Description

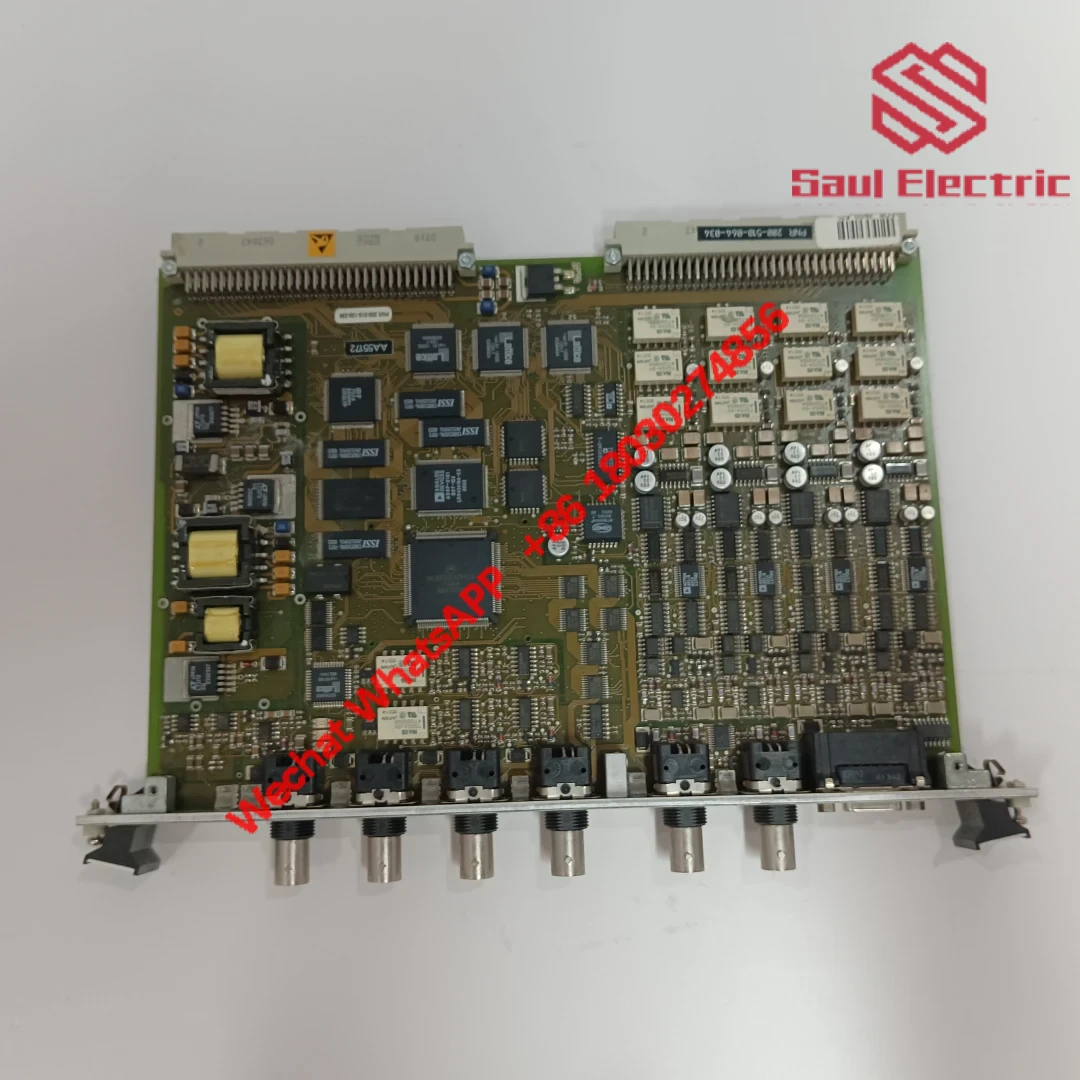

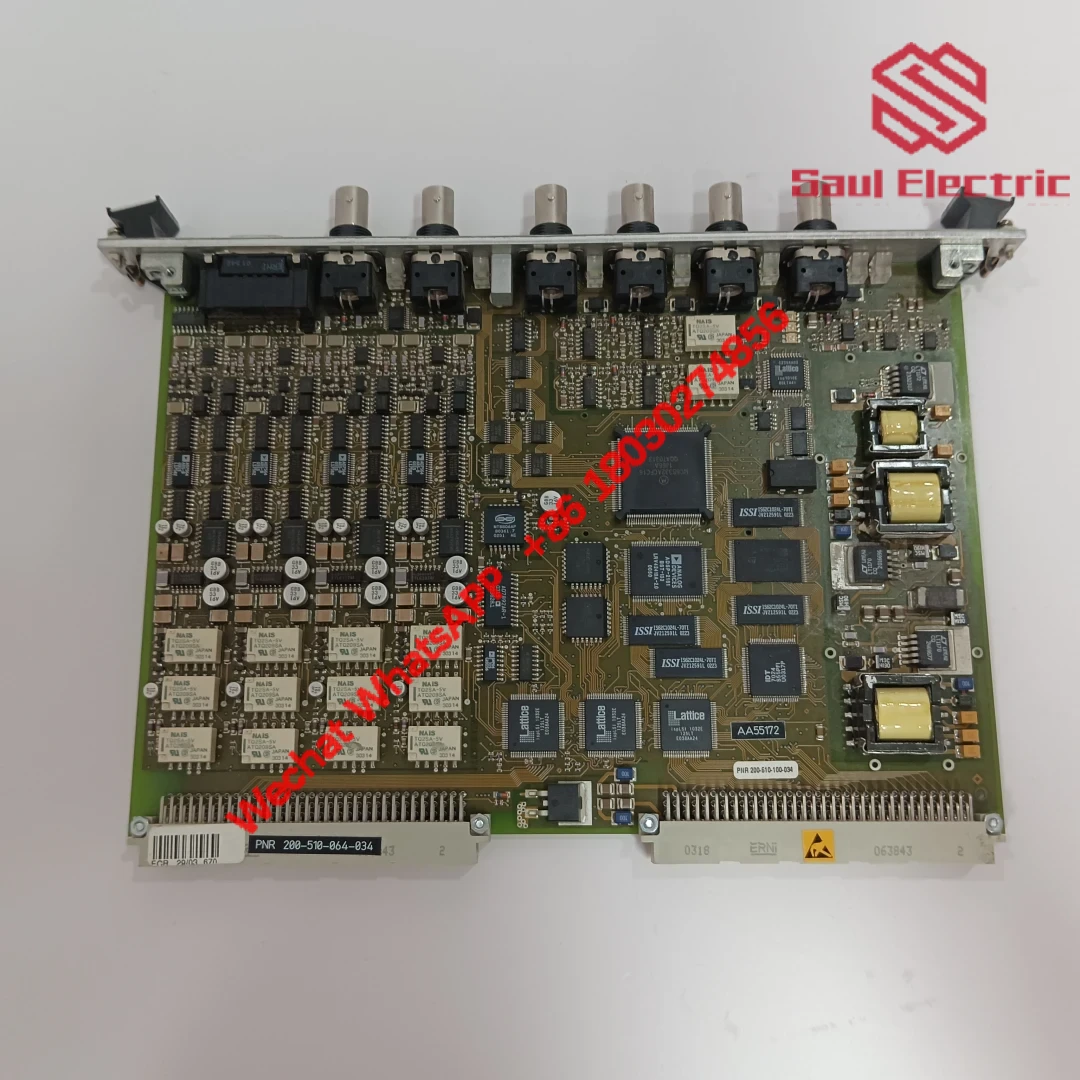

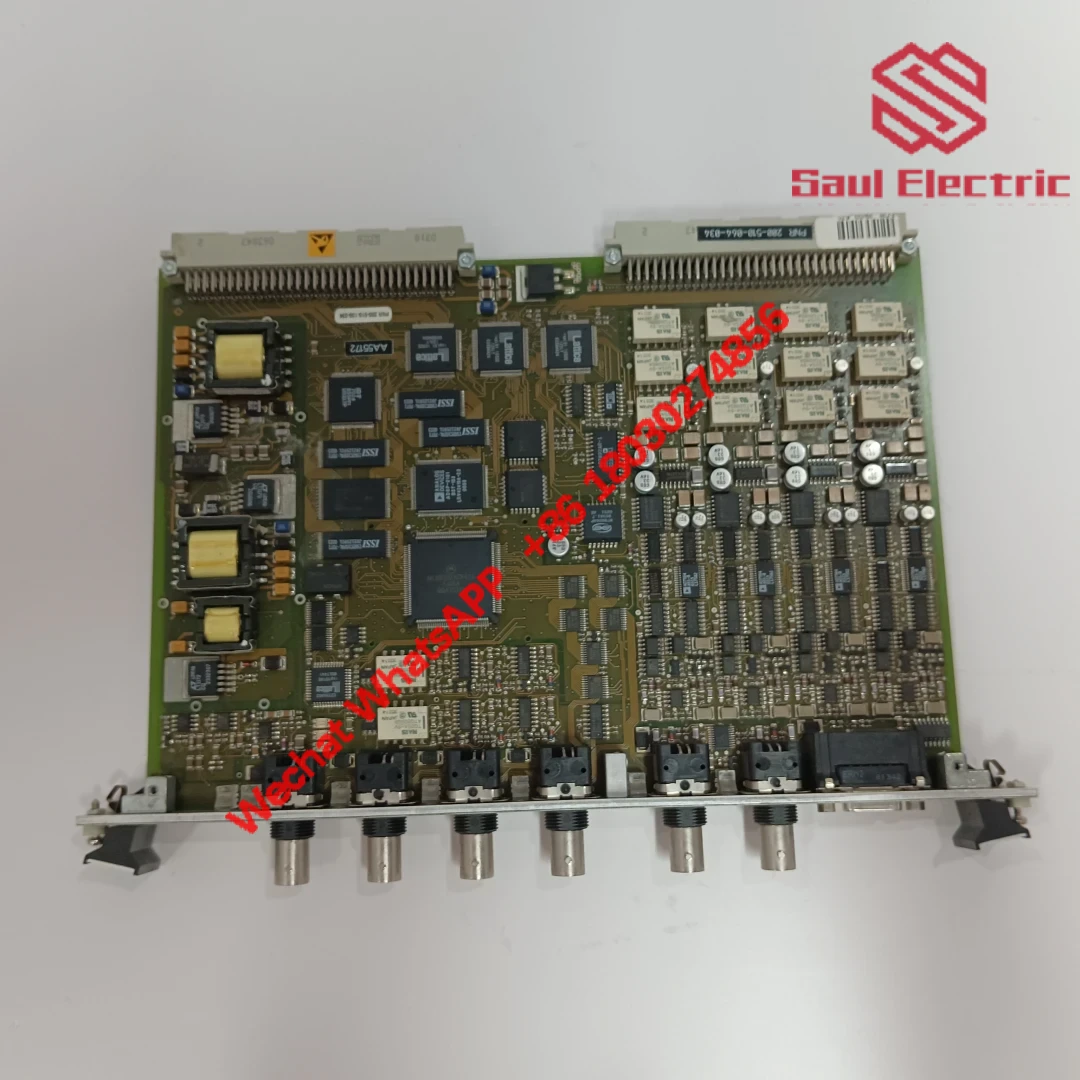

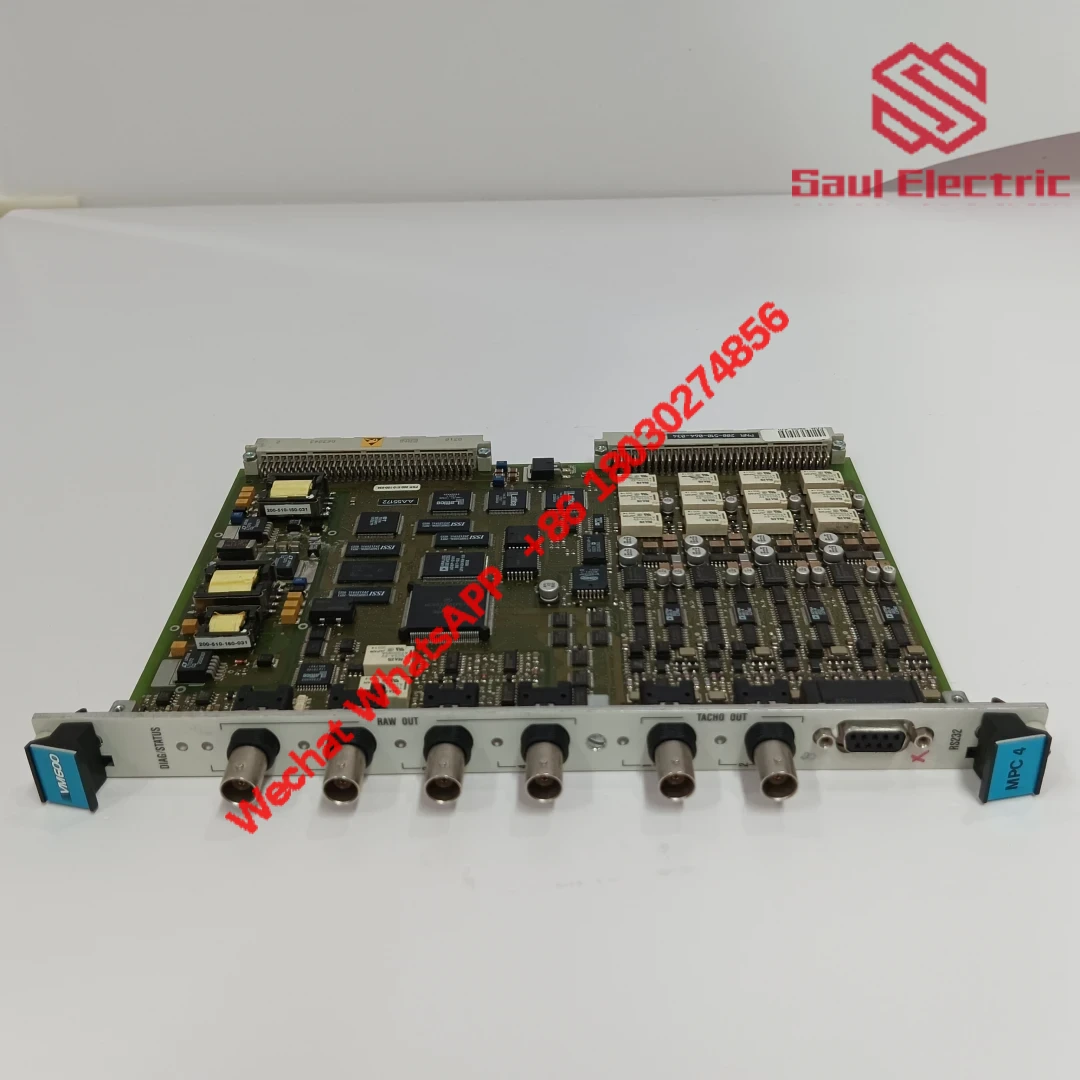

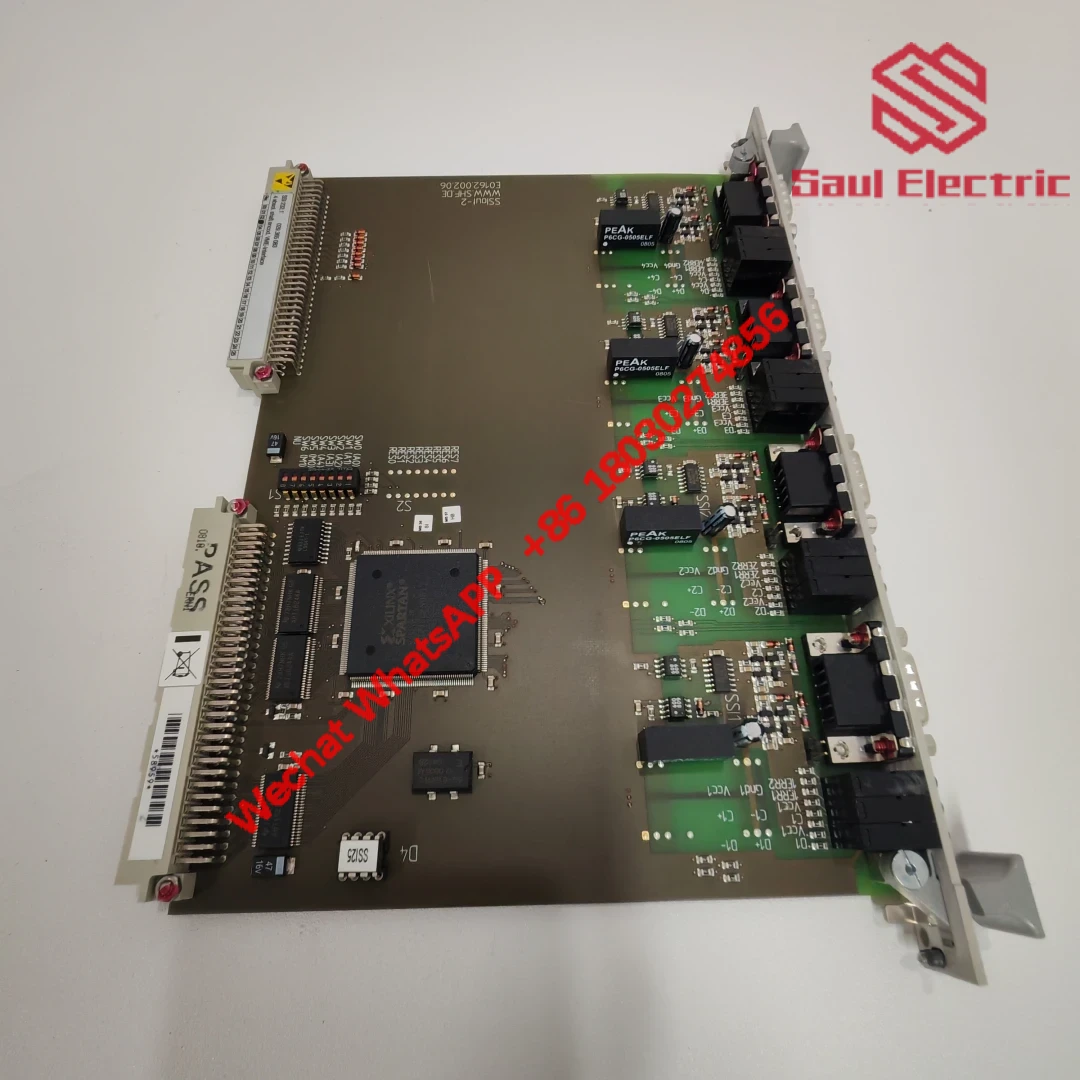

Vibro-Meter VM600 MPC4 200-510-100-034 Mechanical Protection Module

The Vibro-Meter VM600 MPC4 200-510-100-034 serves as a critical component for vibration monitoring in industrial