Description

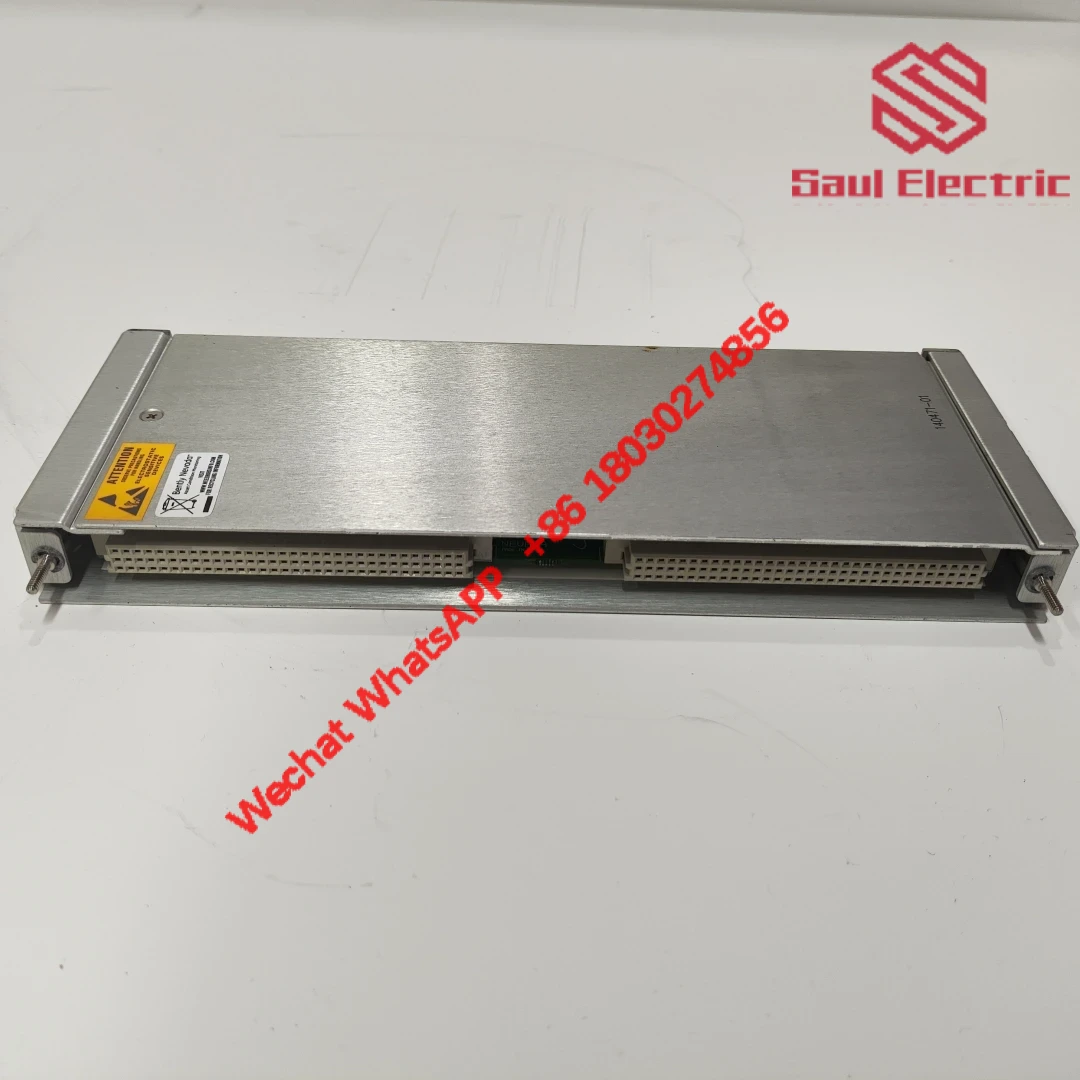

Bently Nevada 3500/70 140471-01 Vibration Monitoring Module

Monitoring rotating machinery vibrations isn’t just about preventing breakdowns – it’s about keeping production lines running smoothly. The 3500/70 module handles this by continuously tracking vibration levels across 16 channels, giving operators early warnings about potential issues in equipment like turbines, pumps, and compressors. We’ve seen this module catch bearing wear issues weeks before they’d become critical in offshore oil platforms.

| Manufacturer | Bently Nevada |

| Model Number | 3500/70 140471-01 |

| Input Channels | 16 channels |

| Signal Inputs | 4-20mA / 0-10V / Frequency |

| Communication | Modbus RTU over RS-485 |

| Power | 24VDC @ <1A |

| Operating Temp | -20°C to +70°C |

| Weight | 1.5kg (3.3lbs) |

When we installed these modules at a natural gas processing plant, they handled everything from monitoring compressor vibrations to tracking turbine shaft movements. The Modbus RTU interface made integration with their Siemens S7 PLC system straightforward. Other common applications include:

- Steam turbine monitoring in power plants

- Centrifugal compressor protection in refineries

- Pump vibration tracking in chemical processing facilities

Our inventory includes related models like the 3500/44 Proximitor interface modules and 3500/92 relay modules that often work alongside this unit.

What makes this module stand out isn’t just its specs – it’s how those specs translate to real-world performance. The -20°C to +70°C operating range means it can handle both Arctic oil fields and desert power plants. I remember one installation where electrical noise from nearby VFDs would’ve caused false readings with lesser modules, but the 3500/70’s shielding kept the data clean.

Key advantages include:

- Redundant power supply connections prevent single-point failures

- Field-upgradable firmware maintains compatibility with evolving systems

- Channel-specific alarm settings allow tailored protection per machine

- ATEX/IECEx certifications for use in hazardous areas

This isn’t just another vibration monitor – it’s a system that grows with your needs. Adding more modules to expand monitoring coverage takes just a few minutes thanks to the standardized rack mounting system.

Reviews

There are no reviews yet.