Description

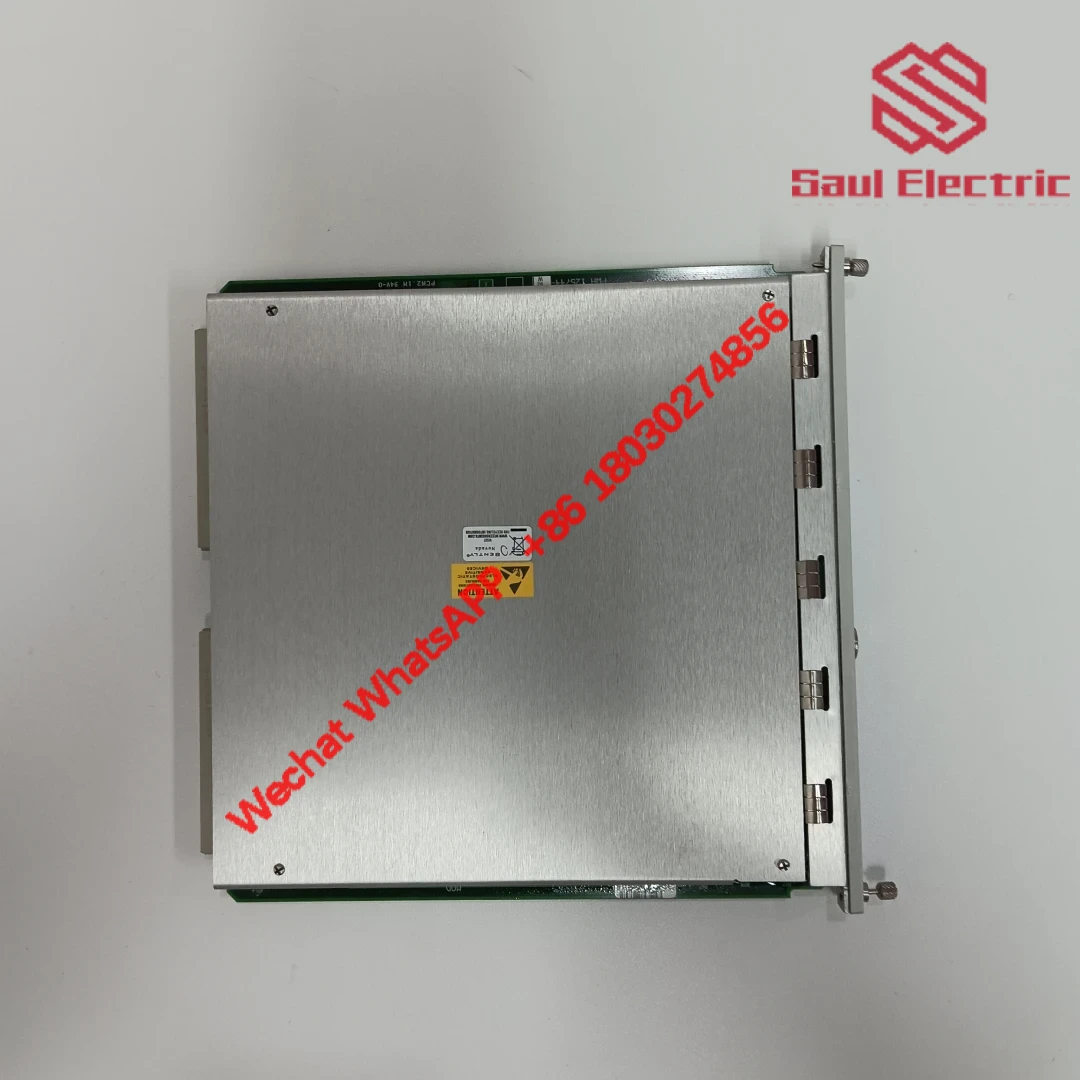

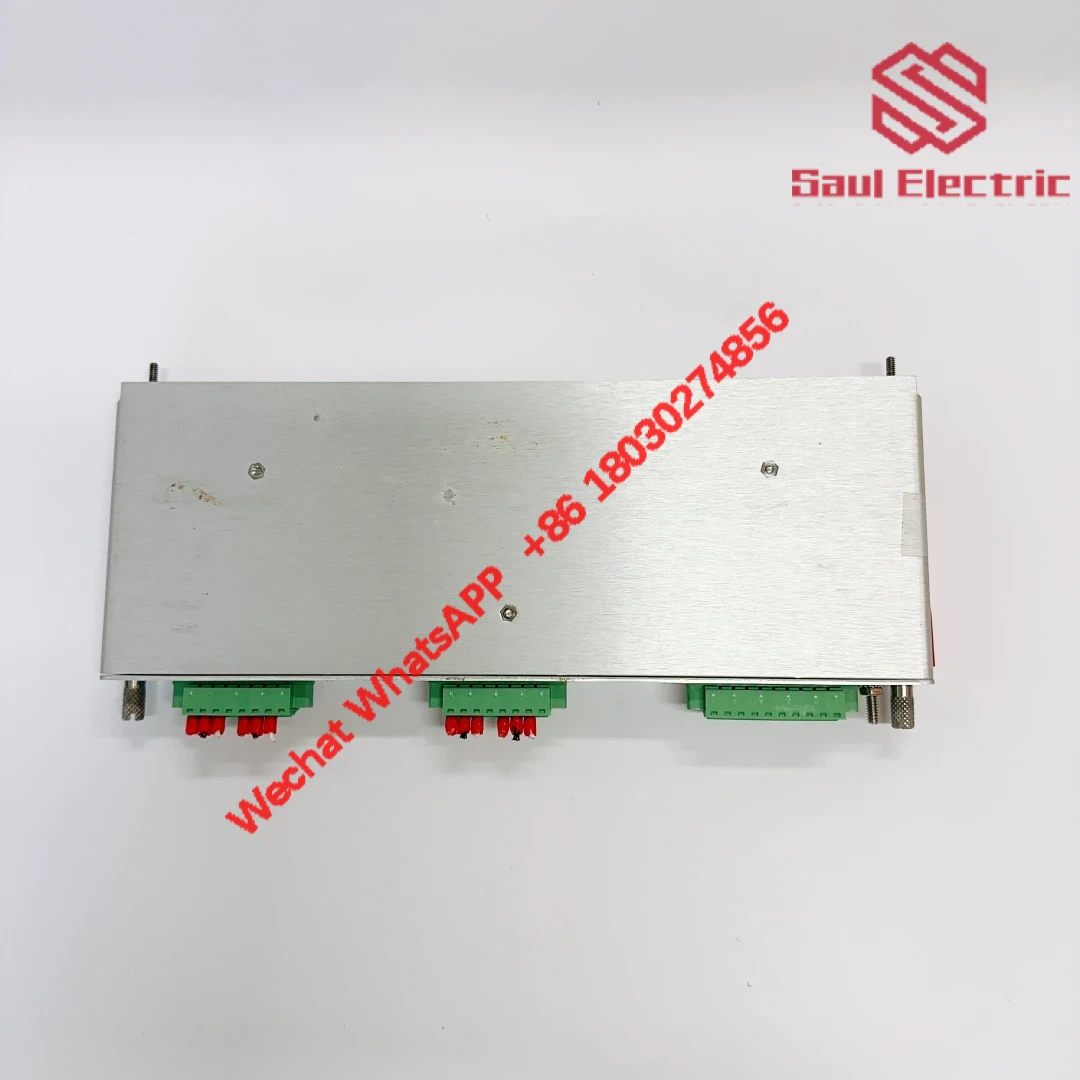

BENTLY 3500/20 Controller Module for Precision Machinery Monitoring

Engineered for demanding industrial environments, the BENTLY 3500/20 controller module delivers continuous vibration analysis and real-time monitoring of rotating machinery. Its robust design makes it ideal for maintaining operational safety in power plants, oil refineries, and manufacturing facilities where equipment failure could lead to costly downtime.

Technical Specifications

| Attribute | Details |

|---|---|

| Brand | BENTLY NEVADA |

| Model | 3500/20 |

| Item Number | 125744-02 |

| Operating Voltage | 220 V |

| Output Frequency | 30 kHz |

| Certification | CE, UL |

| Custom Options | Available |

In heavy industrial settings like gas compression stations or steel mills, this module excels at tracking shaft vibrations and bearing health. One chemical plant reported a 40% reduction in unplanned turbine shutdowns after integrating it with their 3500/44 and 3500/32 modules. We frequently pair it with Proximitor probes in 1900-series systems for oil & gas applications where temperature extremes challenge conventional sensors.

The module’s military-grade aluminum housing maintains calibration accuracy within ±0.5% even during sudden temperature swings. Its dual-channel architecture allows redundant monitoring of critical assets – if one circuit detects abnormal vibration patterns, the backup channel automatically takes over without interrupting data logging. Users appreciate how easily it integrates with existing DCS systems through standard Modbus protocols, avoiding costly infrastructure overhauls.

Reviews

There are no reviews yet.