Description

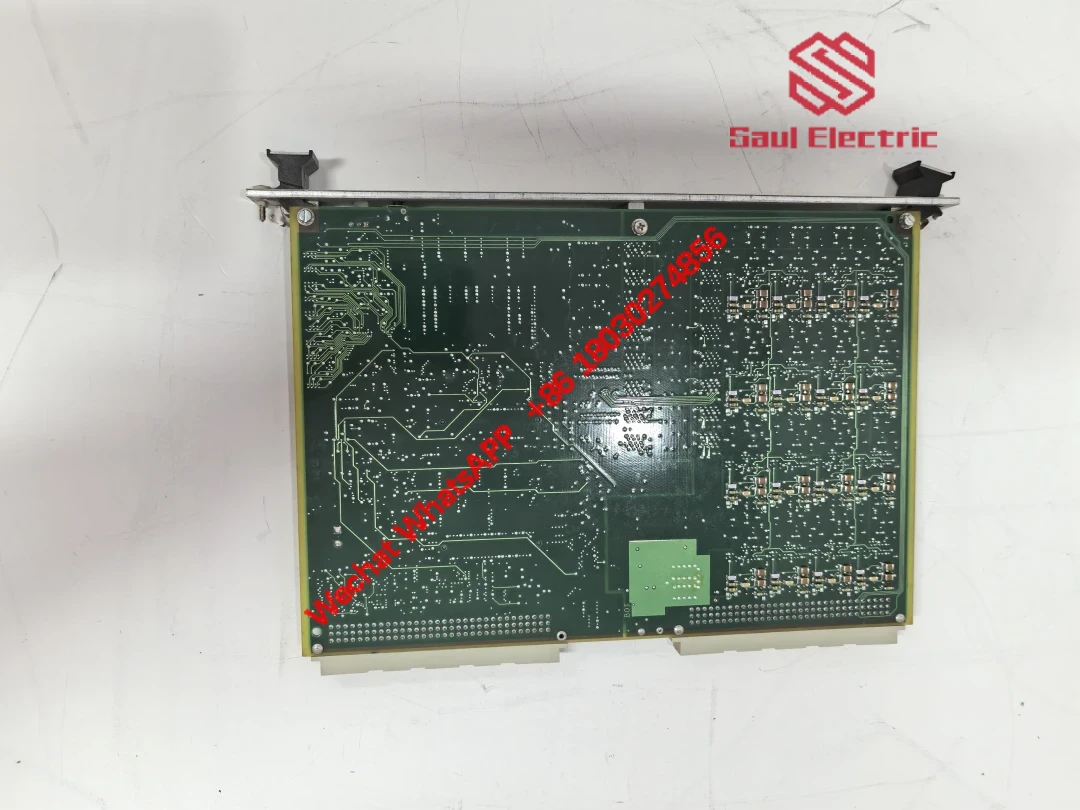

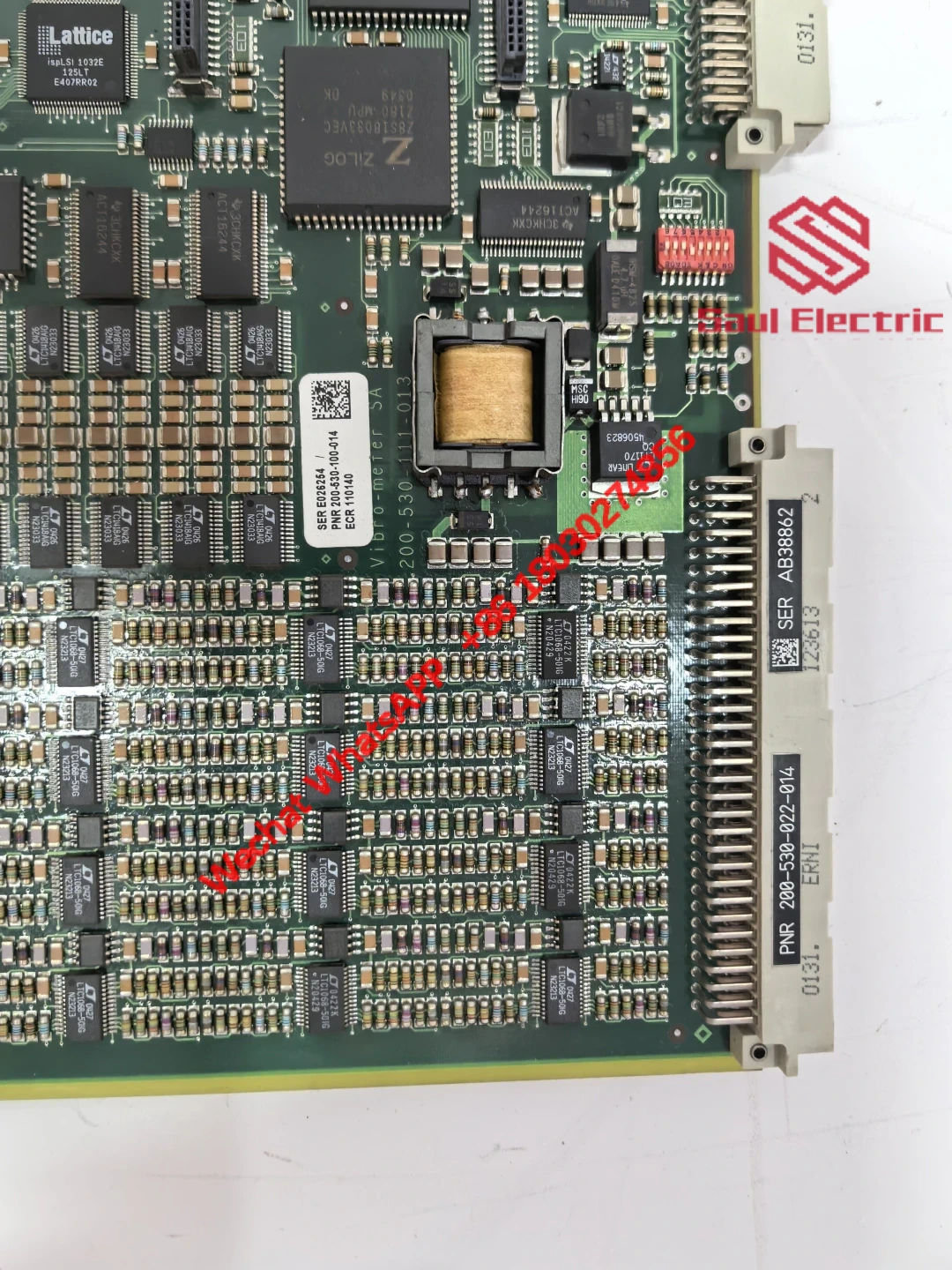

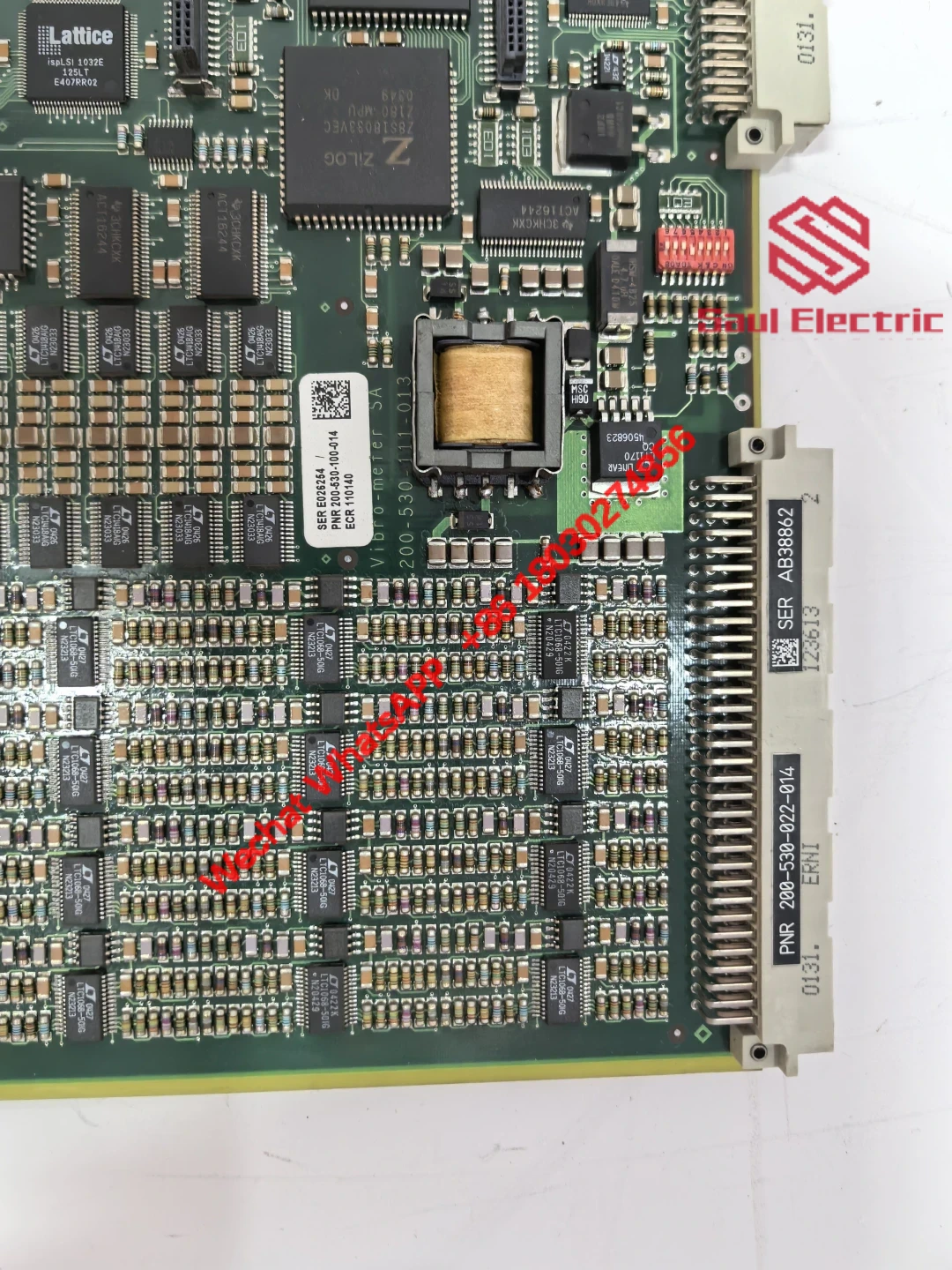

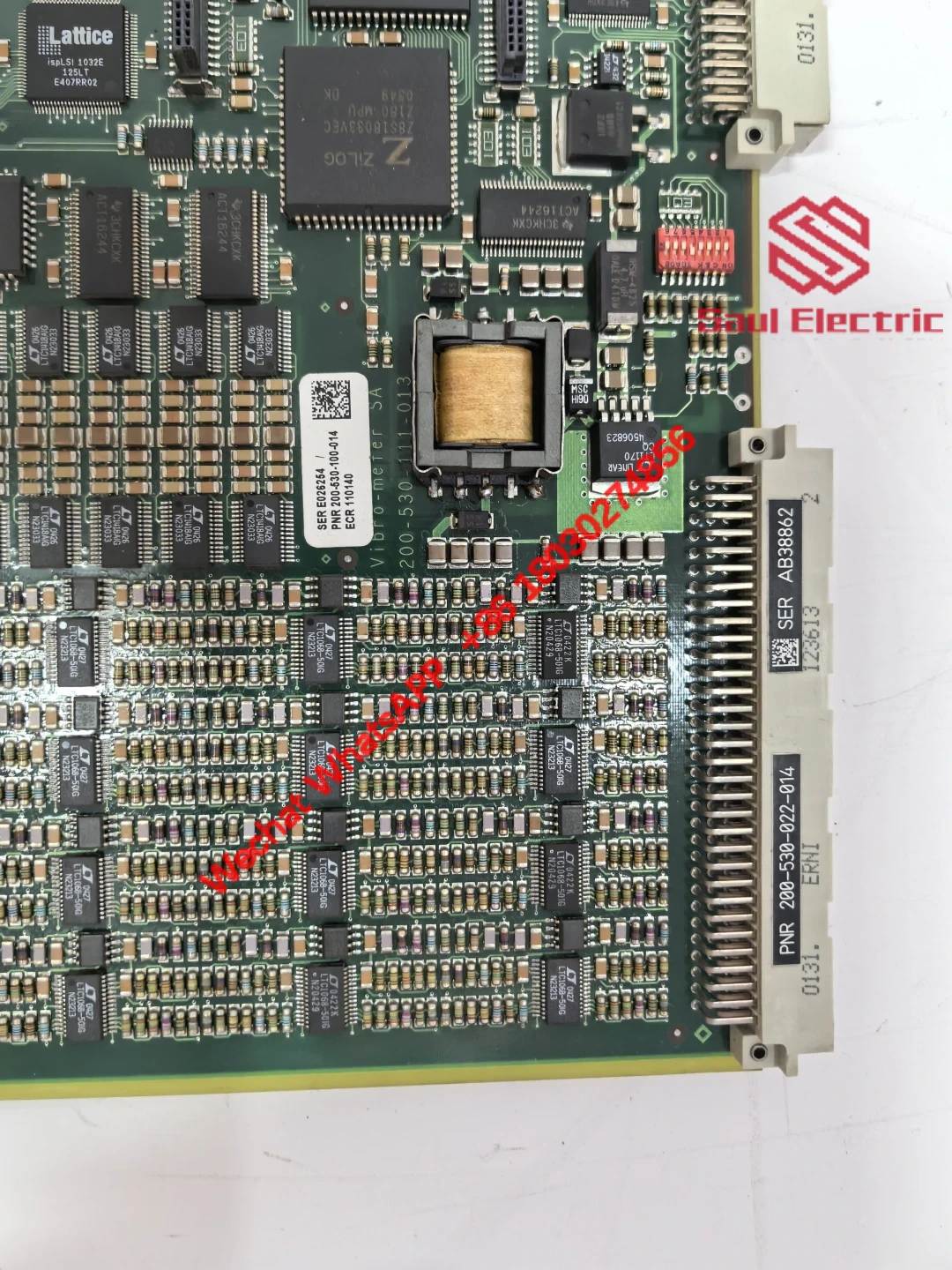

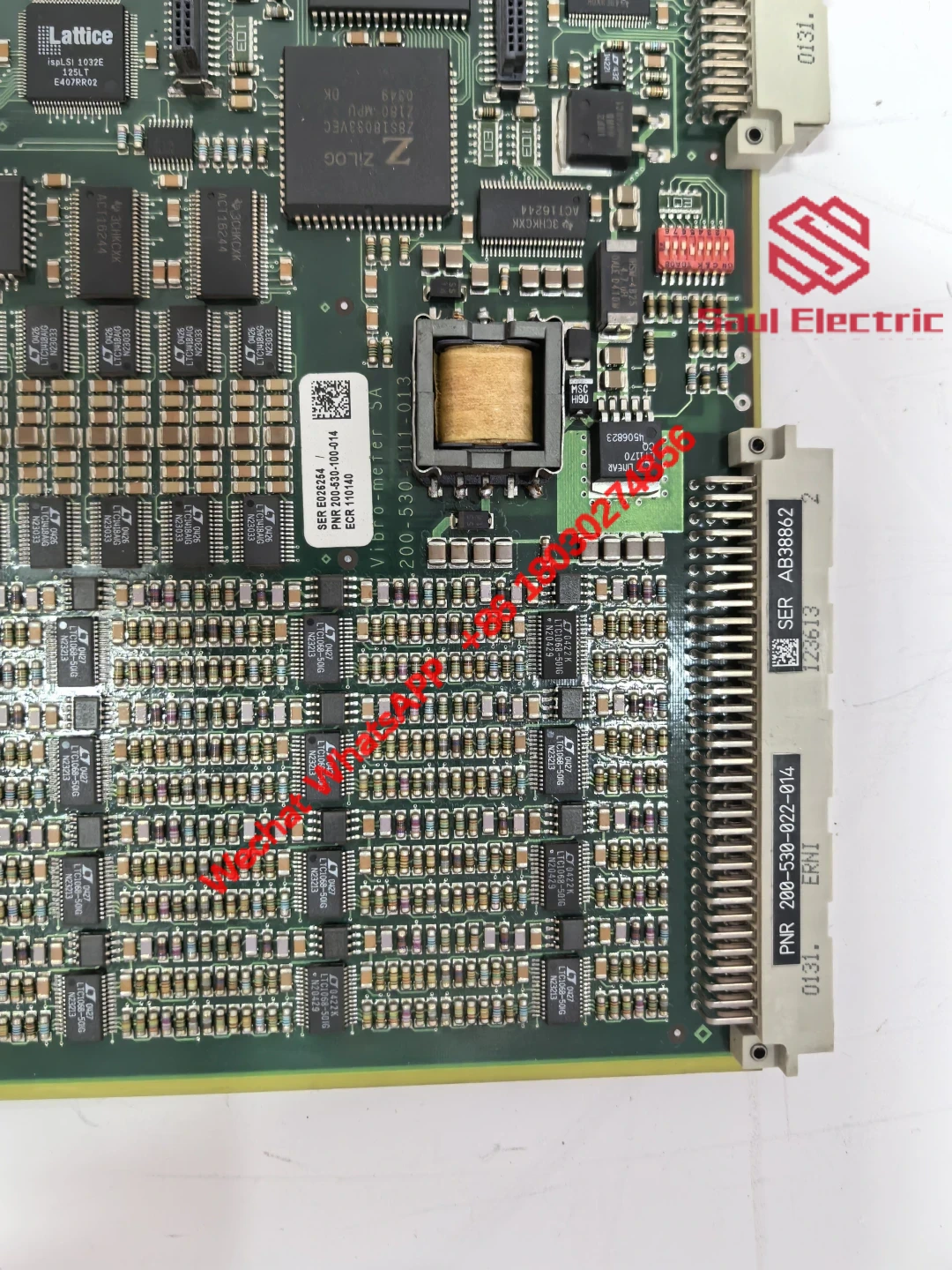

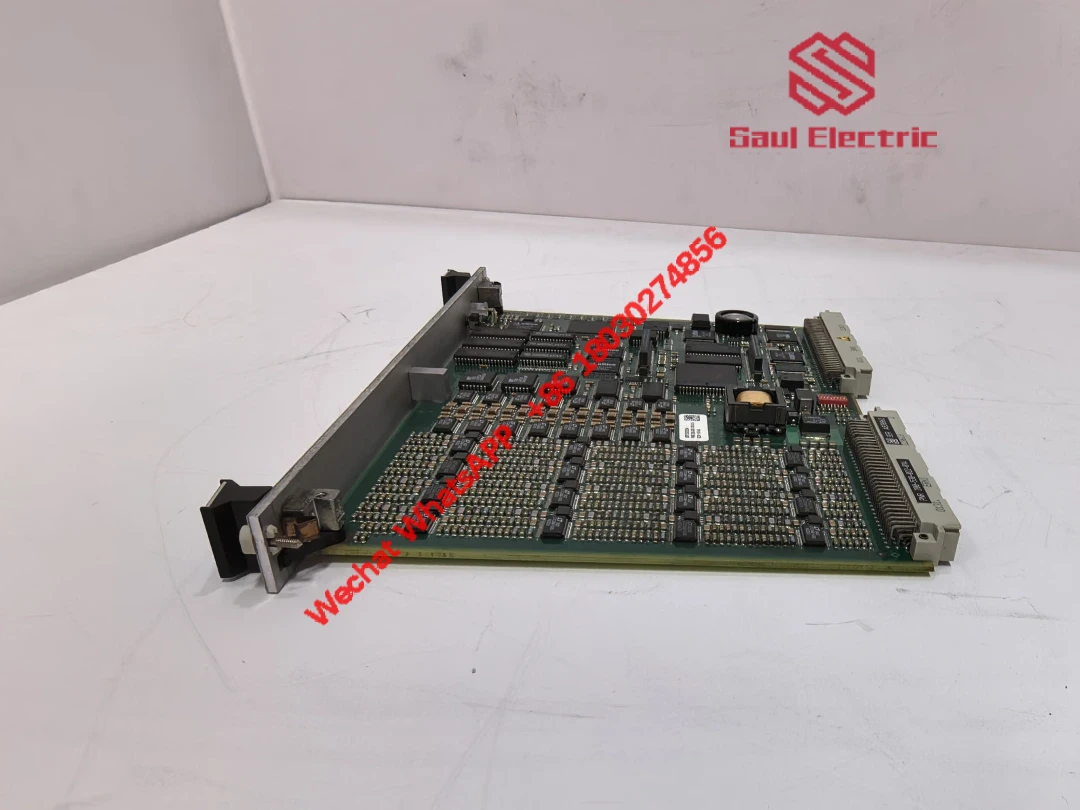

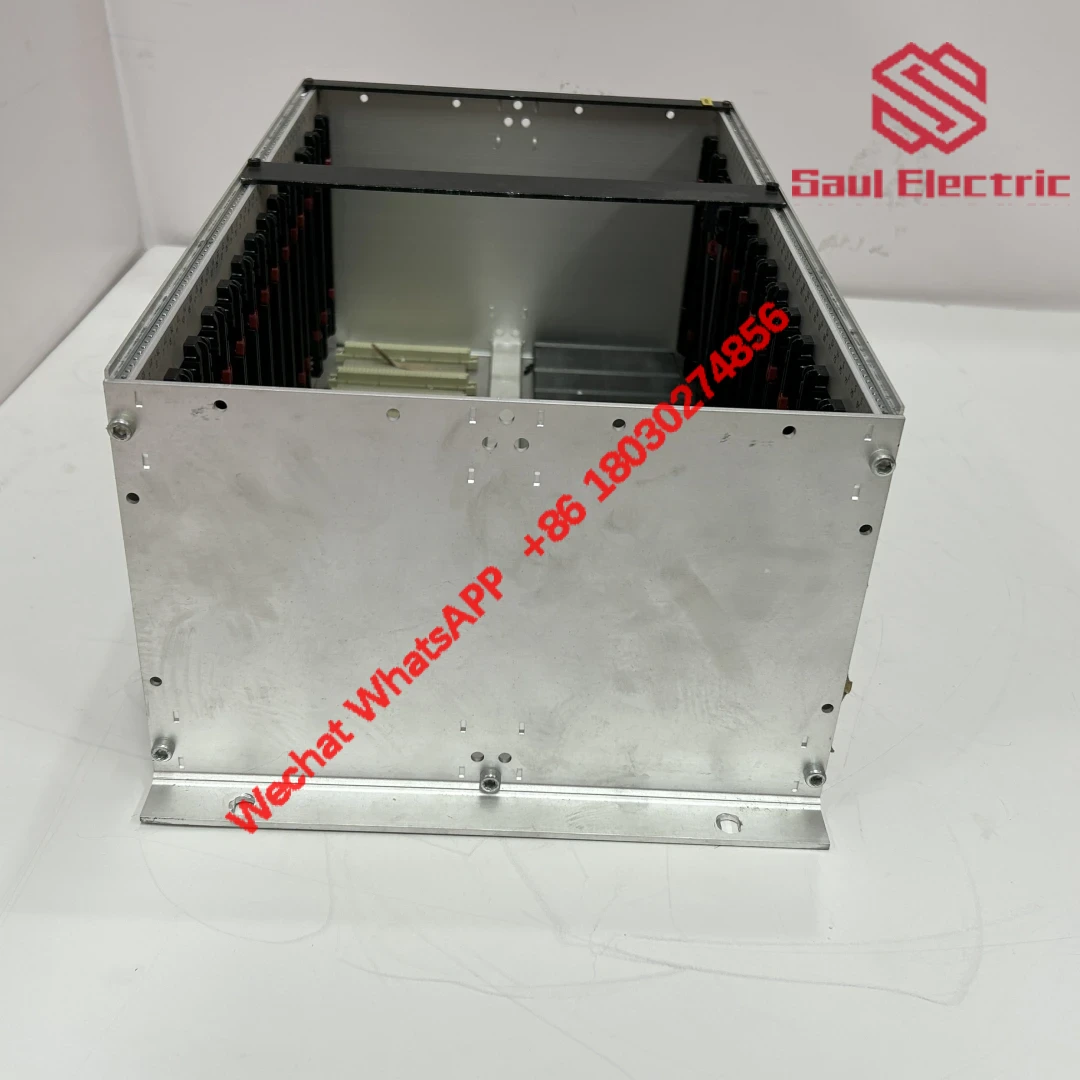

Moog CMC16-200-530-111-013 Industrial Control Module

