Description

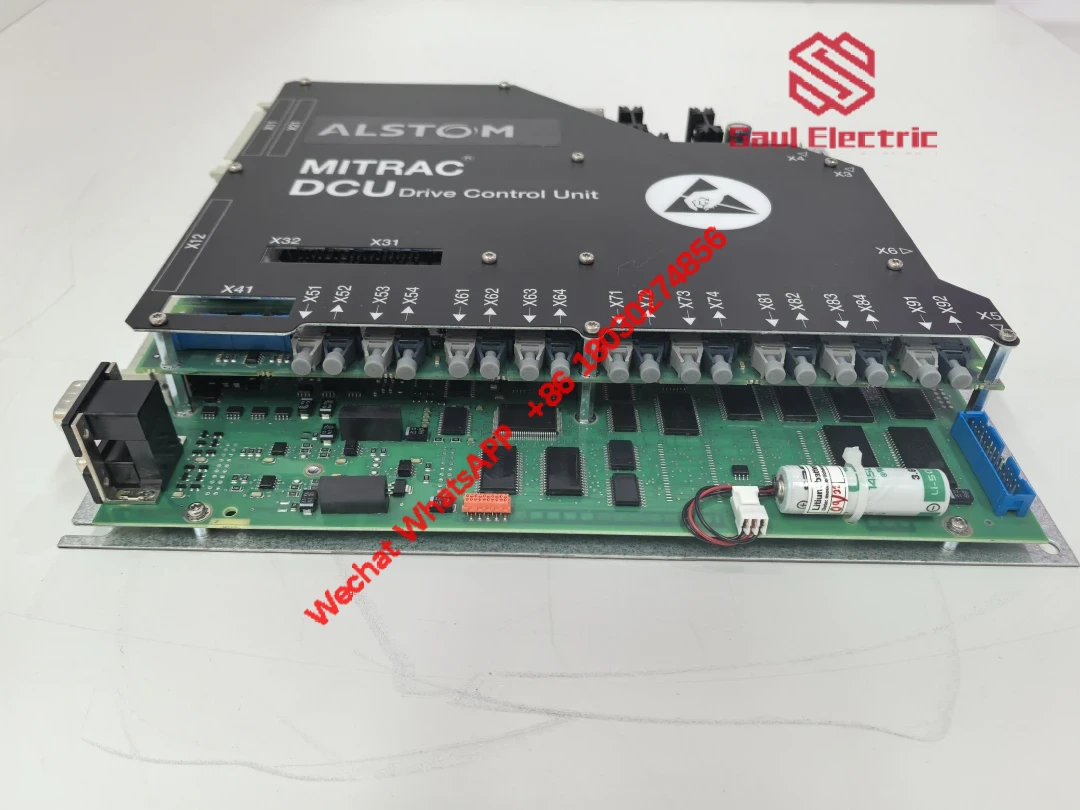

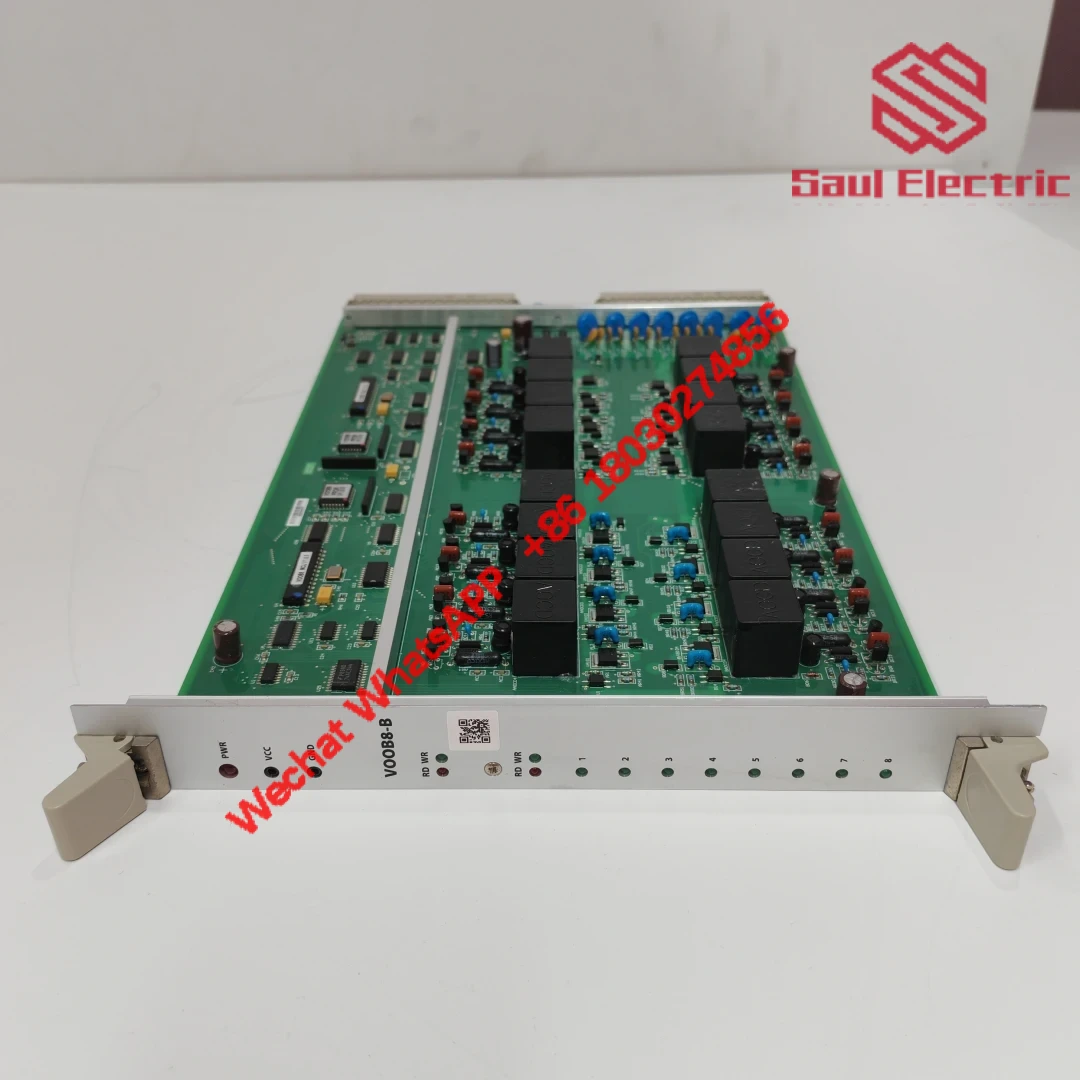

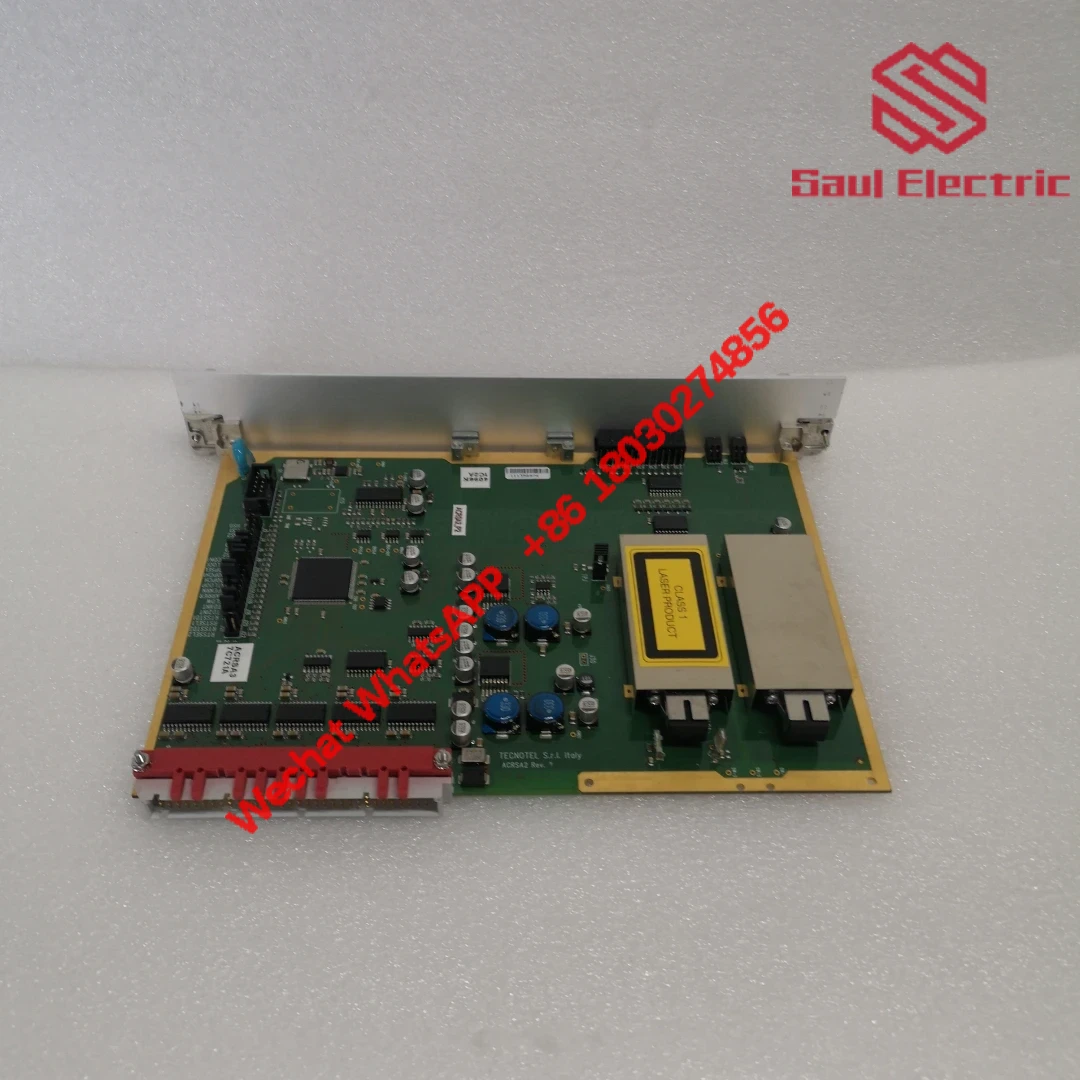

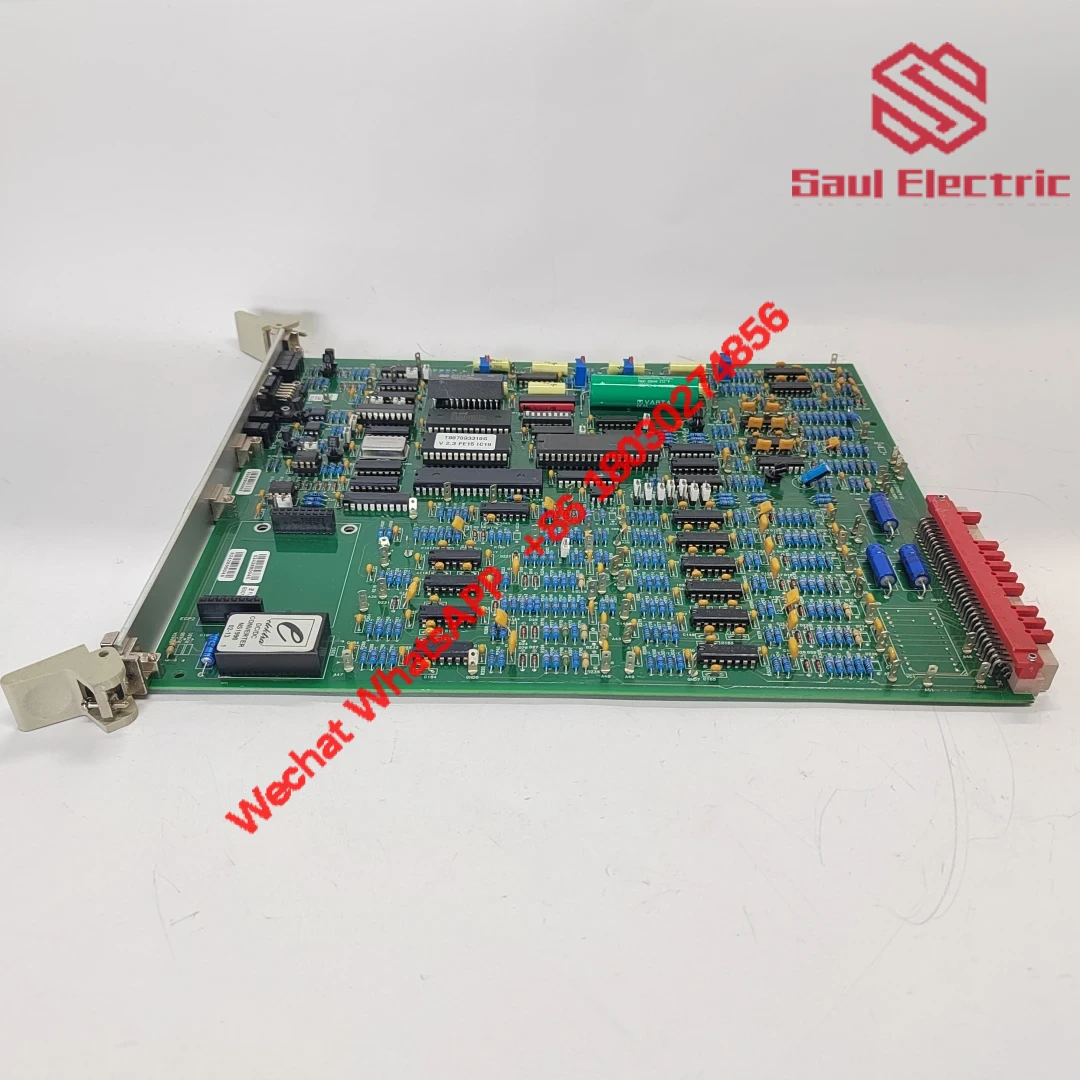

ALSTOM 3EST125-975 DCC2382A Industrial Control Module

Engineered for precision control in high-stakes industrial environments, the ALSTOM 3EST125-975 DCC2382A module delivers rock-solid performance where it matters most. Designed to manage complex automation tasks, this module shines in applications requiring tight control over motor drives, process synchronization, and real-time monitoring.

