Description

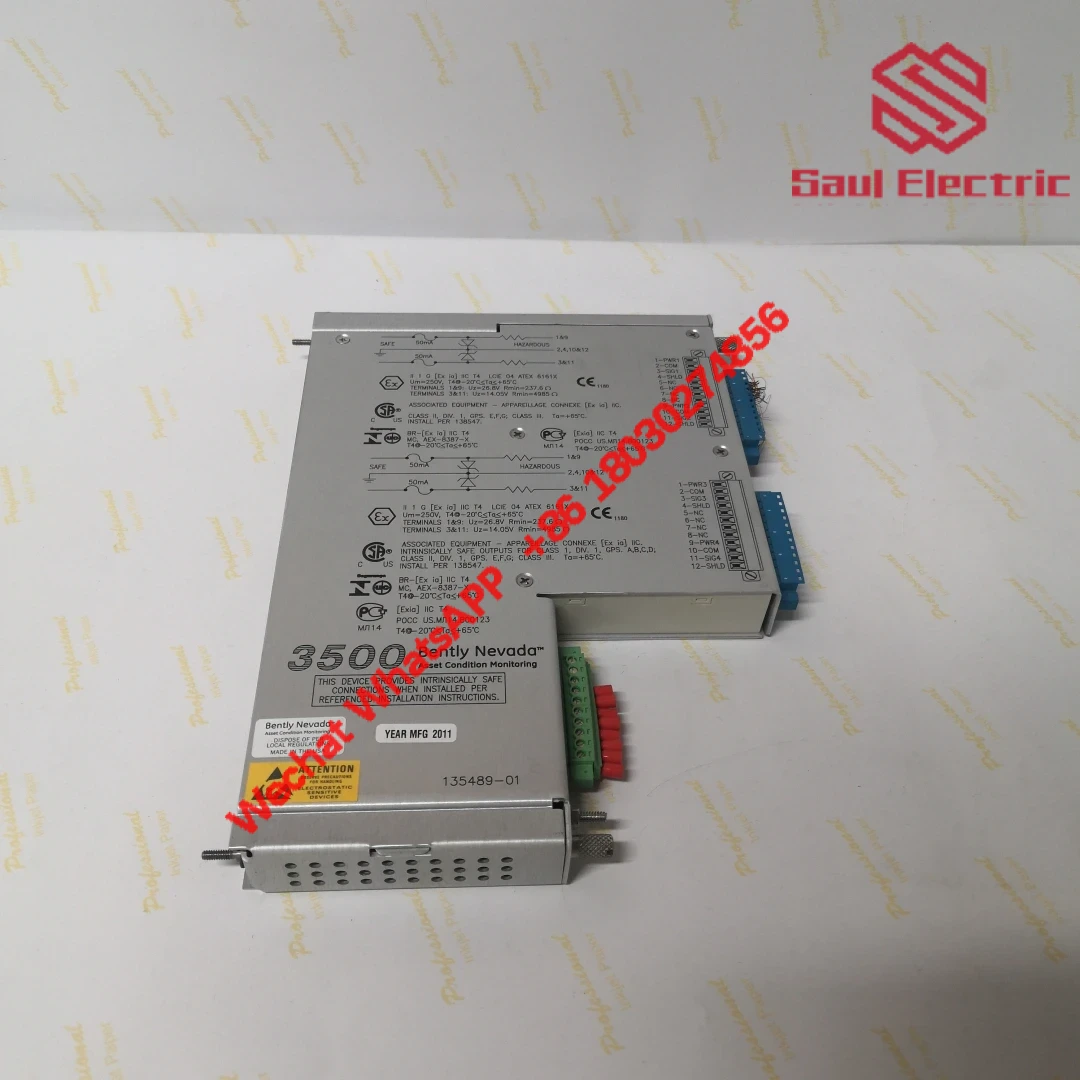

BENTLY 135489-01 & 135489-03 High-Precision Vibration Monitoring Modules

The BENTLY 135489-01 and 135489-03 modules deliver industrial-grade vibration monitoring for critical machinery. Designed for real-time diagnostics, these modules help prevent unplanned downtime by detecting mechanical imbalances, misalignments, or bearing wear in turbines, compressors, and rotating equipment. Their reliability makes them staples in power plants, oil refineries, and heavy manufacturing facilities.

