Description

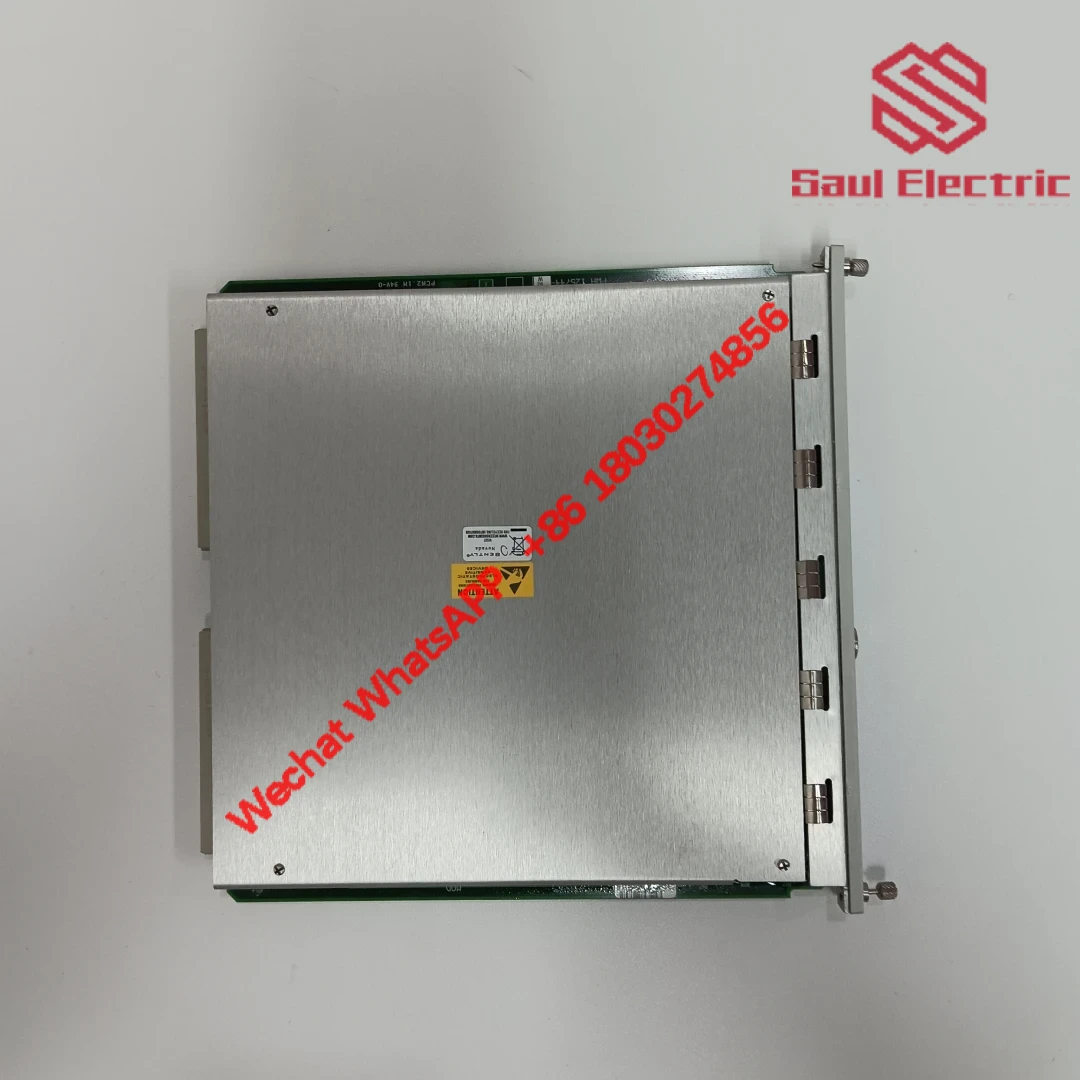

Bently Nevada 133396-01 Overspeed Detection Module

Engineered for precision in high-stakes environments, the Bently Nevada 133396-01 serves as a critical safeguard for rotating machinery like turbines and compressors. This module excels in detecting overspeed conditions, delivering real-time alerts to prevent equipment damage and ensure operational continuity. Its robust design makes it a go-to solution for industries prioritizing safety without compromising performance.

| Brand | Bently Nevada |

| Model | 133396-01 |

| Voltage | 220 V |

| Output Frequency | 30 kHz |

| Mounting | DIN Rail/Panel |

| Dimensions | Approx. 150 x 100 x 30 mm |

| Weight | ~0.5 kg |

Commonly deployed in power plants and offshore drilling rigs, this module has proven its mettle in extreme conditions. A customer once shared how it prevented a turbine shutdown during a sudden pressure spike at their facility. We frequently pair it with other 3500 Series components like the 3500/44 and 3500/22M, offering bundled solutions for vibration monitoring systems. Its versatility extends to compatibility with legacy Bently Nevada setups, ensuring seamless upgrades without overhauling existing infrastructure.

The module’s digital signal processing architecture ensures sub-millisecond response times – a lifesaver when milliseconds determine equipment integrity. Unlike older analog models, its immunity to electrical noise in industrial environments reduces false alarms by up to 60%. The dual mounting options simplify retrofitting into cramped control cabinets, while the galvanic isolation between channels protects connected systems from voltage surges. When integrated with Bently Nevada’s 3500 monitoring platform, users gain access to predictive maintenance features via Modbus RTU protocols, enabling preemptive repairs before failures escalate.

Reviews

There are no reviews yet.