Description

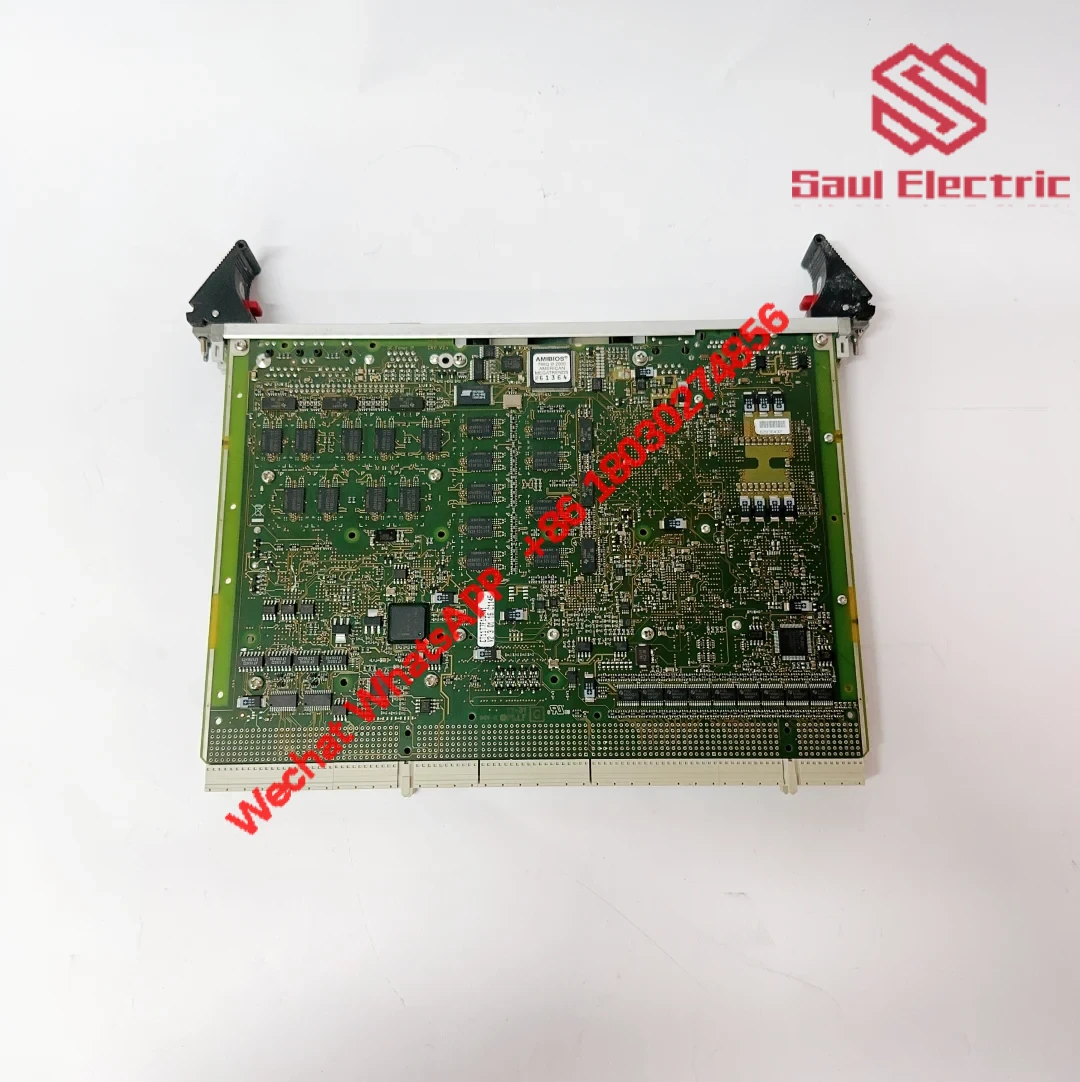

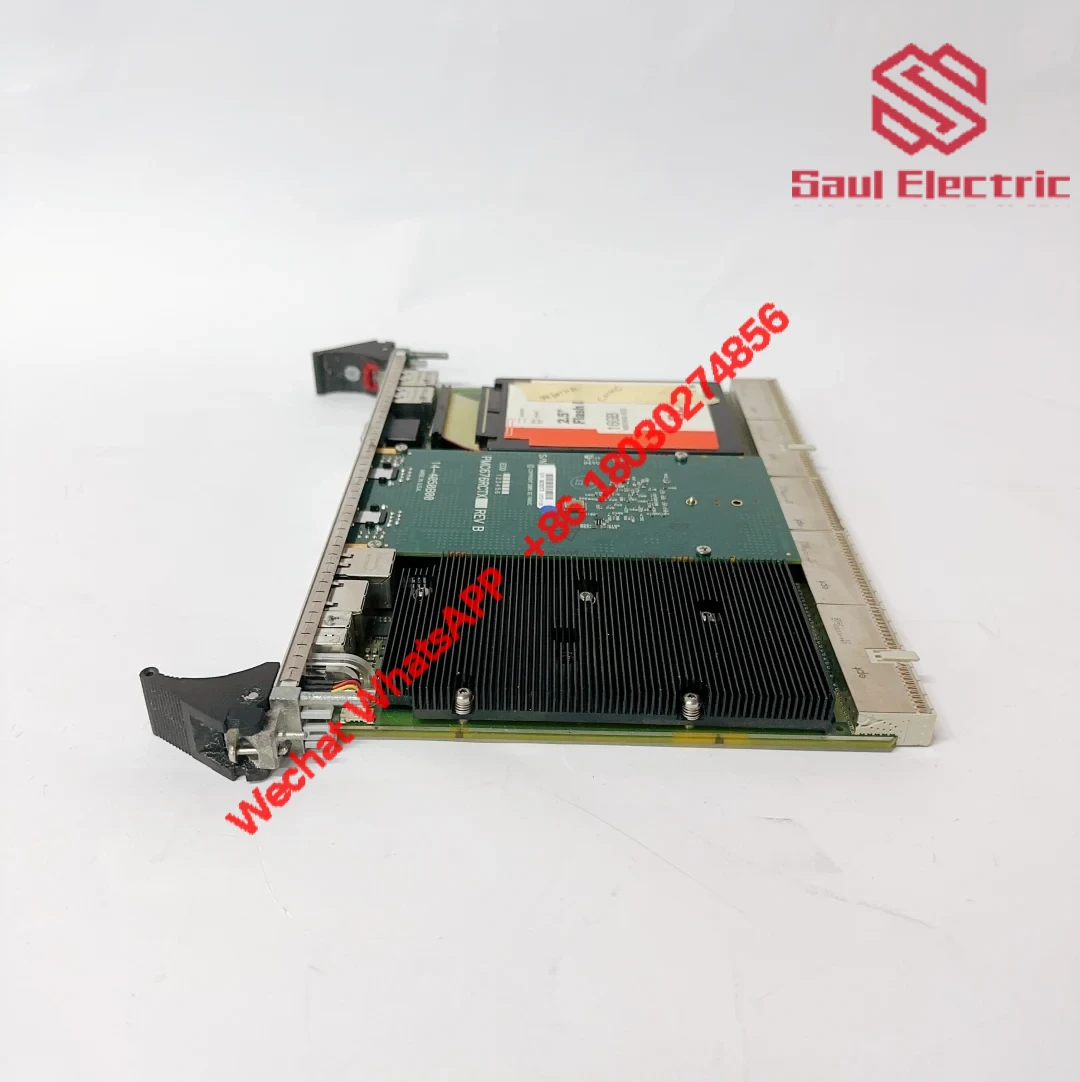

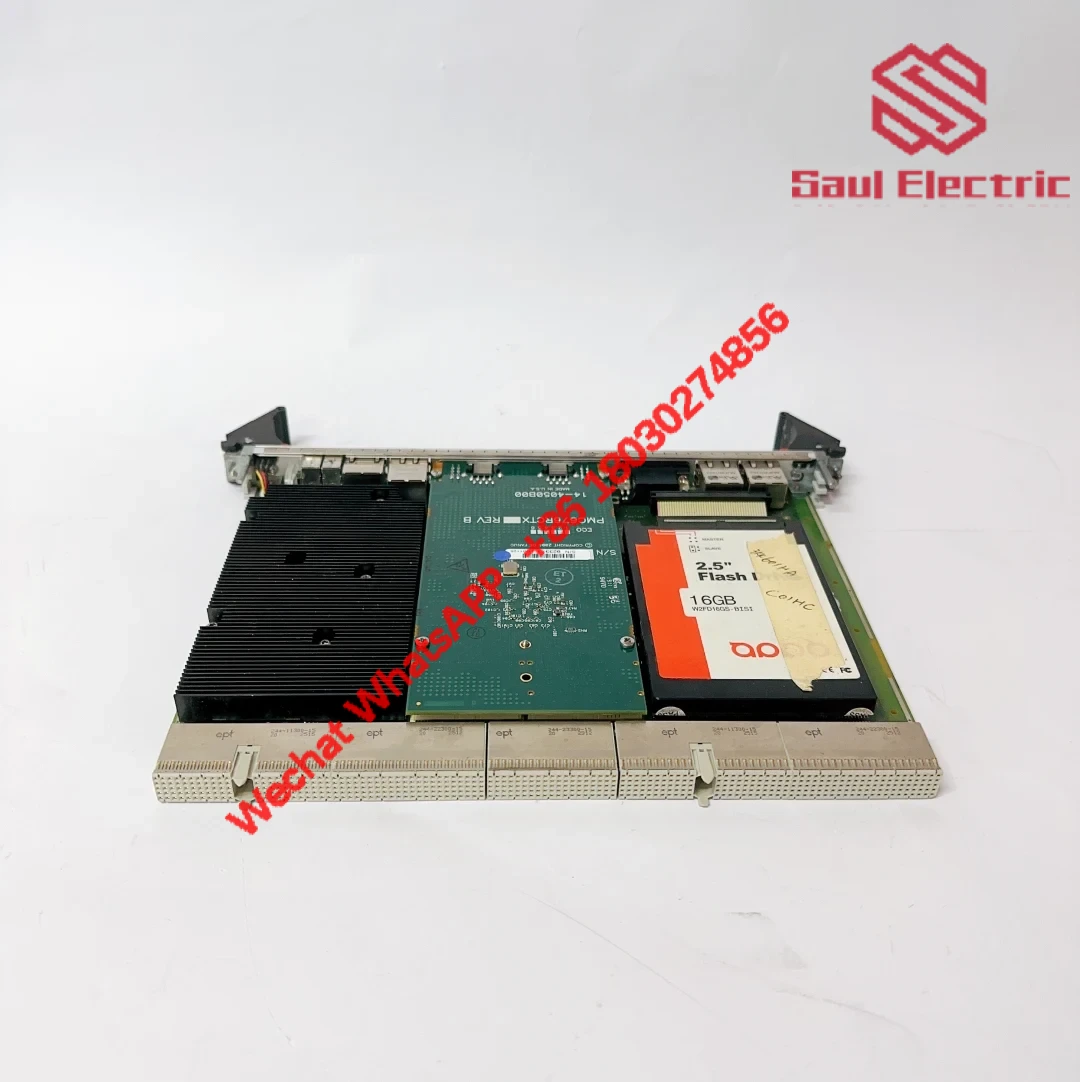

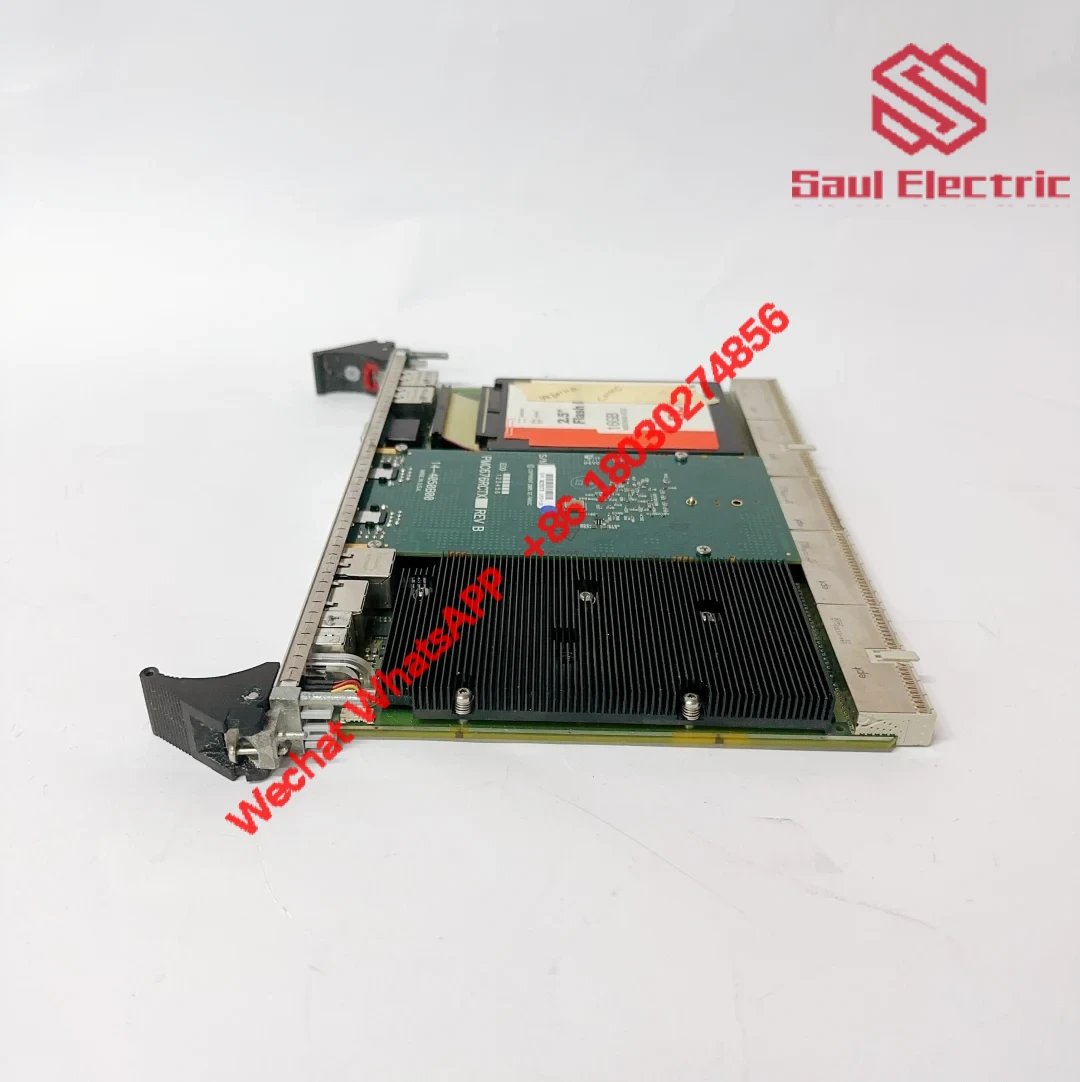

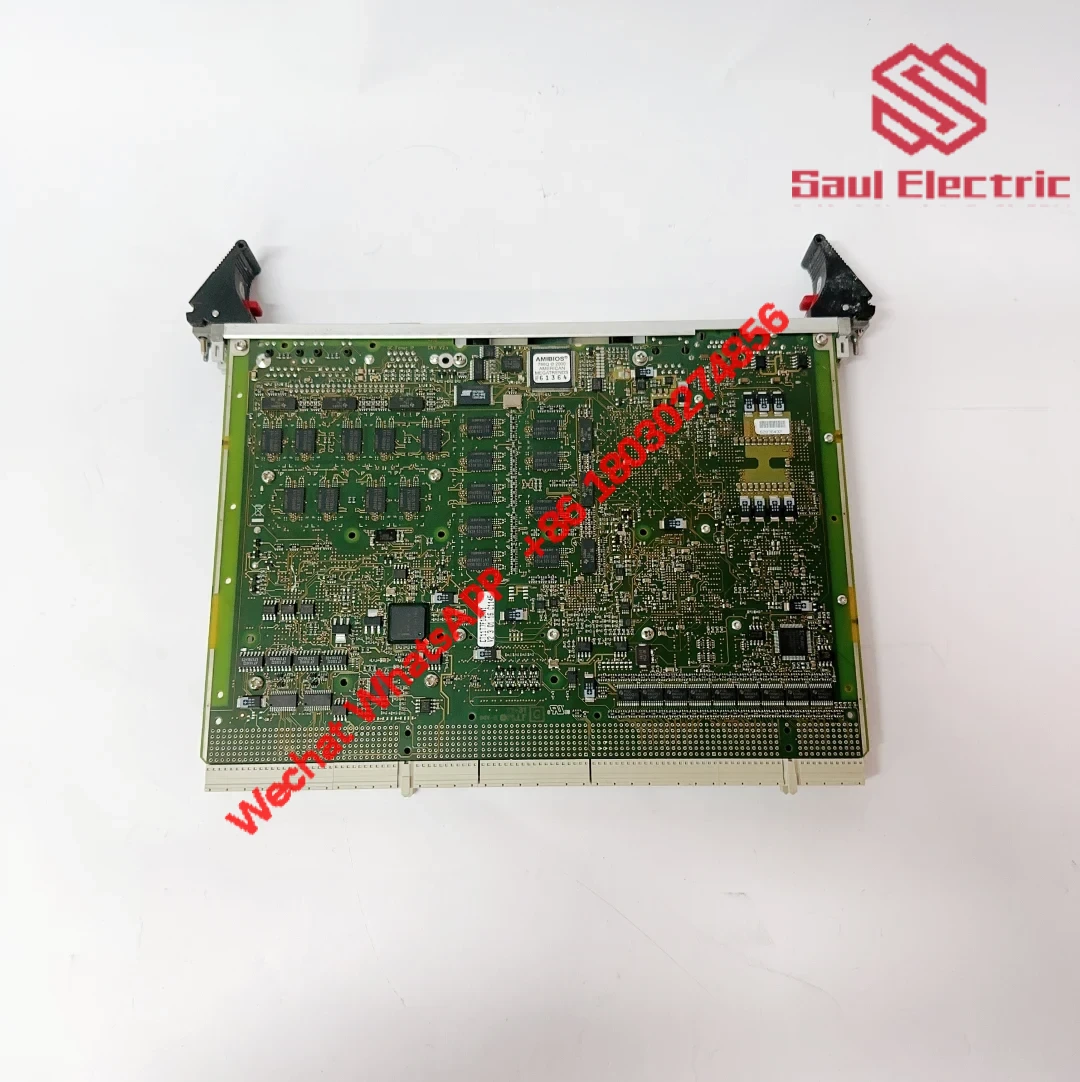

PMC676RCTX V2.3 01 16 C1145 CR11 V2.x CT11T7F10PN1 – Precision Control Module

This industrial control module delivers rock-solid performance for complex automation systems. Designed to handle demanding tasks