machinery. Designed to protect rotating equipment like turbines, compressors, and pumps, it provides real-time data to prevent catastrophic failures. Engineers in power plants and offshore platforms often rely on this module to maintain operational safety while extending equipment lifespan.

| Parameter | Specification |

|---|---|

| Brand | Vibro-Meter (now part of Baker Hughes) |

| Channels | 4 configurable (vibration/displacement) |

| Signal Compatibility | IEPE, velocity sensors, eddy current probes |

| Output Types | Relay contacts + 4-20mA analog |

| Power Supply | 24V DC via VM600 backplane |

| Operating Temp | -20°C to +65°C |

| Certifications | API 670 compliant (configuration dependent) |

Common applications include steam/gas turbine monitoring in power plants, offshore oil rig compressors, and chemical plant pumps. This module integrates seamlessly with VM600 systems alongside companion cards like the VM600 PWB4 power supply modules and VM600 MPC4 variants (e.g., 200-510-100-035). One customer in Norway reported catching early bearing wear in wind turbines using this module, avoiding $150k+ downtime costs.

The module’s dual-level alarm system (Alert/Danger thresholds) enables proactive maintenance. Channel-to-channel isolation reduces electrical noise interference, a lifesaver in high-EMI environments like refineries. While the 4-20mA output directly interfaces with PLCs/DCS systems, the relay contacts handle emergency shutdown circuits. Fact: I’ve seen this module survive in desert mining operations where daytime temps hit 58°C—well within its 65°C max rating.

Reviews

There are no reviews yet.