Description

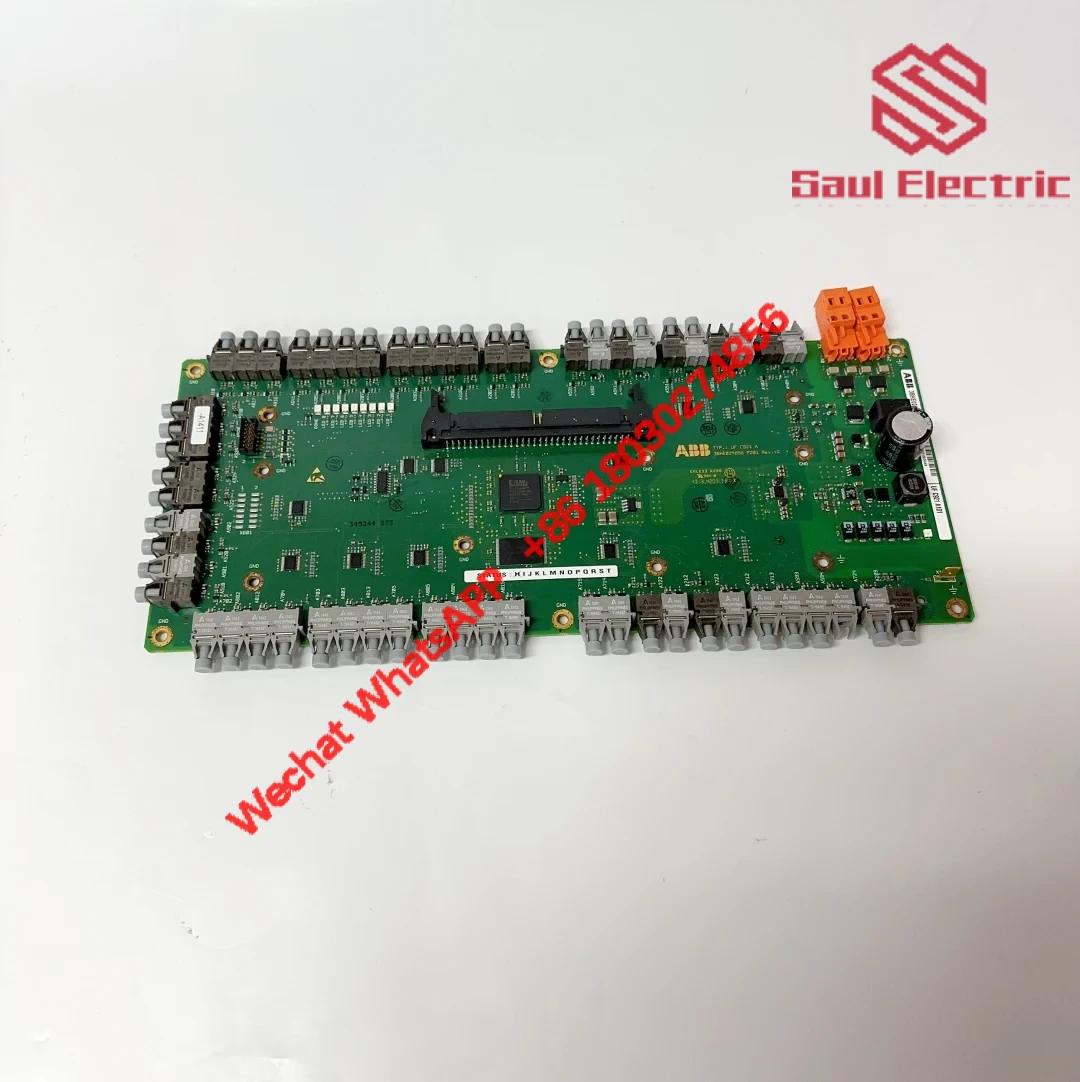

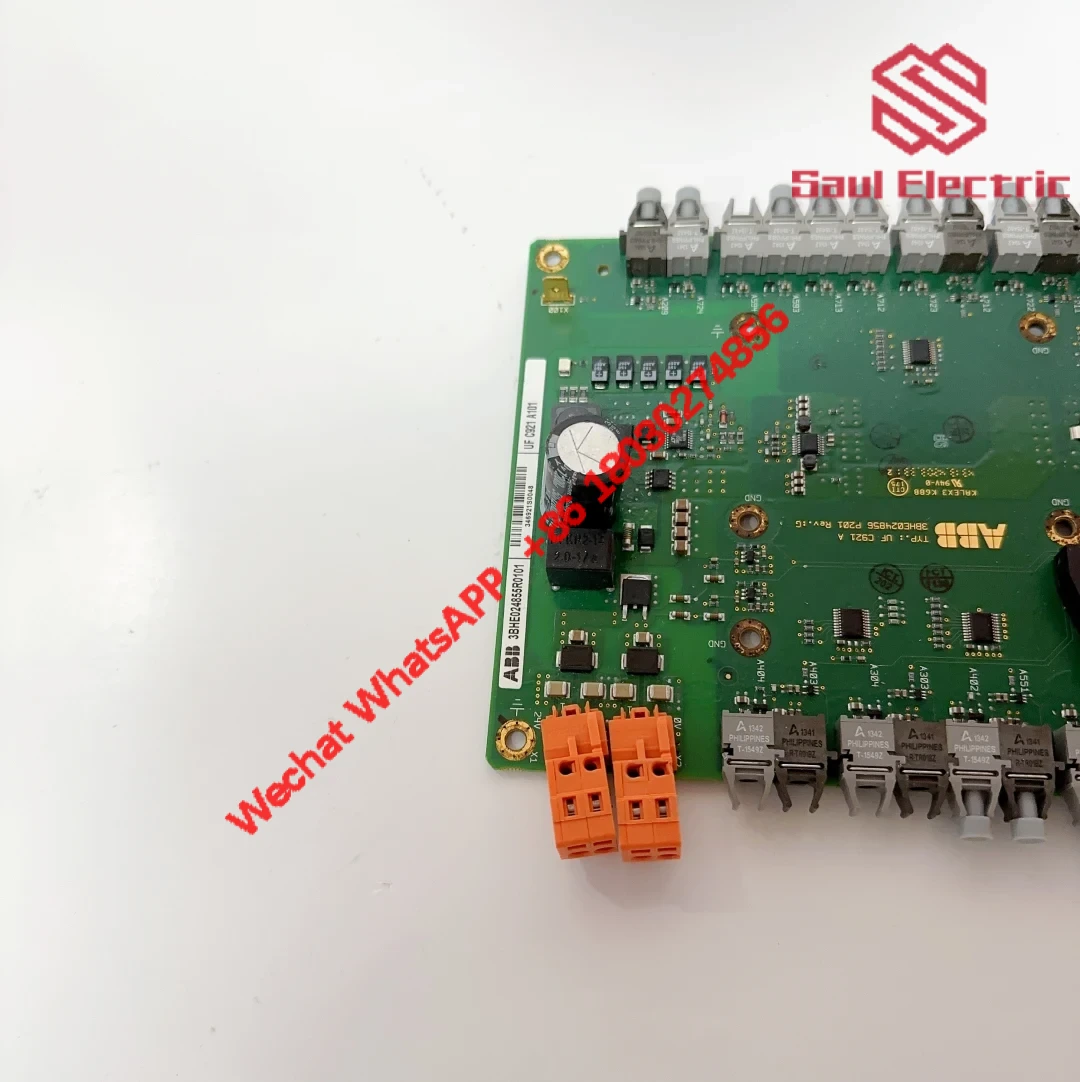

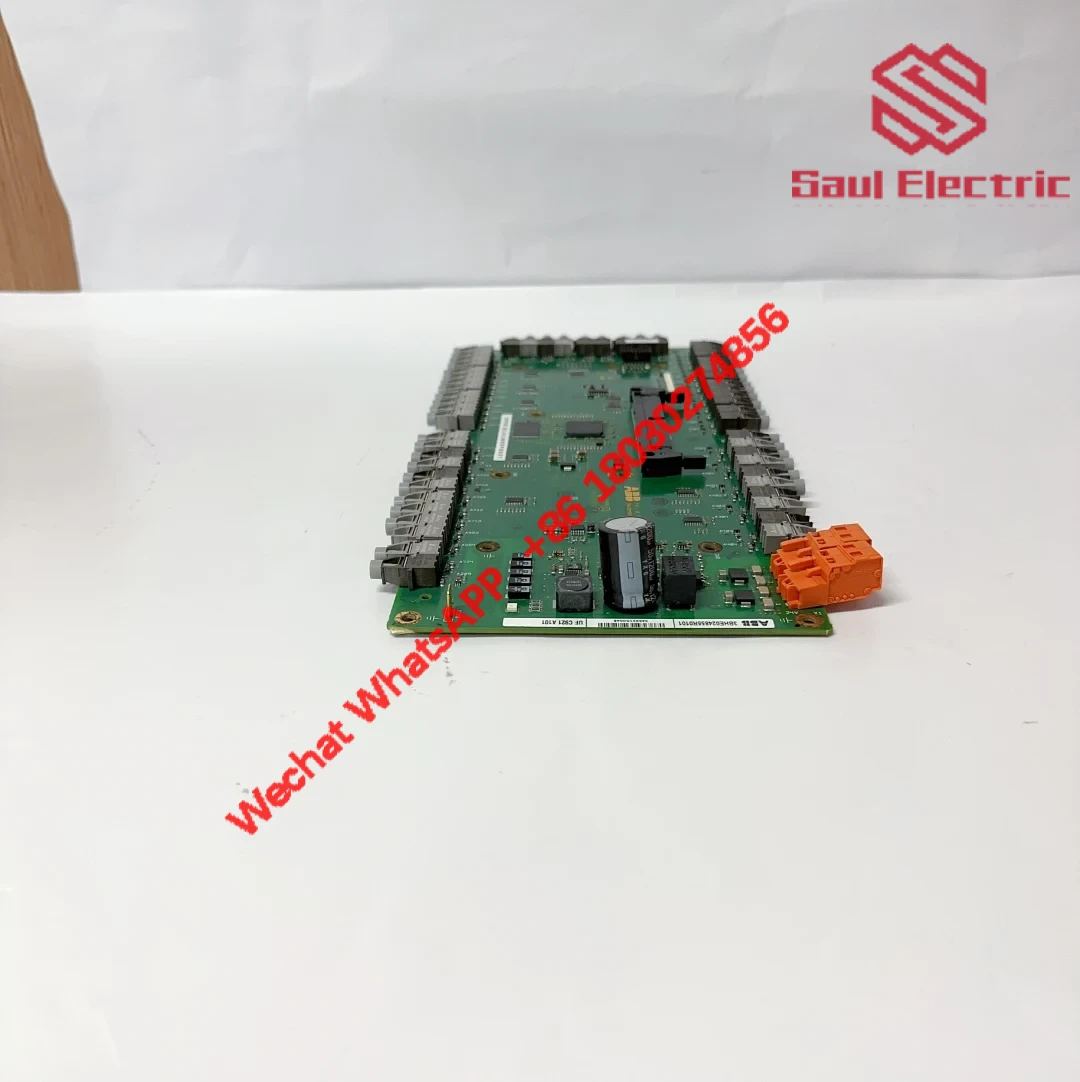

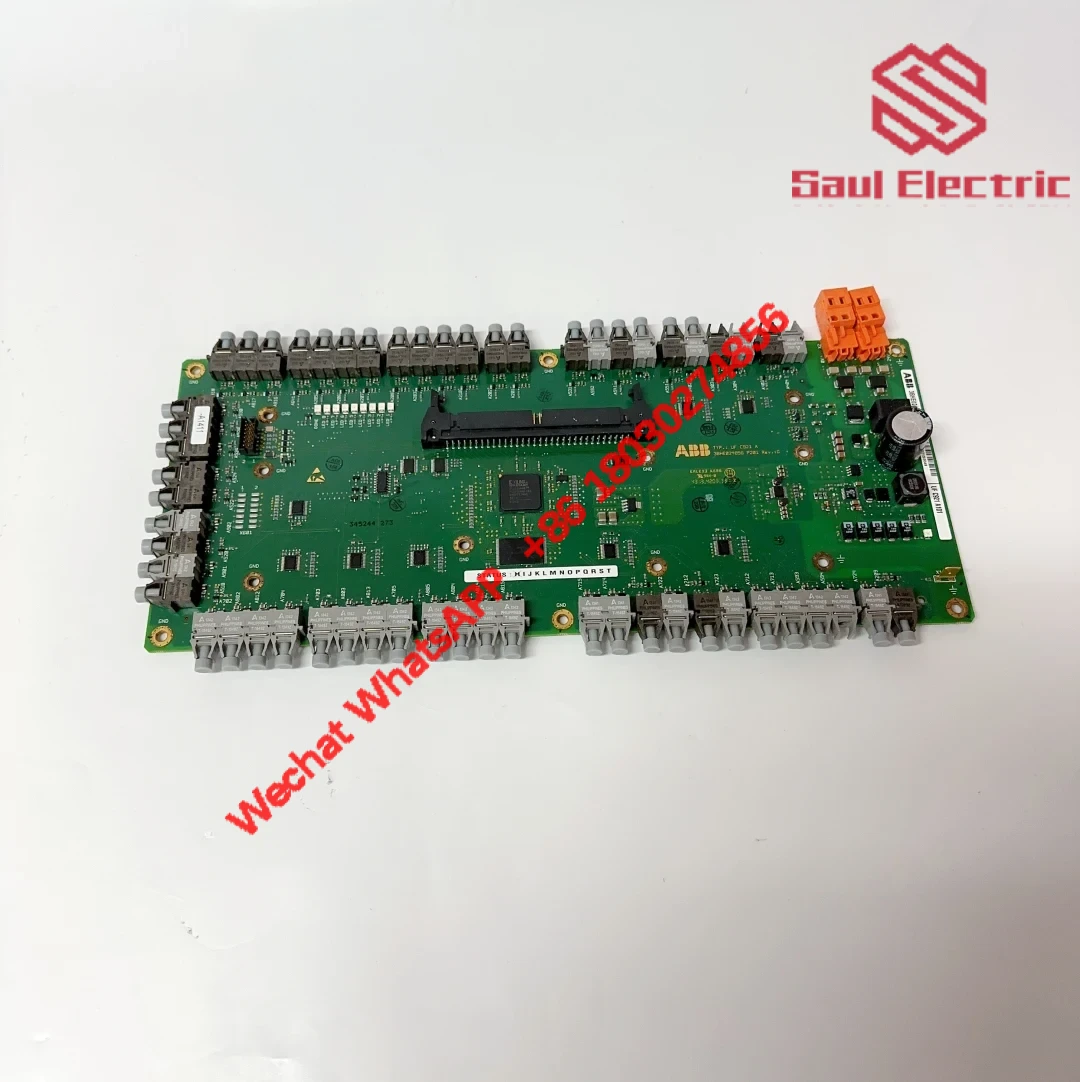

ABB UFC921A101 3BHE024855R0101 Industrial Control Module

The ABB UFC921A101 3BHE024855R0101 industrial control module serves as a critical component for precision automation systems across manufacturing and process industries. Designed for demanding environments, this module excels in motor speed control, conveyor synchronization, and real-time data acquisition tasks where reliability directly impacts production uptime.

| Attribute | Specification |

|---|---|

| Operating Voltage | AC 220V / DC 24V |

