Description

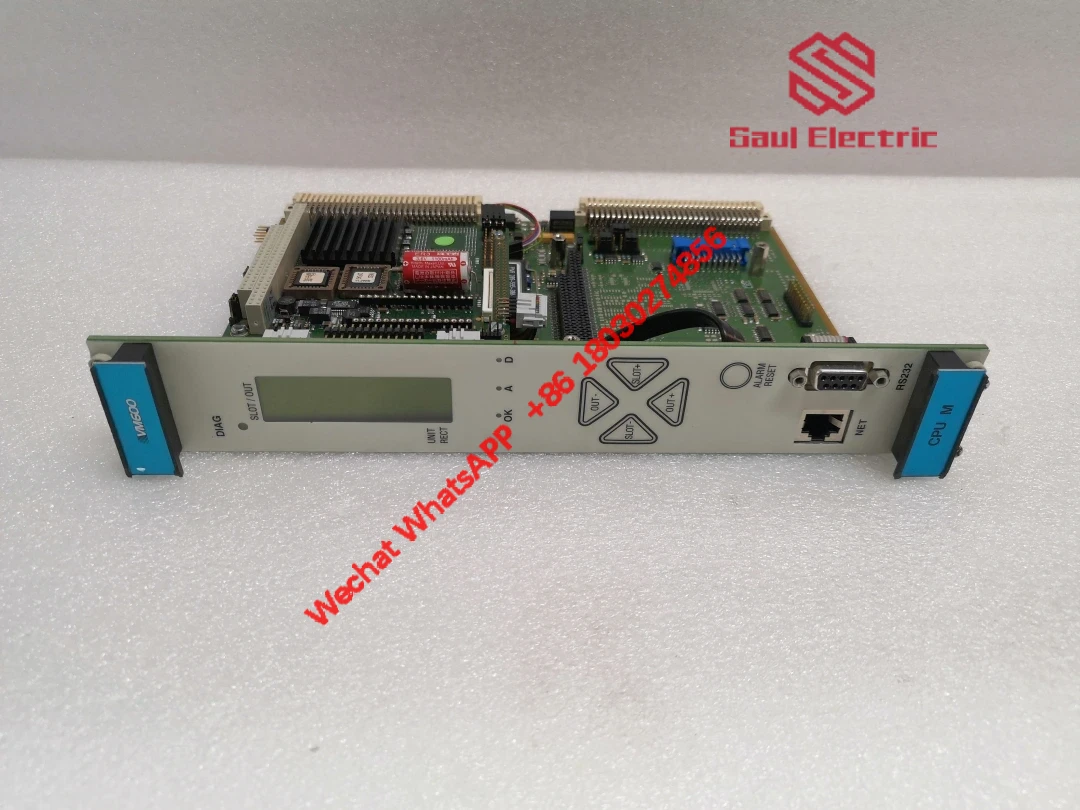

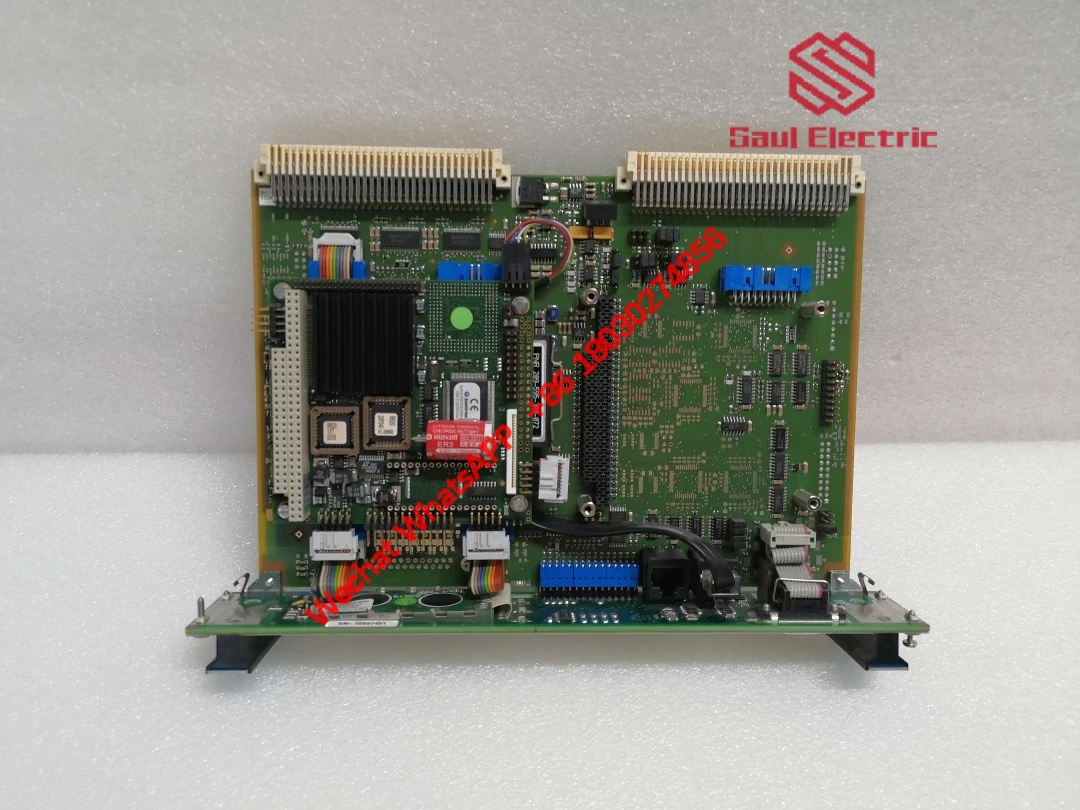

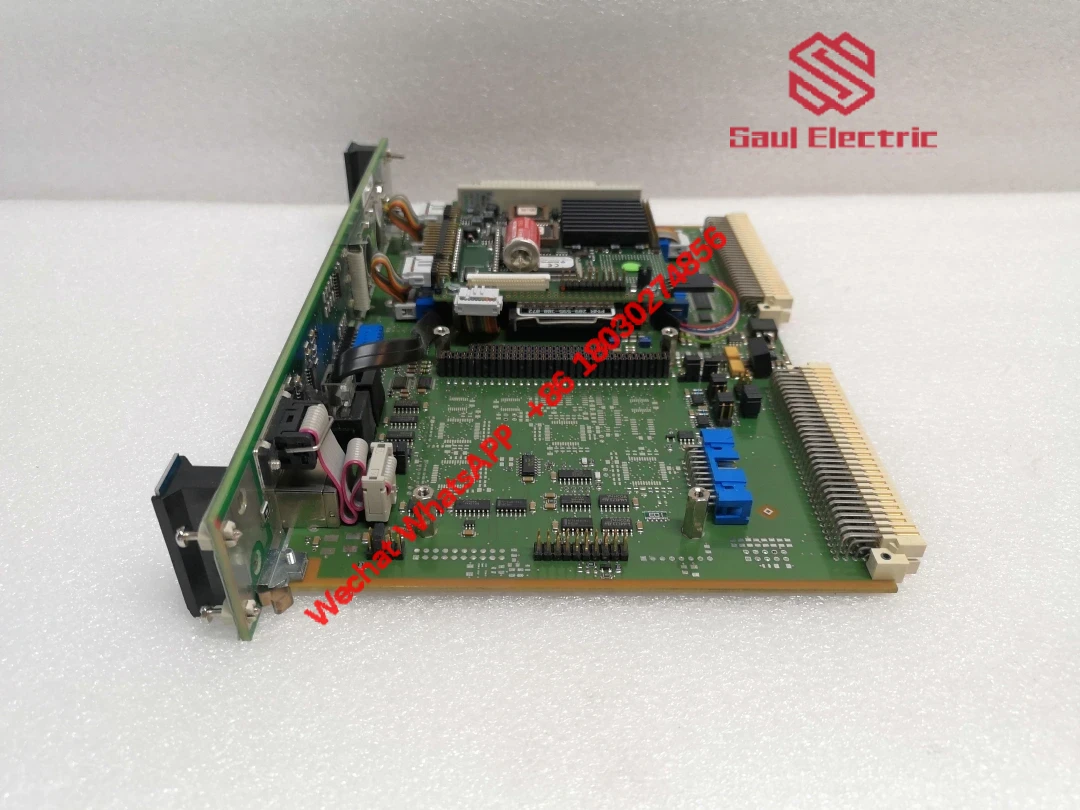

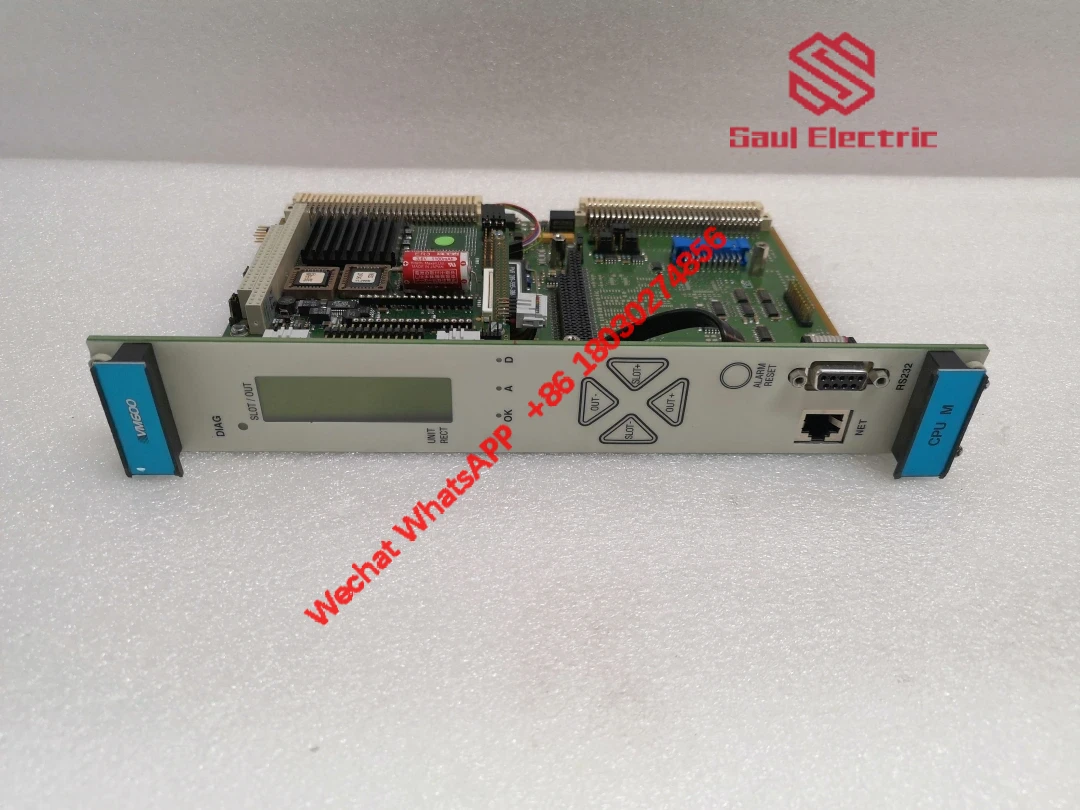

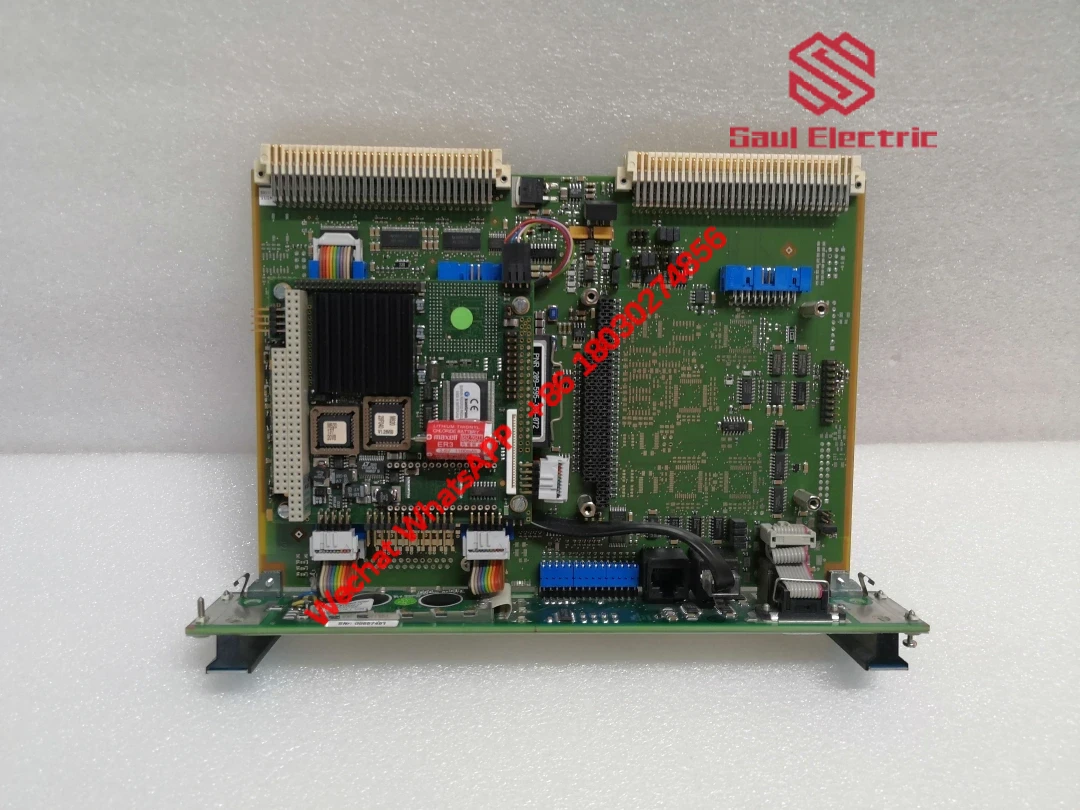

Vibro-meter VM600 CPUM Module 200-595-100-014 / 200-595-072-122

The Vibro-meter VM600 CPUM is a high-performance industrial CPU module engineered for precision control in demanding environments. Designed to handle complex automation tasks, it serves as the computational backbone for vibration monitoring