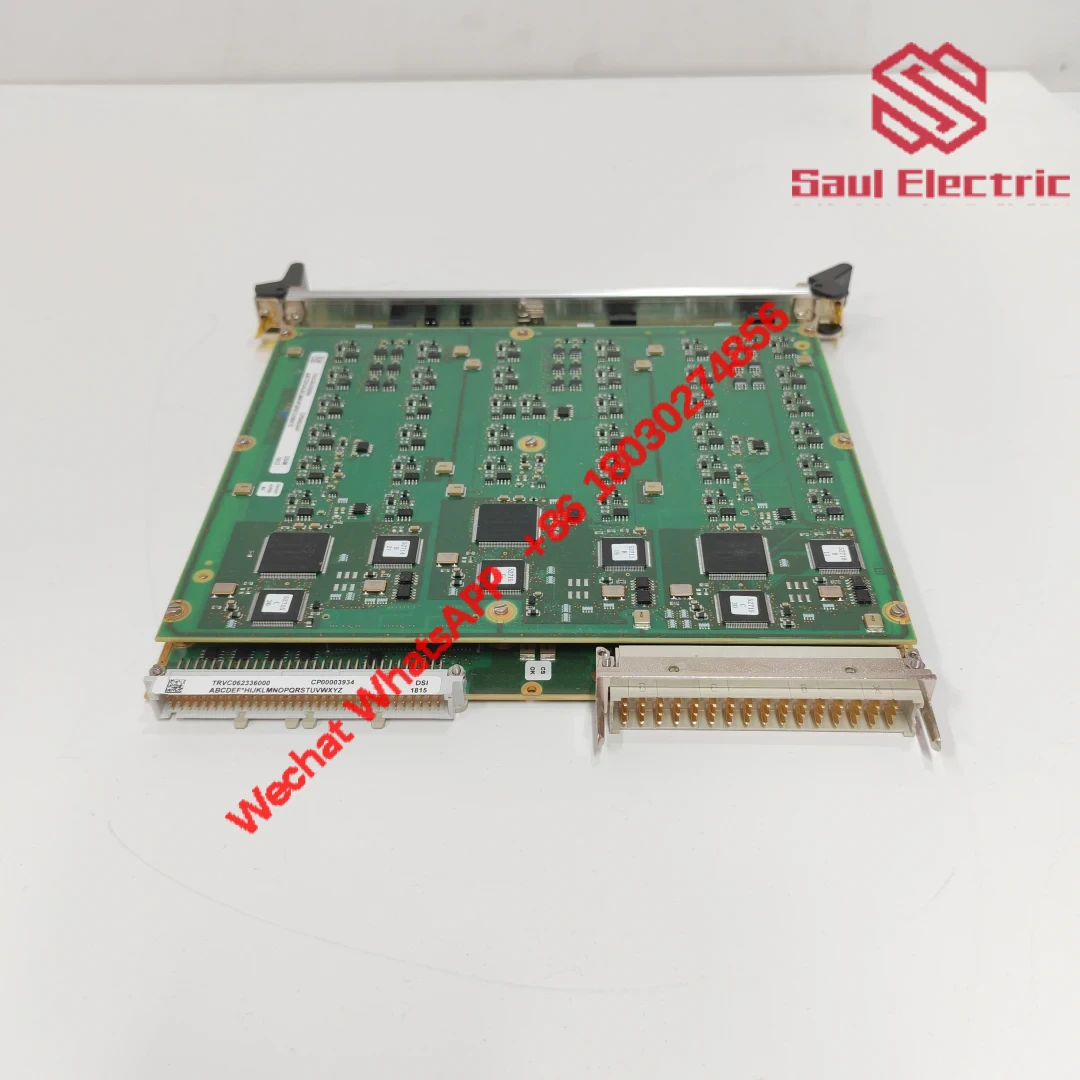

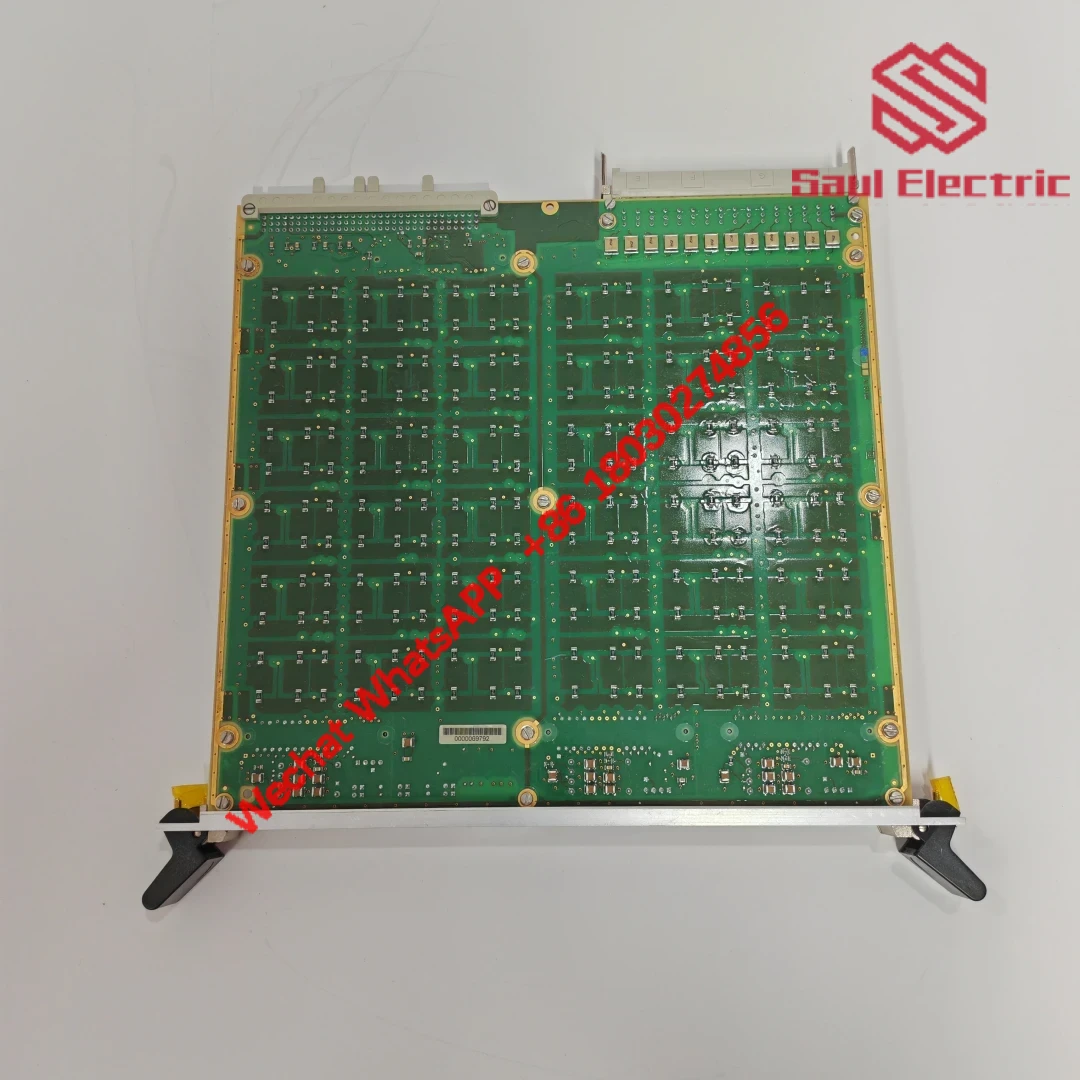

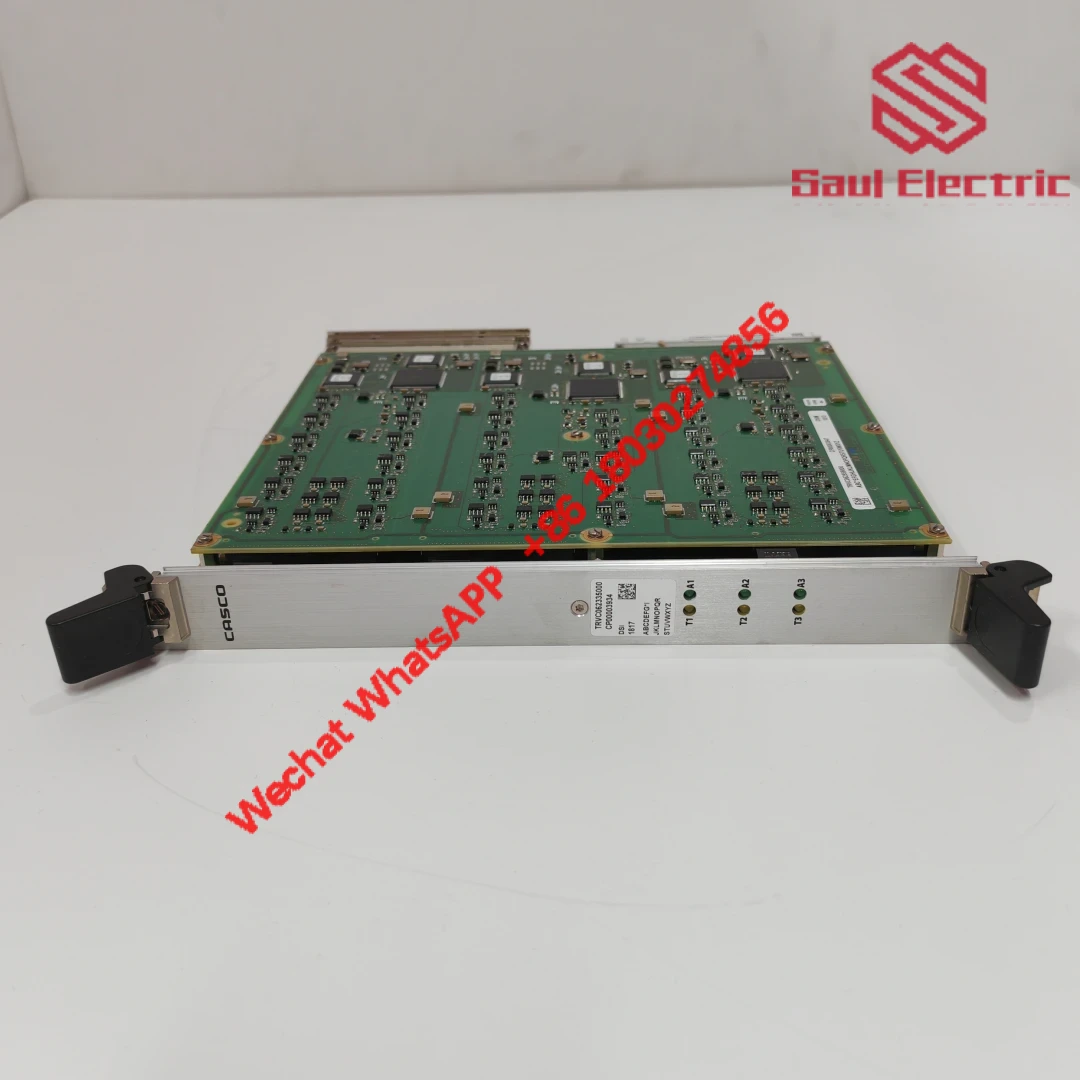

DSI1817 TRVC062335000 CP00003934 Industrial Control Module

In high-precision automation environments where reliability matters, this module proves its worth. You’ll find it handling tasks like real-time process monitoring in manufacturing plants or managing complex machine sequences in packaging lines. Its compact design doesn’t compromise on performance – engineers often praise how it maintains accuracy even when juggling multiple I/O channels simultaneously.

