Description

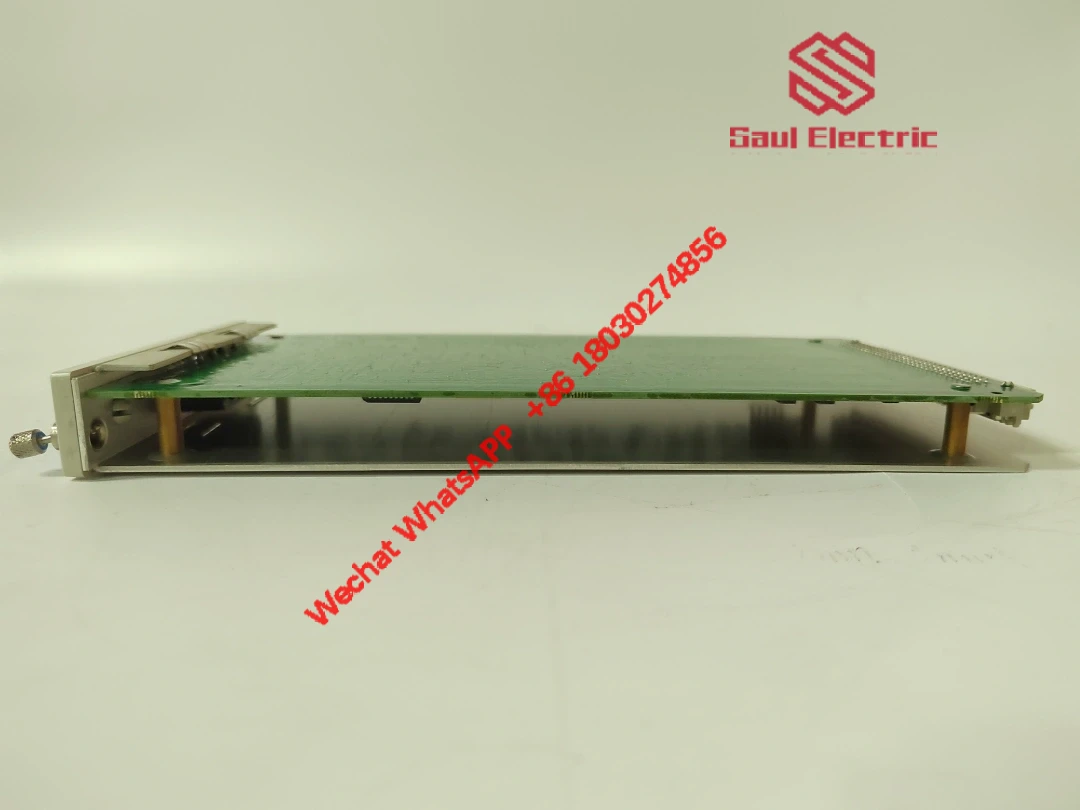

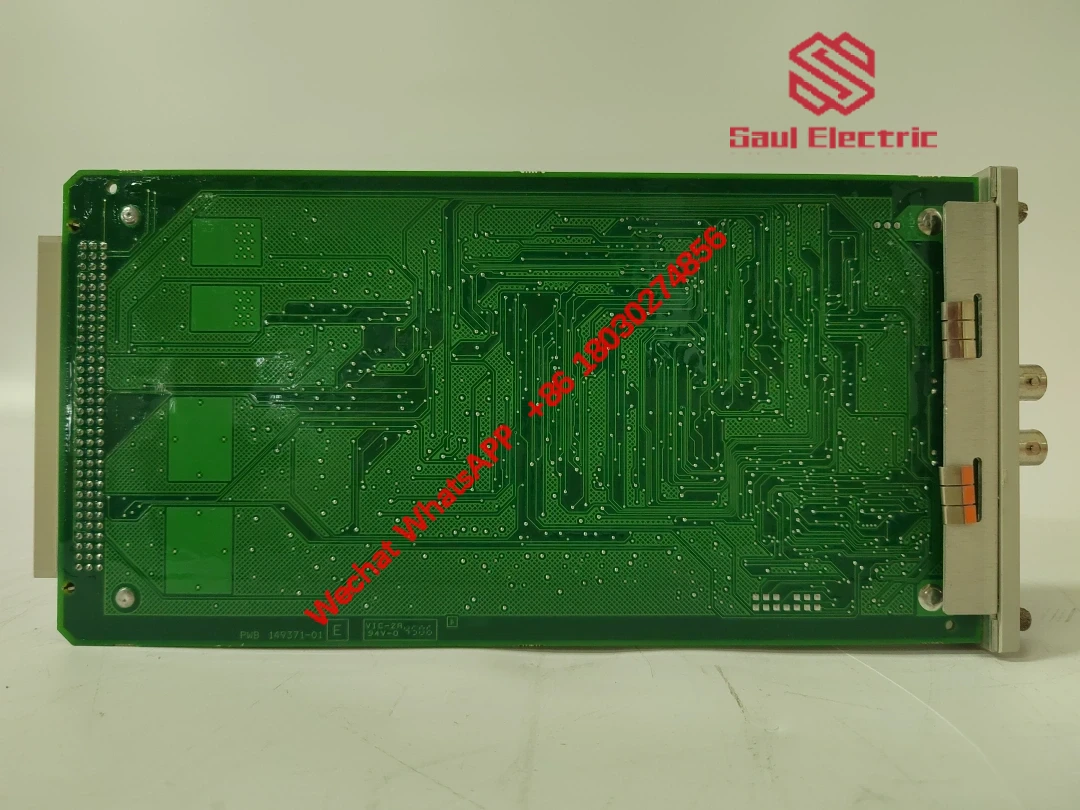

BENTLY 3500-25 149369-01 Vibration Monitoring Module

Monitoring machinery vibrations isn’t just about numbers – it’s about preventing catastrophic failures before they happen. The BENTLY 3500-25 149369-01 module serves as the nervous system for critical rotating equipment, continuously translating mechanical movement into actionable data. Found in power plants and offshore platforms, this device quietly safeguards operations by catching early signs of imbalance or misalignment.

Technical Specifications

Series: 3500 System

Weight: 1.2 kg

Material: Aluminum Alloy

Operating Voltage: 24 VDC

Range: 0-500 mils (0-12.7mm) p-p

Comm: Modbus RTU/RS485

Temp Range: -25°C to +70°C

Protection: IP65 Enclosure

Frequency: 5-1000 Hz

Output: 4-20 mA

When you’re dealing with massive turbines or gas compressors, precision matters. This module works particularly well with BENTLY’s 3500 system racks, where its dual-channel capability shines. I’ve seen engineers use it for simultaneous shaft vibration and casing monitoring on offshore drilling equipment. The aluminum housing holds up surprisingly well in salty environments, though I’d still recommend regular inspections if you’re operating near marine conditions.

What sets this apart from basic vibration sensors? The onboard diagnostics constantly check internal components while monitoring equipment. For instance, when we installed these on a refinery’s steam turbines, the self-test feature caught a faulty sensor connection before it caused any issues. The 24-bit ADC provides such fine resolution that operators could detect bearing wear patterns months before scheduled maintenance. Plus, the ability to daisy-chain modules via RS485 made integrating them into the existing DCS system straightforward.

Reviews

There are no reviews yet.