Description

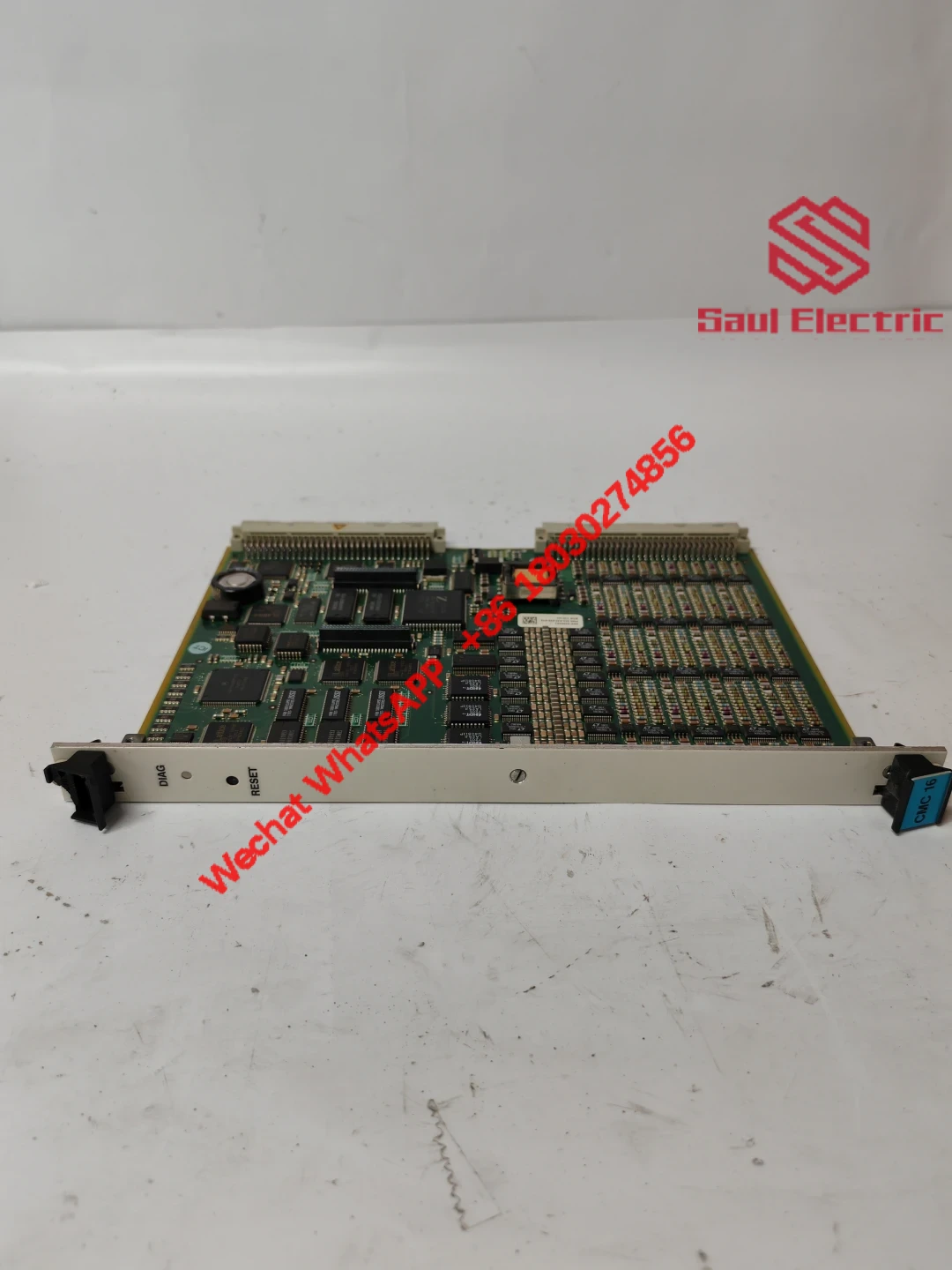

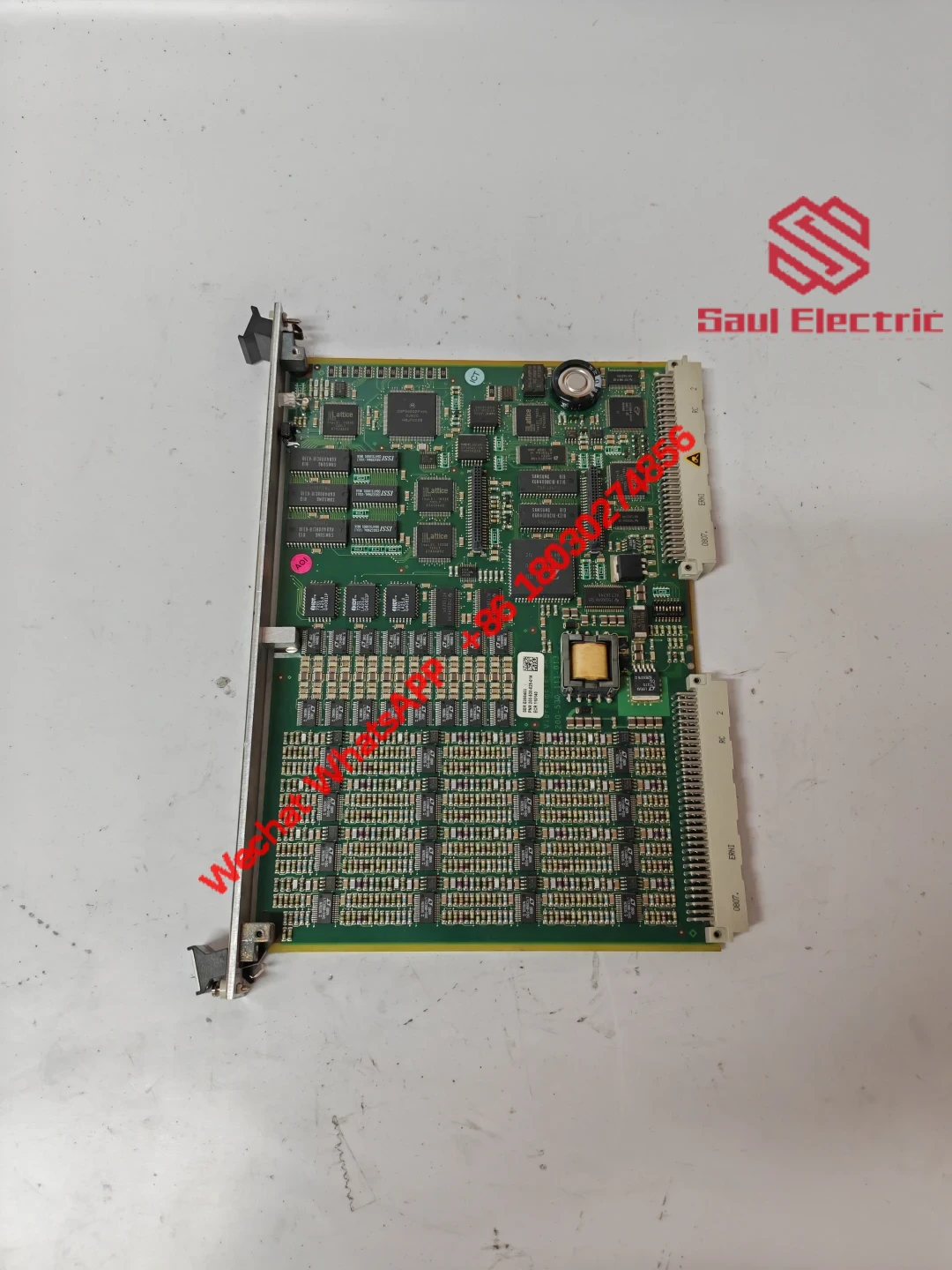

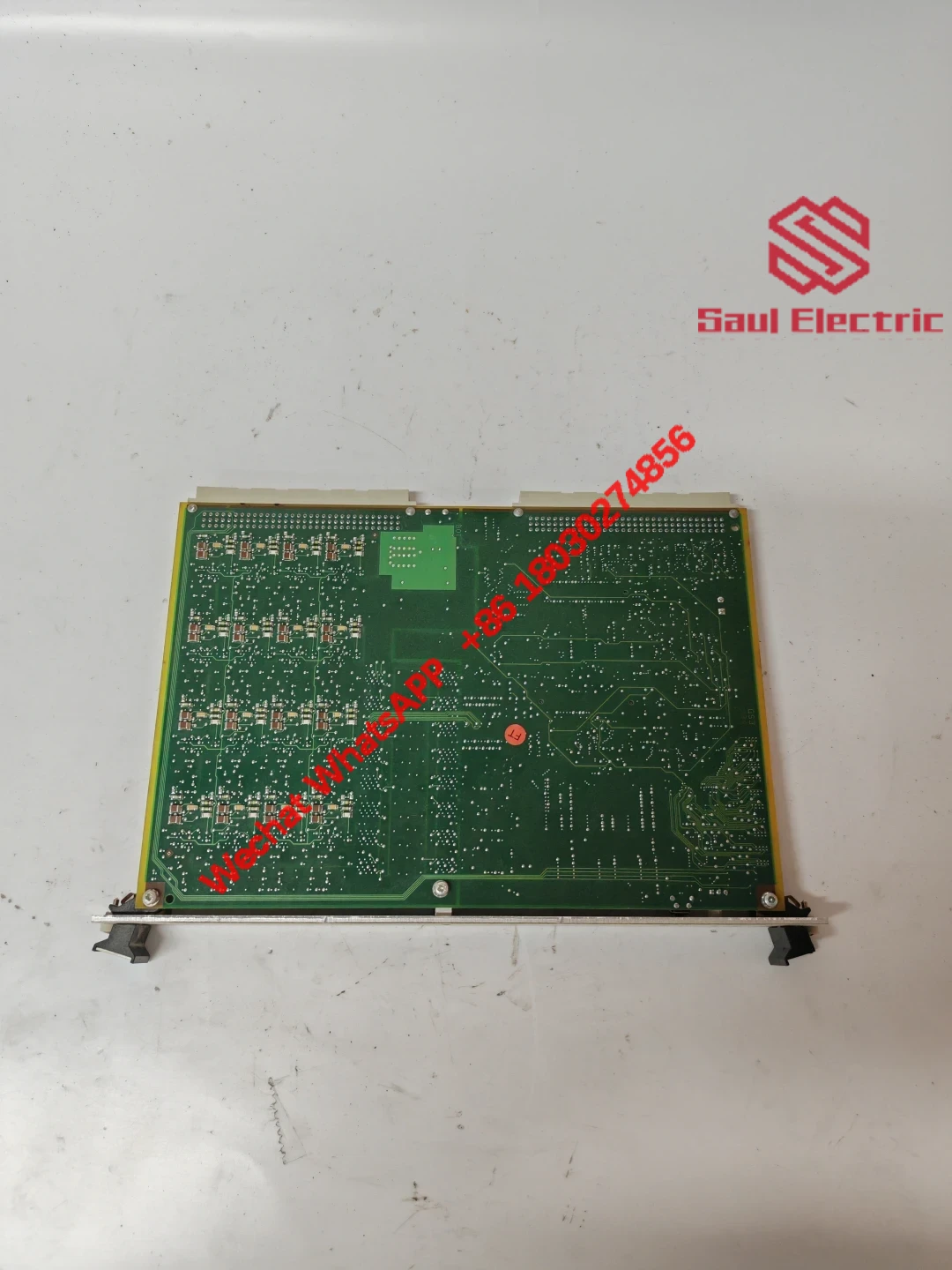

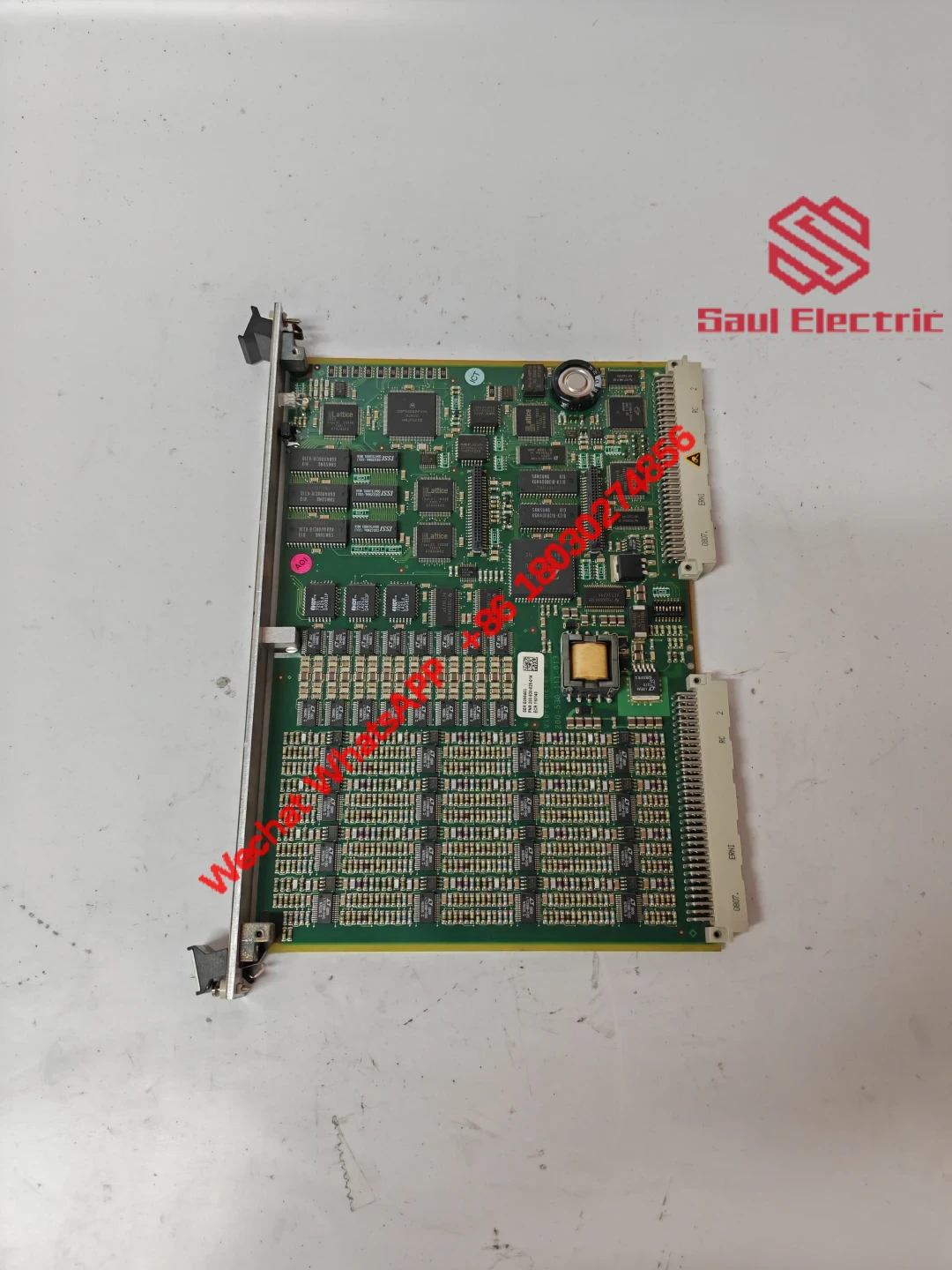

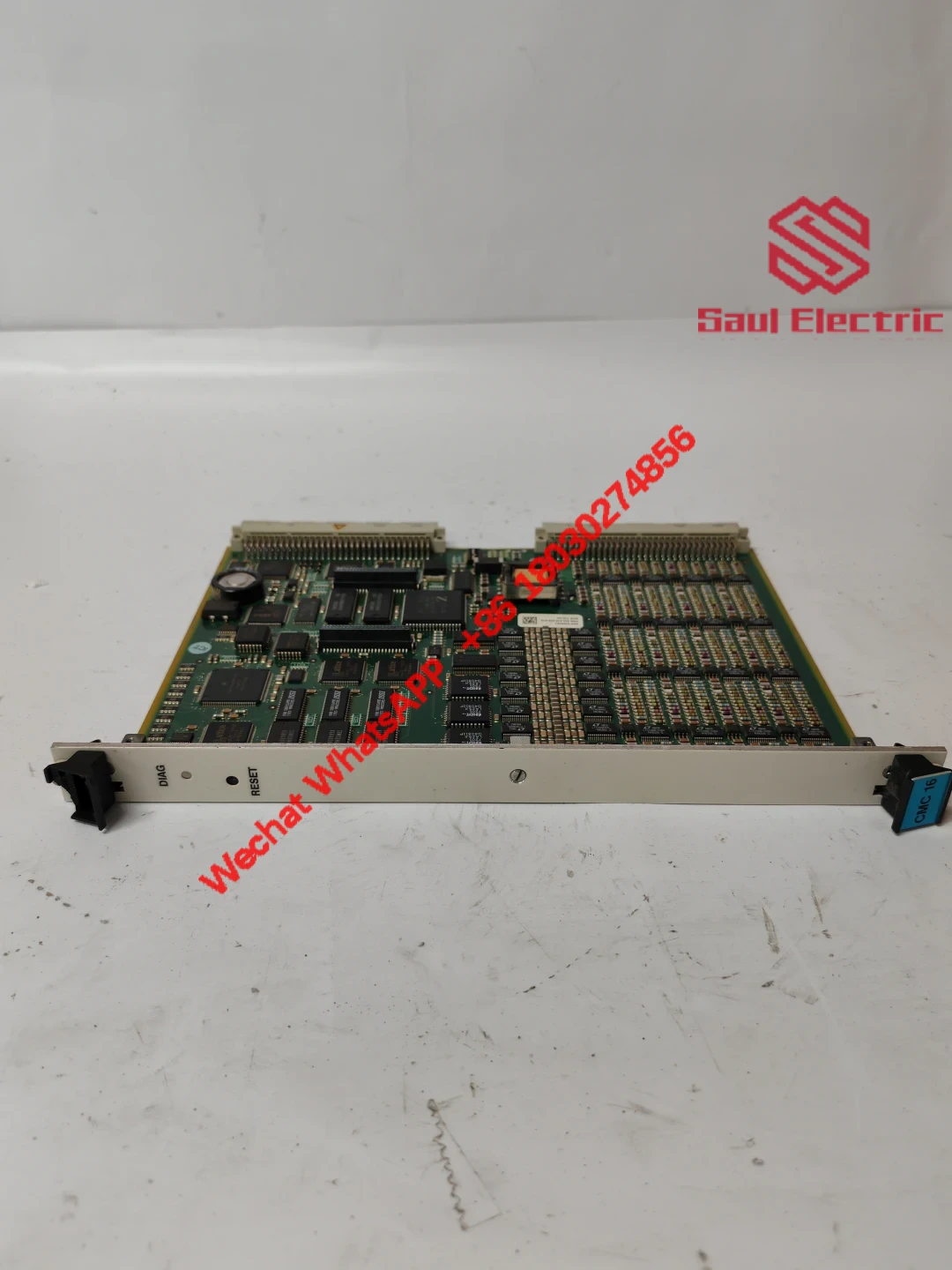

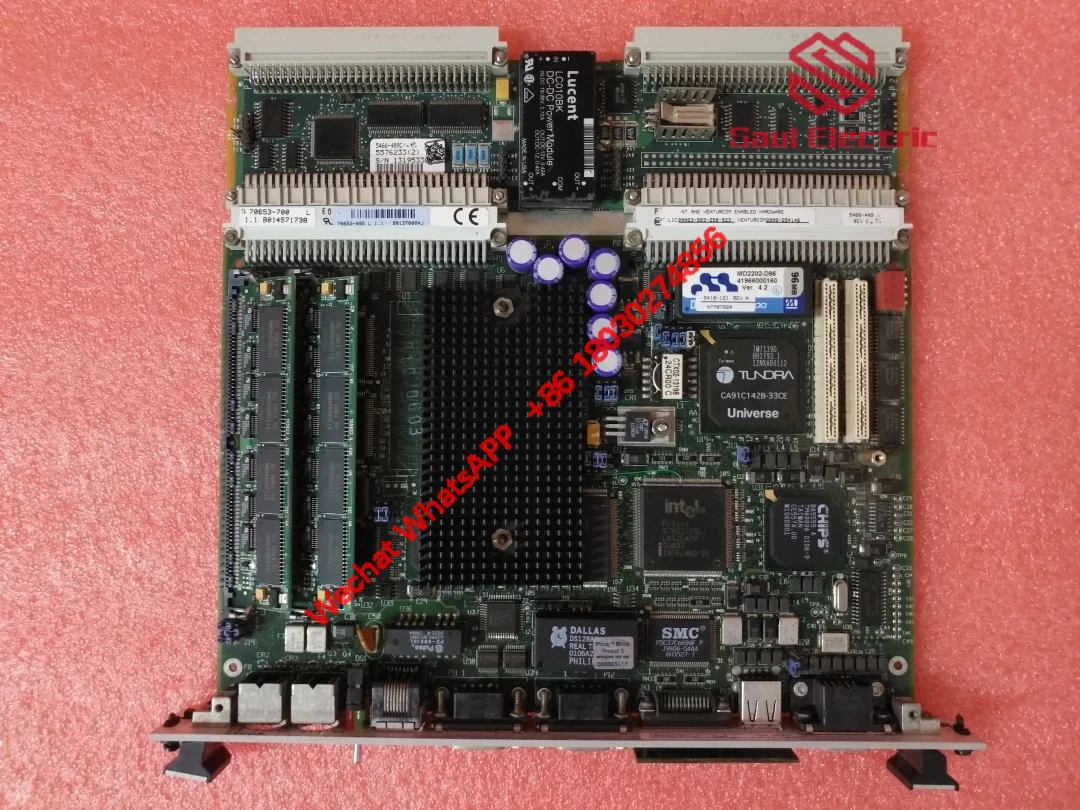

Vibro-Meter VM600 CMC16 Combustion Monitoring Module

This high-precision combustion monitoring module delivers real-time vibration analysis and combustion state tracking for critical industrial equipment. Designed for heavy-duty environments like power plants and oil refineries, it handles 16 dynamic channels plus 4 tachometer channels – perfect for monitoring turbine combustion dynamics or compressor performance.

| Specification | Details |

|---|---|

| Manufacturer | Vibro-Meter |

| Model Number | VM600 CMC16 200-530-025-014 / 200-530-111-013 |

| Channel Configuration | 16 Dynamic + 4 Tachometer Channels |

| Sampling Rate | 200 kHz |

| Measurement Range | 200-530 Hz |

| Accuracy | ±1% of Reading |

| Operating Temp | -20°C to +70°C |

Commonly deployed in gas turbine combustion monitoring systems and refinery compressor installations, this module pairs well with vibration protection systems like the VM600 series. Users in steel mills have reported catching early bearing wear signs through its dynamic pressure measurements, while power plant engineers appreciate the phase reference tracking during turbine startups. The asynchronous/synchronous sampling flexibility really shines when monitoring equipment with variable load conditions.