| Specification | Details |

|---|---|

| Brand | ALSTOM |

| Model | 3EST125-975 DCC2382A |

| Operating Voltage | 220 V |

| Output Frequency | Adjustable up to 30 kHz |

| Certifications | CE, ISO 9001 |

| Origin | France |

From power generation plants to heavy-duty manufacturing lines, this module thrives in settings where reliability can’t be compromised. We’ve seen it excel in motor control cabinets for steel mills and as a synchronization hub in hydroelectric turbine systems. Customers often pair it with ALSTOM’s 3EST125 series drives for seamless compatibility – a combo we’ve supplied repeatedly for large-scale energy projects. Its rugged build handles temperature swings from -20°C to 60°C, making it a go-to for outdoor installations like wind farms and mining operations.

Built like a tank, this module’s circuitry resists electrical noise even in high-vibration environments – a lifesaver for clients in cement plants where dust and shock loads are constant. The adaptive frequency control lets engineers tweak response times on the fly, which one customer used to reduce energy consumption by 12% in a conveyor system. While it lacks hot-swappable redundancy (unlike newer GE Fanuc models), its dual watchdog timers prevent crashes better than older Siemens S7-400H setups. Installation’s straightforward too – just remember to torque those terminal blocks to 0.5 Nm, or you’ll end up with intermittent faults like a client in Brazil learned the hard way.

Reviews

There are no reviews yet.