Description

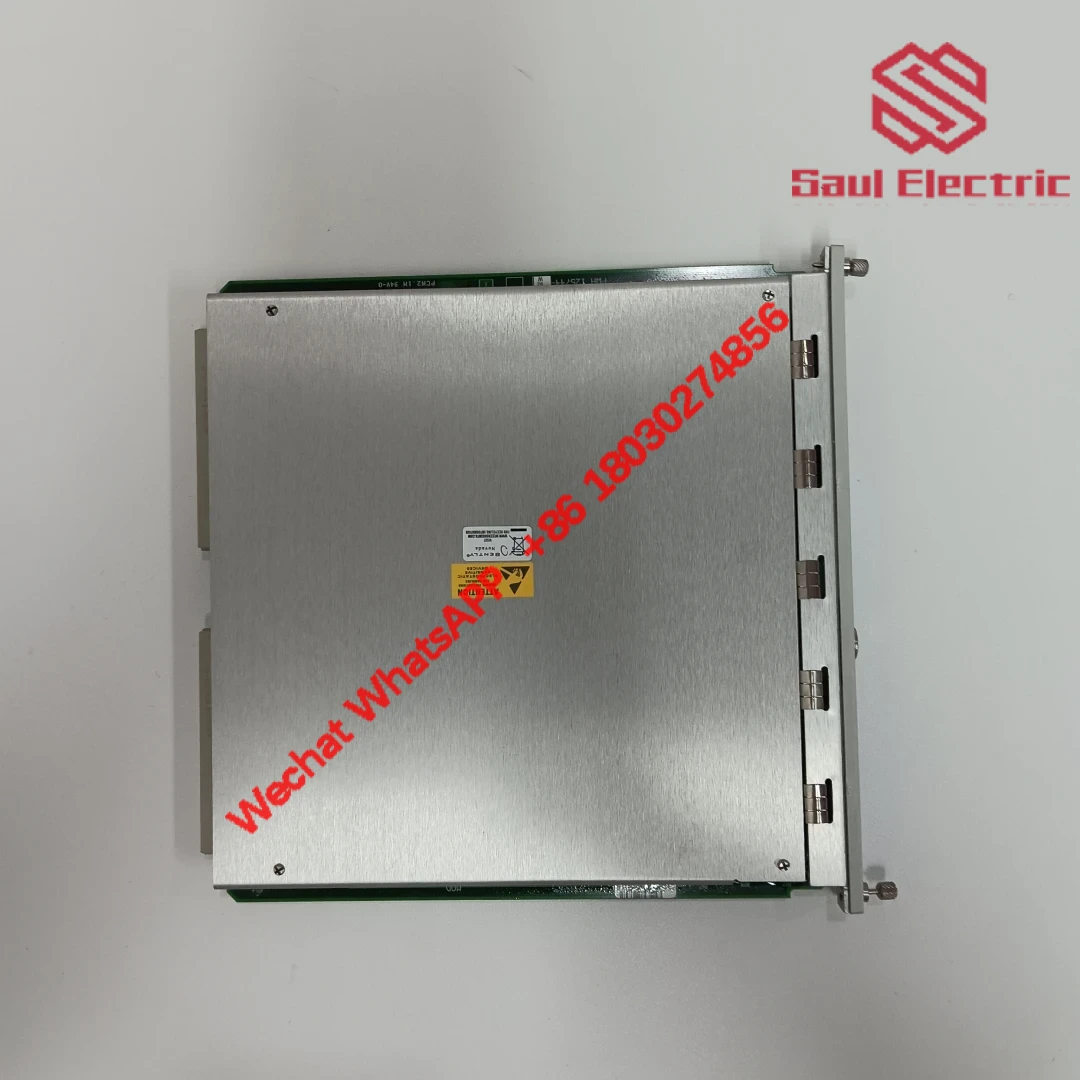

BENTLY 3500/42M 176449-02 Vibration Monitoring Module

This four-channel vibration monitoring module serves as the backbone for machinery protection systems in critical industrial applications. Designed for continuous monitoring of turbines, compressors, and generators, it processes signals from proximity and seismic sensors to detect abnormal vibration patterns that could indicate impending mechanical failures.

| Manufacturer | Bently Nevada |

| Model | 3500/42M 176449-02 |

| Channels | 4 independent channels |

| Input Types | Proximity & seismic sensors |

| Output | 10/100Base-T Ethernet & RS232 |

| Environmental Rating | -20°C to +70°C operation |

| Mounting | 19″ rack or DIN rail compatible |

Commonly deployed in power generation facilities and offshore platforms, this module excels in environments where equipment failure could lead to catastrophic losses. For instance, a technician at a gas processing plant recently reported how the 3500/42M successfully prevented turbine damage during an unexpected imbalance event at 12,000 RPM. The module works seamlessly with other 3500 series components like the 3500/25 Keyphasor Monitor and 3500/92 Dual Channel Vibration Monitor.

What sets this module apart is its dual redundancy design – both power supplies and communication paths can be duplicated for uninterrupted operation. Each channel supports independent alarm configuration with programmable thresholds that can trigger protective actions like emergency shutdowns. The integrated signal conditioning handles complex vibration signatures, distinguishing between normal operational vibrations and dangerous harmonic frequencies. When combined with the 3500 System 1 software, users gain access to advanced diagnostics including orbit plots and spectral analysis.

Reviews

There are no reviews yet.