Description

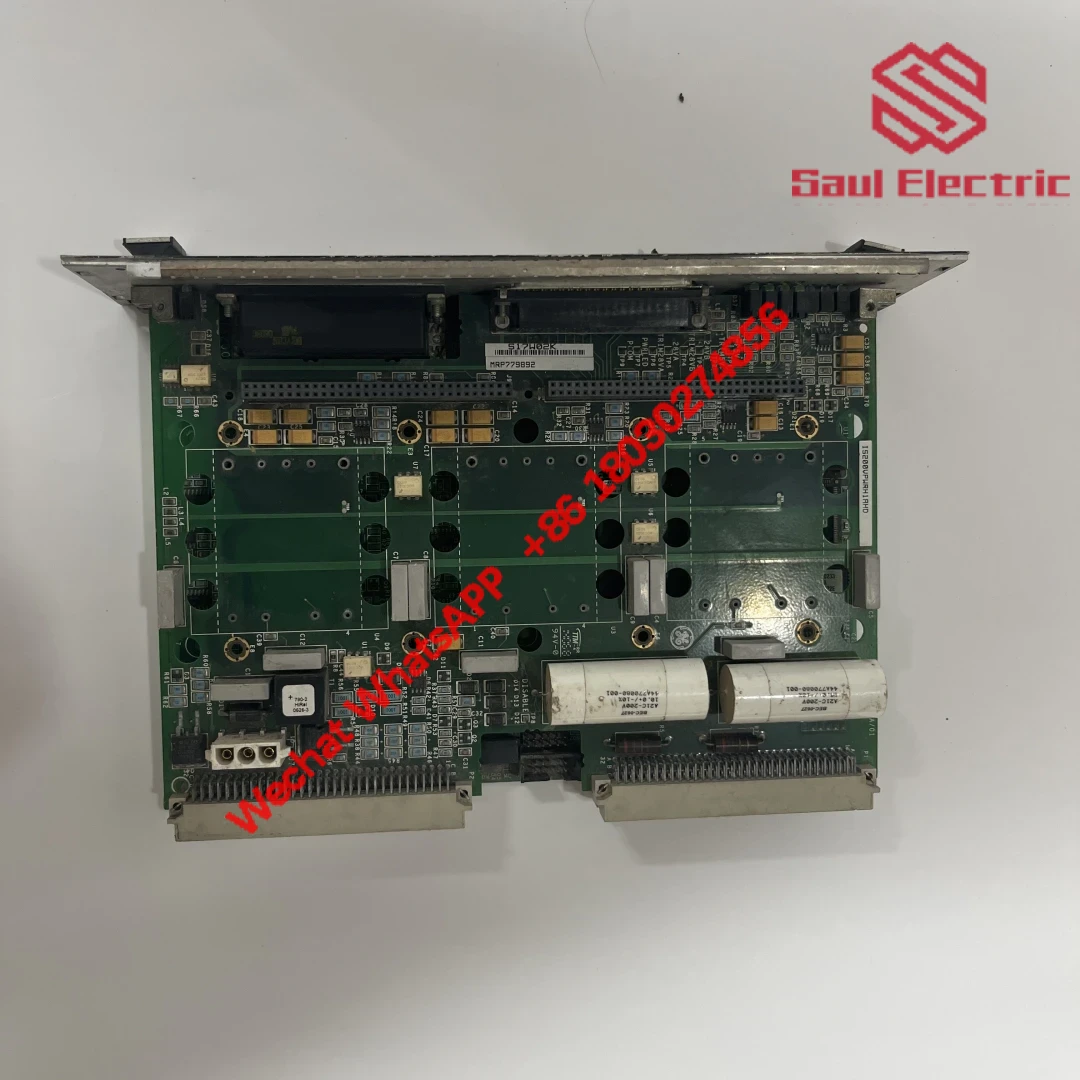

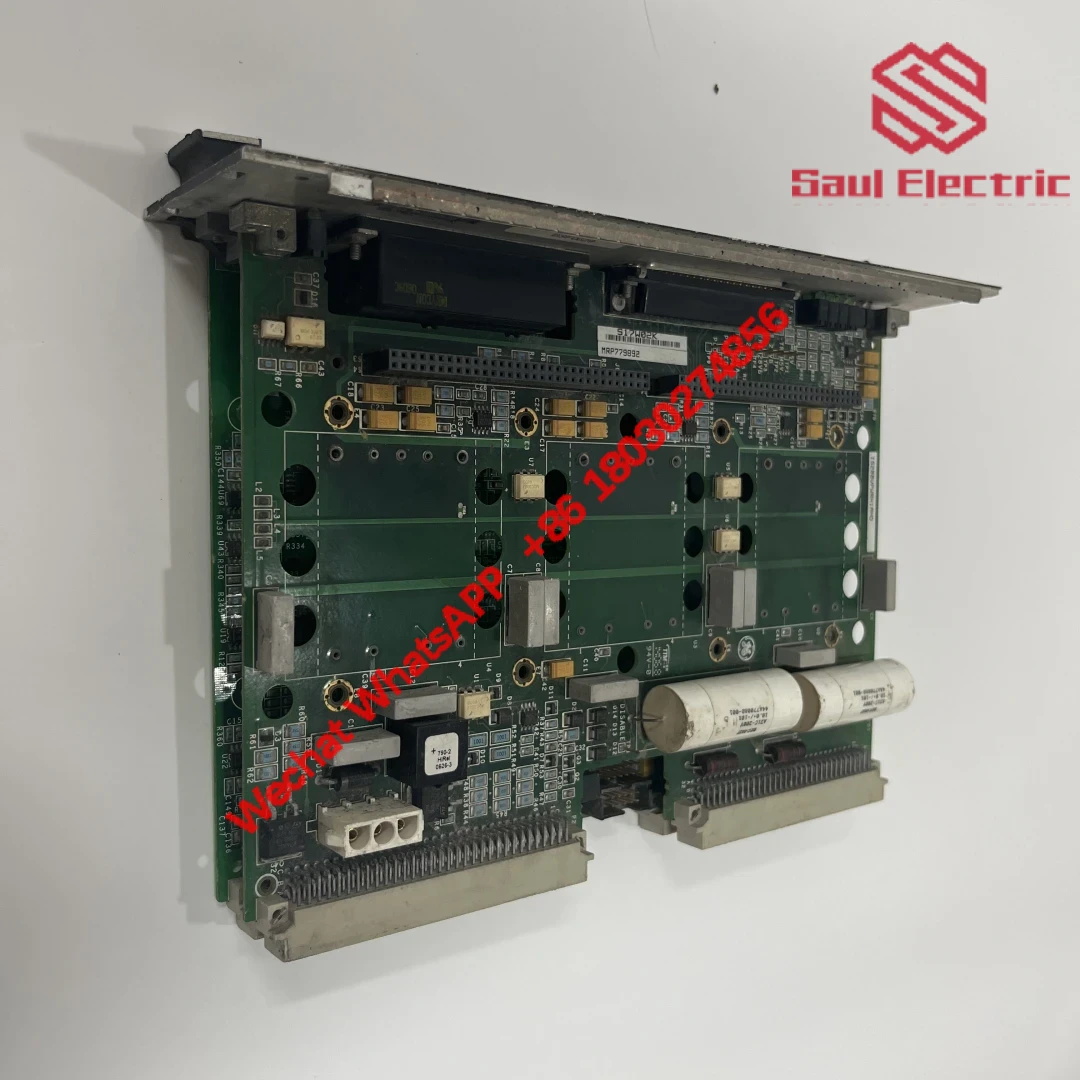

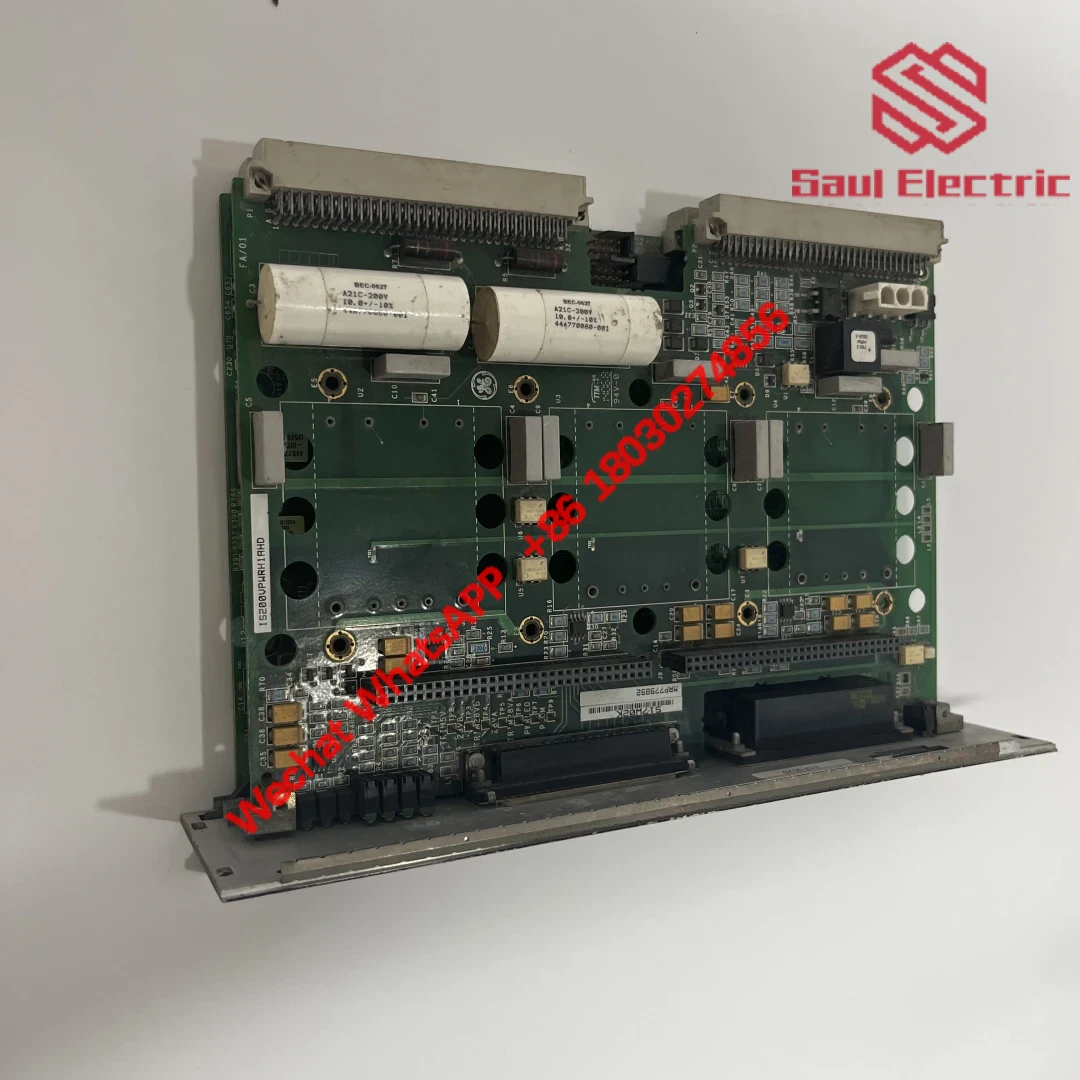

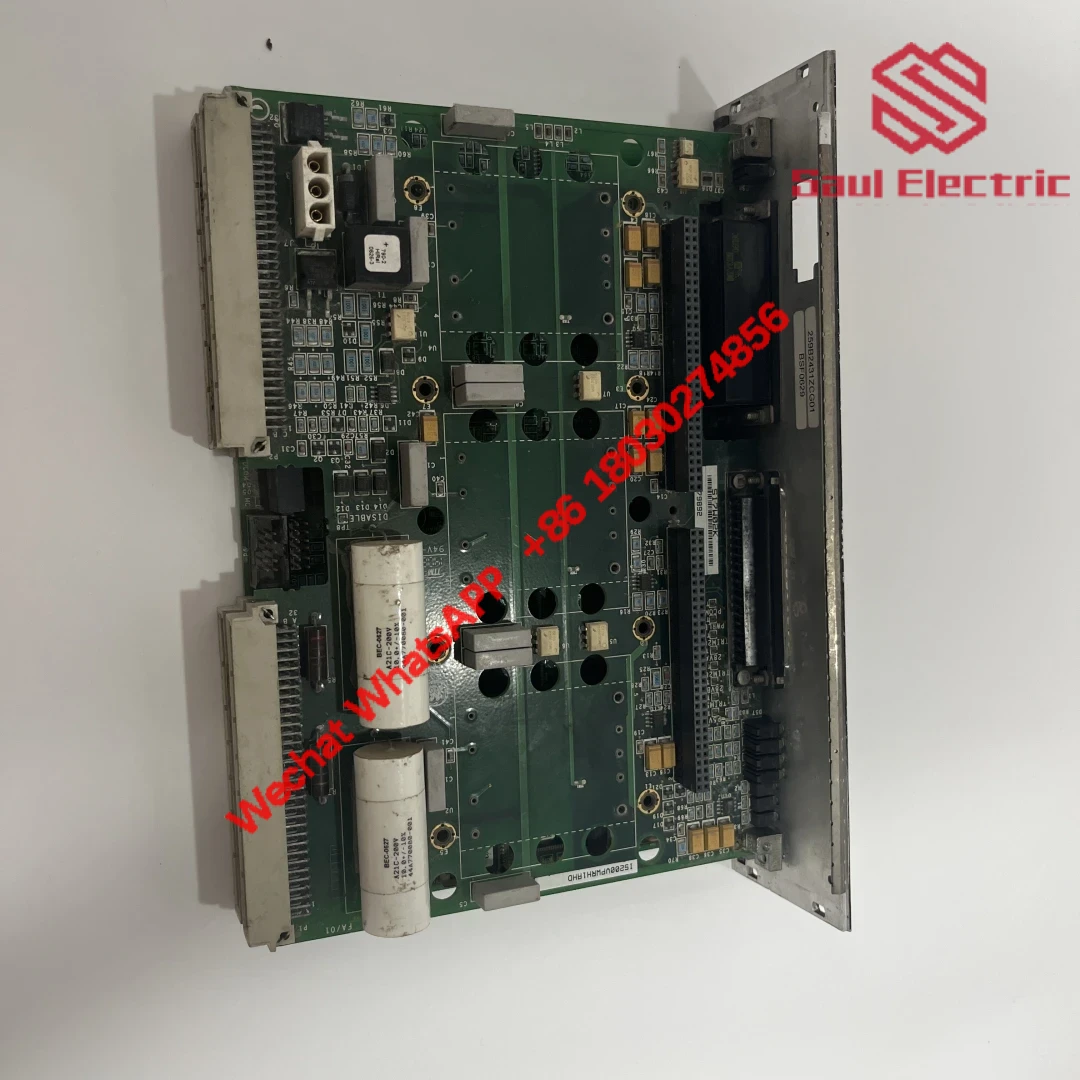

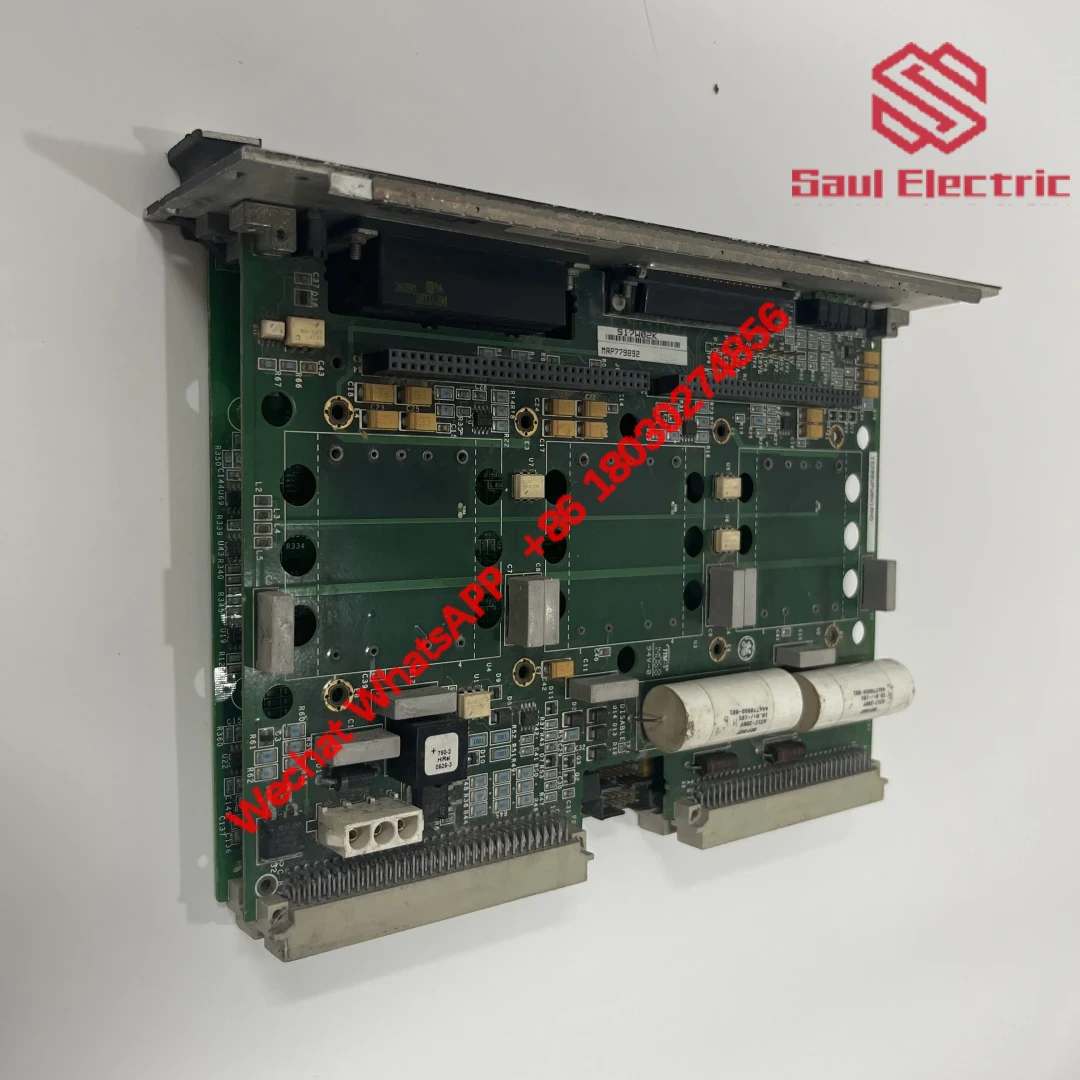

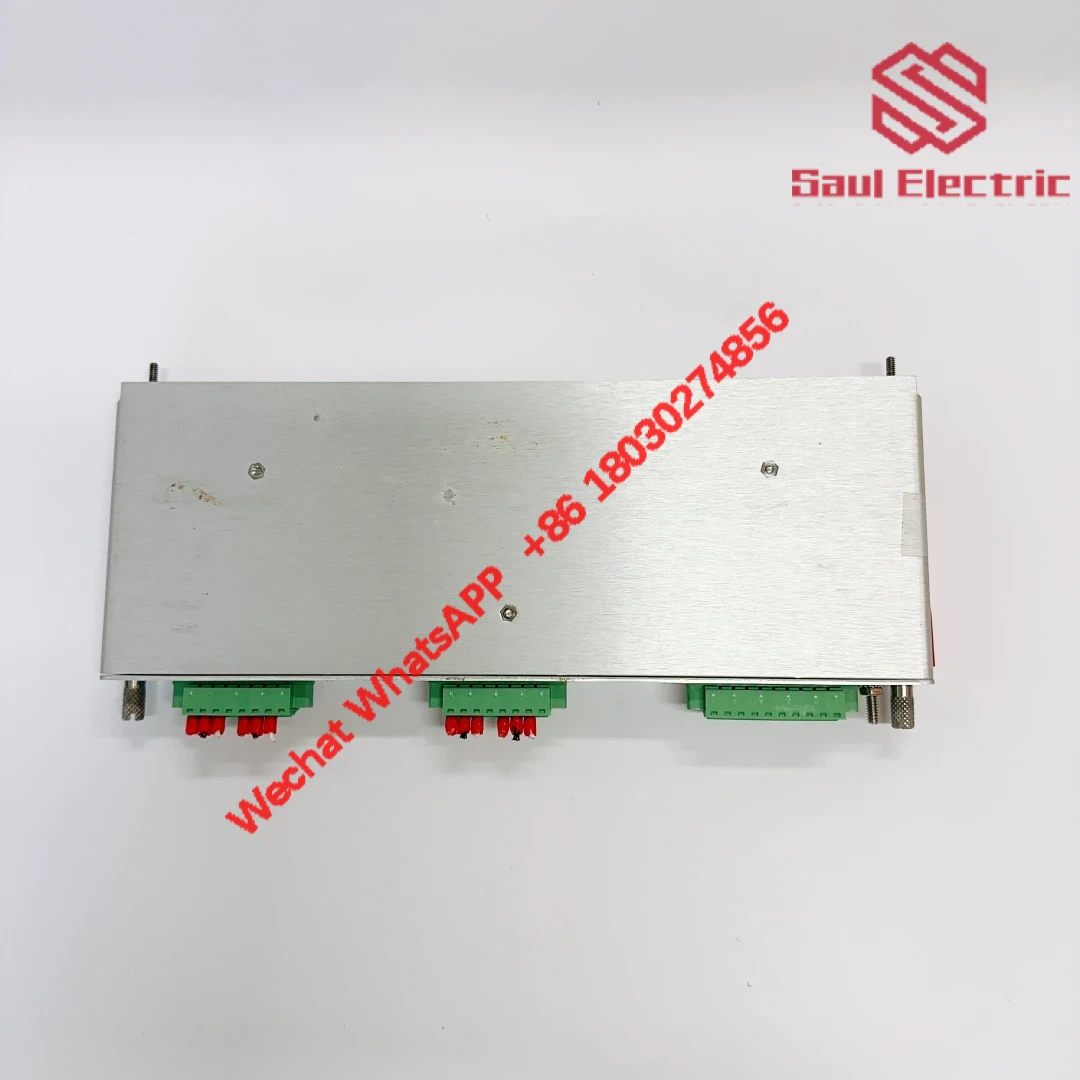

GE IS200VPROH Series Industrial Control Modules

