Description

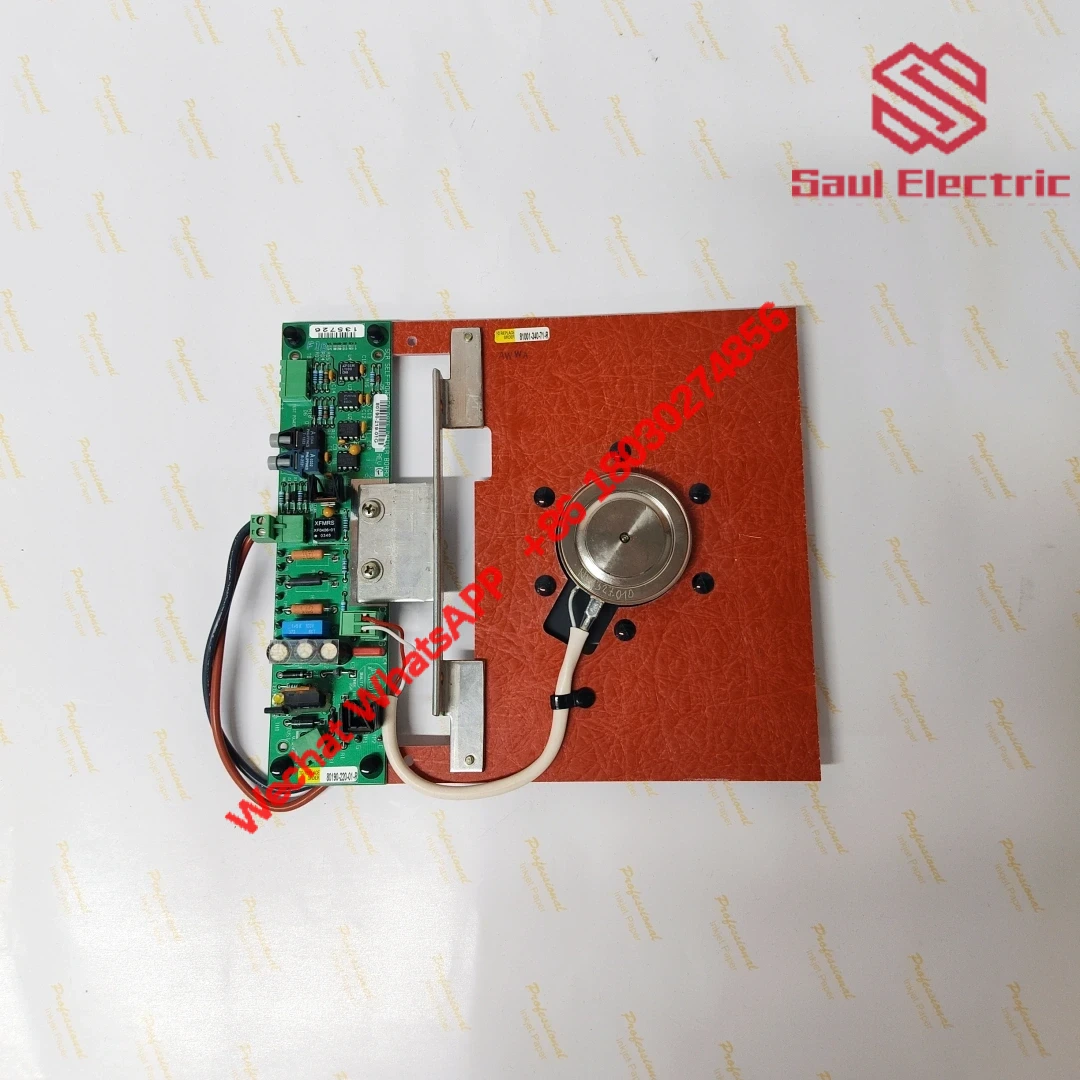

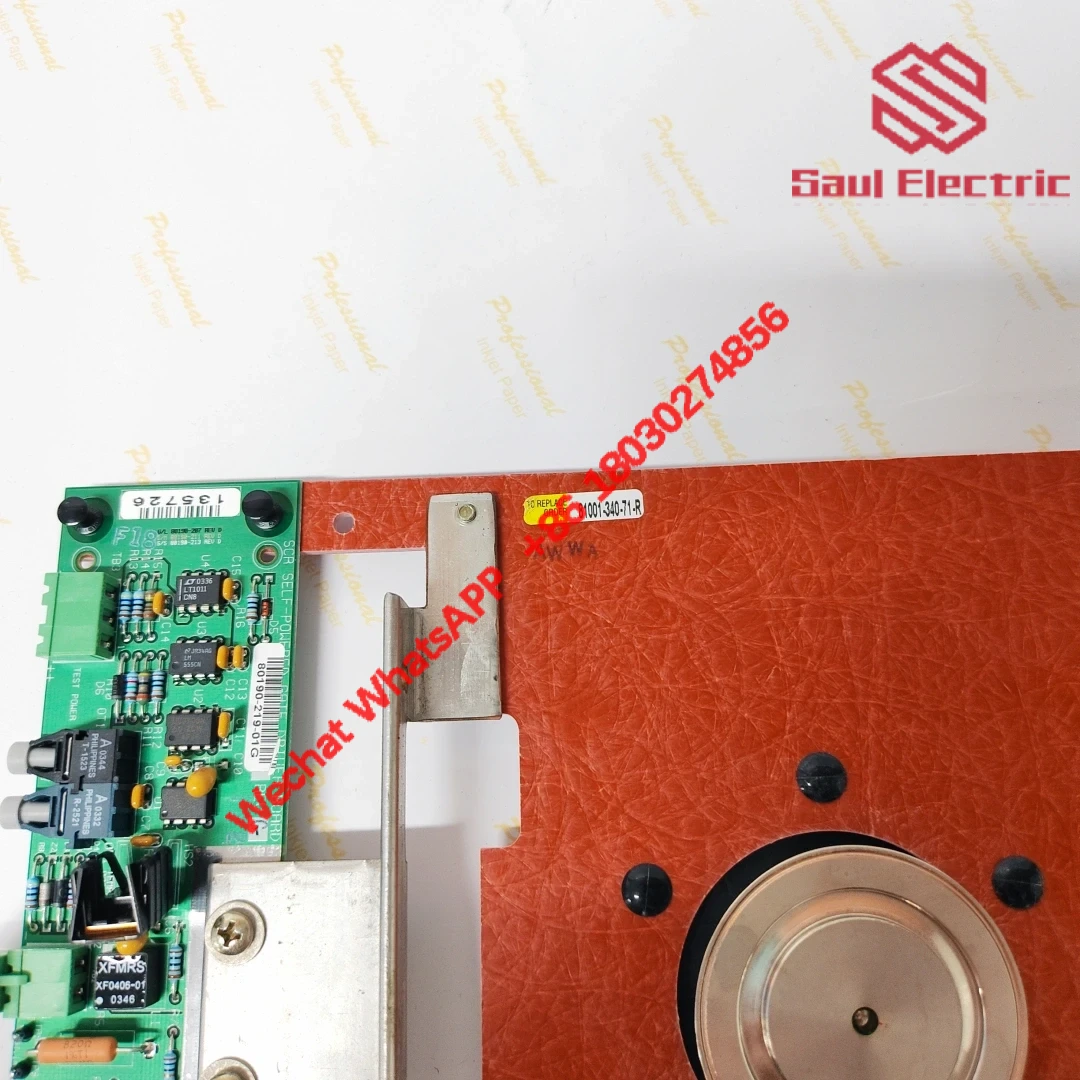

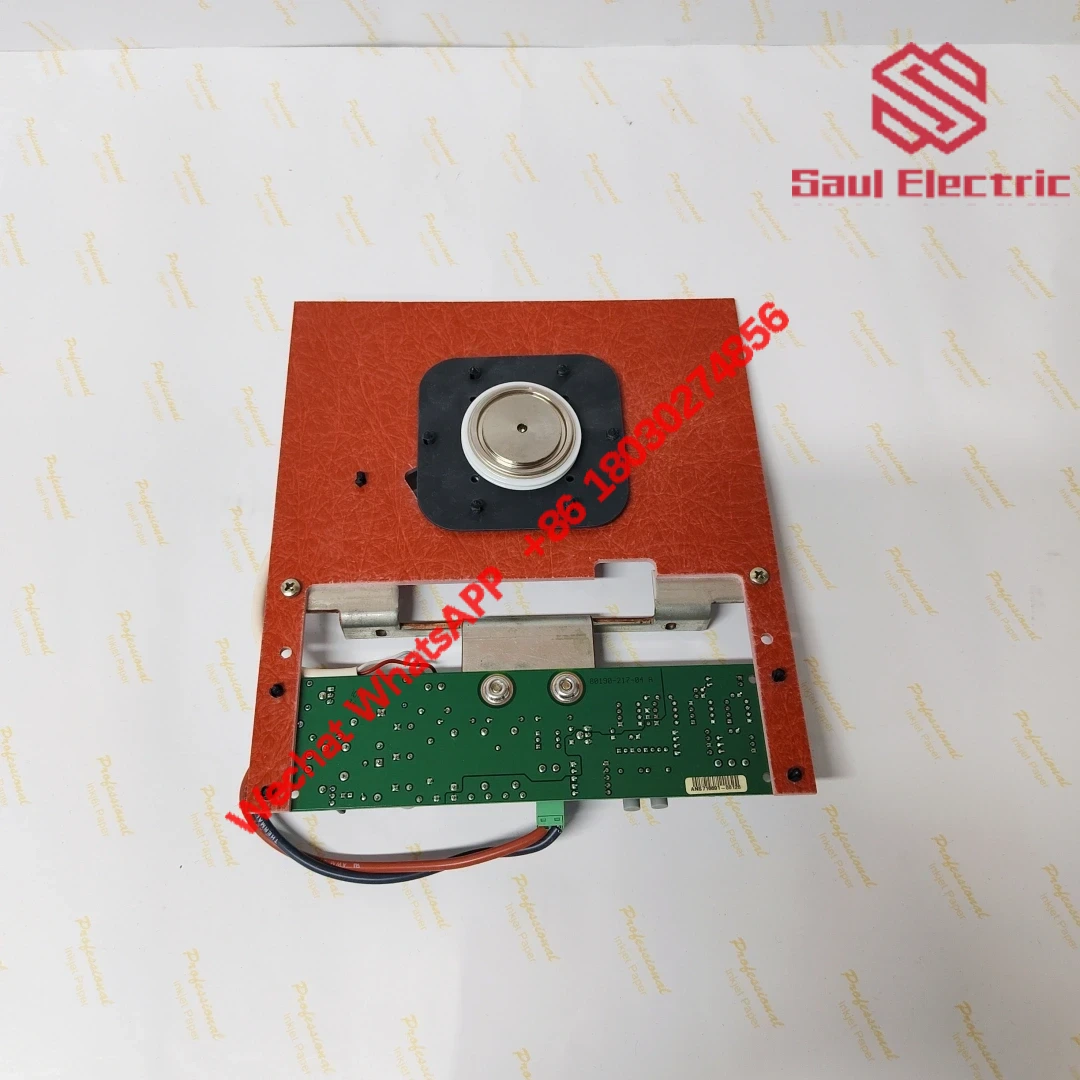

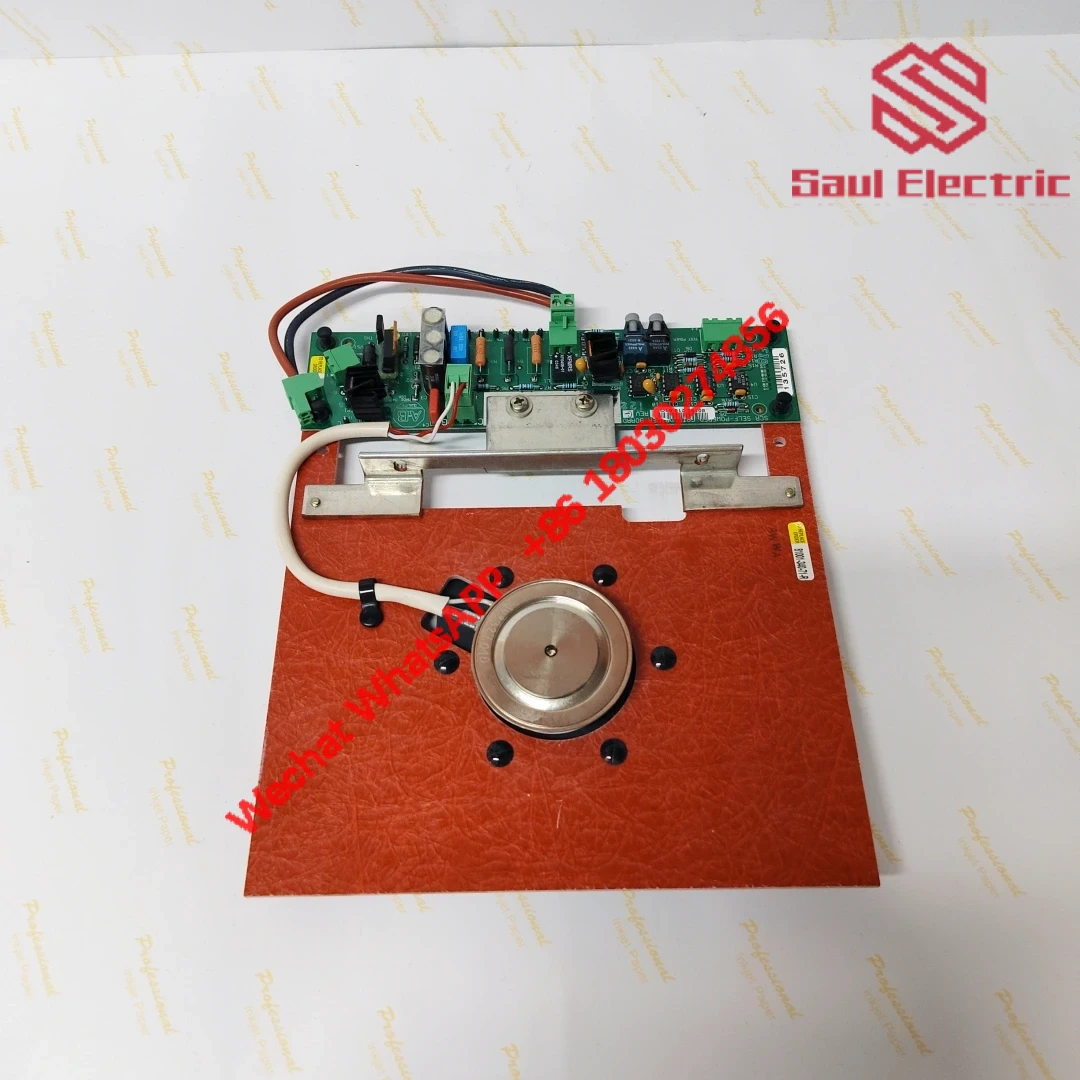

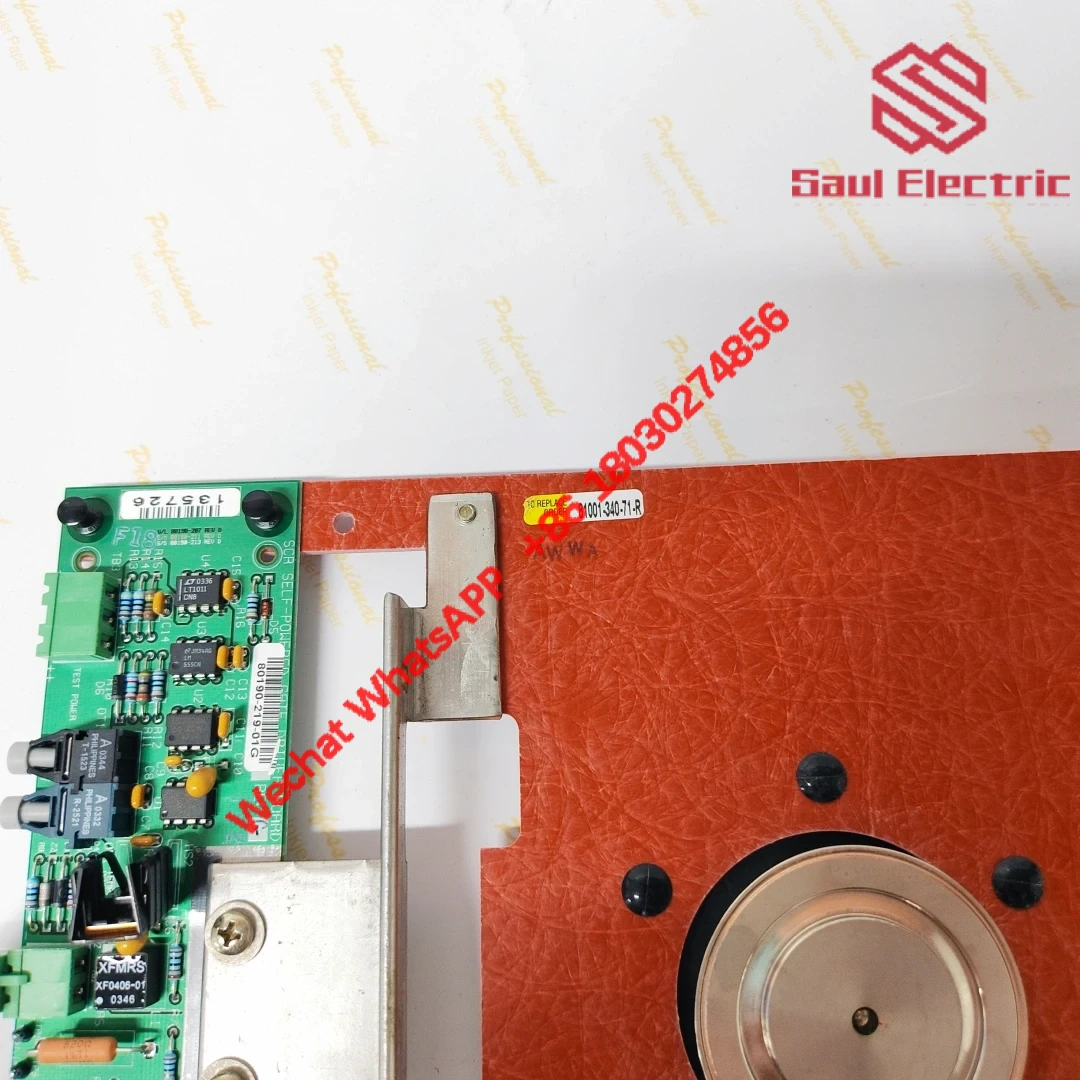

