Description

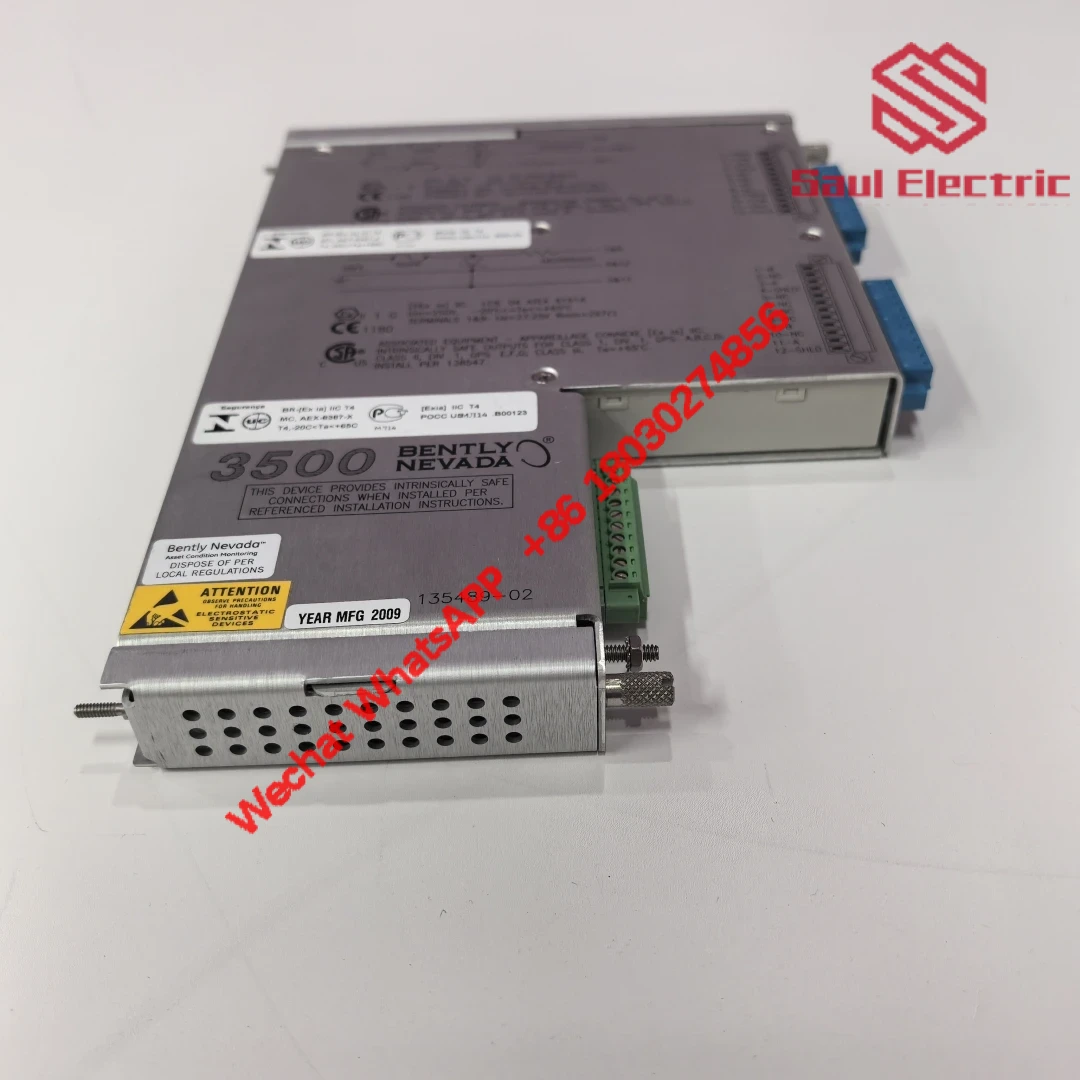

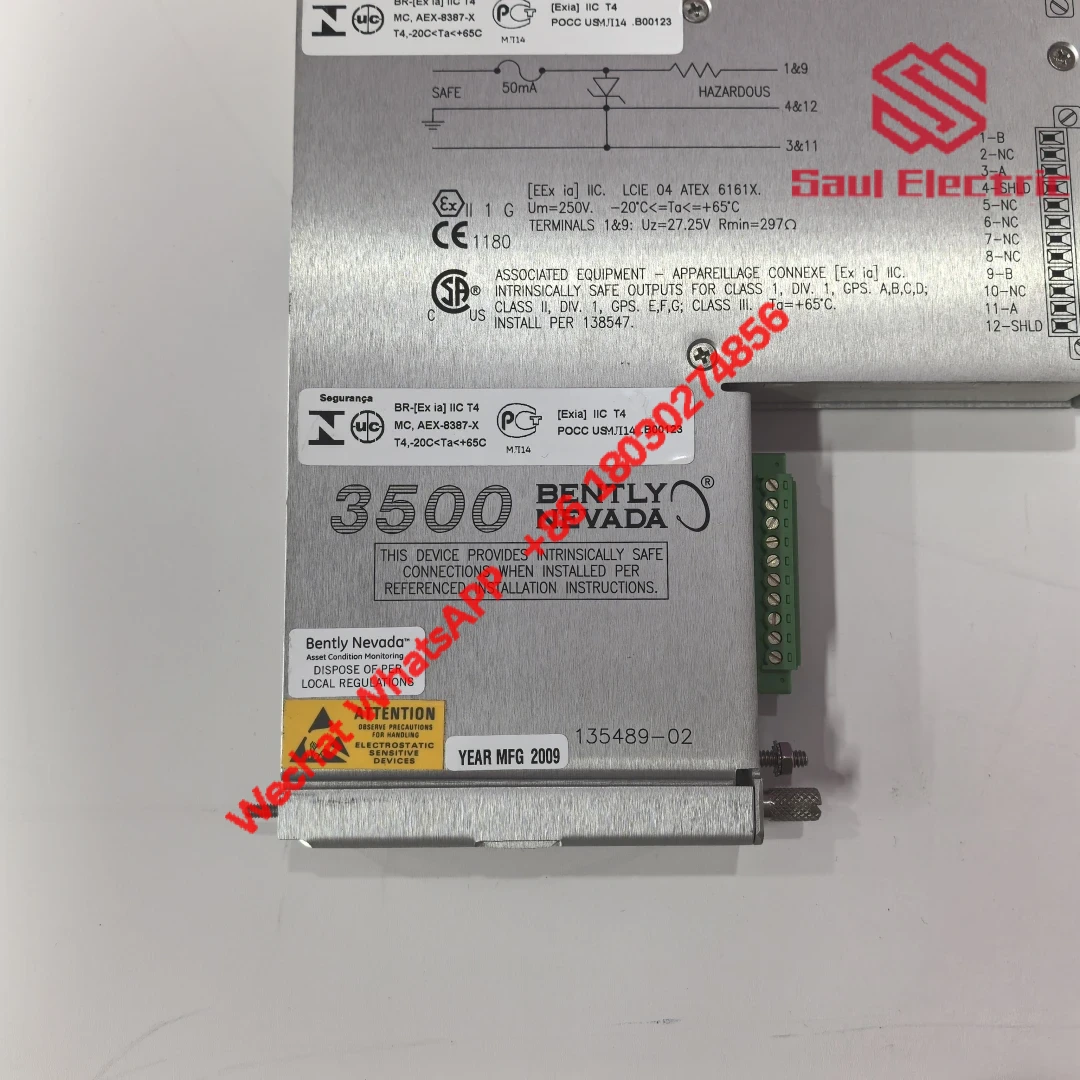

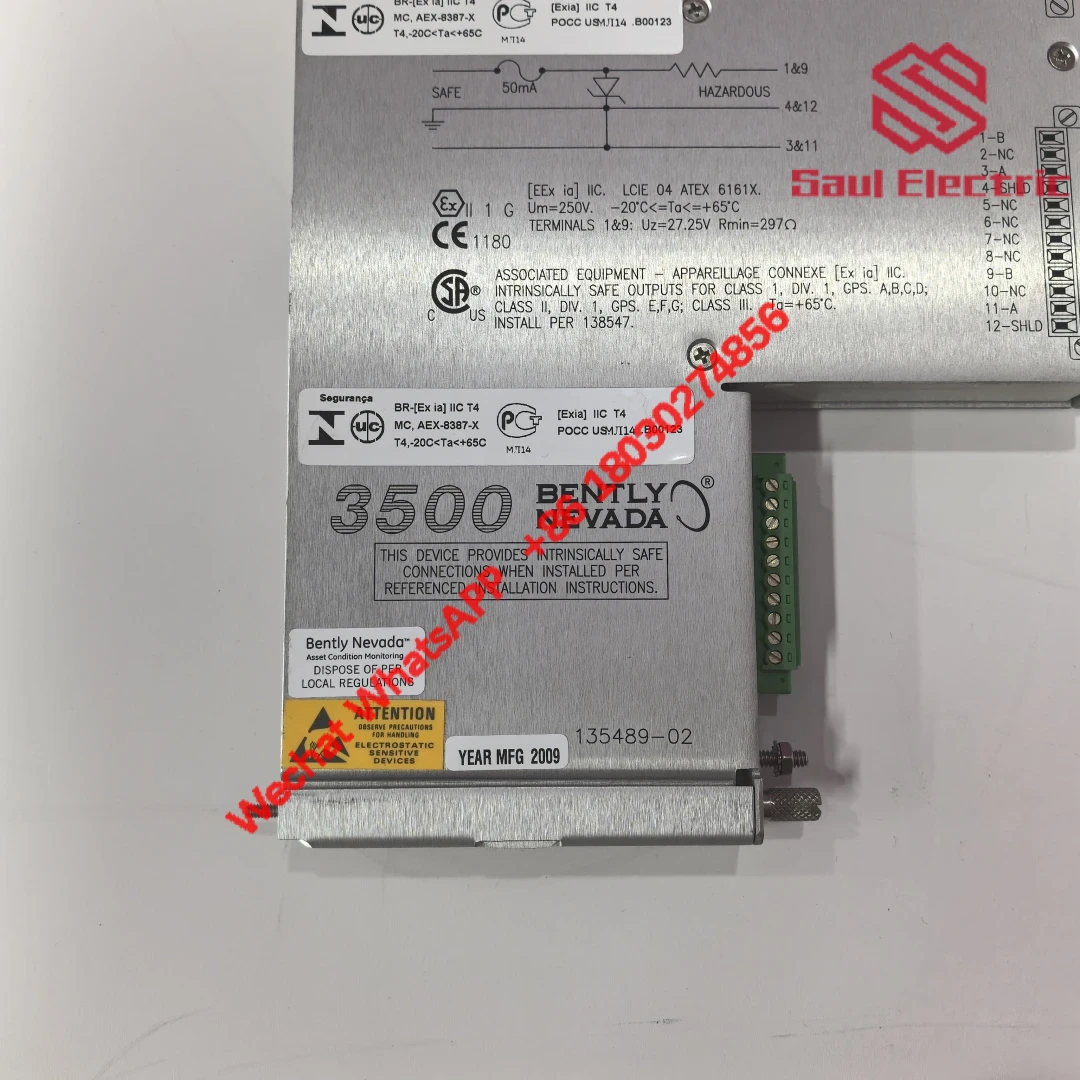

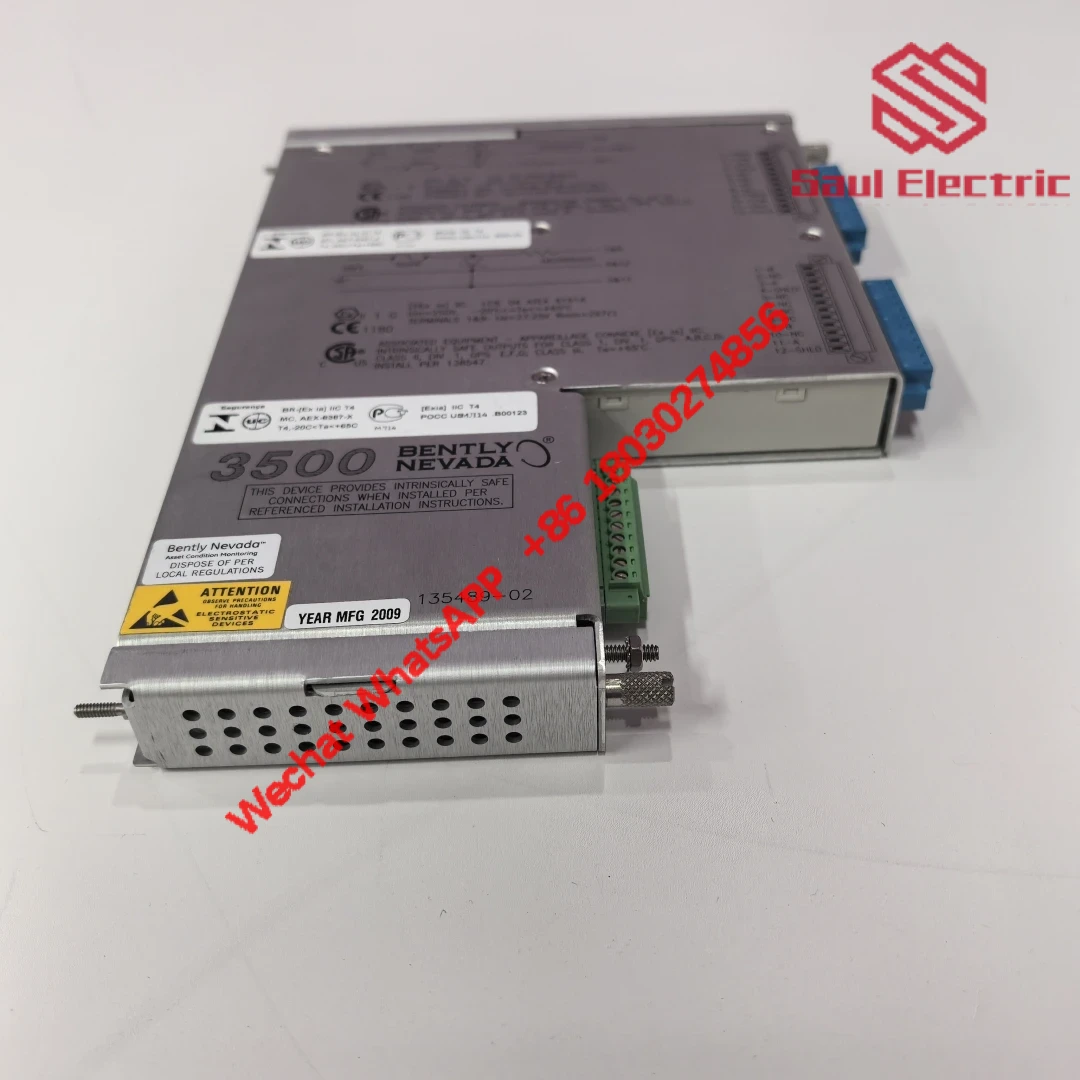

Bently Nevada 135489-02 I/O Module for Industrial Automation

This Bently Nevada 135489-02 I/O module isn’t just another industrial component – it’s the backbone of vibration monitoring systems where precision matters most. Designed for environments where equipment health directly impacts operational safety, this module handles signal