These modules from GE’s Mark VI family handle critical turbine operations with industrial-grade reliability. Designed for power plants and heavy machinery, they manage tasks like system synchronization, real-time diagnostics, and process automation where precision matters most.

| Attribute | Spec |

|---|---|

| Brand | General Electric |

| Series | Mark VI |

| Module Type | Digital I/O Controller |

| Voltage | 24 VDC |

| Comm Protocols | Ethernet/IP, Modbus TCP |

| Operating Temp | -40°C to +85°C |

| Mounting | DIN Rail |

| Certifications | CE, UL, CSA |

Real-World Applications

These modules are workhorses in environments like natural gas processing plants and combined cycle power facilities. I’ve seen the IS200VPWRH1AHD model maintain stable turbine control even during voltage fluctuations that would trip lesser systems. They handle tasks like:

- Generator protection systems

- Compressor station automation

- Refinery process control

We commonly supply these alongside related models like the IS220PPDAH1B and IS230SRTDH2A for integrated turbine management solutions.

Technical Advantages

What makes these modules stand out isn’t just the specs sheet. The built-in watchdog timer automatically resets communication faults – I’ve watched this feature prevent unplanned downtime during network storms. Key benefits include:

- Redundant power inputs for continuous operation

- EMI shielding that survives next to 480V motor starters

- Web-based diagnostics accessible from any smartphone

The DIN rail design saves panel space compared to older rack-mount systems. One client mentioned it took half the time to swap modules during a retrofit at their hydroelectric facility.

Reviews

There are no reviews yet.