Technical Specifications

| Attribute | Details |

|---|---|

| Brand | BENTLY NEVADA™ |

| Series | 135489-01, 135489-03 |

| Operating Voltage | 24V DC (typical for BENTLY modules) |

| Output Frequency | 0–10 kHz (adjustable range) |

| Certification | ATEX, IECEx (hazardous location compliance) |

| Material | Industrial-grade aluminum alloy housing |

| Dimensions | Approx. 120 x 80 x 30 mm |

| Weight | 0.45 kg (1 lb) |

Applications & Compatible Systems

These modules are commonly used in BENTLY NEVADA’s 3500 and 3300 system ecosystems. For example, in a gas turbine monitoring setup, they interface with Proximitor® probes to track shaft vibration and bearing health. They’re also deployed in:

- Petrochemical plant compressors

- Wind turbine gearboxes

- Steam turbine generators

- Refinery centrifugal pumps

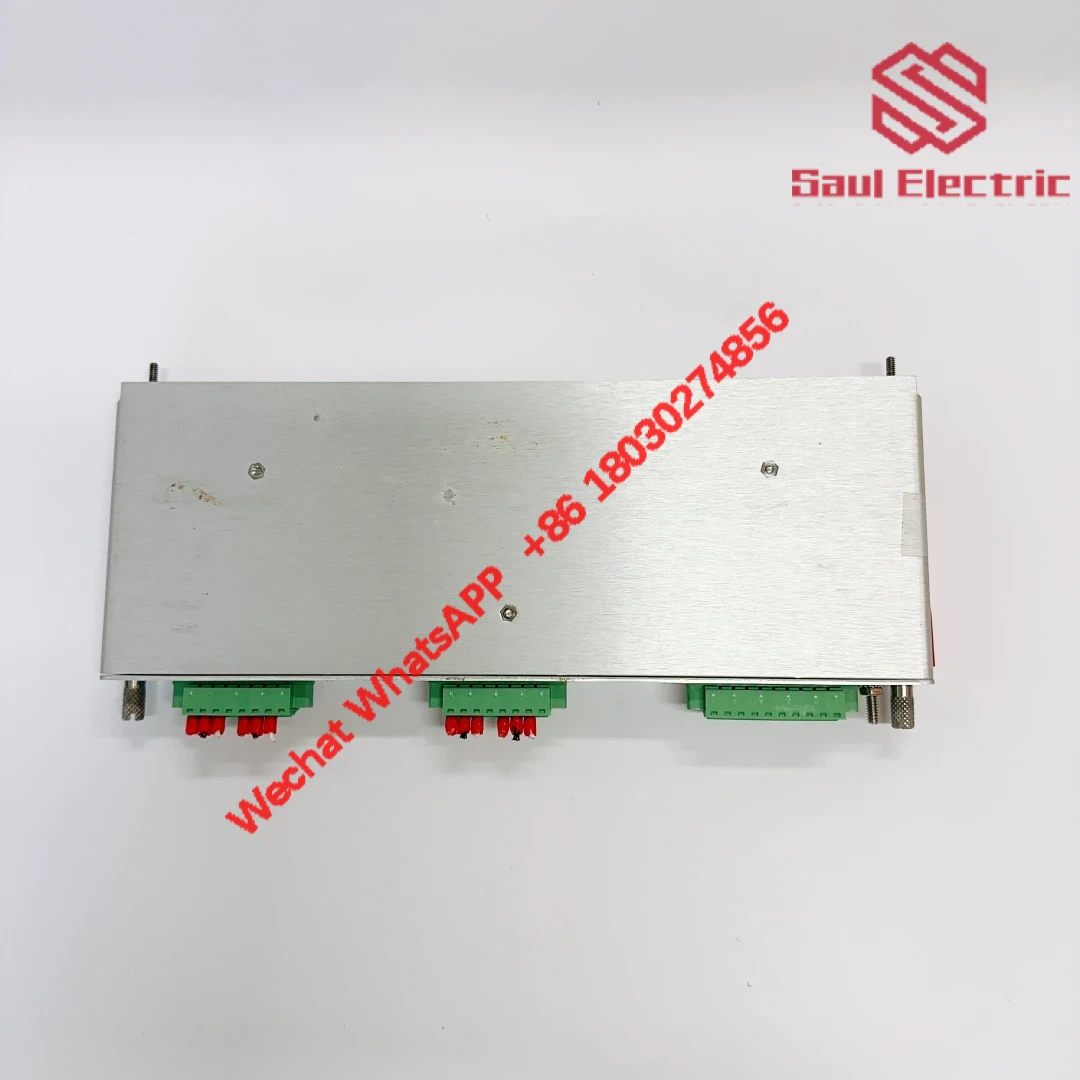

We frequently handle related models like the 3500/44, 3500/22M, and 3300 XL probes. Their modular design allows integration with legacy systems like the 1900 series or newer platform-based solutions.

Technical Advantages

Engineers appreciate the modules’ electromagnetic interference (EMI) shielding, which ensures stable readings in electrically noisy environments like switchgear rooms. The built-in self-diagnostics flag issues like sensor cable faults or power fluctuations—features that saved one offshore platform operator 12 hours of downtime monthly.

Key benefits include:

- Redundant signal paths for critical applications

- Compatibility with 4–20 mA and Modbus protocols

- Adjustable alarm thresholds via BENTLY software

- Operating temperature range: -40°C to +85°C

While the 135489-01 focuses on velocity measurements, the 135489-03 adds phase analysis for advanced rotor dynamics troubleshooting. Both support hot-swapping, minimizing process interruptions during maintenance.

Reviews

There are no reviews yet.