acquisition for displacement, acceleration, and velocity measurements with rock-solid reliability.

| Module Type | Multi-channel I/O Module |

| Signal Inputs | 2 Displacement/Acceleration + 2 Velocity Signals |

| Power Supply | 24VDC (via 3500 rack) |

| Input Range | ±10V analog |

| Communication | Backplane Bus + Modbus RTU |

| Operating Temp | -30°C to +65°C |

| Dimensions | 160x120x25mm |

| Weight | 0.5kg |

| Certification | Intrinsically Safe |

Engineers working with critical machinery like steam turbines or centrifugal compressors will appreciate how this module integrates into the 3500 series monitoring system. A refinery in Texas recently used it to replace aging vibration monitoring hardware on their gas processing units – the result? 15% faster fault detection during startup sequences. It pairs perfectly with Bently’s 3300 series eddy current probes and 3561 accelerometers, but also works with third-party 4-20mA vibration transmitters through proper configuration.

What makes this module stand out isn’t just the specs – it’s the practical benefits. The hot-swappable design means you can replace faulty modules mid-operation, which saved a paper mill in Canada $12k in downtime last year. The isolation between channels? That’s what helped an offshore platform maintain signal integrity despite constant mechanical vibration from drilling operations. Plus, the built-in safety barriers let you connect directly to Zone 1 hazardous areas without additional protection measures.

Reviews

There are no reviews yet.