Description

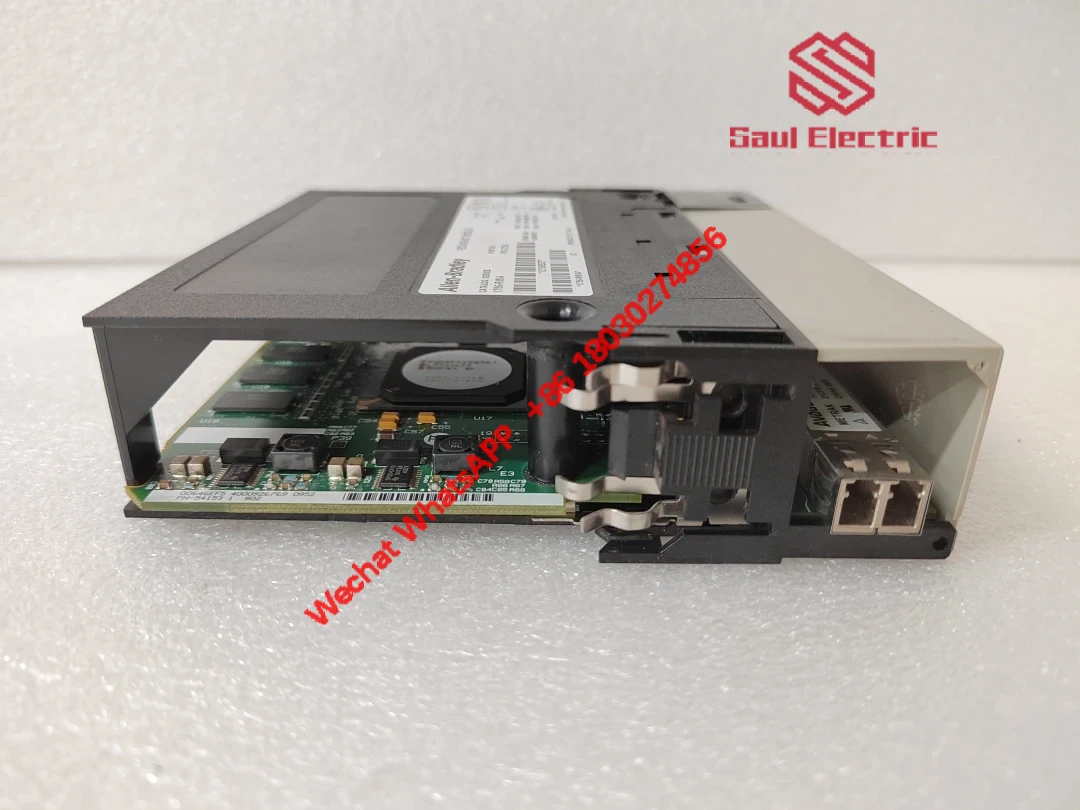

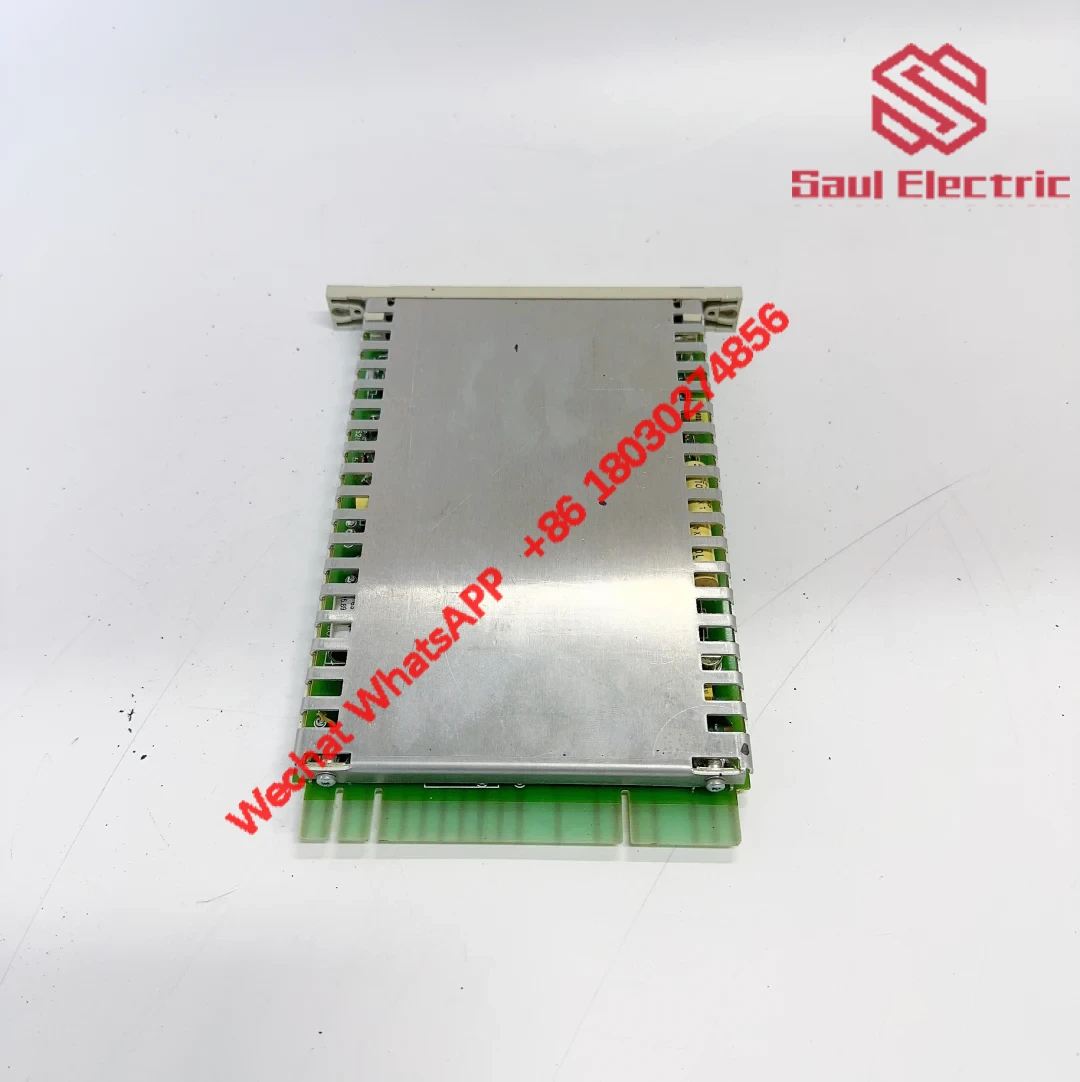

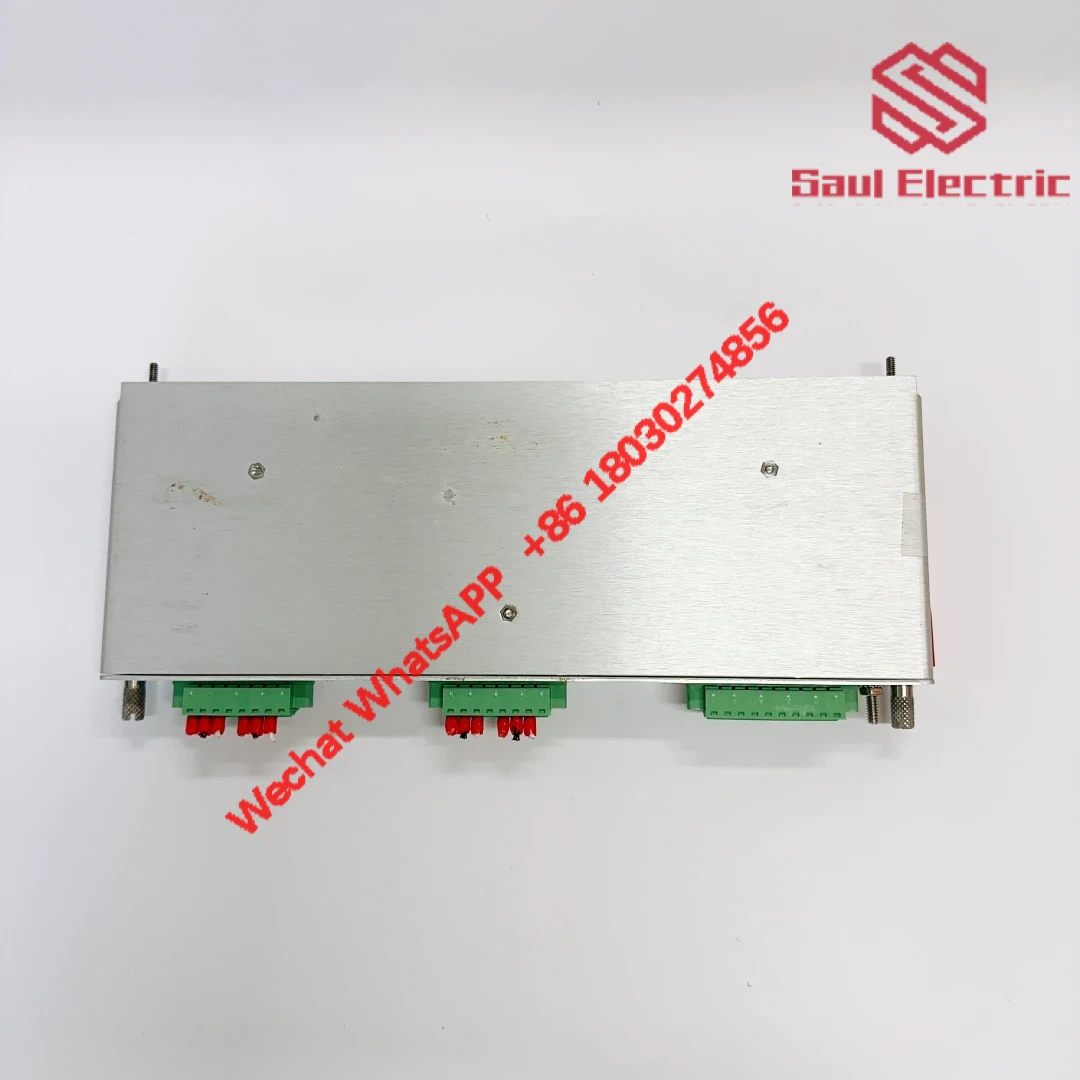

Allen-Bradley 1756-RM A ControlLogix Enhanced Redundancy Module

The 1756-RM A module from Allen-Bradley serves as a backbone for maintaining operational continuity in industrial settings where system failures aren’t an option. Designed for ControlLogix systems, this redundancy module ensures seamless switchover between primary and backup controllers, keeping critical processes like assembly lines, chemical processing, and power generation running without hiccups.

| Manufacturer | Allen-Bradley |

|---|---|

| Series | ControlLogix |

| Model Number | 1756-RM A |

| Channels | Dual (2) |

| Dimensions | 120mm x 50mm x 200mm (approximate) |

| Weight | ~320g |

| Current Rating | 1.16A @ 5.1VDC, 3.4mA @ 24VDC |

| Enclosure Type | Open-style industrial chassis mount |

Industries like pharmaceutical production lines and oil & gas pipelines often rely on this module to prevent costly shutdowns. For example, one customer in beverage manufacturing reported zero downtime during a controller failure thanks to its real-time synchronization. We frequently pair this with other ControlLogix hardware—think 1756-L71 processors, 1756-ENBT communication modules, and 1756-IB16 input cards—when building fail-safe automation architectures.

What sets this module apart isn’t just its dual-channel design. The built-in RFI suppression handles harsh electrical environments better than similar modules, surviving radiated interference up to 10V/m across multiple frequency ranges. The four-character LED display gives instant feedback on system health—no need for external diagnostic tools. While most redundancy modules struggle with heat buildup, the open chassis design here allows for continuous operation at temperatures up to 60°C. Compatibility-wise, it plays nicely with both legacy ControlLogix systems and newer Logix platforms, supporting hot-swapping during maintenance without rebooting the entire rack.

Reviews

There are no reviews yet.