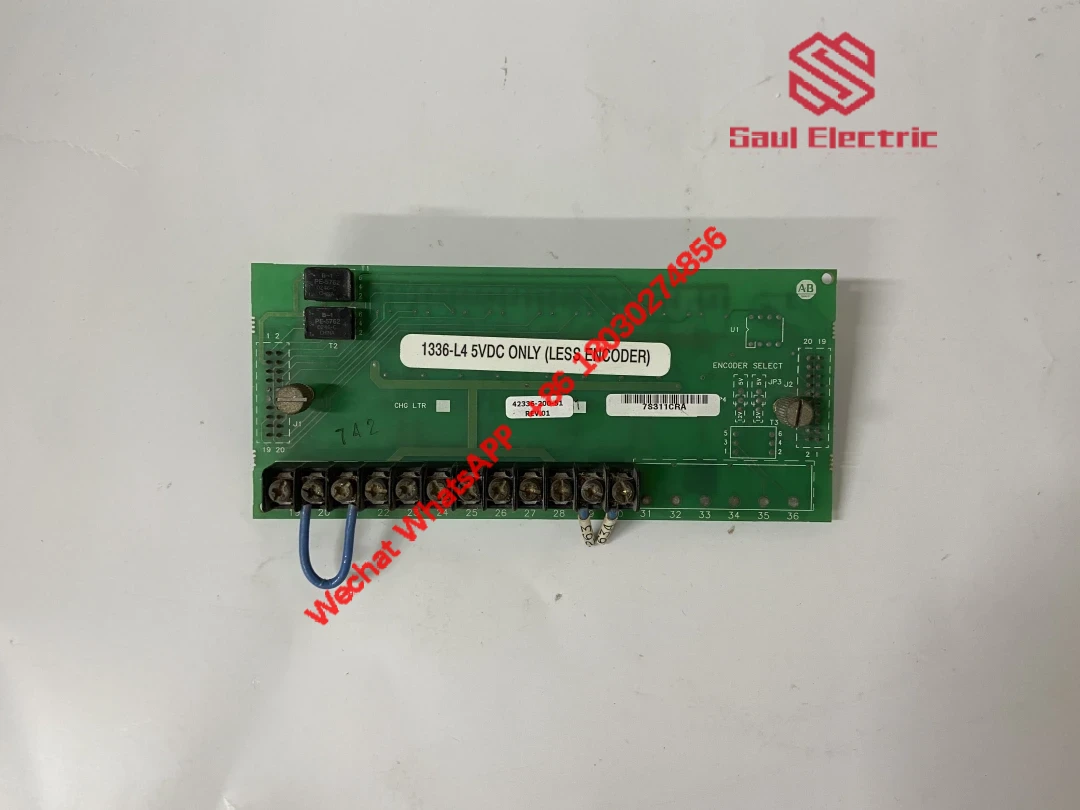

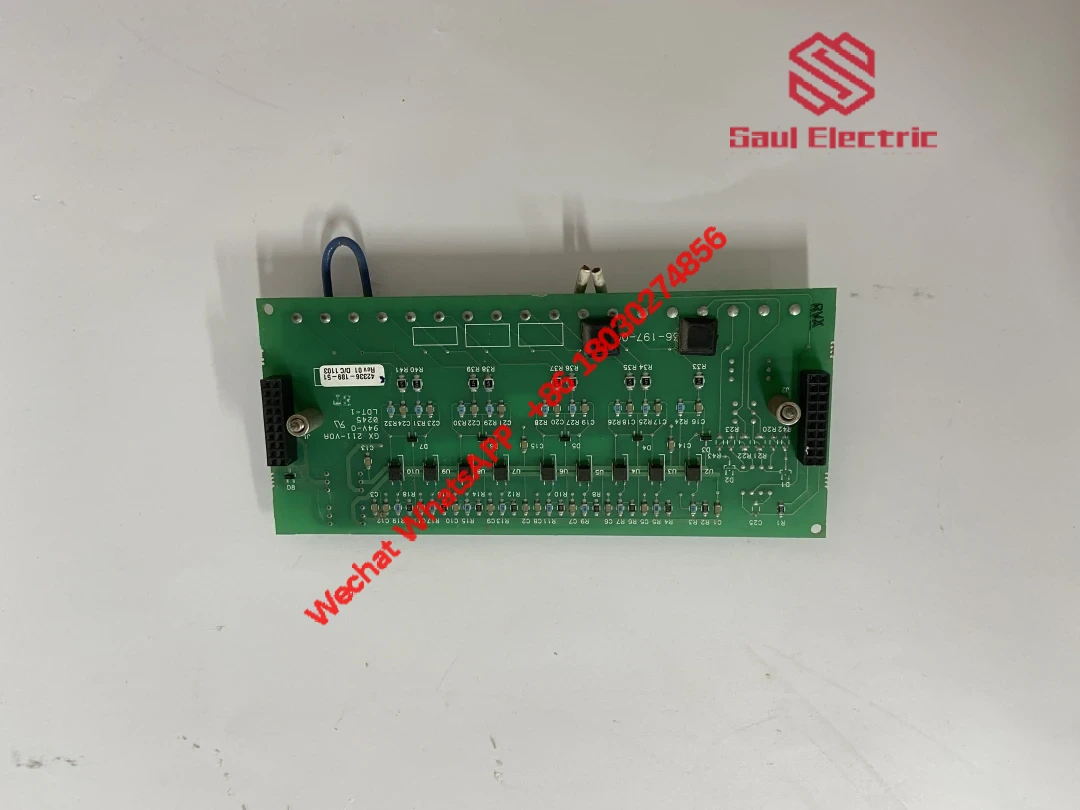

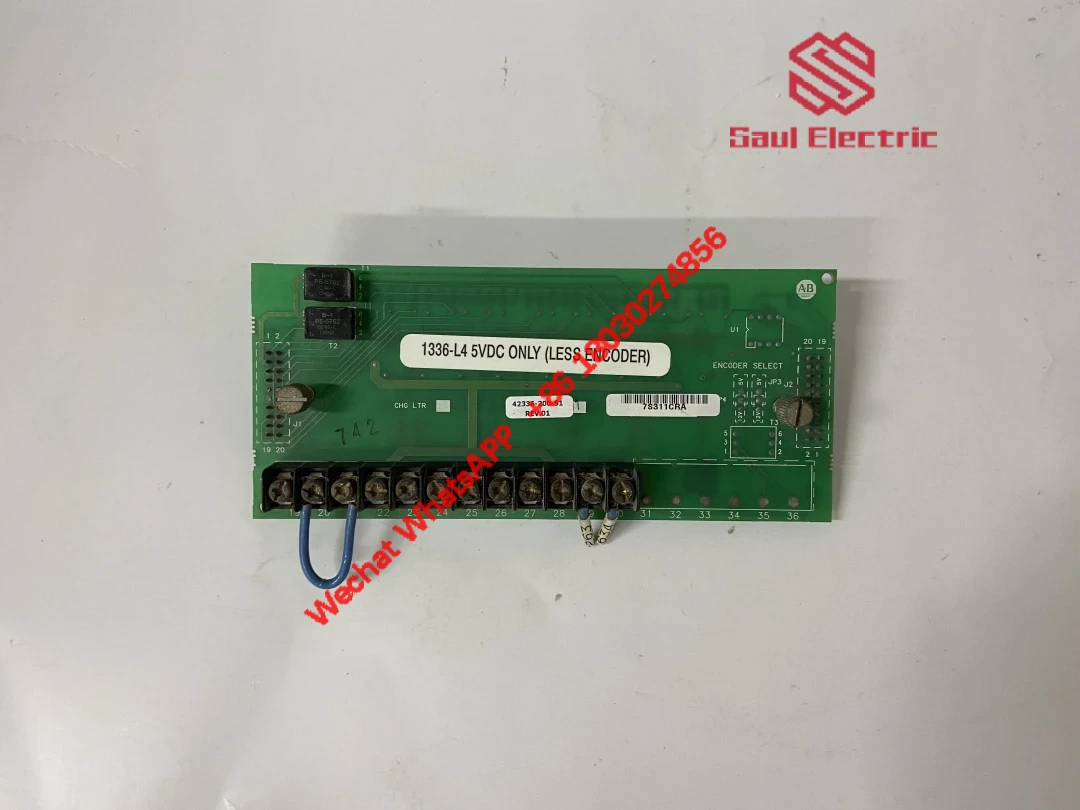

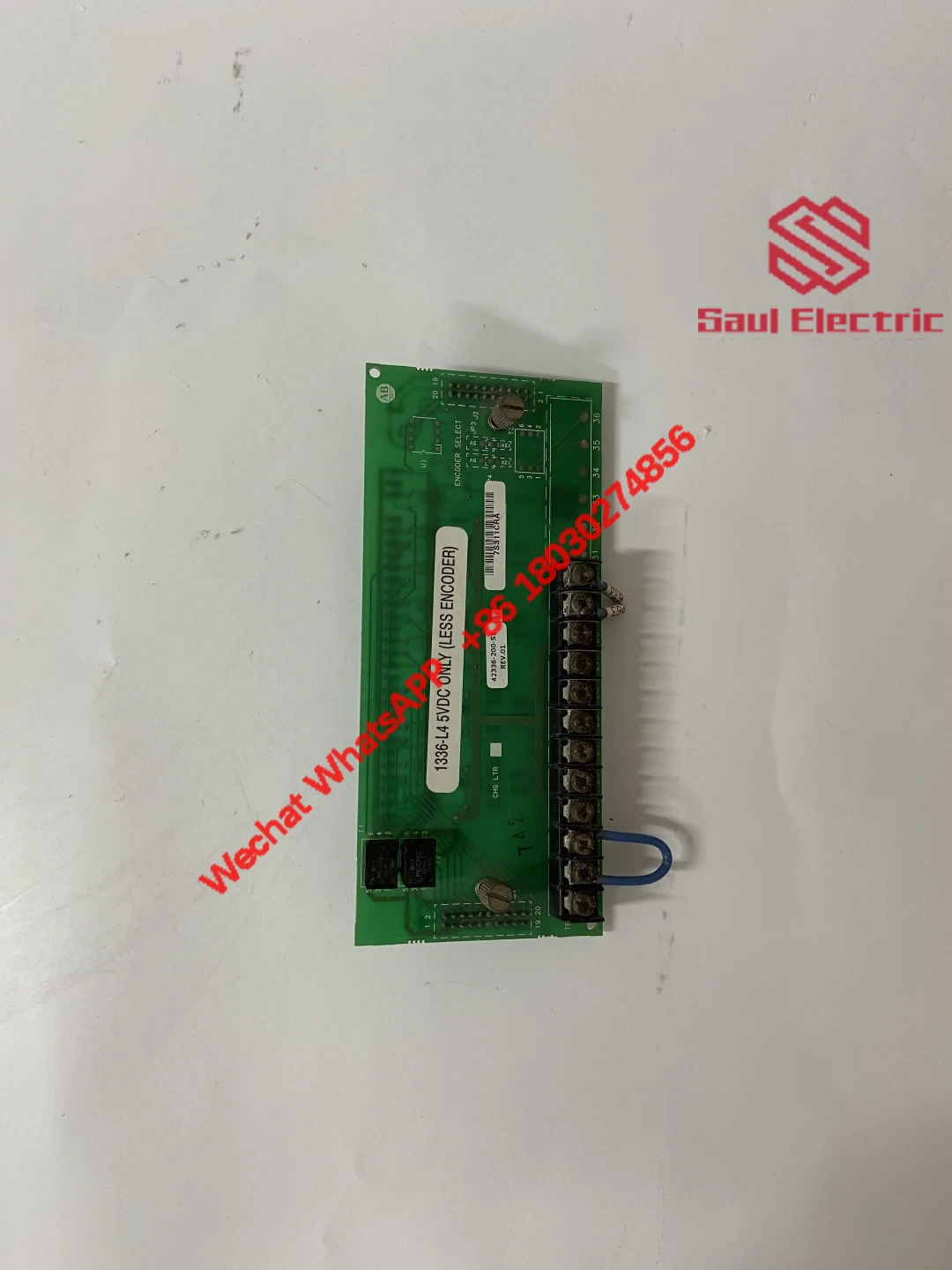

Description

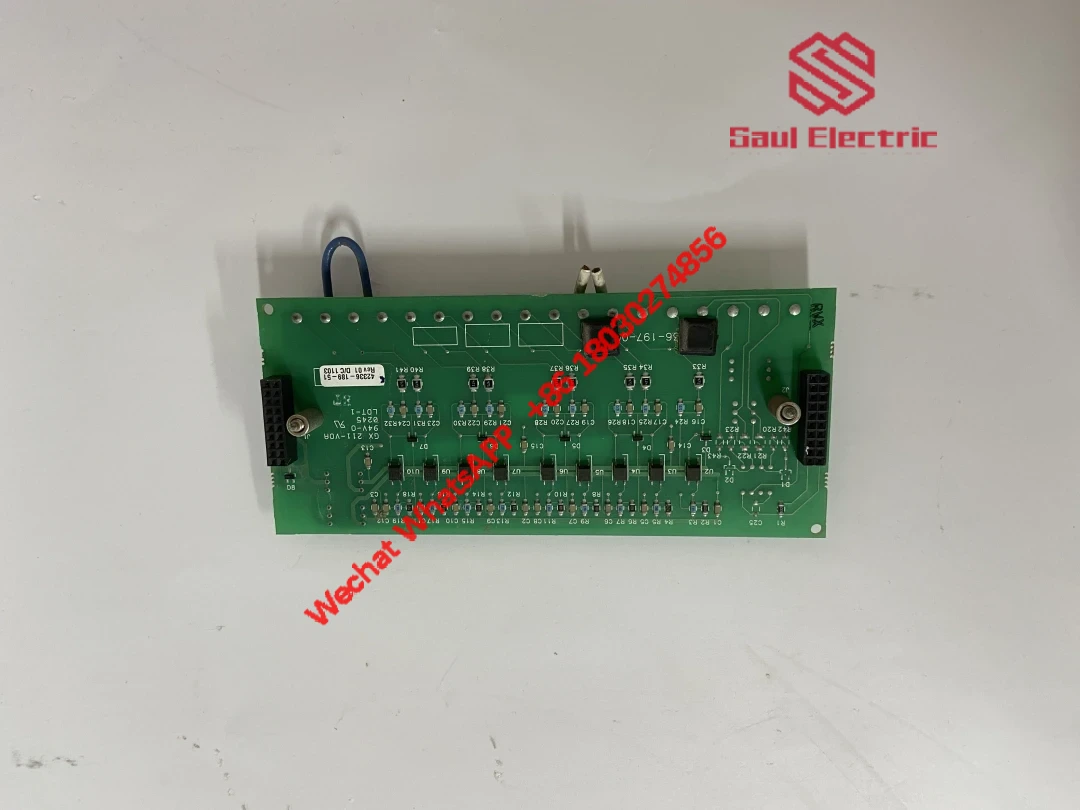

Allen Bradley 1336-L4 Adjustable Frequency AC Drive Module

The Allen Bradley 1336-L4 is a robust AC drive designed for precise motor control in industrial settings. Its primary function? Delivering energy-efficient variable speed control for machinery like conveyors, pumps, and fans. This drive stands out for maintaining stable performance even when faced with fluctuating loads, which is critical for operations where downtime isn’t an option.

| Manufacturer | Rockwell Automation |

| Model Number | 1336-L4 |

| Drive Type | Adjustable Frequency Drive |

| Input Voltage | 460 VAC |

| Output Range | 0-460 VAC, 0-400 Hz |

| Control Modes | Vector & V/Hz Control |

| Certifications | UL, CE, cUL |

| Cooling | Forced Air |

Real-World Applications & Compatible Systems

Factories across North America have deployed this drive for demanding tasks. For example, a Midwest manufacturing plant used it to retrofit an aging conveyor system, achieving 15% energy savings while improving throughput. The 1336-L4 integrates seamlessly with Allen Bradley’s PLC-5 and ControlLogix systems, making it a go-to choice for upgrading legacy automation setups. It’s commonly paired with 1336-JMP AC motor adapters and 1391-DCM dynamic braking modules to optimize performance in high-inertia applications.

