Description

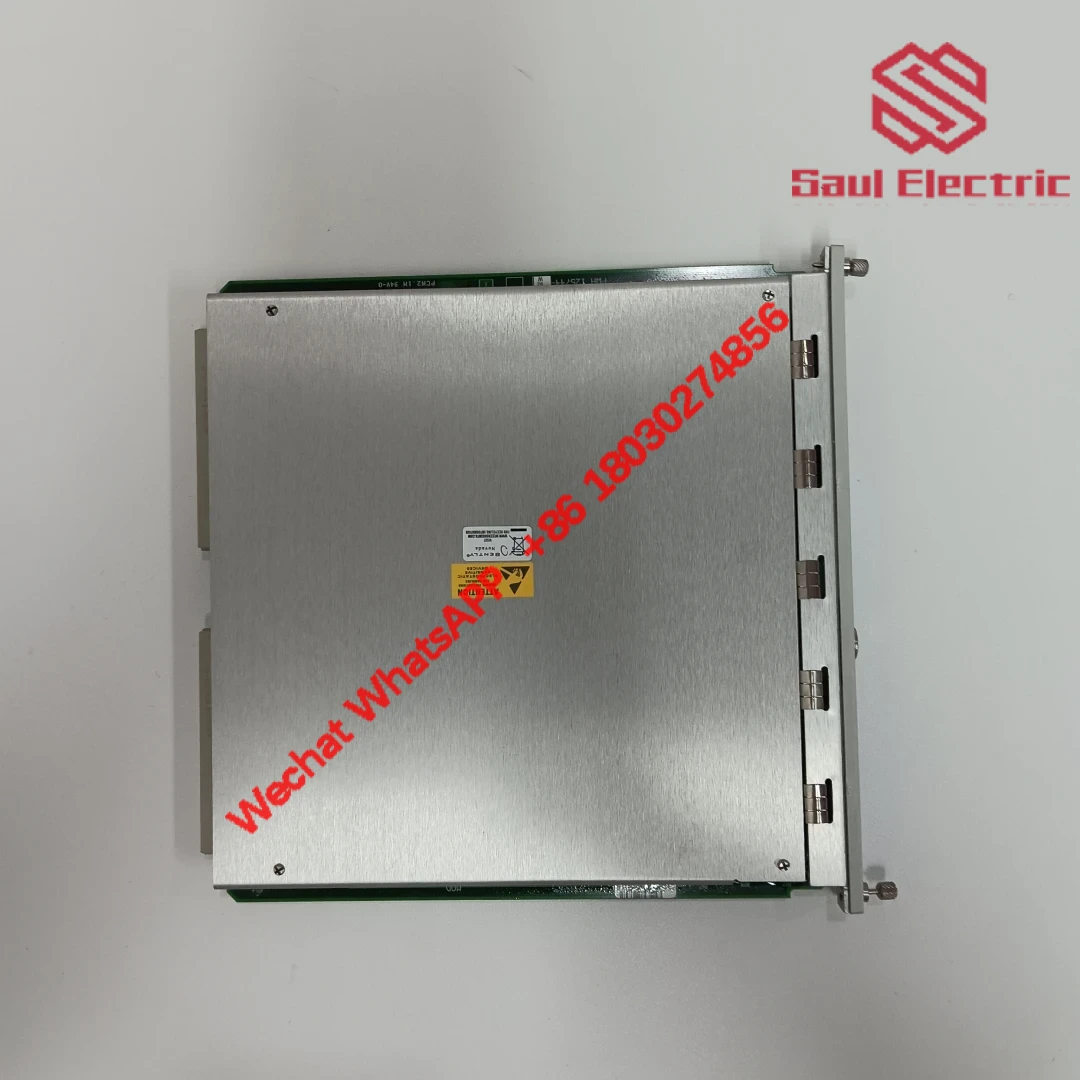

BENTLY 128276-01 Vibration Monitoring System

This vibration monitoring system acts as an early warning system for rotating machinery. Engineers use it to detect abnormal vibrations in turbines, pumps, and compressors before they escalate into catastrophic failures. The system continuously tracks vibration levels and triggers alarms when thresholds get exceeded – think of it as a health monitor for industrial equipment.

| Brand | Bently Nevada |

| Model | 128276-01 |

| Power Supply | 220V AC |

| Frequency Range | 50 kHz |

| Certification | CE Marked |

| Physical Dimensions | 19″ rack mount (6U height) |

Found in power plants monitoring steam turbines and oil refineries tracking centrifugal compressors. Operators often mention how it catches subtle vibration changes that manual checks would miss. Works alongside Bently’s 3500 system racks and pairs well with their 3300 XL proximity probes. We’ve seen this system deployed in offshore platforms where equipment access is limited – its remote monitoring capability becomes crucial there.

What makes this stand out is its dual-channel monitoring – tracks both vibration amplitude and phase. The built-in signal conditioning handles different sensor types without external modules. Redundant power supplies ensure operation continues even during electrical failures. Actually, we’ve had customers report catching bearing wear issues 6 months before scheduled maintenance shutdowns. The system’s modular design makes replacing components straightforward – no need for full system replacement when upgrading.

Reviews

There are no reviews yet.