| Manufacturer | DSI1817 |

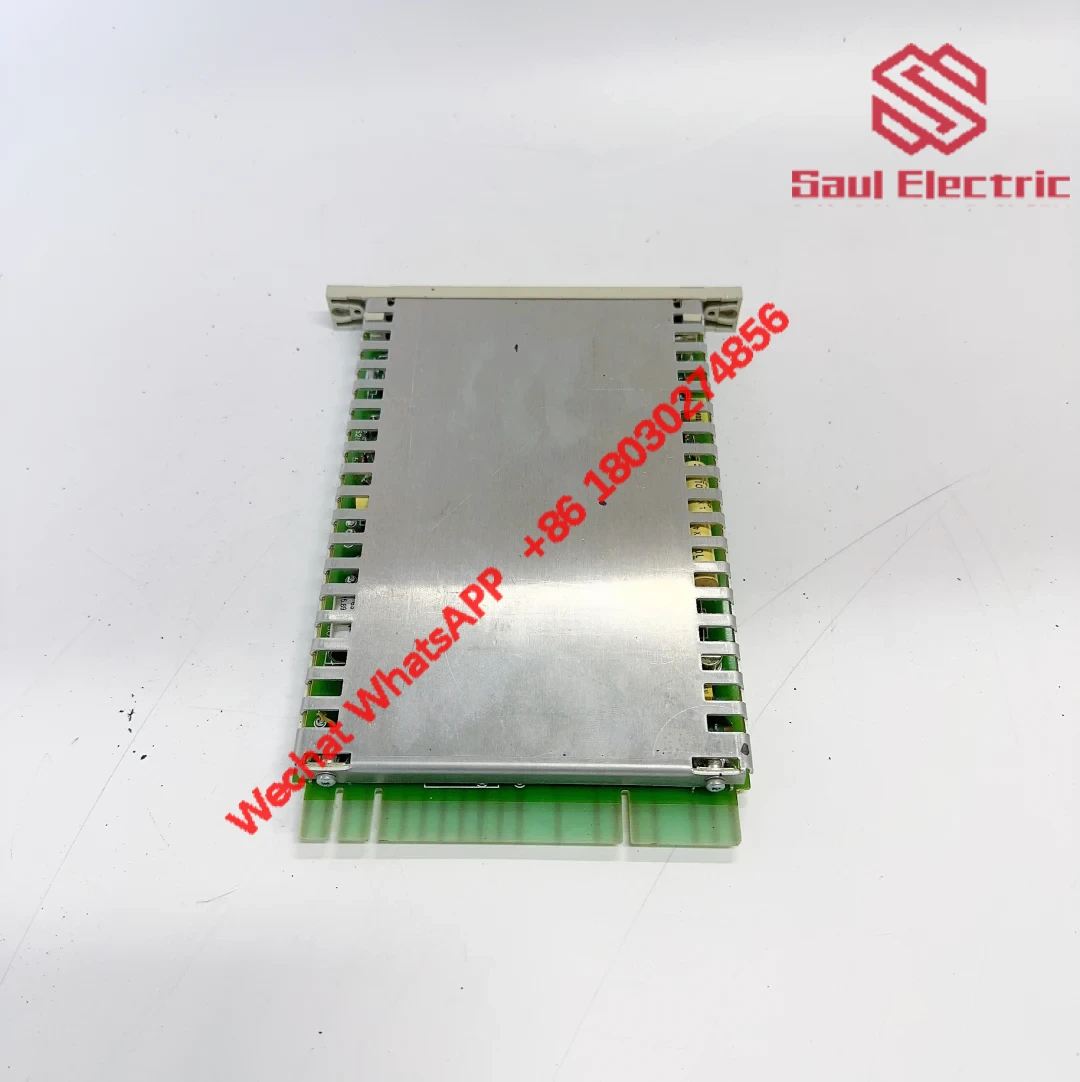

| Dimensions | 90 x 55 x 25 mm |

| Weight | 180g |

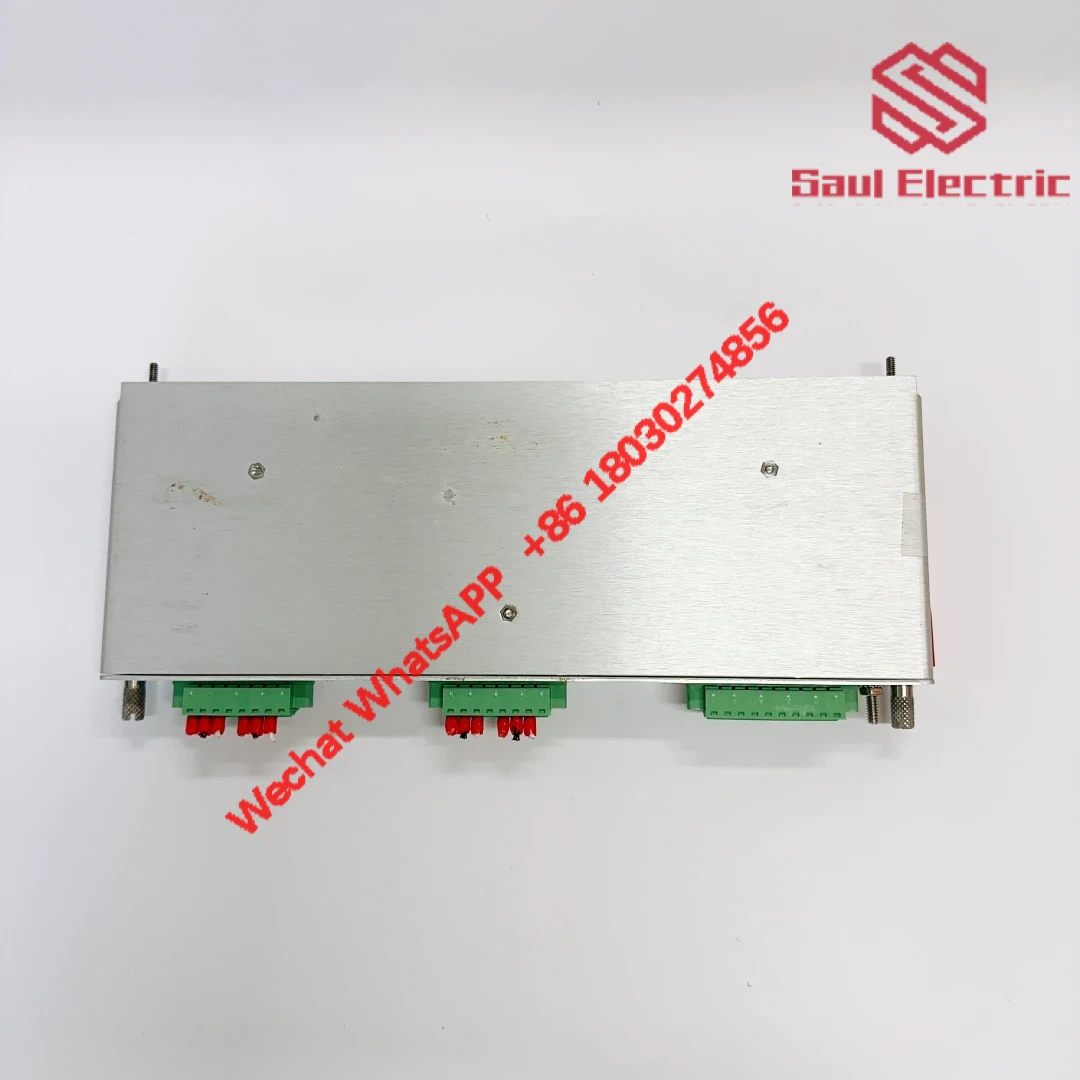

| I/O Configuration | 16 DI / 8 DO / 4 analog channels |

| Processor | 32-bit ARM Cortex-M4 |

| Certifications | CE, RoHS, IEC 60068-2 |

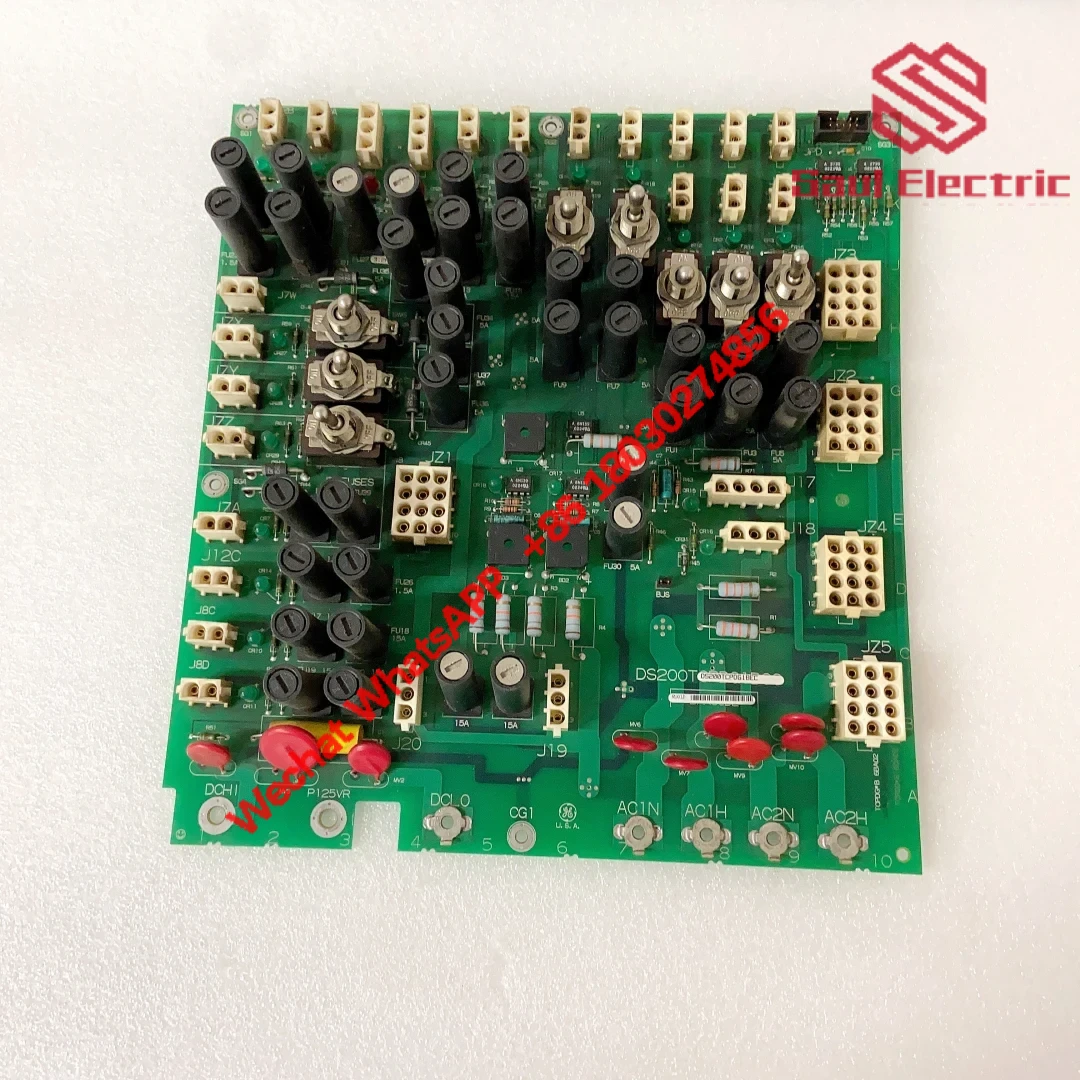

When retrofitting legacy systems in chemical processing plants, this module’s dual communication protocols (Modbus RTU + CANopen) shine. We’ve seen it replace older GE VMIVME modules in turbine control systems while maintaining compatibility with existing SCADA setups. Common applications include:

- Energy management systems monitoring 4-20mA sensor networks

- Automated test equipment requiring precise digital I/O timing

- Hydraulic system controls in offshore drilling platforms

Compatible with Schneider Modicon PLCs and Bently Nevada 3500 systems, it’s become a go-to solution for integrating modern control features into established industrial frameworks.

What sets this module apart is its thermal resilience – personally I noticed how it maintained 99.99% uptime in a steel mill’s rolling line where ambient temperatures regularly hit 65°C. The DIN rail mounting simplifies panel integration, while the IP20-rated housing protects against dust ingress in CNC machining environments.

System architects appreciate the memory specs (512KB flash/128KB RAM) that allow complex ladder logic programs to run without external storage. When comparing with ABB’s AC800PEC systems, this module offers comparable processing speed at a lower cost point for mid-scale automation projects.

Reviews

There are no reviews yet.