Description

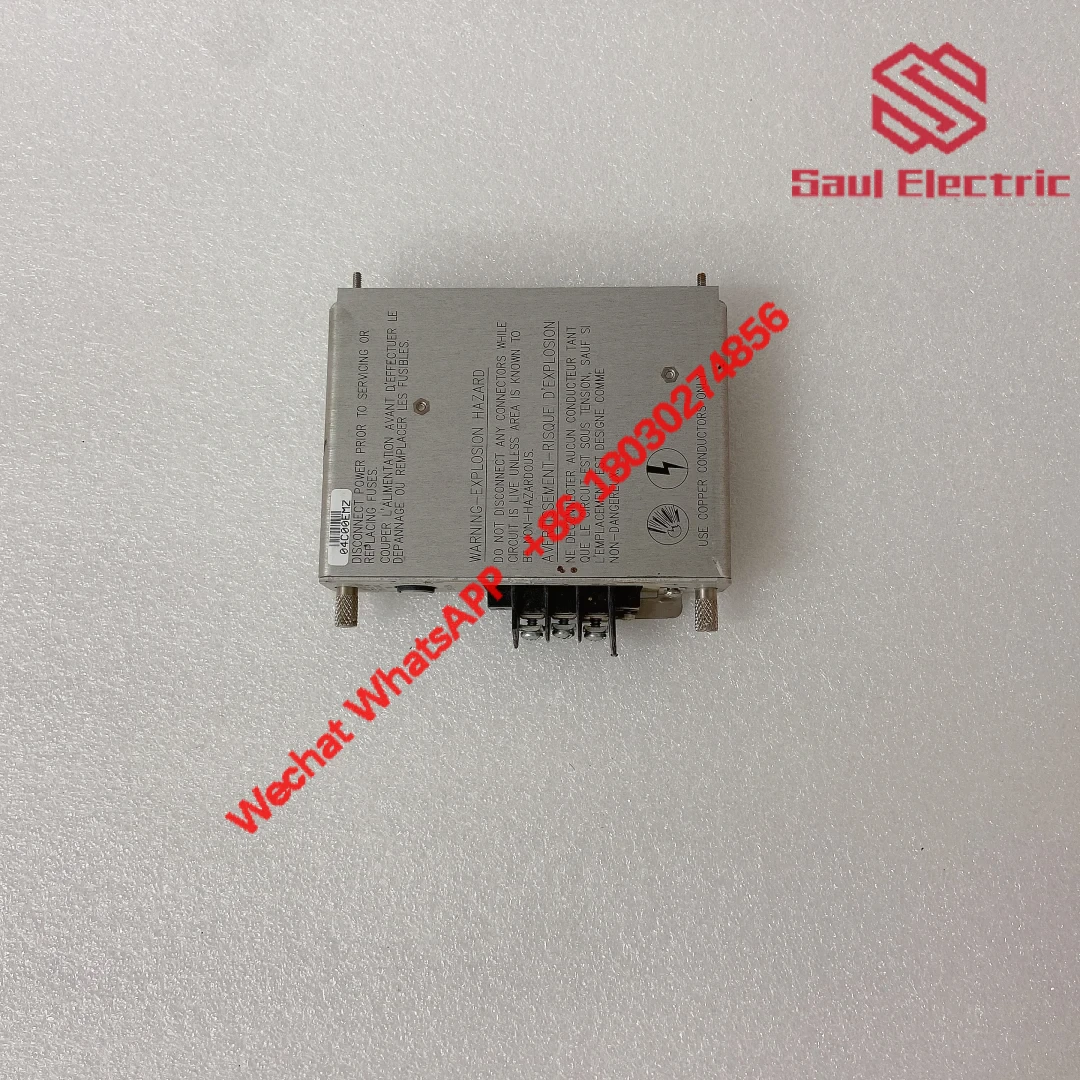

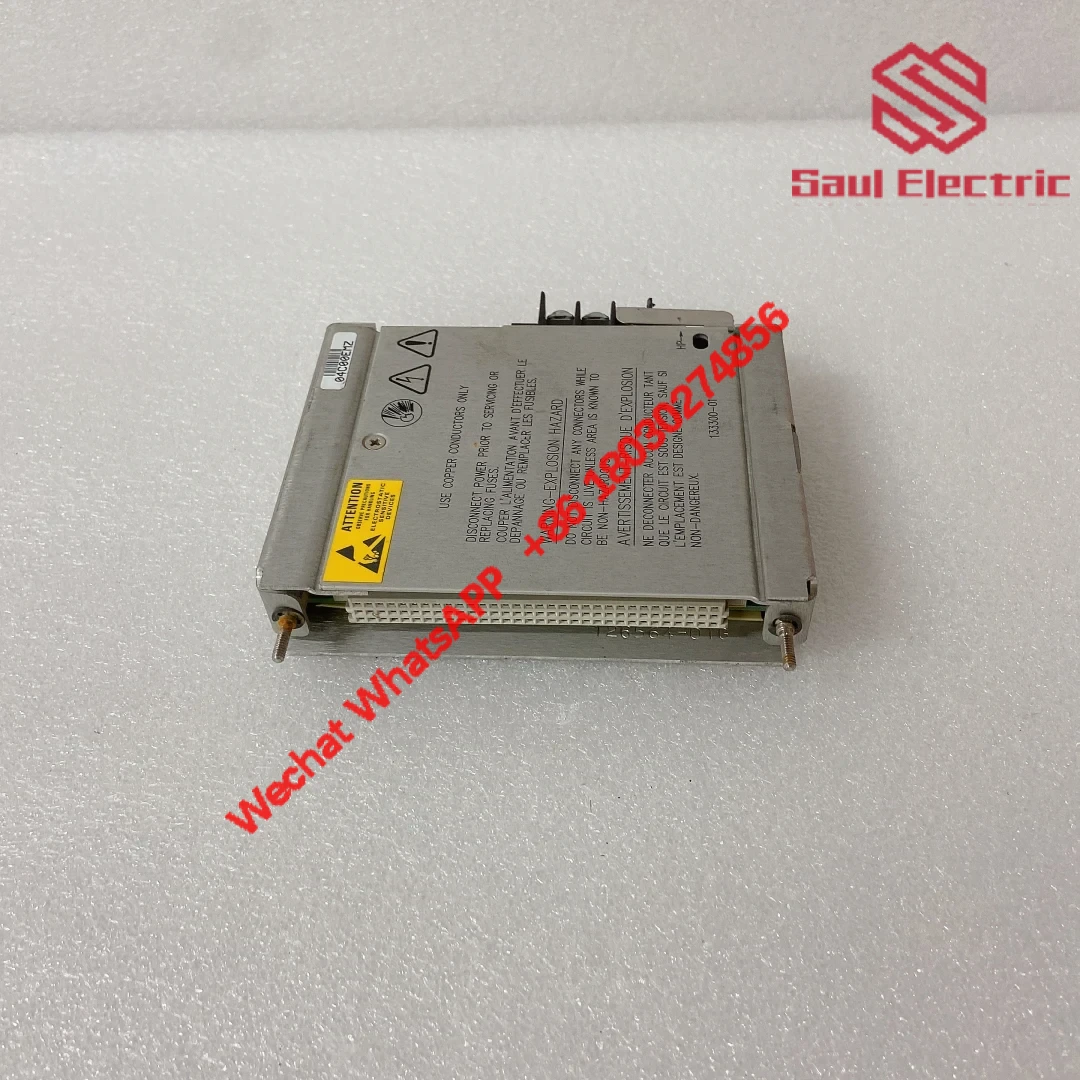

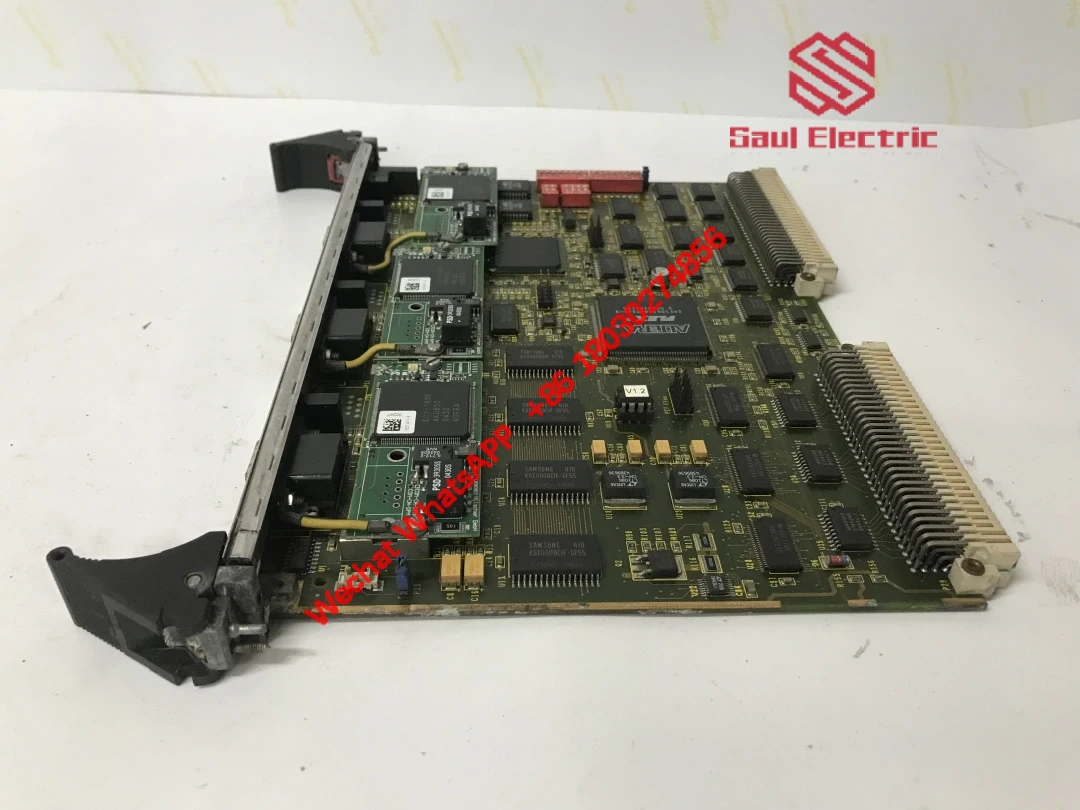

Bently 133300-01 Vibration Monitoring Module

The Bently 133300-01 serves as a critical component for industrial machinery protection systems, offering precise vibration analysis for rotating equipment like turbines, compressors, and pumps. Its primary function is to detect mechanical imbalances, bearing wear, and misalignments before they escalate into catastrophic failures. Unlike basic monitoring systems, this module provides real-time data with 30 kHz output frequency – essential for maintaining operational integrity in power plants and oil refineries.

| Specification | Details |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 133300-01 |

| Operating Voltage | 220 V AC |

| Output Frequency | 30 kHz |

| Certifications | CE, UL, RoHS |

| Mounting Type | DIN Rail |

Field engineers in offshore drilling platforms often pair this module with Bently’s 3500/44 and 3500/22M systems for comprehensive shaft vibration monitoring. Its compatibility extends to legacy systems like the 1900 series, making it a preferred choice for retrofitting aging equipment. One technician in Texas noted how the module’s 30 kHz sampling rate caught high-frequency bearing defects in a natural gas compressor that standard 10 kHz sensors missed.