in manufacturing plants, energy facilities, and process control environments, it combines rapid response times with rock-solid construction for 24/7 reliability.

Firmware: V2.3 01 16 C1145 CR11 V2.x

System Match: CT11T7F10PN1

Temp Range: -20°C to +60°C

Power Draw: ≤ 25W

Comms: RS485, CANopen, Ethernet

Memory: 32MB Flash + 16MB RAM

I/O Channels: 8 Digital Inputs/Outputs

Speed: ≤ 2ms Response Time

Factories using legacy CT11T7F10PN1 systems have successfully upgraded with this module for precision tasks like turbine control and conveyor synchronization. We’ve seen it integrate smoothly with existing Bently Nevada monitoring systems in power plants, and it’s become a go-to replacement for aging Schneider Quantum modules in oil & gas applications. Its compact 120x80x25mm frame fits tight spaces while maintaining serviceability.

What makes this module stand out? The dual-processor architecture handles complex PID loops while maintaining real-time communication. Unlike typical modules that struggle with simultaneous tasks, this one maintains ≤2ms response even during network heavy lifting. The built-in watchdog timer automatically resets fault conditions – we’ve seen this prevent unplanned downtime in steel mill operations.

Redundancy features deserve special mention. The dual power inputs and hot-swappable design let technicians replace modules mid-process without shutting down production lines. One automotive plant we worked with reduced maintenance windows by 40% after switching to this system. The diagnostic LEDs provide instant status checks, which field engineers appreciate for troubleshooting vibration monitoring systems on offshore rigs.

Reviews

There are no reviews yet.