Description

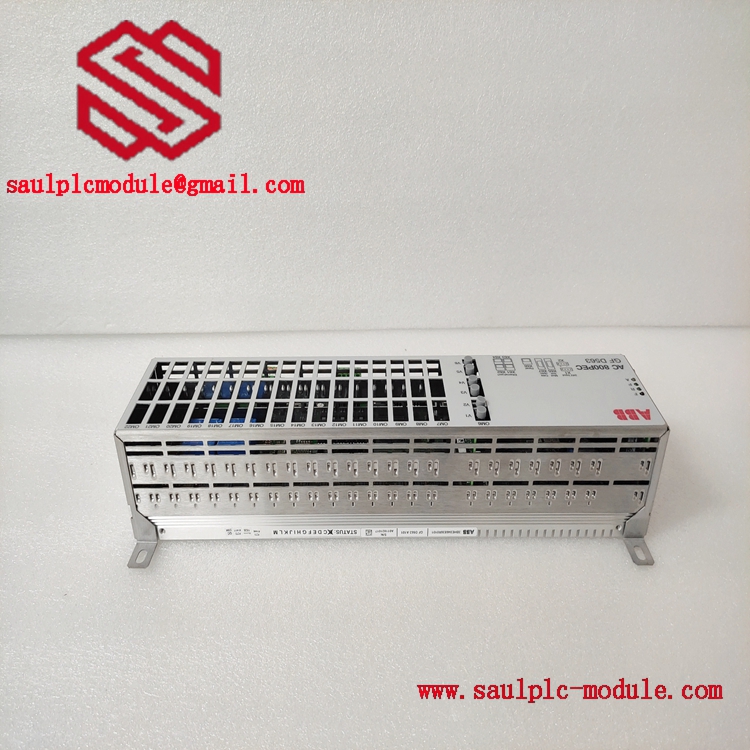

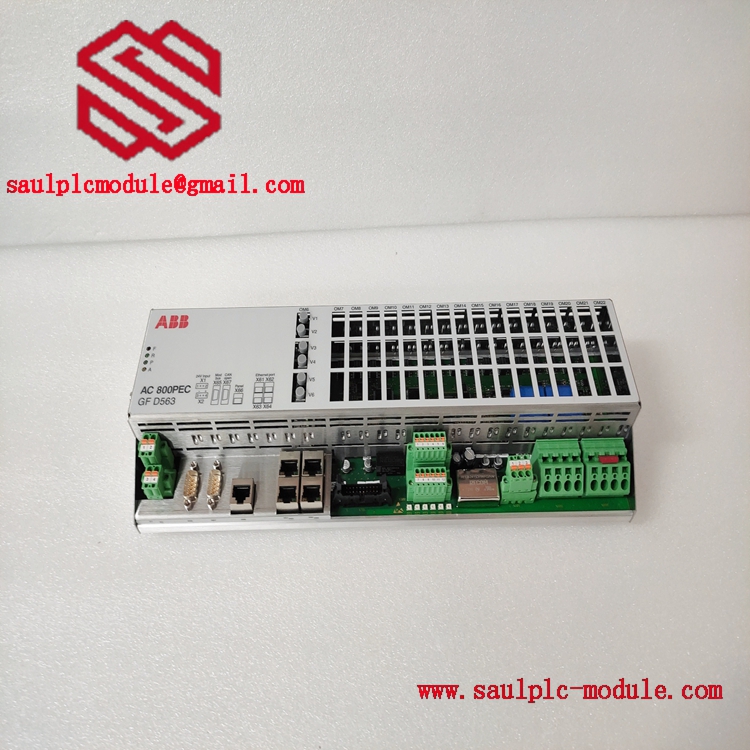

ABB GFD563A101 (3BHE046836R0101) Industrial Ethernet Communication Module Product Description

Product Overview

The ABB GFD563A101 (3BHE046836R0101) is a high – reliability industrial Ethernet communication module designed for ABB Symphony Plus DCS and AC 800M/AC 800PEC control systems. It serves as a core network communication gateway, responsible for high – speed, low – latency data exchange between controllers, remote I/O stations, and upper – level monitoring systems. It supports redundant network configuration and multiple industrial Ethernet protocols, ensuring stable and reliable data transmission in harsh industrial environments. It is widely used in power generation, petrochemical, metallurgical and other fields, and is an essential component to ensure the efficient operation of the distributed control system.