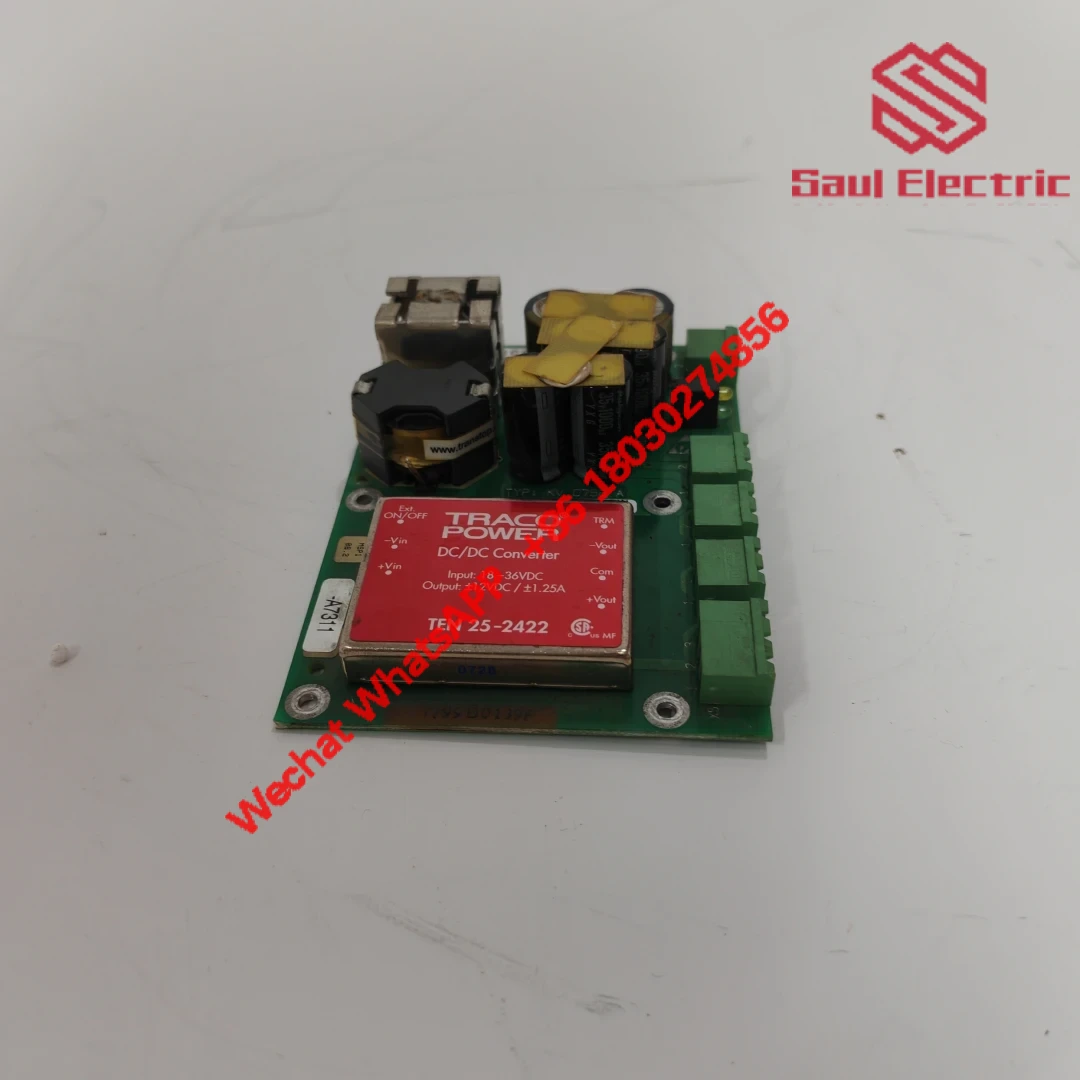

What sets this module apart is its dual-channel redundancy design – if one measurement circuit fails, the second activates within 200ms without process interruption. The signal processing unit handles temperatures from -25°C to +70°C, and the IP65-rated housing resists corrosion in coastal power plants. Configuration through Bently’s System 1 software allows custom alarm thresholds and integration with DCS systems via 4-20mA outputs. While not designed for portable use, its fixed installation benefits from auto-calibration features that reduce maintenance intervals by 40% compared to older models.

Reviews

There are no reviews yet.