| Output Frequency Range | 0Hz – 400Hz |

| Input Current | ≤10mA |

| Communication Protocols | RS-485, Modbus-RTU |

| Load Capacity | Up to 100kHz |

| Control Precision | ±0.5% accuracy |

| Operating Temperature | -10°C to +55°C |

Common applications include packaging line automation, HVAC system optimization, and material handling equipment control. This module particularly shines in legacy system upgrades where Modbus compatibility is required alongside modern control precision. For instance, one automotive plant successfully integrated this module into their conveyor belt system, reducing positioning errors by 37% compared to their previous setup.

While the exact dimensions and weight aren’t specified in standard documentation, users report it fits standard 19″ rack enclosures with minimal space requirements. Our inventory includes complementary ABB modules like the PM866 and DSQC series robot controllers, along with compatible Triconex safety systems (e.g., 3008/3703X series) for integrated control architectures.

Technical advantages emerge through its dual-voltage design allowing AC/DC flexibility, which simplifies power supply configurations in mixed-voltage control cabinets. The RS-485 interface with Modbus-RTU ensures backward compatibility with older SCADA systems while maintaining sufficient throughput for modern applications. Notably, the thermal design enables operation at 55°C without derating – a critical factor in steel mill environments where ambient temperatures frequently exceed 40°C.

Field engineers appreciate the module’s hot-swappable design that minimizes process interruptions during maintenance. One textile factory maintenance supervisor noted: “Replacing faulty modules takes less than 3 minutes without shutting down the entire loom line.” This redundancy capability, combined with ABB’s electromagnetic interference shielding, contributes to MTBF ratings exceeding 100,000 hours in typical deployments.

Reviews

There are no reviews yet.