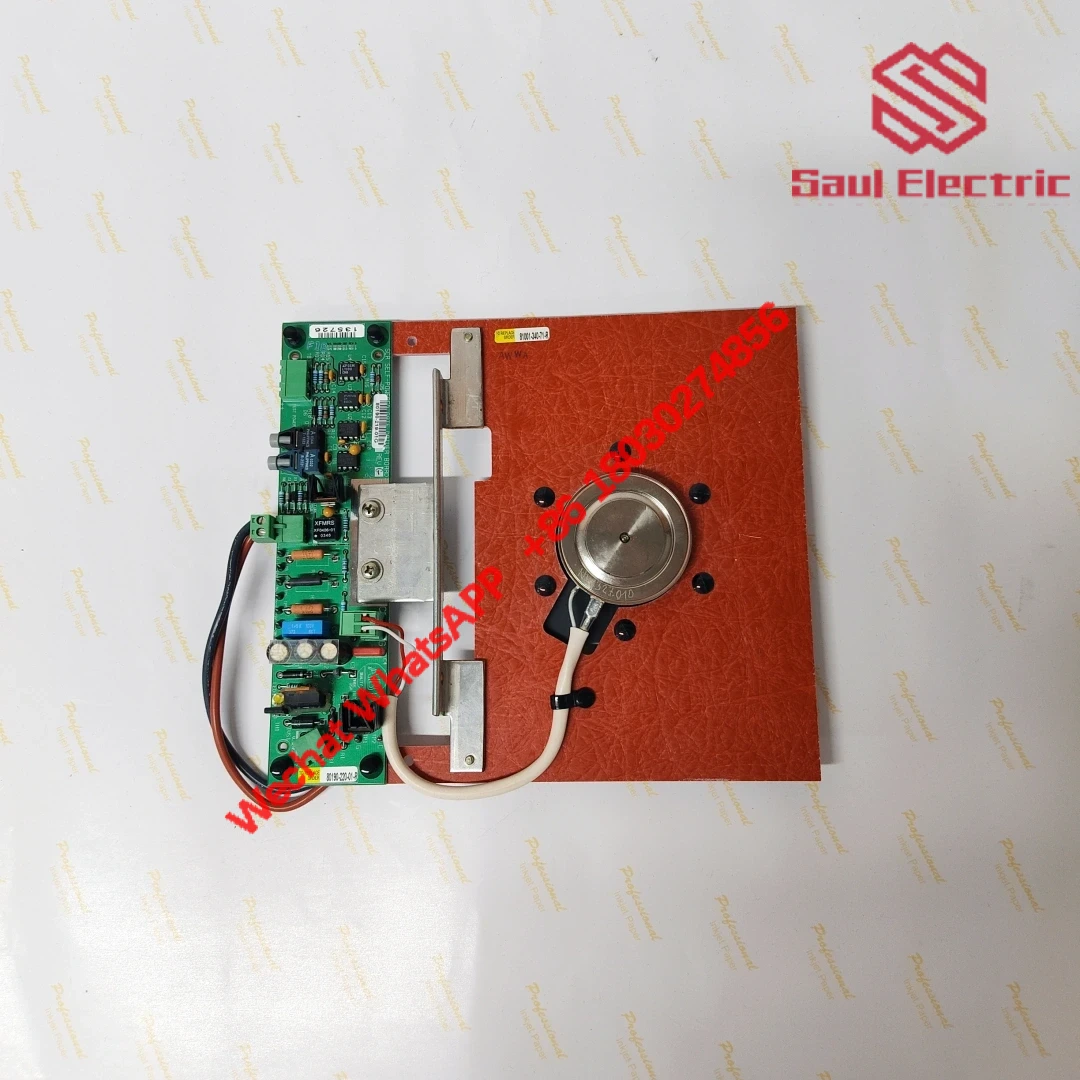

A-B 81001-340-71-R: Precision Industrial Control Module

This Allen Bradley module serves as a critical component for automating complex machinery across manufacturing, energy, and process industries. Designed for high-precision tasks like motor control in assembly lines or sensor data aggregation in oil refineries, it bridges the gap between rugged industrial environments and sensitive control systems.

| Brand | Allen Bradley (Rockwell) |

| Operating Temp | -20°C to 55°C |

| Power | 50W max @ 85-264V AC |

| Comms | RS-485 + CANopen |

| Dimensions | 100x100x25mm |

| Weight | 0.2kg |

Commonly found in packaging lines managing 1200+ I/O points or wastewater treatment plants coordinating pump arrays, this module thrives where reliability matters. Our clients frequently pair it with Allen Bradley’s 1756 control platforms for food processing automation, or integrate it into legacy PLC-5 systems during gradual factory upgrades. One Midwest automotive plant even uses it to synchronize robotic welders across three shifts without downtime.

