Description

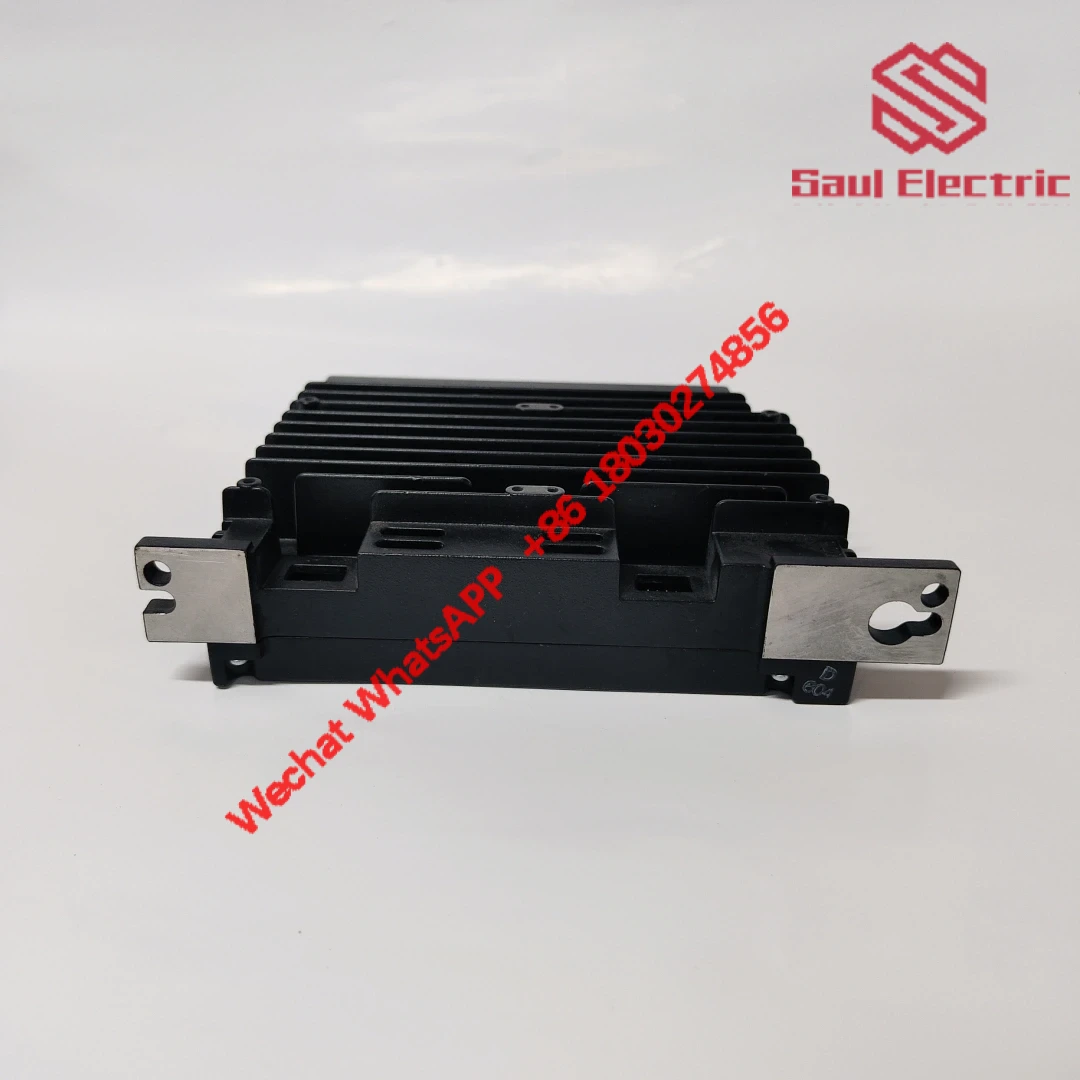

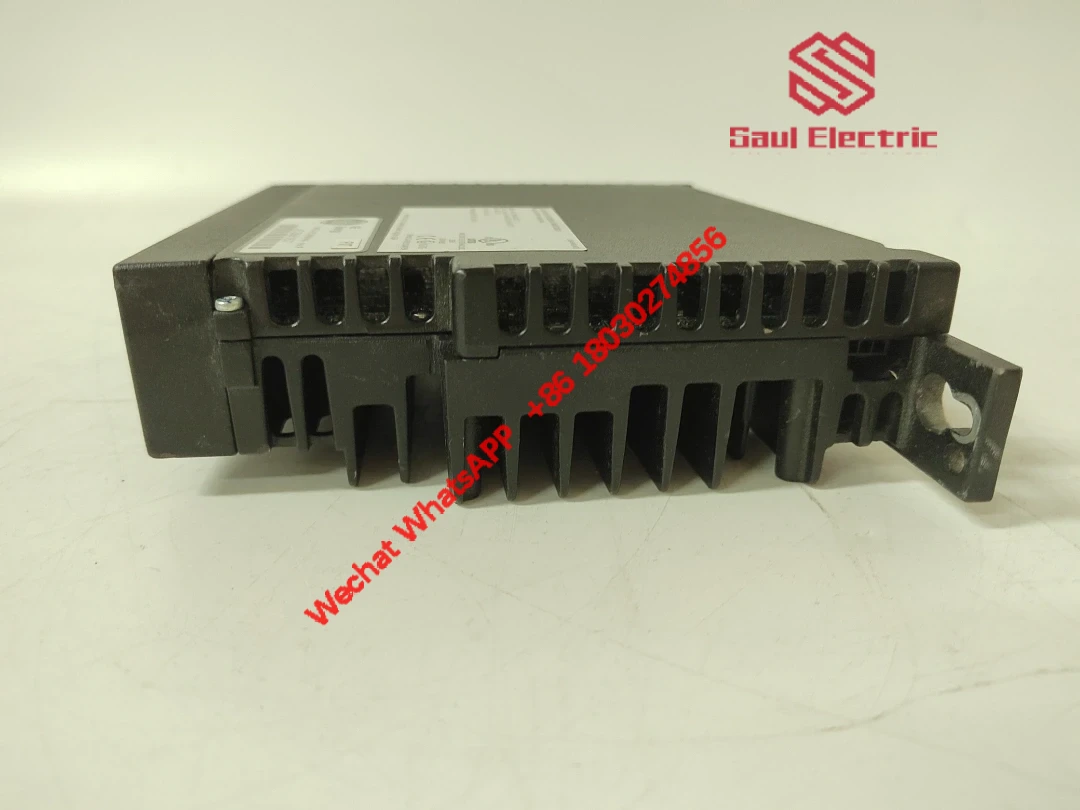

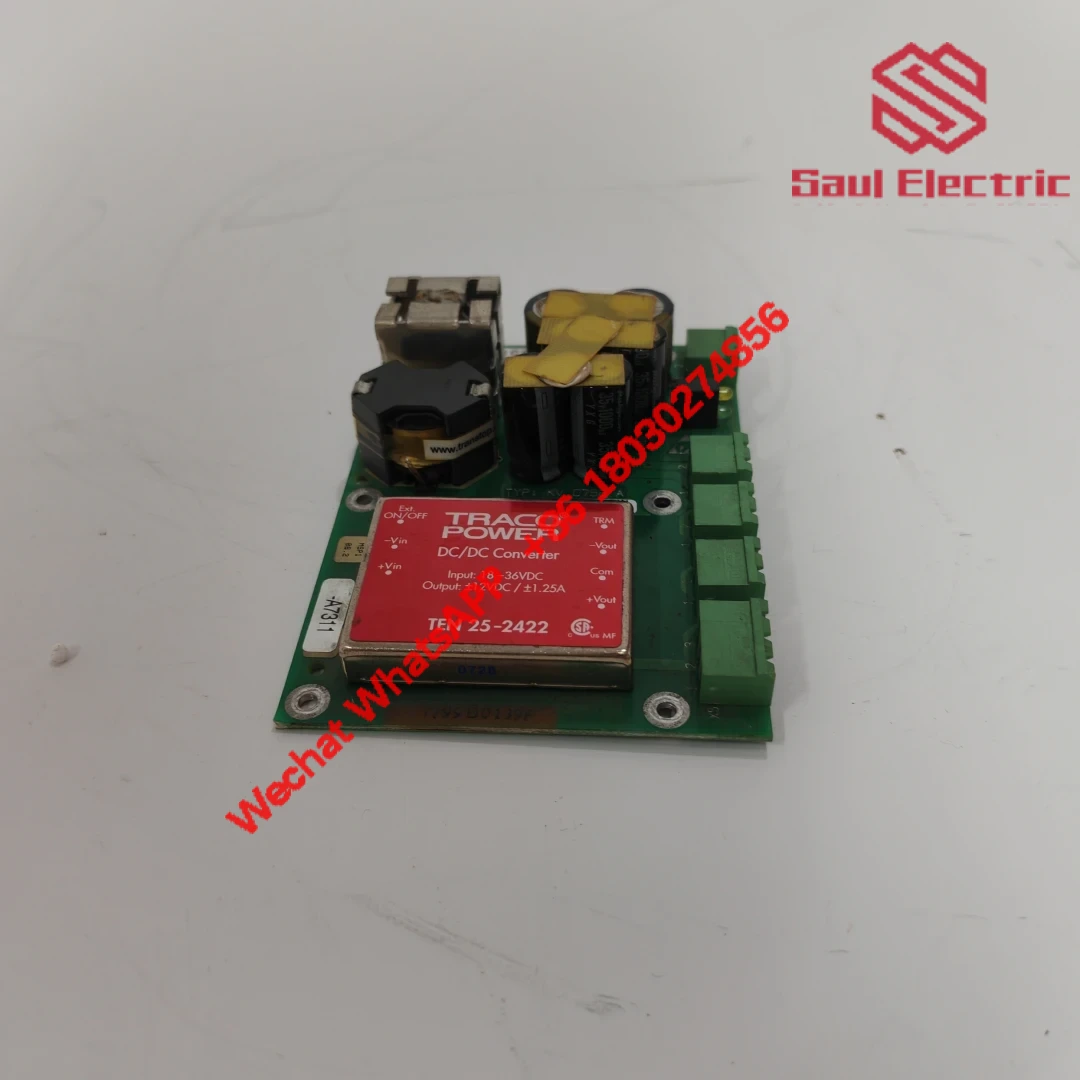

GE IS420UCSBH4A Industrial Control Module

This control module from General Electric serves as a high-performance brain for complex automation systems. I’ve seen it deployed in environments where split-second decision-making matters – think turbine control rooms with fluctuating temperature extremes or chemical plants requiring millisecond-level process adjustments. Its Intel processor isn’t just a spec sheet number; in real-world use, it handles multiple I/O channels simultaneously without breaking a sweat.

| Specification | Detail |

|---|---|

| Processor | 1066 MHz EP80579 Intel |

| Compatibility | Mark VIe/EX2100e/LS2100e |

| Certification | Industrial Automation Standard |

| Dimensions | Standard 19″ rack mount |

| Operating Temp | -40°C to +85°C |

In actual deployments, this module shines when integrated with GE’s EX2100e excitation systems or LS2100e safety platforms. A power plant engineer once told me how it maintained stable turbine control despite nearby welding operations causing electrical noise spikes. You’ll find these units commonly in combined cycle gas plants using Mark VIe control systems, handling both basic process control and emergency shutdown sequences through their redundant I/O architecture.

What makes this different from generic PLCs? The Intel processor allows running complex PID algorithms alongside communication protocols simultaneously. I’ve seen installations where it maintained 100ms scan times while handling 512 I/O points and Ethernet/IP traffic. The module’s backplane redundancy ensures no single point of failure – if one communication path drops, the secondary channel takes over without process interruption. This isn’t just about uptime; in a recent oil refinery project, this feature prevented a potential $2M production loss during a control network upgrade.

Reviews

There are no reviews yet.