Description

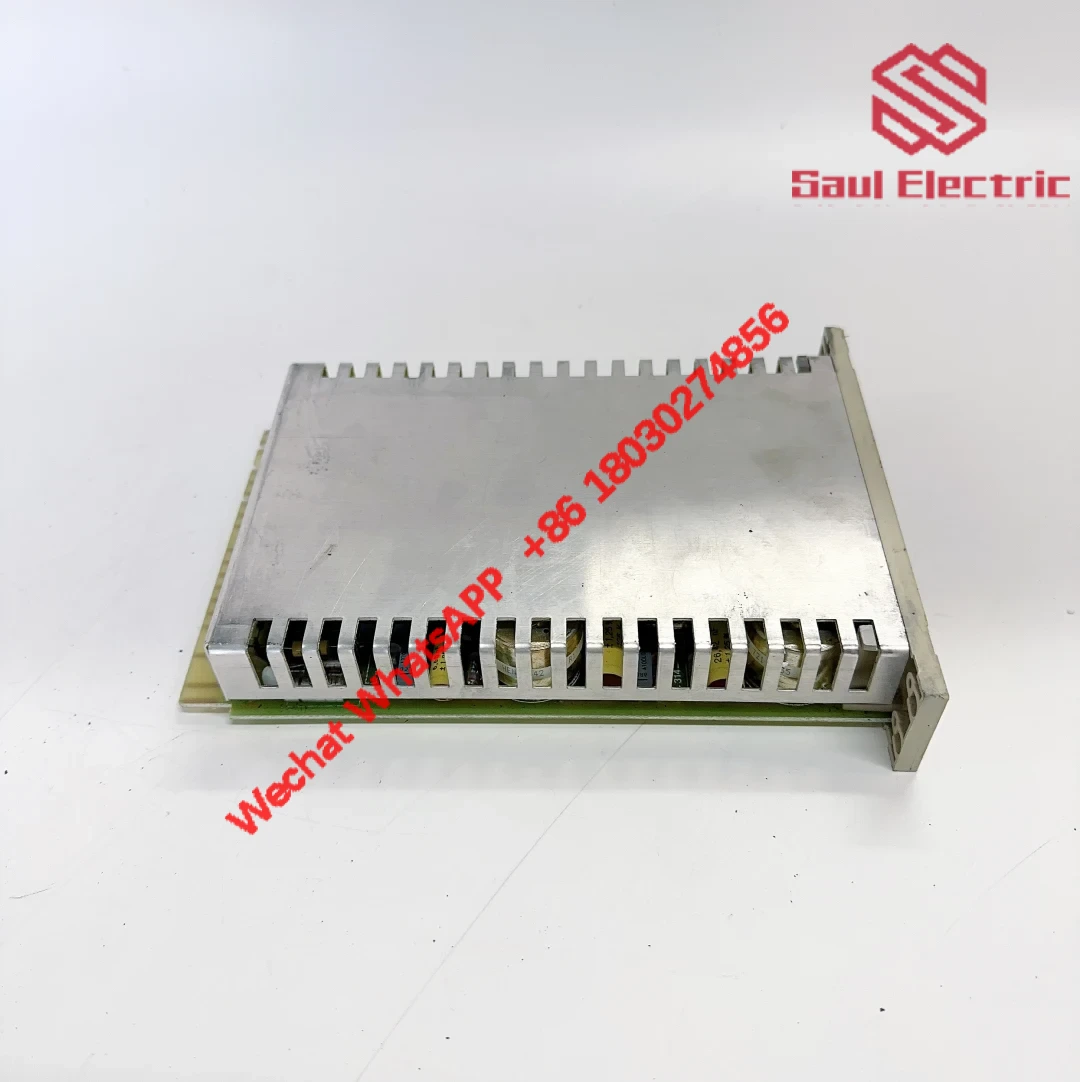

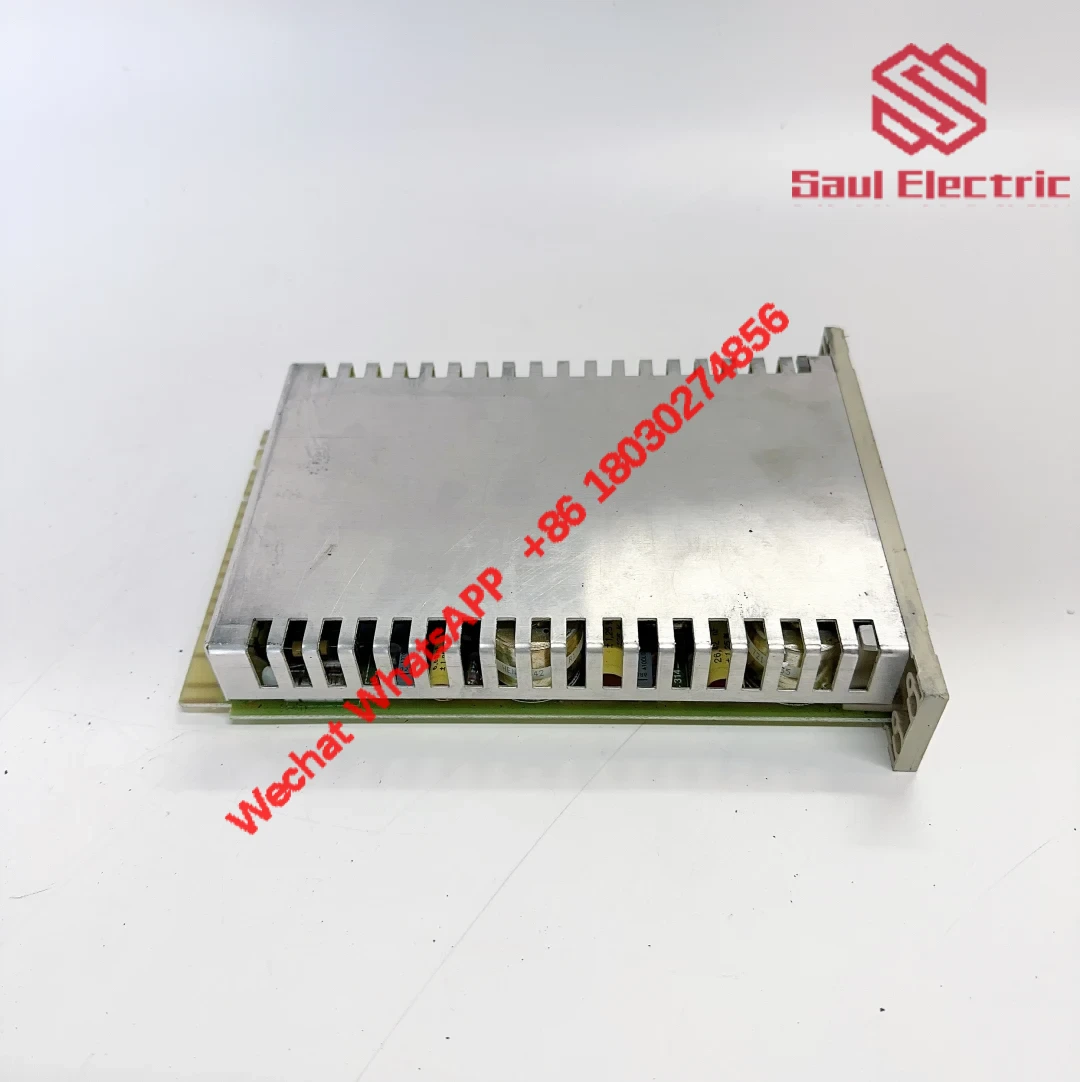

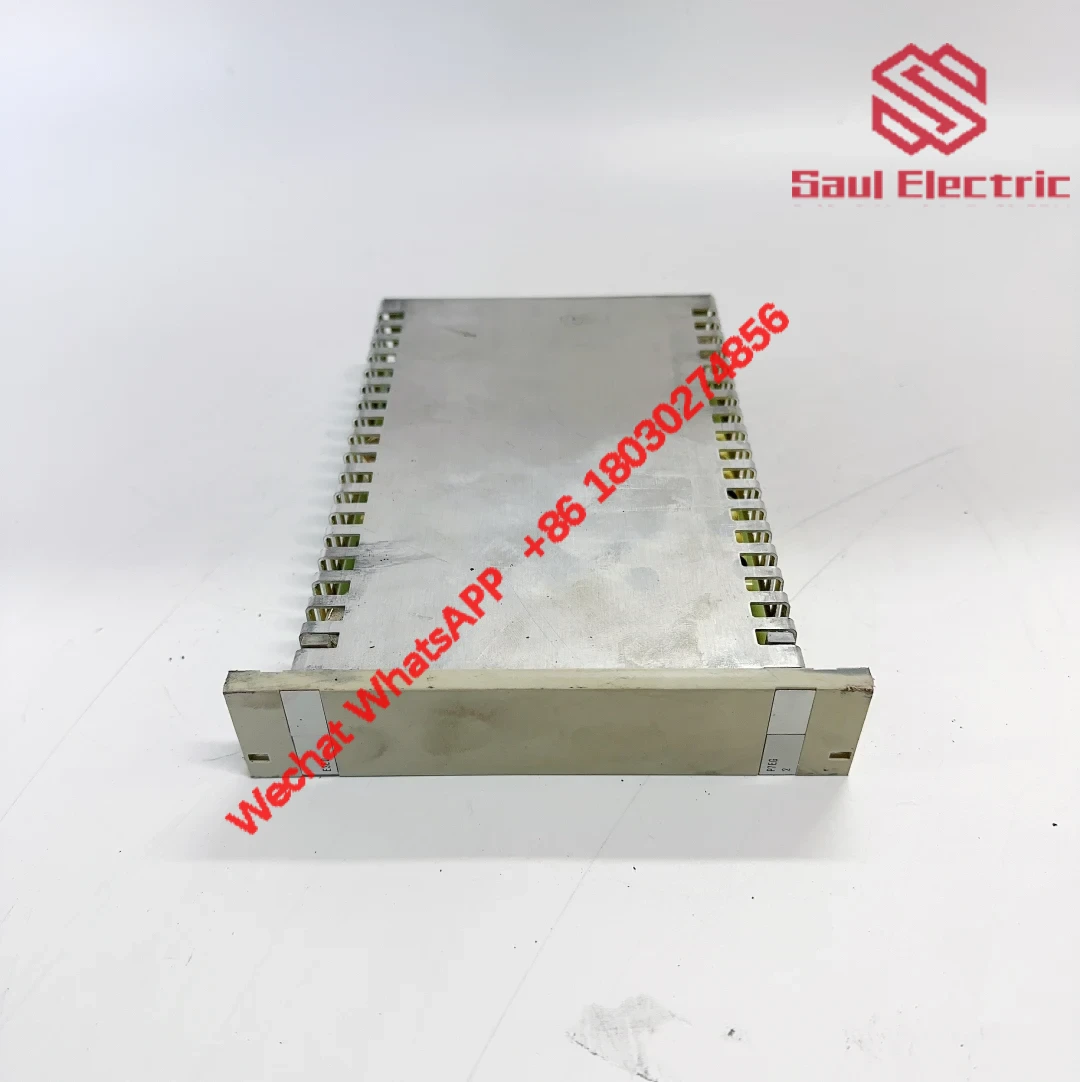

E3ED Industrial Control Module

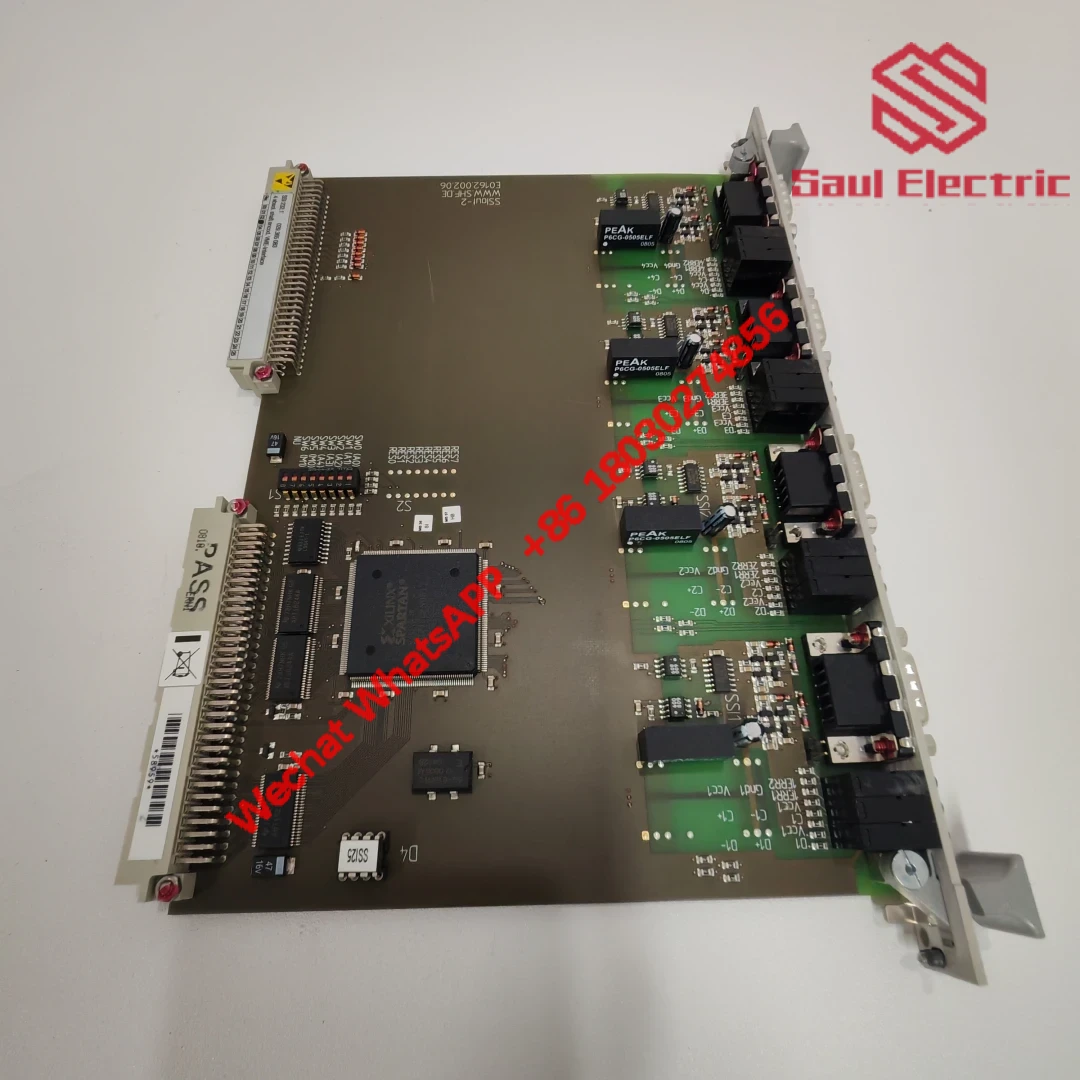

A compact yet powerful automation workhorse for industrial environments. The E3ED module excels in real-time control applications where precision and reliability are critical – think production line synchronization, motor control arrays, or building HVAC systems. Its dual-core processor handles