Description

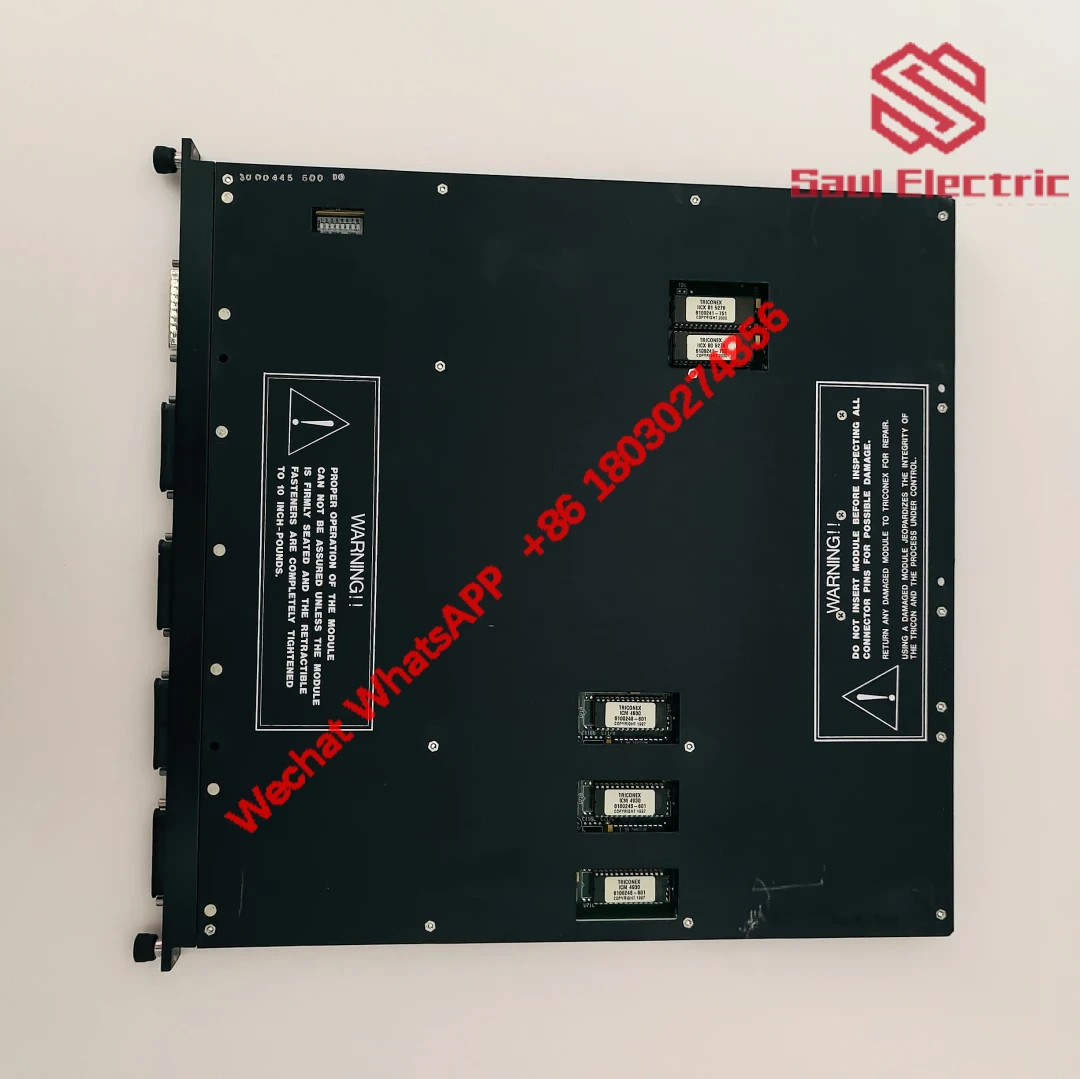

TRICONEX 4119A Process Control Module

Engineered for industrial environments where precision and durability matter most, the TRICONEX 4119A Process Control Module delivers rock-solid performance in critical applications. This module isn’t just about basic control—it’s built to handle complex automation tasks in harsh conditions, from offshore oil platforms to high-temperature manufacturing lines. Users consistently praise its ability to maintain stability when other systems might falter.

| Specification | Details |

|---|---|

| Brand | TRICONEX (Schneider Electric) |

| Input/Output Channels | 16 Inputs / 8 Outputs |

| Communication Protocols | MODBUS RTU, DeviceNet |

| Physical Dimensions | 185 x 120 x 45 mm (approximate) |

| Weight | 1.2 kg (standard 19″ rack mount) |

When a Texas-based refinery needed to upgrade their emergency shutdown system, this module became their go-to choice. Its dual-protocol capability (MODBUS RTU + DeviceNet) allowed seamless integration with legacy PLCs while supporting new safety instrumentation. Other common applications include chemical processing plants, gas compression stations, and power generation facilities. We regularly supply this alongside complementary TRICONEX hardware like the 3703X communication modules and 3511 I/O cards.

What sets this module apart isn’t just the 10 MIPS processing speed or 128MB memory—it’s the redundancy design baked into every unit. The triple modular redundancy (TMR) architecture means critical processes keep running even during hardware faults. One Midwest chemical plant reported zero downtime over 18 months despite operating in -30°C winter conditions. Compatibility with TRICONEX’s safety systems (SIL 3 certified) makes it a favorite for high-risk environments where failure isn’t an option.

Reviews

There are no reviews yet.