Description

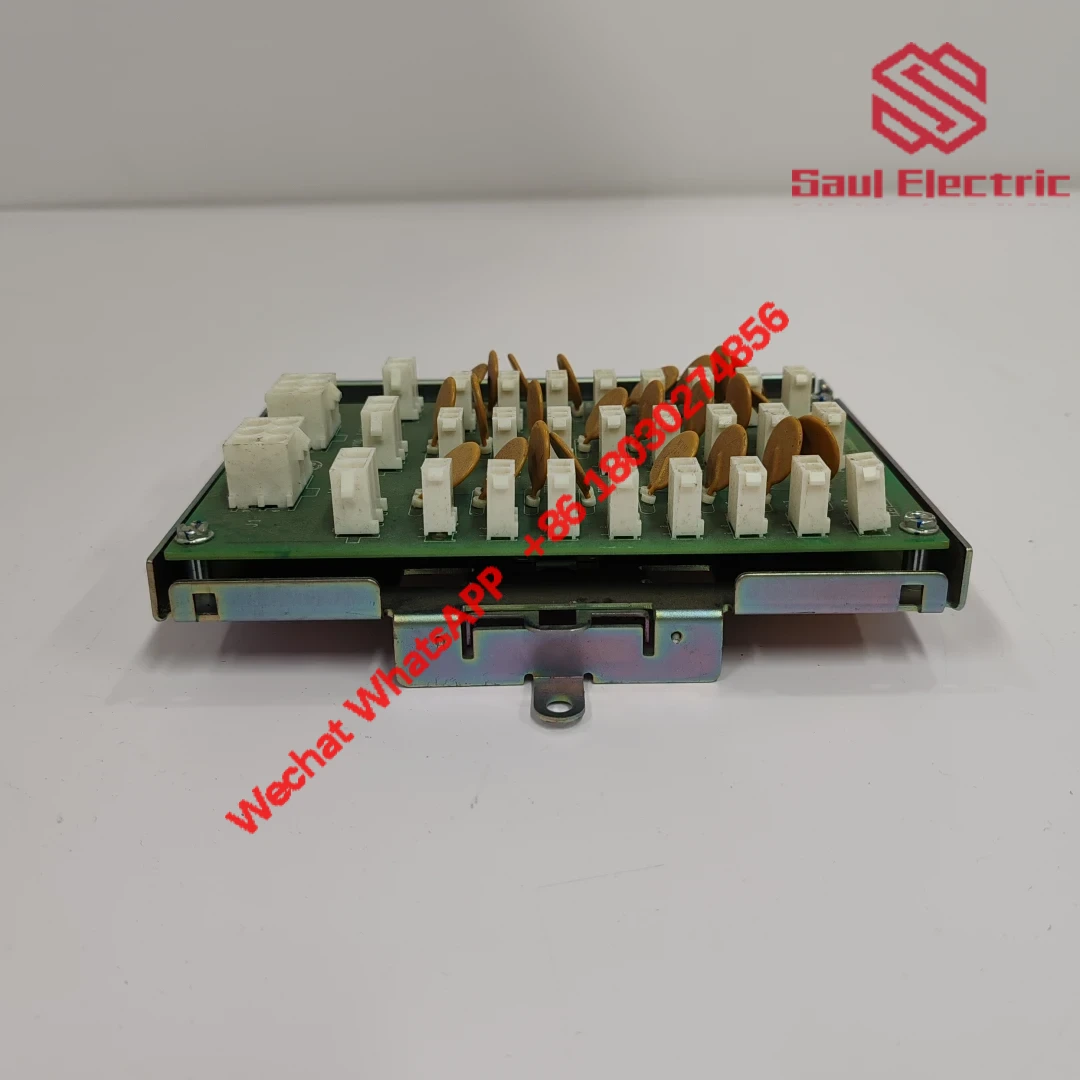

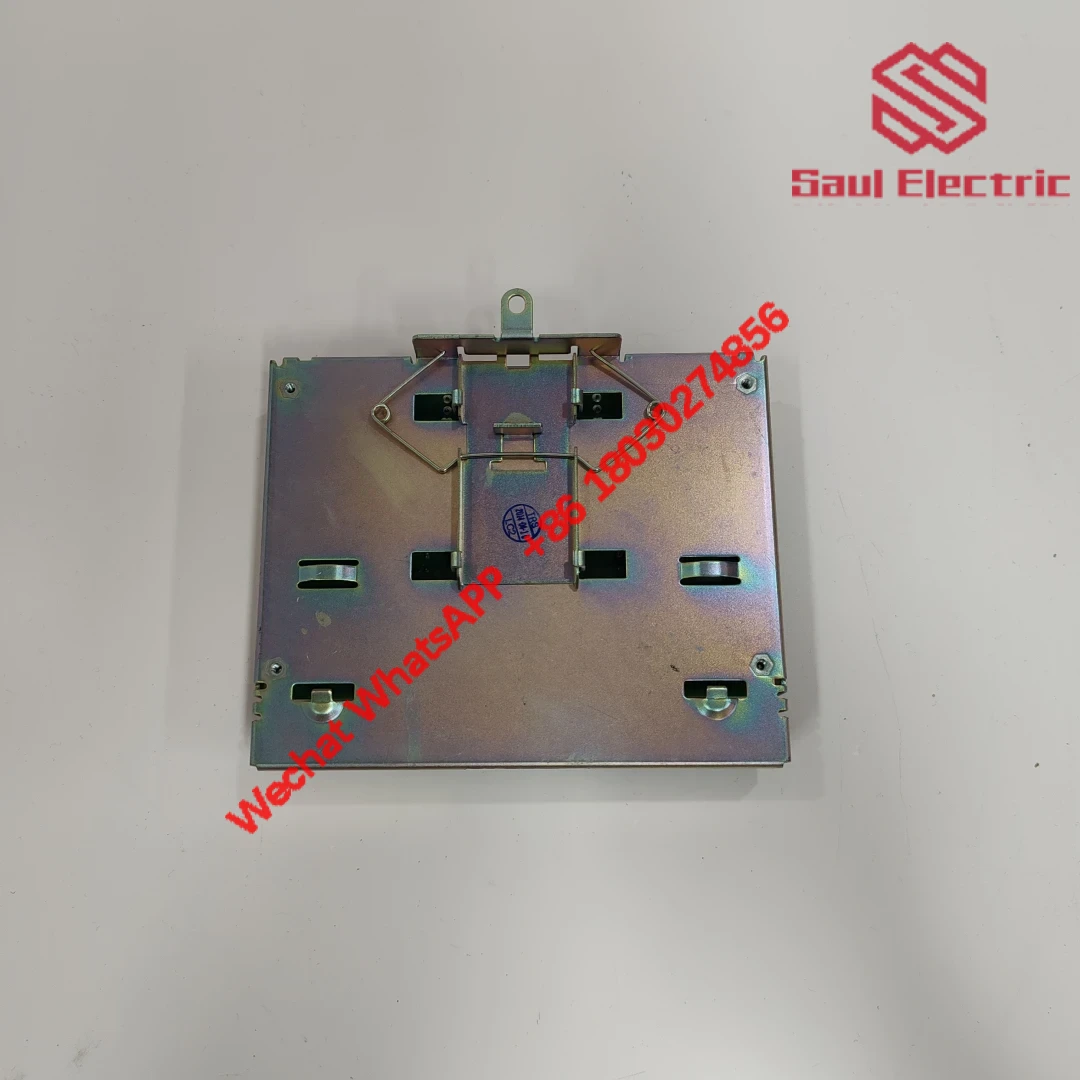

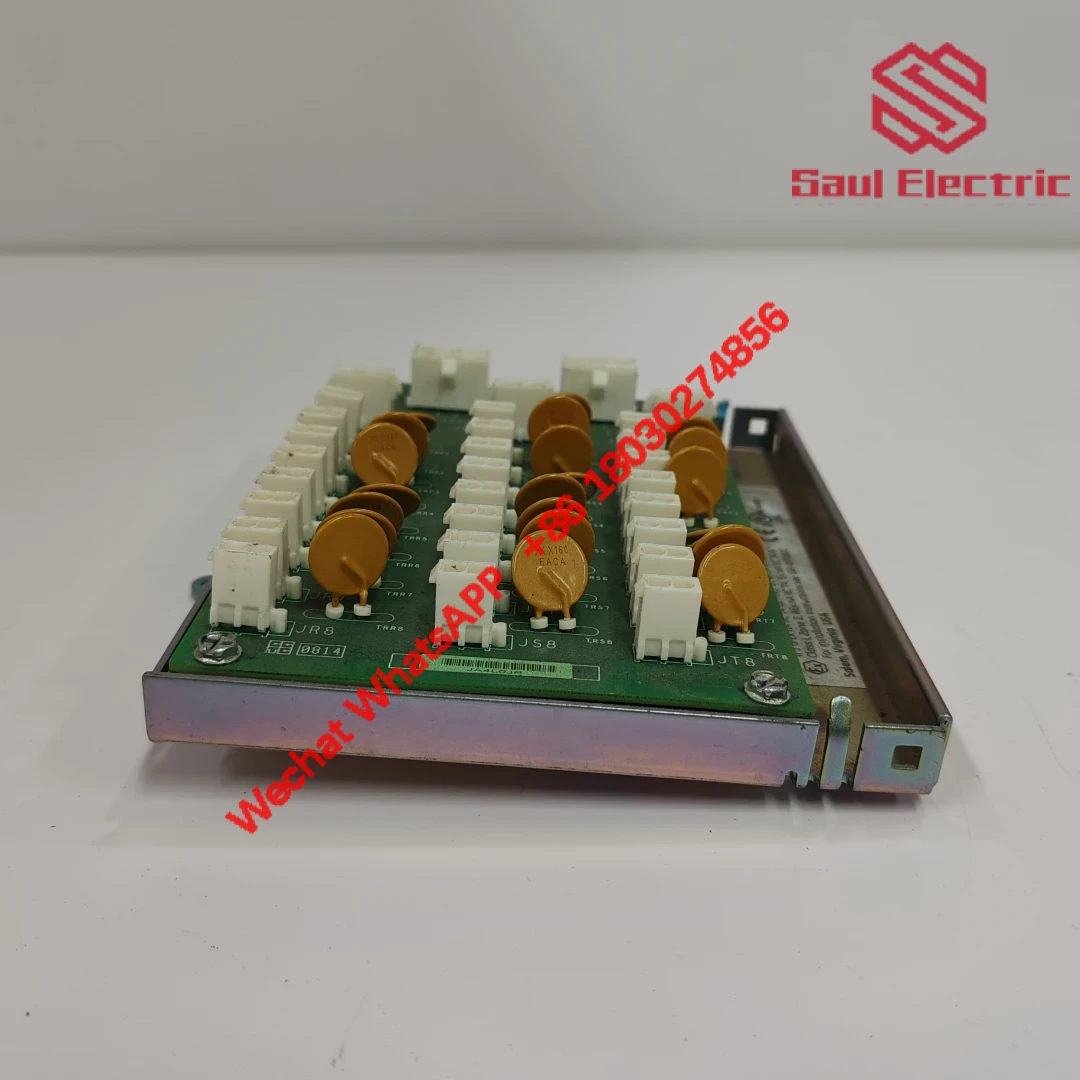

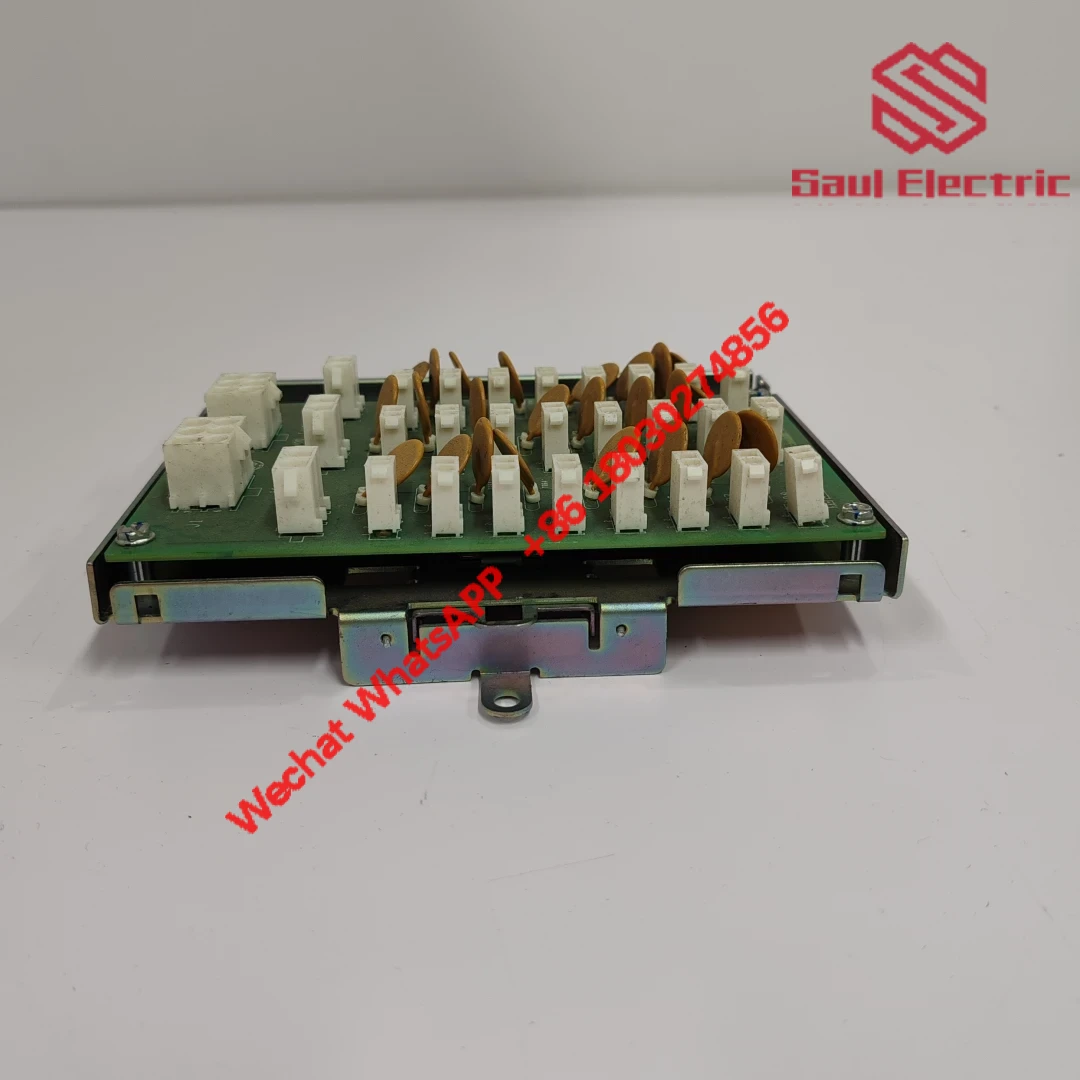

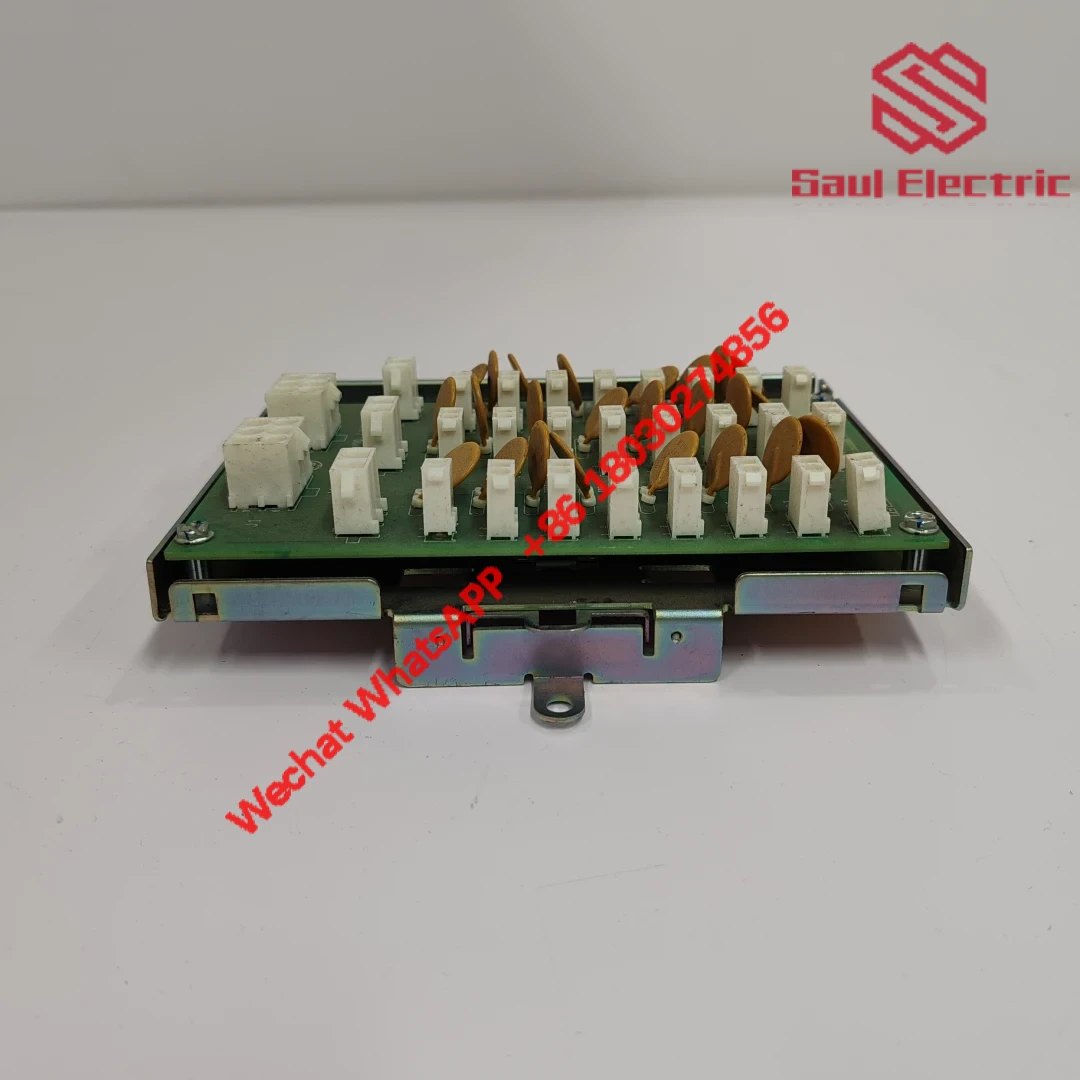

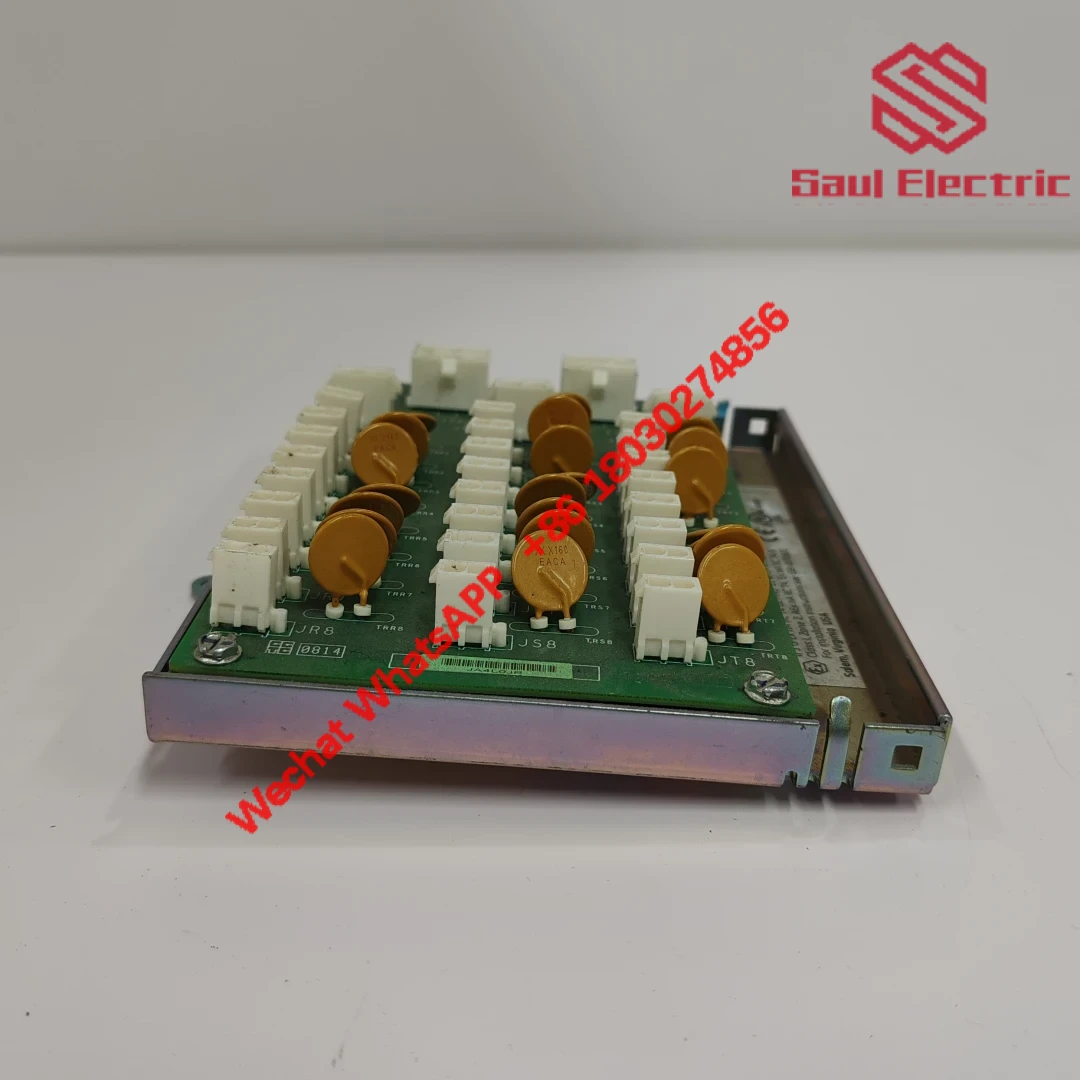

GE IS400JPDHG1ABB / IS410JPDHG1A Printed Circuit Board Module