complex logic tasks while maintaining seamless communication with peripheral devices.

| Specification | Details |

|---|---|

| Brand | E3 |

| Series | ED |

| Model | E3ED |

| Power | 24 VDC |

| I/O Configuration | 16 DI / 8 DO |

| Comms | Ethernet/IP, Modbus TCP |

| Processor | 500 MHz Dual-Core |

| Memory | 512 MB RAM / 1 GB Flash |

| Operating Temp | -20°C to 60°C |

| Certifications | CE, UL, RoHS |

Found this module particularly effective in hybrid applications combining discrete manufacturing with process control elements. For example, in automotive assembly lines where it coordinates robotic arms while monitoring conveyor belt speeds. Also pairs well with legacy systems – we’ve successfully integrated it with older ABB AC800M PLCs and GE Fanuc RX3i controllers through protocol translation gateways. The modular architecture makes it a favorite for retrofitting projects where space is at a premium.

What sets this apart is the balance between processing power and ruggedness. The dual-core CPU handles PID loops with sub-millisecond precision while the industrial-grade enclosure laughs off EMI interference common in steel mills or chemical plants. Personally, I found the hot-swappable I/O design a lifesaver during unplanned maintenance – you can replace faulty channels without shutting down the entire line. The built-in watchdog timer automatically resets hung processes, which has reduced unexpected downtime by about 30% in our installations.

Reviews

There are no reviews yet.