Technical Specifications

| Parameter | GFD563A101 (3BHE046836R0101) |

|---|---|

| Model Number | GFD563A101 (Ordering Part Number: 3BHE046836R0101) |

| Product Type | Industrial Ethernet Communication Module (Redundant Network Interface) |

| Communication Interface | 2×RJ45 (10/100 Mbps Ethernet, IEEE 802.3 compliant) |

| Supported Protocols | TCP/IP, UDP, Modbus TCP, PROFINET, ABB S800 I/O Modulebus |

| Power Supply | 24V DC (redundant input, reverse – polarity protection), Power Consumption: ≤10W |

| Operating Temperature | -20°C to +70°C, Storage Temperature: -40°C to +85°C |

| Physical Dimensions | 180mm×170mm×50mm, Weight: 0.22-0.24kg |

| Mounting Type | DIN rail/rack mounting (compatible with ABB standard control cabinets), hot – swappable design |

| Protection Level | IP20 (module), ESD protection (±8kV contact, ±15kV air) |

| Compliance | CE, RoHS 2, IEC 61131-3, IEC 61850 (power system communication standard) |

Core Features & Advantages

- Redundant Network Assurance: The dual – Ethernet port design supports redundant ring network topology. When a network link fails, it can switch to the standby link within 50ms, ensuring zero data loss and continuous operation of the control system, which is suitable for high – reliability application scenarios such as power plant DCS and energy storage PCS6000.

- Multi – Protocol Adaptability: It is compatible with mainstream industrial Ethernet protocols, realizing seamless integration with third – party devices (such as PLC, frequency converter, and monitoring software). It can also convert Modbus TCP data into ABB S800 I/O internal protocol, simplifying the system integration process and reducing engineering costs by 30% – 40%.

- Low – Latency Data Transmission: The hardware – optimized protocol stack ensures that the data transmission delay between the controller and the I/O station is less than 1ms, meeting the real – time control requirements of fast process loops (such as generator excitation control and medium – voltage drive speed regulation). It can perfectly match the PPD539A102 controller and 3BHE055094R0002 gate drive board to form a high – performance control chain.

- Comprehensive Diagnostic & Management: It has built – in network status monitoring, fault self – diagnosis, and clock synchronization functions. It can real – time monitor link quality, node connection status, and automatically record fault logs, which is convenient for maintenance personnel to quickly locate problems and shorten the system downtime by more than 50%.

- Industrial – Grade Robustness: It adopts industrial – grade components and anti – vibration design, which can resist electromagnetic interference (EMI) and voltage fluctuations in the industrial environment. The working temperature range of -20°C to +70°C ensures stable operation in harsh working conditions such as outdoor control cabinets and high – temperature workshops.

Application Fields

- Power Plant DCS System: It is used in ABB Symphony Plus DCS to connect the AC 800M controller and S800 remote I/O station, realizing the data acquisition and control of boiler, turbine, and generator systems. It supports the redundant network configuration of the power plant to meet the high – reliability requirements of power generation equipment.

- Medium – Voltage Drive & Energy Storage: It is matched with the AC 800PEC controller (PPD539A102) and PCS6000 energy storage system to realize the real – time communication between the drive control unit and the upper – level monitoring platform, ensuring the stable operation of the variable – frequency speed regulation system and the grid – connected energy storage system.

- Petrochemical Process Control: It is used in the distributed control system of the petrochemical production line to connect the process controller and the on – site instrument, realizing the precise control of parameters such as temperature, pressure, and flow, and meeting the safety and reliability requirements of the explosive environment.

- Metallurgical & Mining Automation: It is applied to the control system of large – scale metallurgical equipment (such as blast furnace, rolling mill) and mining machinery, realizing the high – speed data transmission between the control room and the on – site equipment, and improving the production efficiency and equipment operation stability.

