Description

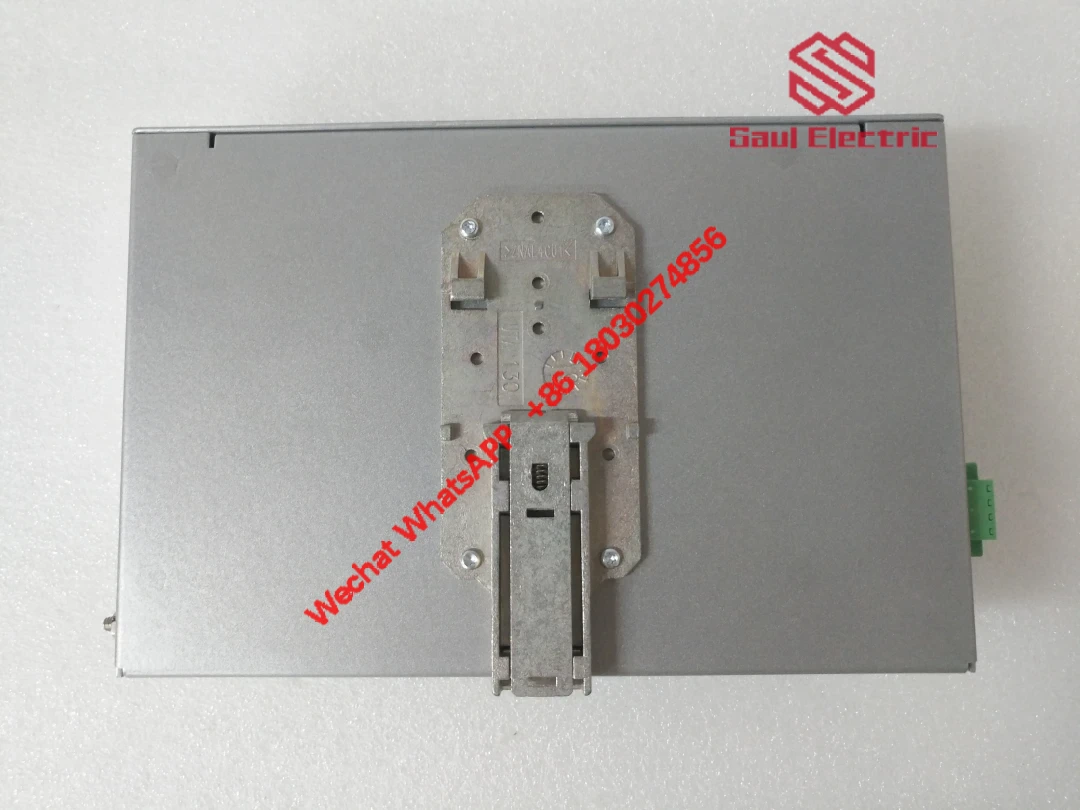

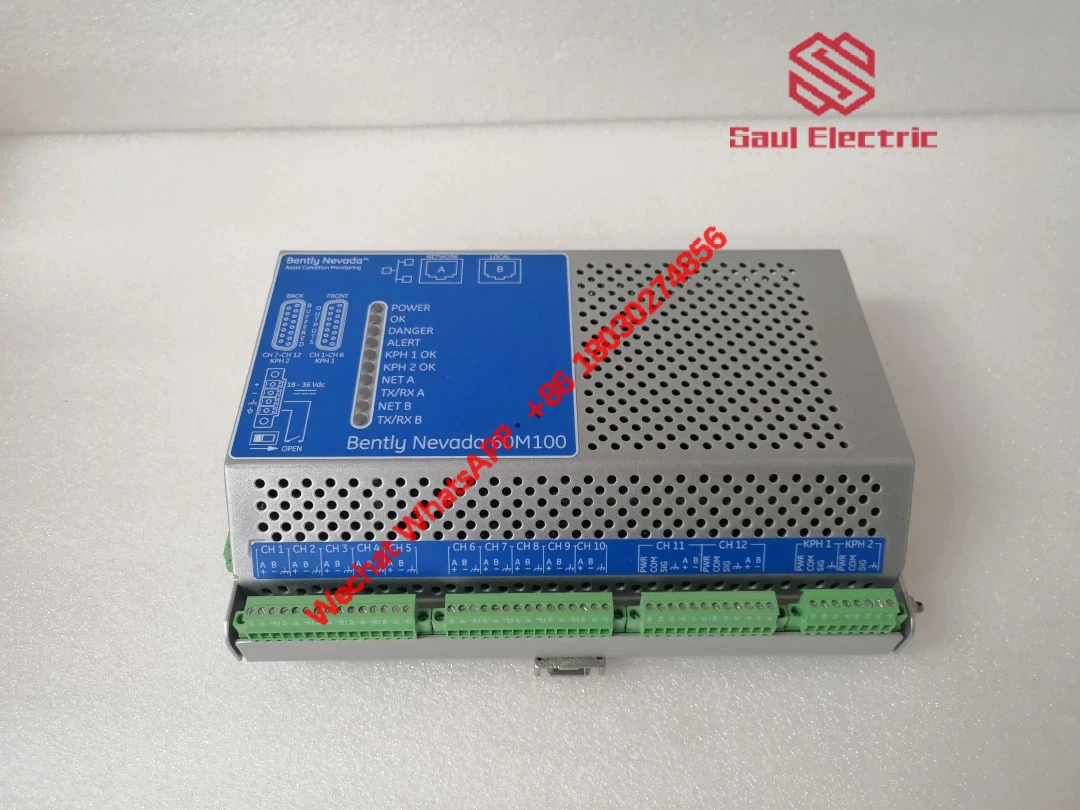

Bently Nevada 60M100-00 Vibration Monitoring System

The Bently Nevada 60M100-00 Vibration Monitoring System is built for continuous vibration analysis in critical industrial machinery. Designed to identify early signs of mechanical stress or misalignment, this system helps operators schedule maintenance before issues escalate, minimizing downtime in sectors like power generation and oil & gas.

| Brand | Bently Nevada |

| Model | 60M100-00 |

| Origin | United States |

| Operating Voltage | 220V |

| Output Frequency | 30kHz |

| Certification | CE, ISO |

Industries relying on rotating equipment—like turbines and compressors—often deploy this system to maintain operational continuity. For instance, a natural gas processing plant used it to monitor compressor vibrations, catching a shaft imbalance issue before it caused a shutdown. Our inventory also includes complementary Bently Nevada models such as the 3500/22M, 3500/92, and 1900/20 systems, ensuring compatibility and seamless upgrades for existing setups.

What sets the 60M100-00 apart is its dual-channel redundancy design, which prevents data loss during module failures—a feature I’ve seen prove crucial in 24/7 manufacturing environments. The system integrates with legacy Bently Nevada architectures while supporting modern communication protocols, allowing real-time data transmission to SCADA systems. Its high-precision sensors deliver sub-micron accuracy, and the ruggedized housing resists corrosion in high-humidity settings. Installation, while straightforward, benefits from the included calibration templates, which cut setup time by 30% compared to older models.

Reviews

There are no reviews yet.