Description

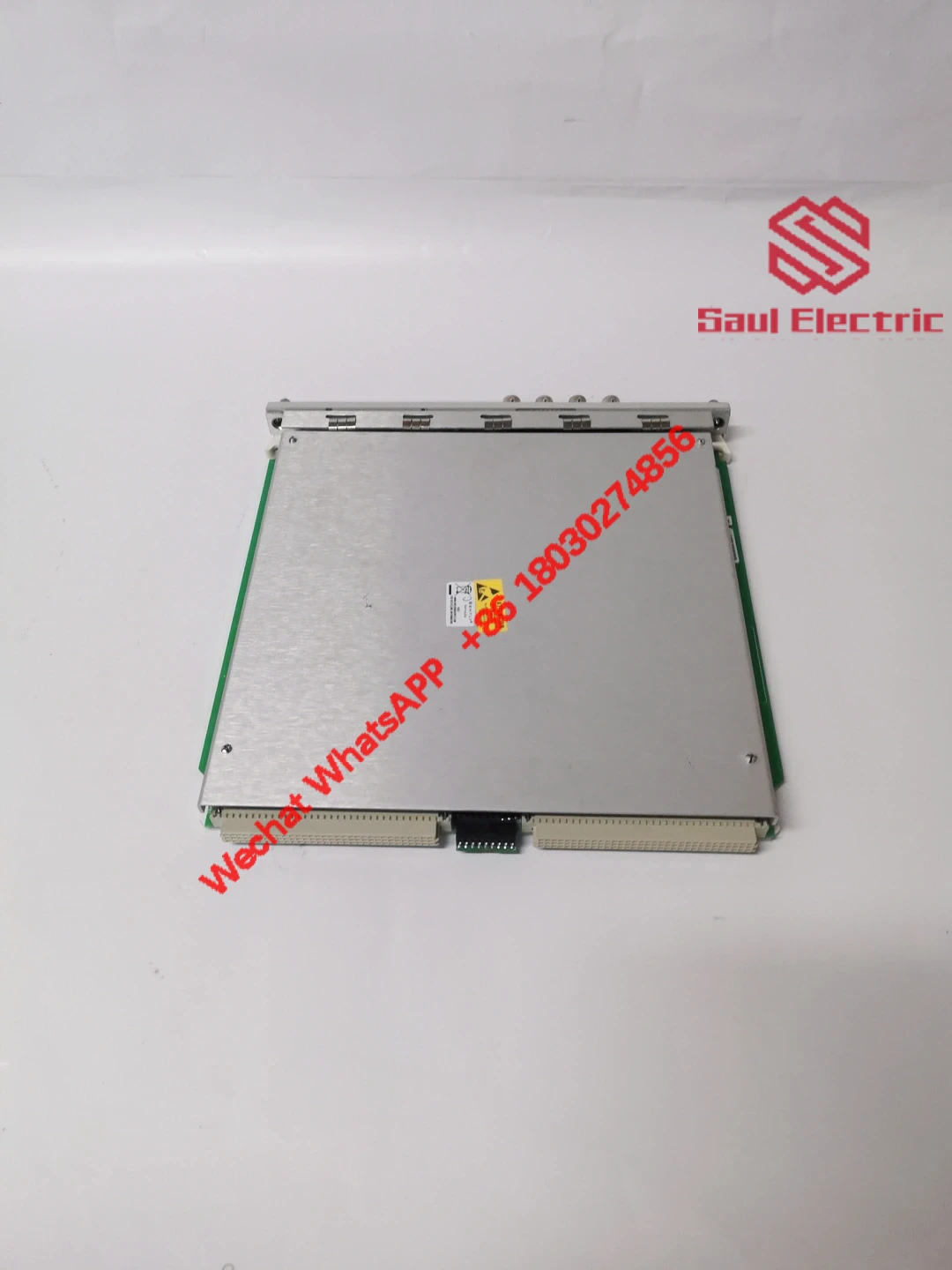

Bently 3500/32 125712-01 Vibration Monitoring Module

The Bently 3500/32 125712-01 serves as a critical component in industrial machinery protection systems. This vibration monitoring module continuously tracks mechanical oscillations in rotating equipment, providing early warning signals to prevent catastrophic failures. Widely used in power generation turbines, gas compressors, and heavy industrial machinery, it ensures operational continuity through real-time vibration analysis.

| Specification | Details |

|---|---|

| Manufacturer | Bently Nevada |

| Series | 3500/32 Series |

| Material Code | 125712-01 |

| Dimensions | Standard 19″ rack mount (133 x 216 x 356 mm) |

| Weight | Approx. 5.2 kg |

| Environmental Rating | IP54 (dust/moisture resistant) |

Commonly deployed in power plants and oil & gas facilities, this module works alongside 3500 series components like the 3500/22M displacement transducer and 3500/92 speed monitor. For instance, in turbine monitoring systems, it pairs with 3500/44 vibration sensors to create comprehensive protection networks. The 3500/32 integrates seamlessly with legacy Bently 3300 systems while supporting modern digital communication protocols, making it suitable for both retrofitting and new installations.

Engineered with dual-redundant signal processing channels, this module delivers ±0.25% measurement accuracy across 0.1-20,000 Hz frequency range. Its modular architecture allows hot-swapping of I/O cards without system shutdown. The built-in self-diagnostic routines automatically verify sensor health and wiring integrity. Unlike standard vibration sensors, the 3500/32 features programmable alarm thresholds and time-weighted averaging functions that reduce false positives during transient operating conditions. Personally, I’ve found its Ethernet/IP connectivity particularly useful for integrating with modern SCADA systems while maintaining compatibility with legacy 4-20mA control loops.

Reviews

There are no reviews yet.