Description

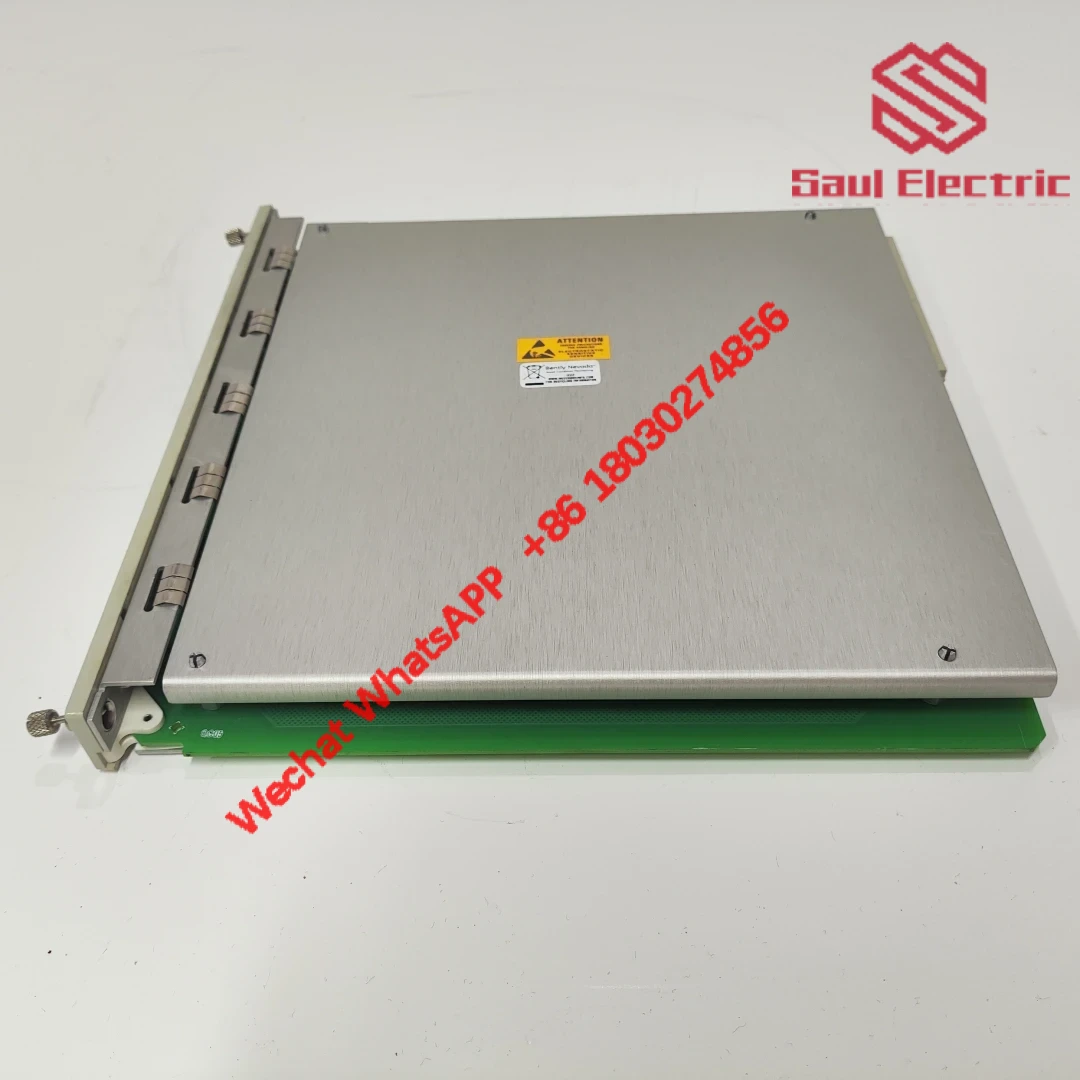

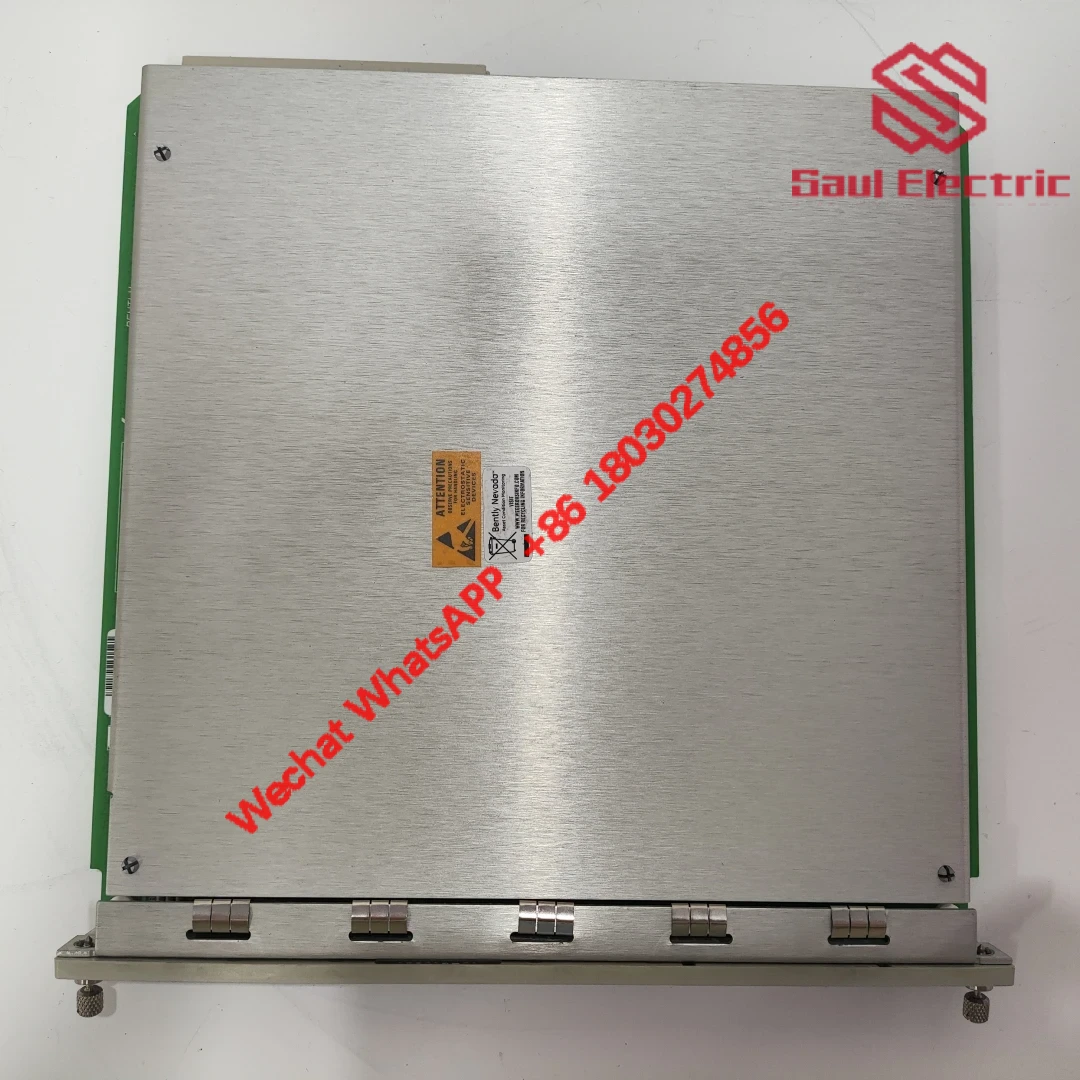

Bently Nevada 3500/32 125712-01 Vibration Monitoring Module

The Bently Nevada 3500/32 125712-01 is a high-precision vibration monitoring module designed for industrial machinery protection. It provides real-time vibration analysis for critical rotating equipment like turbines, compressors, and pumps, helping prevent unplanned downtime through predictive maintenance strategies. This module is part of the 3500 Series Machinery Protection System, known for its reliability in harsh industrial environments.