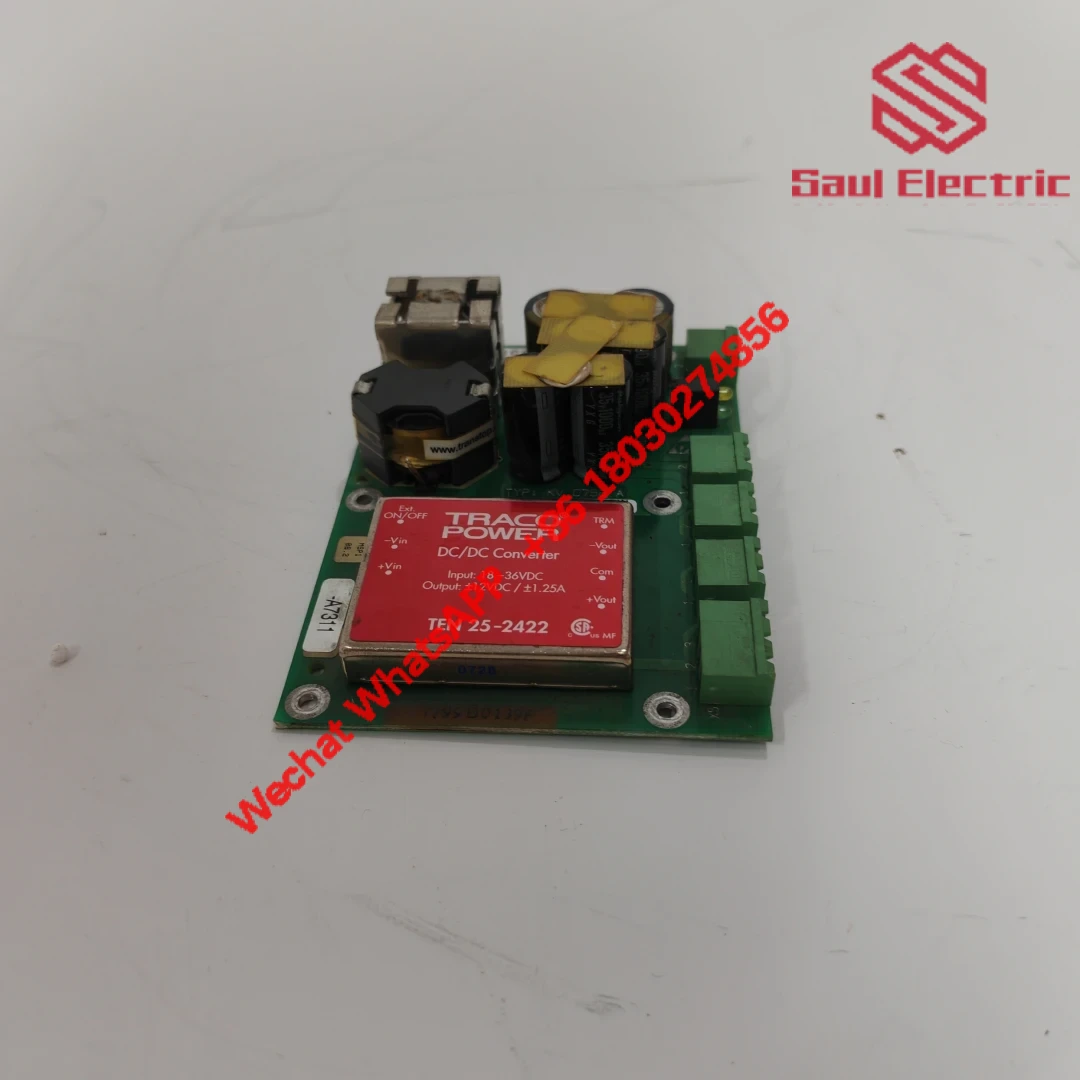

Technical Strengths & Redundancy Features

What makes this drive special? Its dual control modes allow engineers to choose between V/Hz for basic applications or vector control for precision torque regulation down to ±2%. The modular design simplifies maintenance – replacing the internal SMPS unit takes under 10 minutes without special tools. For critical processes, you can configure DeviceNet redundancy using a 1784-SDN card, ensuring communication survives a network failure. The Type 1 enclosure handles factory dust and occasional splashes near washdown areas, though I’d recommend additional protection in high-humidity environments.

Reviews

There are no reviews yet.