systems, turbine controls, and real-time process management. Its dual-role capability as both controller and data processor makes it particularly valuable in energy plants and heavy machinery operations.

Real-World Applications

We’ve seen this module deployed in challenging environments where vibration monitoring is critical. A power plant in Texas, for example, relies on it for turbine shaft vibration analysis—processing 48 channels simultaneously with sub-micron precision. It integrates seamlessly with existing VM600 systems but also works well in hybrid setups alongside:

- Vibro-meter VM600 IOM modules

- Bently Nevada 3500 series

- Woodward 8521 controllers

- GE Fanuc RX3i systems

One customer mentioned, “It kept running through three hurricanes—no reboots, no data loss. That reliability matters when you’re monitoring $20M turbines.”

Technical Advantages

What makes this module stand out isn’t just the specs—it’s how they translate to real-world performance:

- Industrial-grade thermal management handles 0-70°C operating range

- Redundant power paths prevent single-point failures

- Error-correcting memory reduces data corruption risks

- Modular design supports hot-swapping during maintenance

While most CPUs struggle with electrical noise in heavy machinery environments, this one maintains 0.05% signal accuracy thanks to its shielded circuitry. Its 220V design works with both standard and backup power systems, which explains why customers in oil & gas and power generation keep ordering replacements.

Reviews

There are no reviews yet.