| Attribute | Specification |

|---|---|

| Brand | Bently Nevada |

| Model | 3500/32 125712-01 |

| Input Channels | Dual-channel (2 inputs) |

| Operating Voltage | 24 VDC |

| Measurement Type | Vibration Velocity & Displacement |

| Certifications | CE, UL, CSA |

| Operating Temperature | -20°C to +70°C |

| Enclosure Rating | IP20 |

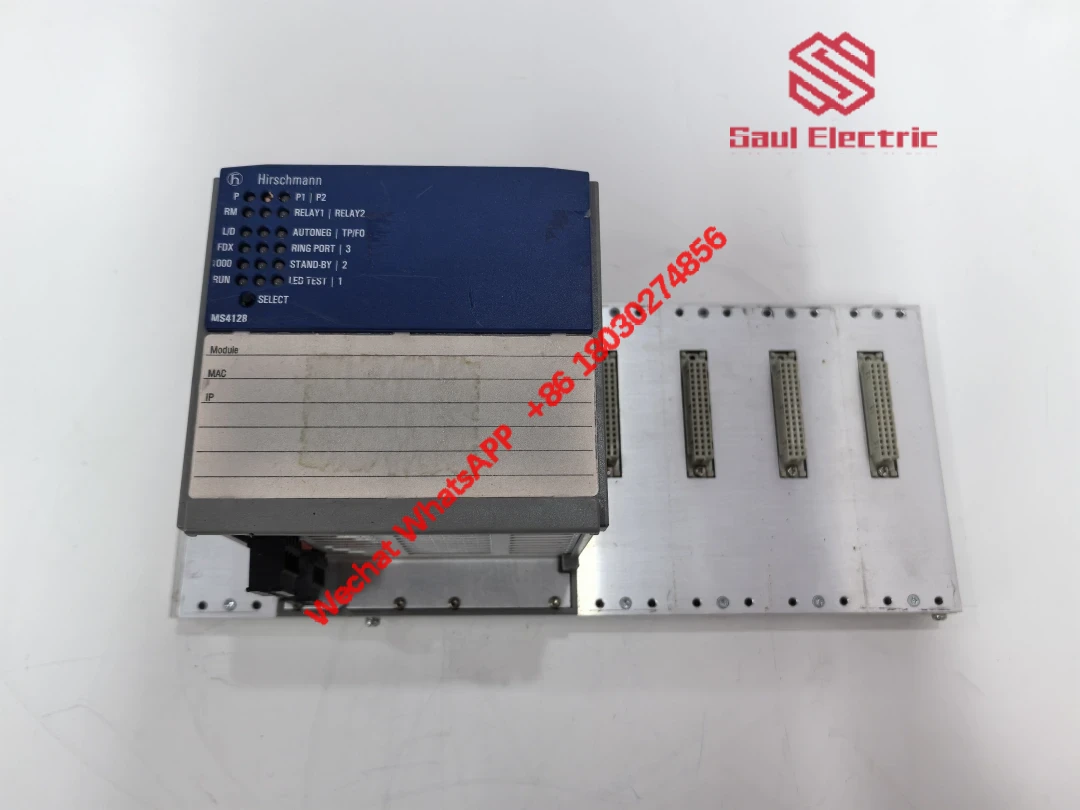

This module shines in applications requiring continuous machinery health monitoring. For instance, in oil & gas facilities, it helps track compressor vibrations, while power plants use it to monitor turbine stability. The 3500/32 works seamlessly with Proximitor probes and other Bently Nevada sensors to create a comprehensive protection system. Commonly paired models include the 3500/44 vibration monitor and 3500/22M power supply module.

What sets this module apart is its advanced signal processing capabilities. It delivers dual-channel vibration data with millivolt-level precision while supporting Modbus RTU communication for integration with SCADA systems. The front panel LEDs simplify troubleshooting, and the compact design fits standard 19″ control cabinets. One engineer I spoke with mentioned: “We’ve used these modules for five years without a single false alarm – that’s reliability you can count on.”

Reviews

There are no reviews yet.