Description

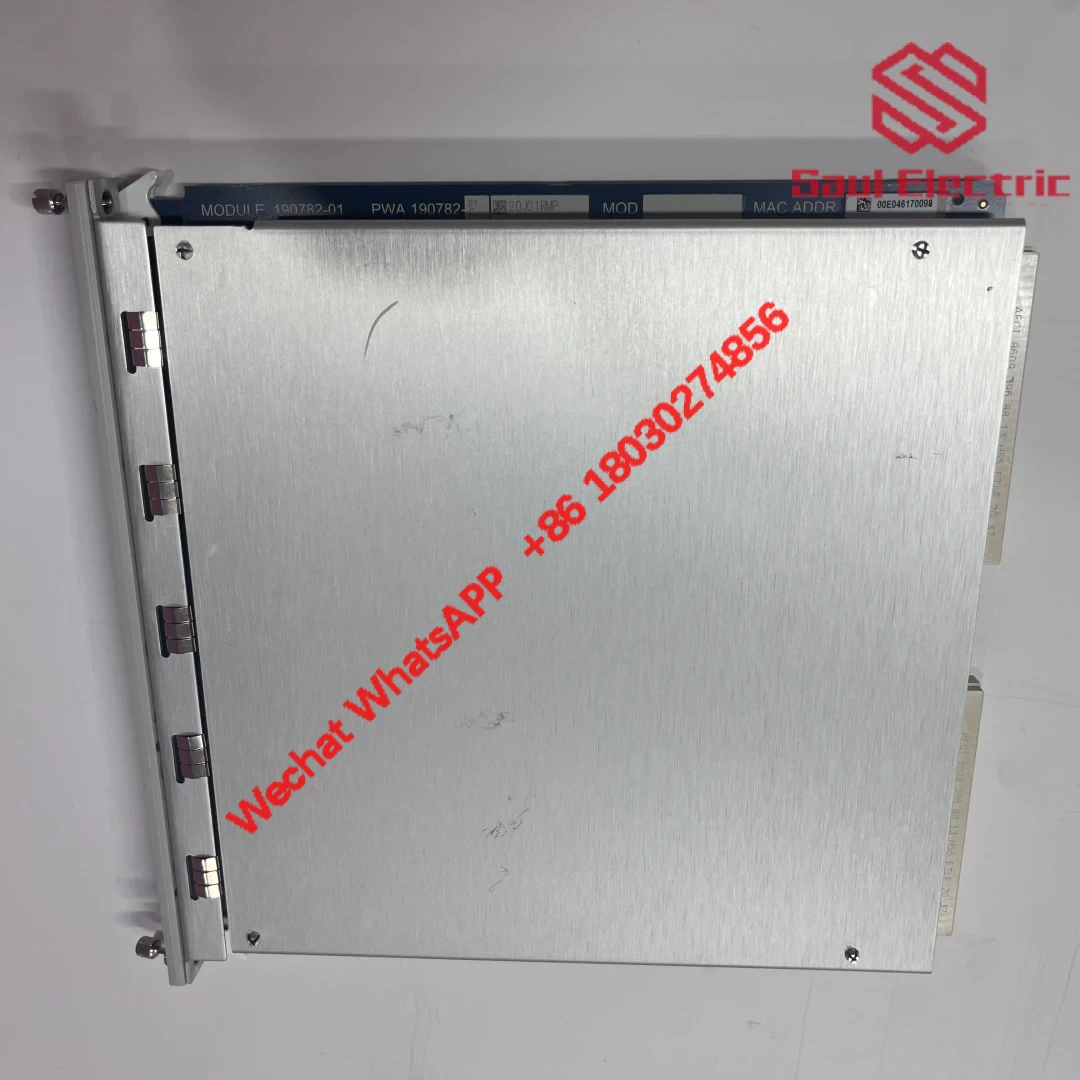

BENTLY 3500-91M 190782-01 Condition Monitoring Module

The BENTLY 3500-91M 190782-01 is a heavy-duty condition monitoring module built for industrial machinery protection. It’s commonly used in power plants, refineries, and manufacturing facilities to track vibration levels, temperature fluctuations, and proximity changes in rotating equipment. Real-time diagnostics help maintenance teams catch issues like shaft misalignment or bearing wear before they escalate into costly failures.

| Attribute | Specification |

| Order Number | 190782-01 |

| Series Compatibility | BENTLY 3500 Series |

| Input Signals | Vibration, Temperature, Proximity |

| Communication | Modbus RTU over RS-485 |

| Environmental Tolerance | -20°C to +70°C operating range |

| Certifications | CE, UL, ATEX |

| Mounting | DIN Rail |

| Dimensions | 120 x 80 x 30 mm (approximate) |

Engineers often pair this module with BENTLY’s 3500/44 relay modules or 3500/22M vibration monitors to create comprehensive protection systems. For example, a natural gas compressor station might use the 3500-91M alongside 3500/32 transmitters to monitor turbine vibrations. Its compact DIN rail design makes it particularly useful for retrofitting older systems in steel mills or paper processing plants where space is tight.

One standout feature is its ability to log historical event data in internal flash memory – this helps troubleshoot intermittent issues that disappear before technicians arrive. The module’s IP20 rating means it’s best suited for controlled environments, though I’ve seen it deployed successfully in dusty factory settings when mounted inside NEMA-rated enclosures. Communication redundancy isn’t built-in, but users often mitigate this by daisy-chaining multiple modules on separate RS-485 segments.

Reviews

There are no reviews yet.