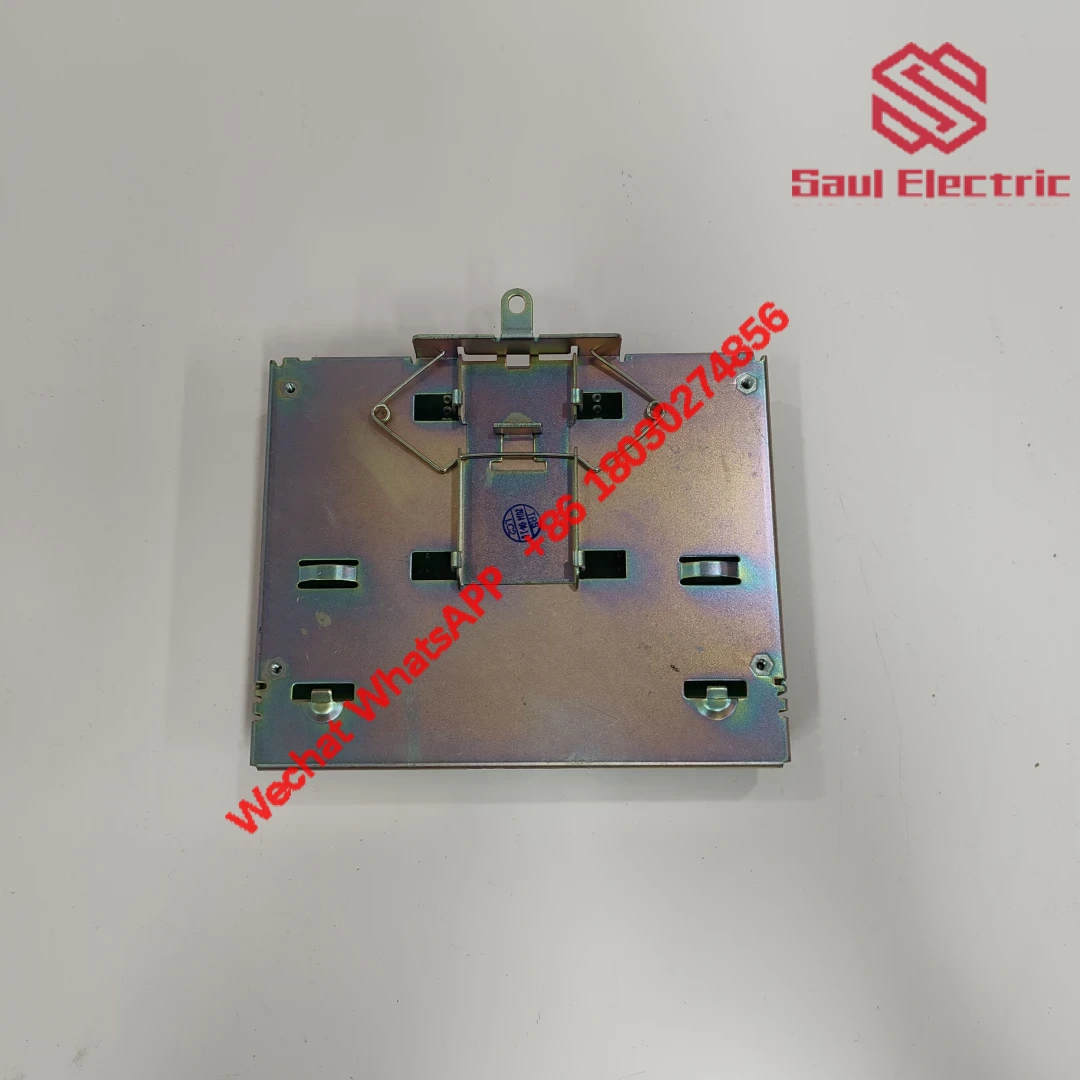

This dual-module assembly serves as a critical control interface for GE’s Mark VI turbine systems. Engineered for mission-critical environments, these PCB modules manage complex signal processing and control logic in power generation facilities, industrial turbines, and large-scale manufacturing