Description

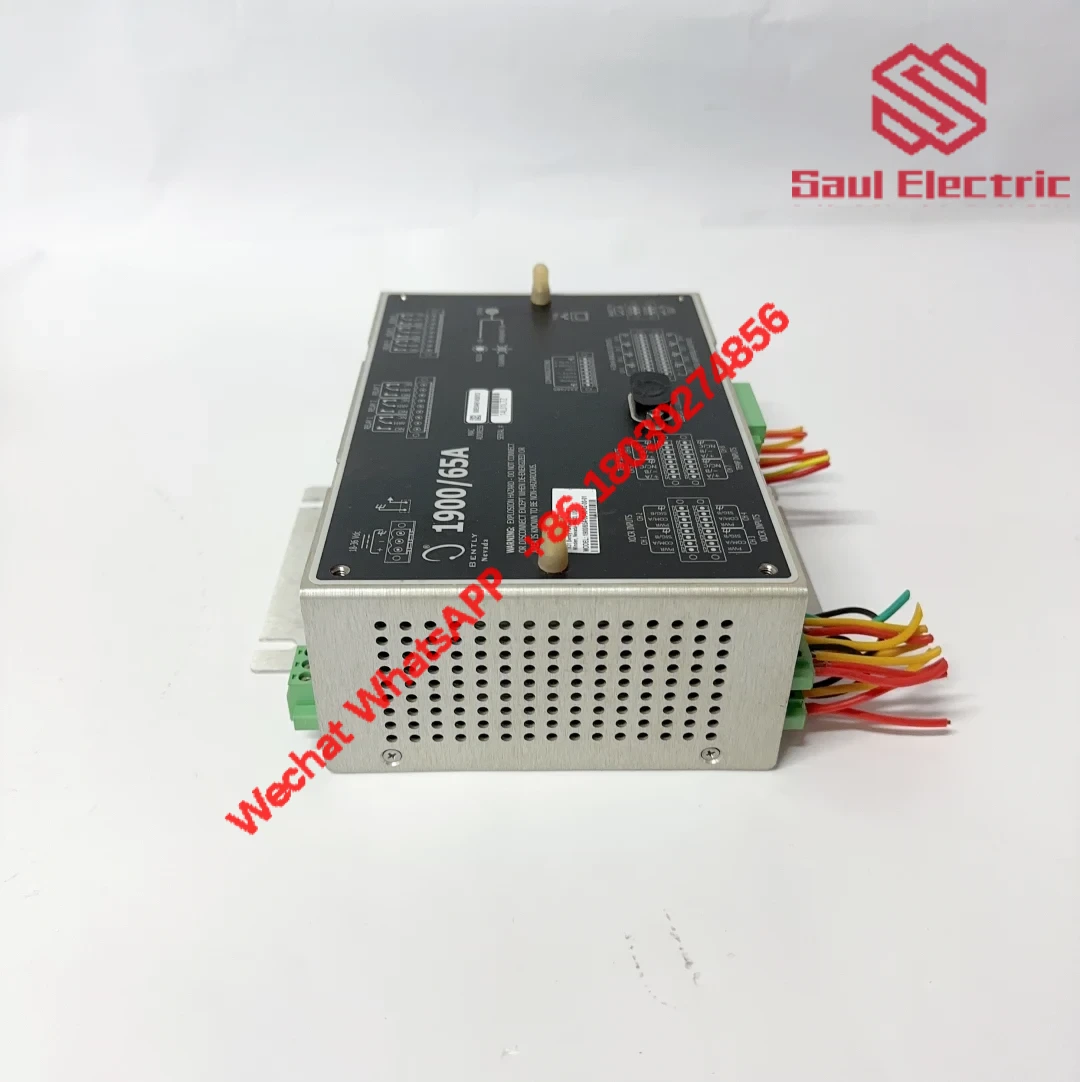

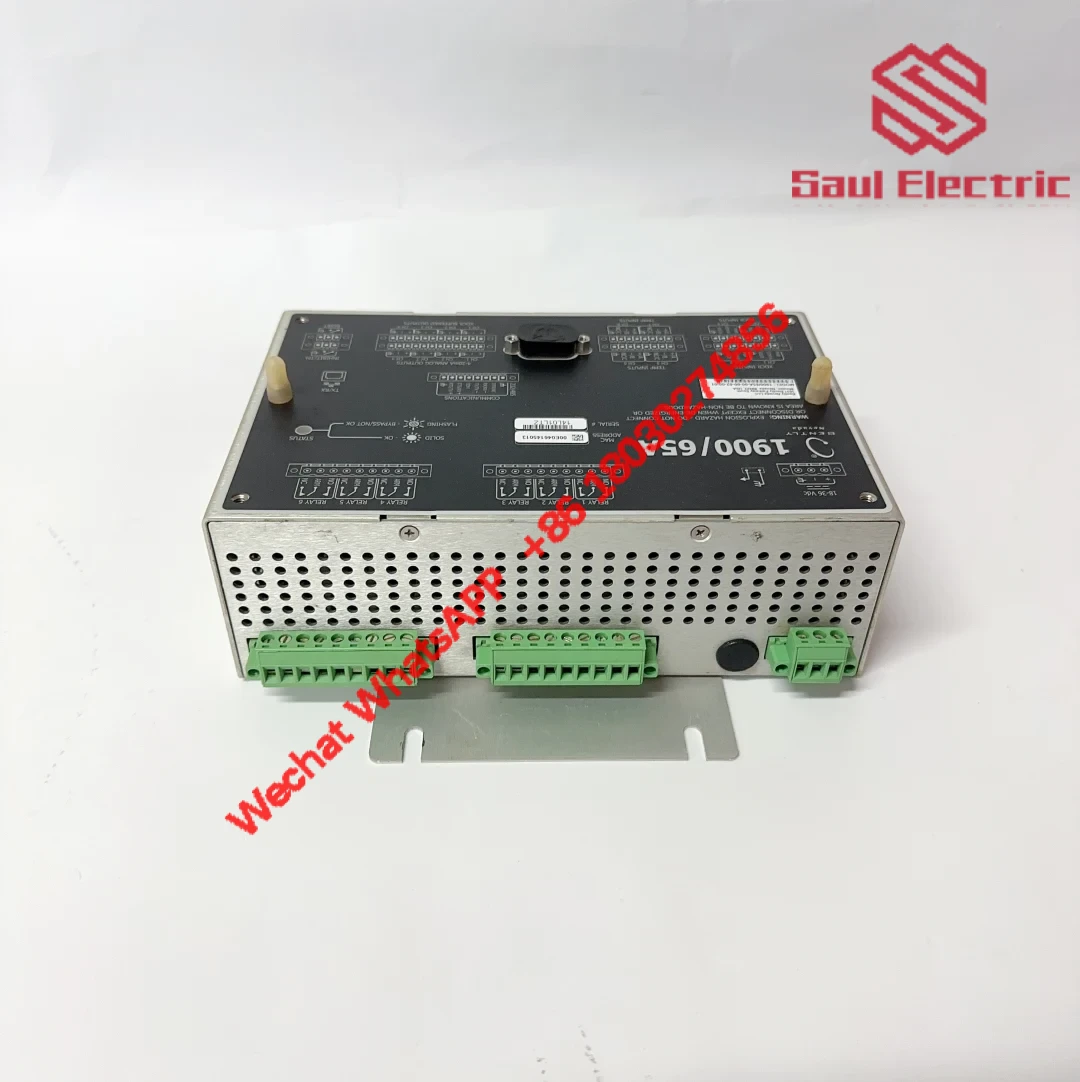

Bently 190065A-00-00-02-00-01 General Equipment Monitor

This compact industrial monitoring system delivers reliable protection for rotating machinery in non-critical applications. Designed by Bently Nevada (a GE company), it continuously tracks vibration, temperature, and other parameters across 8 channels, making it ideal for pumps, fans, compressors, and motors where cost-effective condition monitoring matters.

| Brand | Bently Nevada (GE) |

|---|---|

| Model | 190065A |

| Channels | 8 monitoring channels |

| Input Types | Vibration velocity, acceleration sensors, E/J/K/T thermocouples, RTD |

| Power Supply | 18–36V DC or 110/220V AC |

| Certifications | CSA, ATEX |

Commonly used in cooling tower fans and small turbine setups, this module shines where budget constraints meet reliability needs. Engineers often pair it with 3500/3300 series systems for hybrid monitoring solutions. Its modular design supports DIN rail or backplate mounting, fitting seamlessly into existing control cabinets. For instance, a water treatment plant might use it alongside 3500/20 vibration monitors to protect auxiliary pumps without over-investing in critical system components.

What stands out is its 24-bit A/D conversion paired with multi-pole filtering – this combo reduces electrical noise interference in harsh environments. The dual-level alarm system (warning/danger) with programmable relays lets operators implement tiered shutdown protocols. While not featuring full redundancy, its IP65-rated enclosure with optional fiberglass protection ensures survival in dusty, wet conditions where other systems might fail. Some users note the lack of built-in wireless communication, but Modbus/TCP integration compensates by enabling SCADA connectivity through existing control networks.

Reviews

There are no reviews yet.