Description

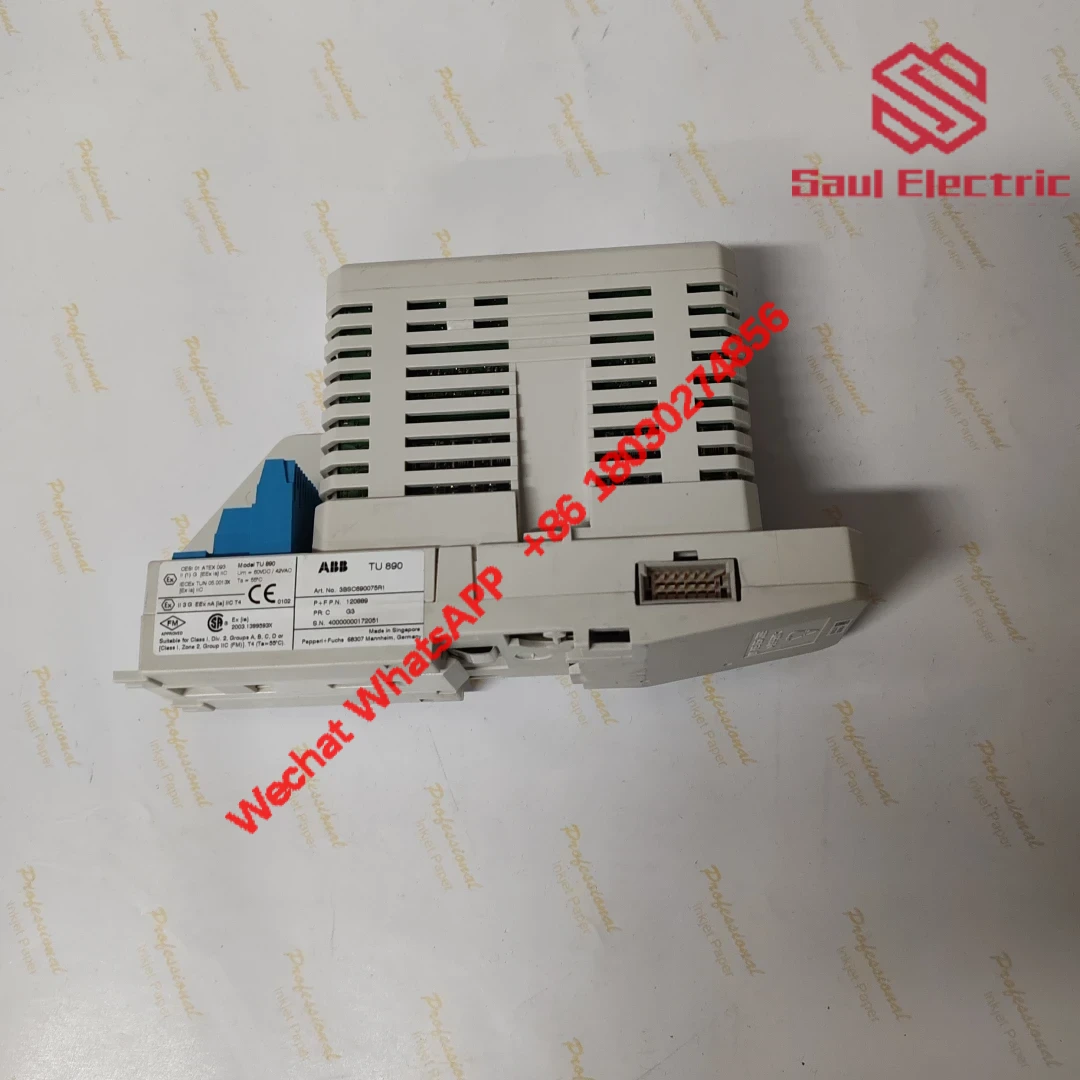

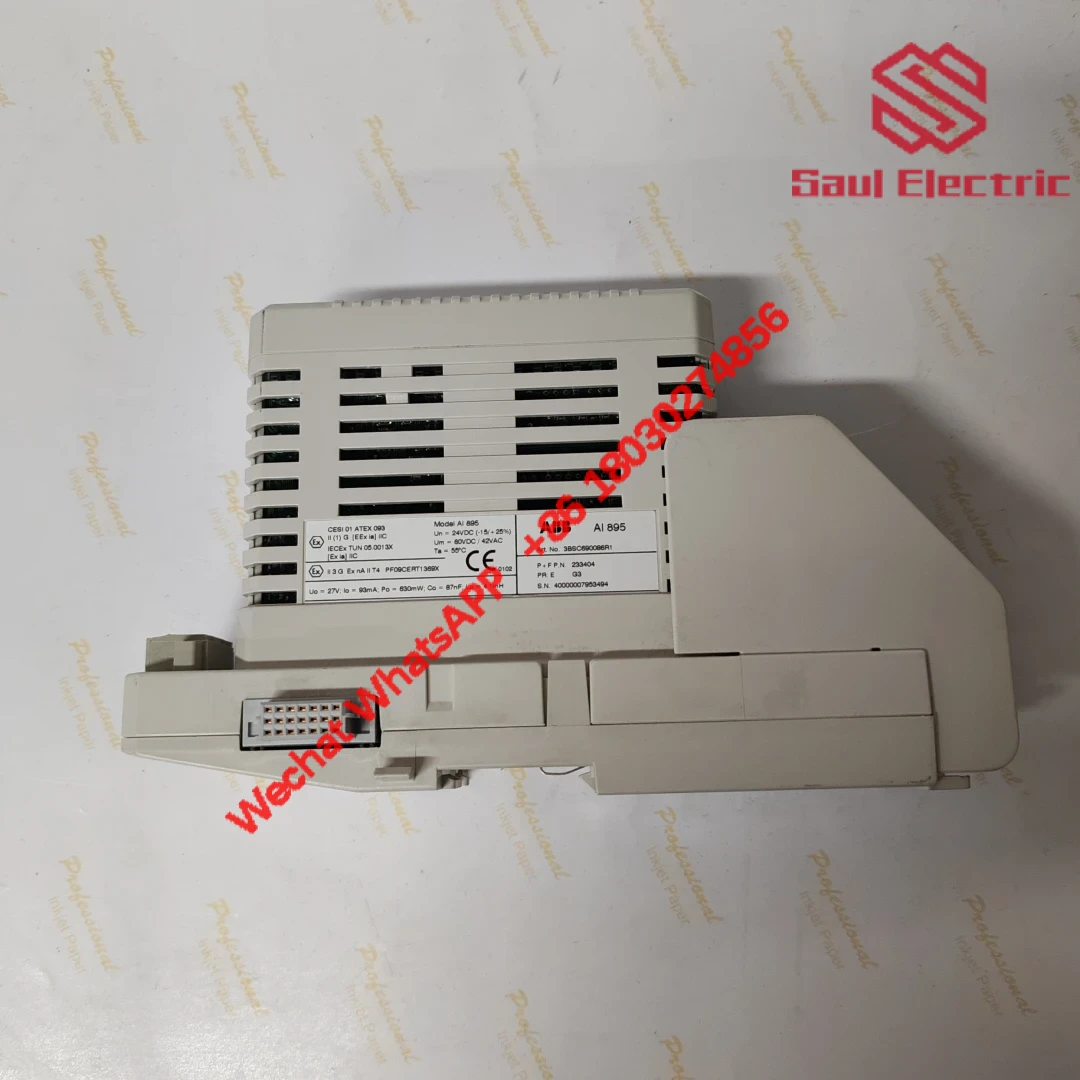

ABB TU890 3BSC690075R1 Module: Precision Feedback for Industrial Automation

This ABB TU890 3BSC690075R1 module serves as a dedicated rotor feedback board, engineered for high-precision motion control applications. Found in environments ranging from steel production lines to CNC machining centers, it delivers critical position and speed data to ensure synchronization accuracy within ±0.001%. The module’s compact design integrates seamlessly with ABB’s AC800M controllers, maintaining signal integrity even in high-vibration settings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ABB TU890 3BSC690075R1 |

| Series | ABB Controller Interface |

| Operating Voltage | 220 V AC |

| Output Frequency | 30 kHz |

| Weight | 0.14 kg |

| Certification | CE, IEC 60068-2-6 |

| Channels | Feedback-specific design |

Commonly deployed in paper mill tension control systems and robotic welding cells, this module forms the feedback backbone for ABB’s servo drive networks. We’ve supplied units for retrofitting legacy packaging machines where its 30kHz output enabled 15% faster cycle times. Compatible with S800 I/O and AC500 PLCs, it supports redundancy configurations through dual-channel signal processing. One customer reported eliminating positioning errors in their precision press after upgrading to this module’s resolver interface.

Engineered with robust aluminum housing and precision-machined connectors, the TU890 withstands temperature fluctuations from -20°C to 65°C. Its lightweight design simplifies installation in tight control cabinets while maintaining EMI resistance through shielded PCB traces. The module’s thermal management system prevents signal drift during extended high-load operations, a feature that proved crucial in a foundry application where ambient temperatures regularly exceed 50°C.

Reviews

There are no reviews yet.