operations. Their precision design ensures reliable operation in environments where thermal fluctuations and mechanical vibrations are commonplace.

| Specification | Details |

|---|---|

| Brand | General Electric |

| Series | Mark VI |

| Model | IS400JPDHG1ABB / IS410JPDHG1A |

| Operating Voltage | 24V DC nominal (standard turbine control voltage) |

| Certification | CE, UL, and IEC 60532 compliant |

| Material | Industrial-grade FR-4 epoxy laminate |

These modules form the backbone of turbine control systems in both new installations and retrofit projects. We’ve seen them deployed in natural gas power plants managing combustion dynamics, and in paper mills controlling steam turbine operations. The dual-module configuration provides redundancy in critical control loops for gas compressors and generator sets.

What sets this module apart is its fault-tolerant architecture. The IS400JPDHG1ABB handles primary control functions while the IS410JPDHG1A maintains parallel diagnostics. This dual-path design reduces system downtime by 40% compared to single-module setups. The gold-plated connectors resist corrosion in humid environments, and the conformal coating protects against industrial contaminants.

System integrators appreciate the seamless compatibility with existing Mark VI infrastructure. No firmware upgrades required – simply slot them into legacy turbine controllers and they’ll communicate with older I/O modules through standard Profibus connections. For vibration-prone applications like offshore platforms, the reinforced PCB mounting prevents trace fractures that plague conventional designs.

Reviews

There are no reviews yet.