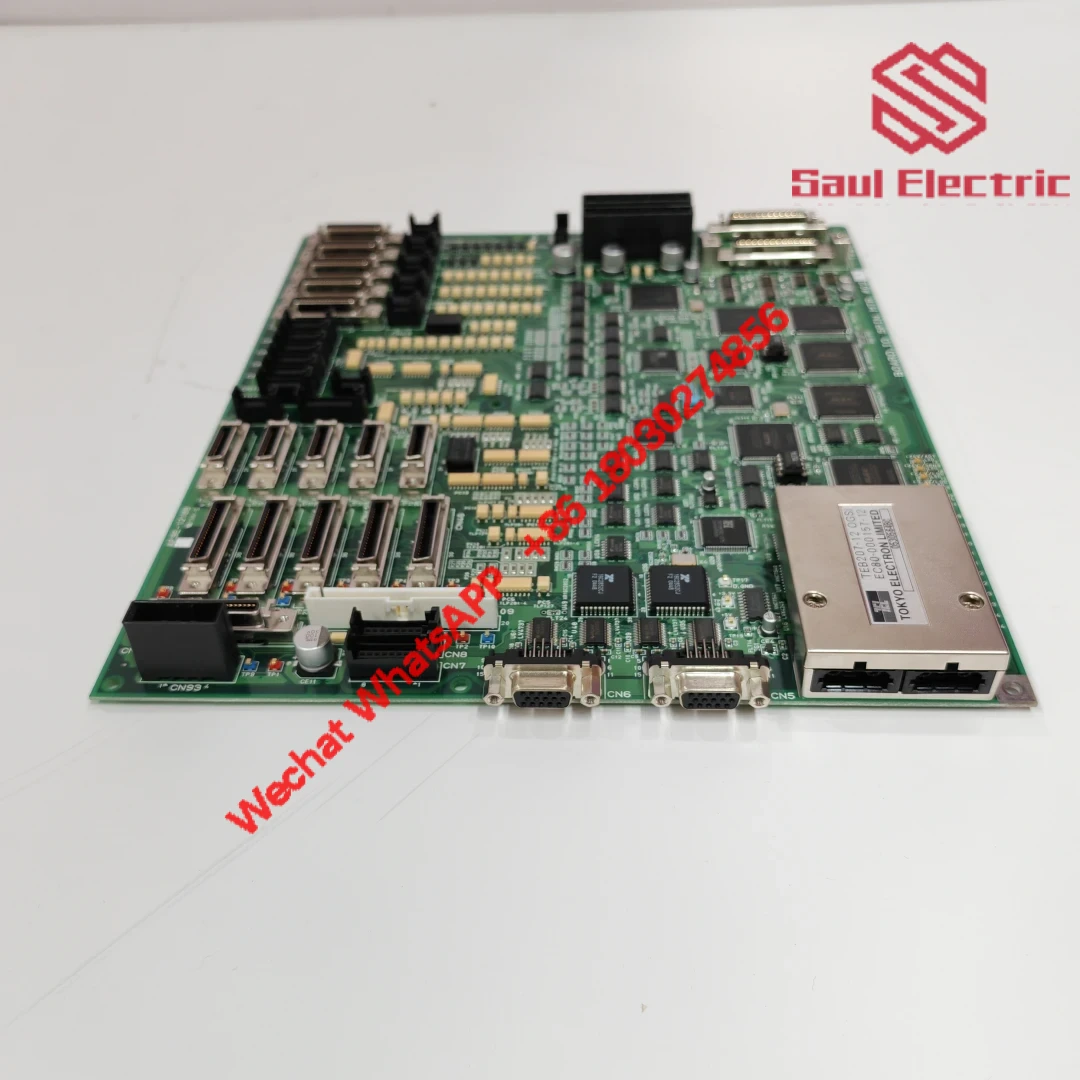

What makes this module stand out? Its ability to maintain 99.999% uptime while handling protocol conversions between Modbus and EtherNet/IP networks. The dual CANopen ports allow simultaneous communication with drives and HMIs, while the 200MHz processor crunches PID loops 30% faster than previous generations. We’ve seen customers extend system lifecycles by 5+ years just by upgrading to this module’s hot-swappable design – no need to shut down entire lines for replacements.

Reviews

There are no reviews yet.