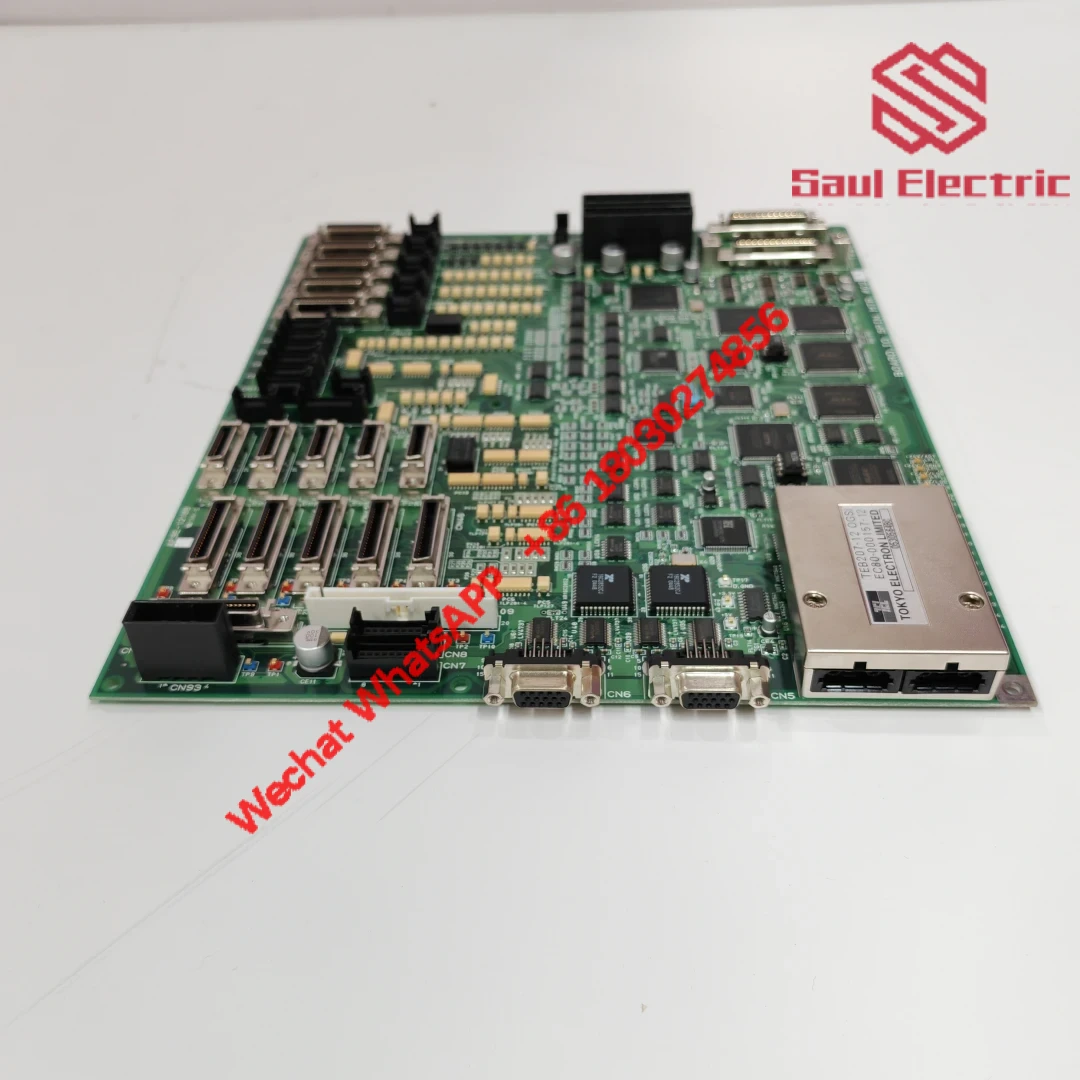

What makes this module stand out? The 24-bit resolution captures subtle vibration changes that lesser systems miss, and the Ethernet/Modbus connectivity plays nice with existing SCADA setups. Truth be told – those electromagnetic interference safeguards really reduce false alarms in electrically noisy environments. Pair it with VibroSight software and you’ve got a powerful combo for trending combustion instability or setting predictive maintenance alerts.

Reviews

There are no reviews yet.