Compatibility & Related Products

| Related Product Model | Product Name | Compatibility Description |

|---|---|---|

| PPD539A102 (3BHE039770R0102) | AC 800PEC Controller | Realizes high – speed data interaction between the controller and the Ethernet network, ensuring the real – time performance of the control loop |

| 3BHE055094R0002 (GBU72) | Gate Drive Board + Rectifier Bridge | Transmits the working status data of the power module to the controller, and supports the remote monitoring of the gate drive unit |

| S800 I/O Modules | ABB Digital/Analog I/O | Connects the remote I/O station to the Ethernet network, realizing the centralized management of the on – site signal |

| 3BHE046836R0102 | GFD563A101 Redundant Module | Forms a redundant communication network to improve the reliability of the system |

| Control Builder M | ABB Configuration Software | Supports the configuration of the module’s network parameters, protocol conversion, and fault diagnosis |

Installation & Maintenance Guidelines

Installation

- Mechanical Installation: Install the module on the standard DIN rail of the control cabinet, and reserve a 50mm ventilation space around the module. Fasten the module with screws with a torque of 2.5N·m to prevent loosening caused by vibration.

- Electrical Wiring: Connect the 24V DC redundant power supply first, and ensure that the power voltage fluctuation is within ±5%. Use shielded twisted – pair cables for the Ethernet cable, and the cable length should not exceed 100m to avoid signal attenuation.

- Network Configuration: Use Control Builder M to set the IP address, subnet mask, and gateway of the module. Configure the redundant network parameters and protocol conversion rules, and test the network communication status to ensure that the data transmission is normal.

Maintenance

- Regular Inspection: Check the module’s power indicator, network status indicator, and fault alarm indicator monthly. Use ABB diagnostic software to read the network communication rate, error rate, and other parameters quarterly.

- Firmware Update: Update the module’s firmware once a year to fix known bugs and improve protocol compatibility. The firmware update can be completed online without stopping the system operation.

- Environmental Maintenance: Clean the dust on the module and the control cabinet regularly to ensure good heat dissipation. Check the power connector and network cable interface every 6 months, and tighten the loose connectors in time.

Product Assurance

Hong Kong Saul Electric Co., Ltd. provides a 1 – year warranty for the ABB GFD563A101 (3BHE046836R0101) module, covering manufacturing defects and performance problems. We have sufficient inventory to meet the urgent needs of customers for spare parts in industrial projects. Our professional technical team can provide on – site installation guidance, network configuration, and fault troubleshooting services. For inquiries or orders, please contact us via WhatsApp: https://wa.me/+8618030274856 or email: saulplcmodule@gmail.com. We are committed to providing you with high – quality industrial automation solutions.

| ABB | GFD563A101 3BHE046836R0101 |

| ABB | PM891K01 3BSE053241R1 |

| ABB | AC800M 3BSE053240R1 PM891 |

| ABB | PM866AK01 |

| ABB | PM864AK01 3BSE018161R1 |

| ABB | PM864AK01 |

| ABB | PM864A |

| ABB | PM861AK01 |

| ABB | PM860K01 3BSE018100R1 |

| ABB | PM665 3BDS005799R1 |

| ABB | PM856AK01 |

| ABB | PM864A 3BSE018162R1 |

| ABB | PM864AK01 3BSE01816R1 |

| ABB | PM866AK01 3BSE076939R1 |

| ABB | PM866K01 3BSE050198R1 |

| ABB | PM866K01 |

| ABB | PPC907BE 3BHE024577R0101 |

| ABB | PPD113B01-10-150000 |

| ABB | PM511V16 3BSE011181R1 |

| ABB | PM511V16 |

| ABB | PM511V08 3BSE011180R1 |

| ABB | PPD113-B03-10-150000 |

| ABB | PPD113B03-10-150000 |

| ABB | PPD113B01-10-150000 3BHE023784R1023 |

| ABB | PPD113A01-10-150000 3BHE013784R1023 |

| ABB | PPD113 |

| ABB | PFSK152 3BSE018877R1 |

| ABB | PFSK151 3BSE018876R1 |

| ABB | PFSK151 |

| ABB | PFSA145 3BSE008843R1 |

| ABB | PFSA140 3BSE006503R1 |

| ABB | LDGRB-01 3BSE013177R1 |

| ABB | KUC755AE117 |

Reviews

There are no reviews yet.