The Moog CMC16-200-530-111-013 industrial control module delivers precision motion control for high-stakes automation tasks. Whether managing complex robotics or high-speed production lines, this component ensures consistent performance in environments where failure isn’t an option. Its 24 V DC power supply and 20 kHz output frequency make it particularly effective for applications requiring rapid, repeatable actions.

| Specification | Details |

|---|---|

| Brand | Moog |

| Model | CMC16-200-530-111-013 |

| Operating Voltage | 24 V DC |

| Output Frequency | 20 kHz |

| Series | CMC16 |

| Certifications | CE, UL, RoHS |

Real-World Applications

This module excels in environments demanding nanometer-level precision. In automotive manufacturing, users report it maintains ±0.02mm accuracy during robotic welding sequences even under voltage fluctuations. Semiconductor processing lines utilize its real-time feedback to control wafer handling systems operating at 1,200 cycles per hour. Energy infrastructure projects leverage its vibration resistance for turbine control systems in offshore wind farms.

Our inventory includes complementary components like ABB’s DSQC series robot interfaces, GE’s VMIVME-7807 signal processors, and Bently Nevada’s 3500/44 vibration monitoring systems. For packaging lines requiring synchronized motion control, customers often pair this module with Schneider’s LXM32 servo drives or Allen Bradley’s Kinetix 5500 controllers.

Technical Advantages

Engineers appreciate the module’s dual-layer PCB design which reduces signal noise by 40% compared to standard industrial controllers. The aluminum housing with IP67-rated seals ensures operation in -40°C to 85°C environments – a critical factor for steel mill automation systems. Unlike similar modules, its built-in watchdog timer automatically resets communication channels during EMI spikes, minimizing unplanned downtime.

The CMC16 series’ modular firmware architecture allows protocol switching between EtherCAT and PROFINET without hardware changes. This flexibility proved valuable for a pharmaceutical client who needed to integrate legacy PLCs with new vision inspection systems. Redundant power input circuits with automatic failover provide continuous operation during maintenance – a feature that reduced mean time to repair by 65% in field tests.

Reviews

There are no reviews yet.