Description

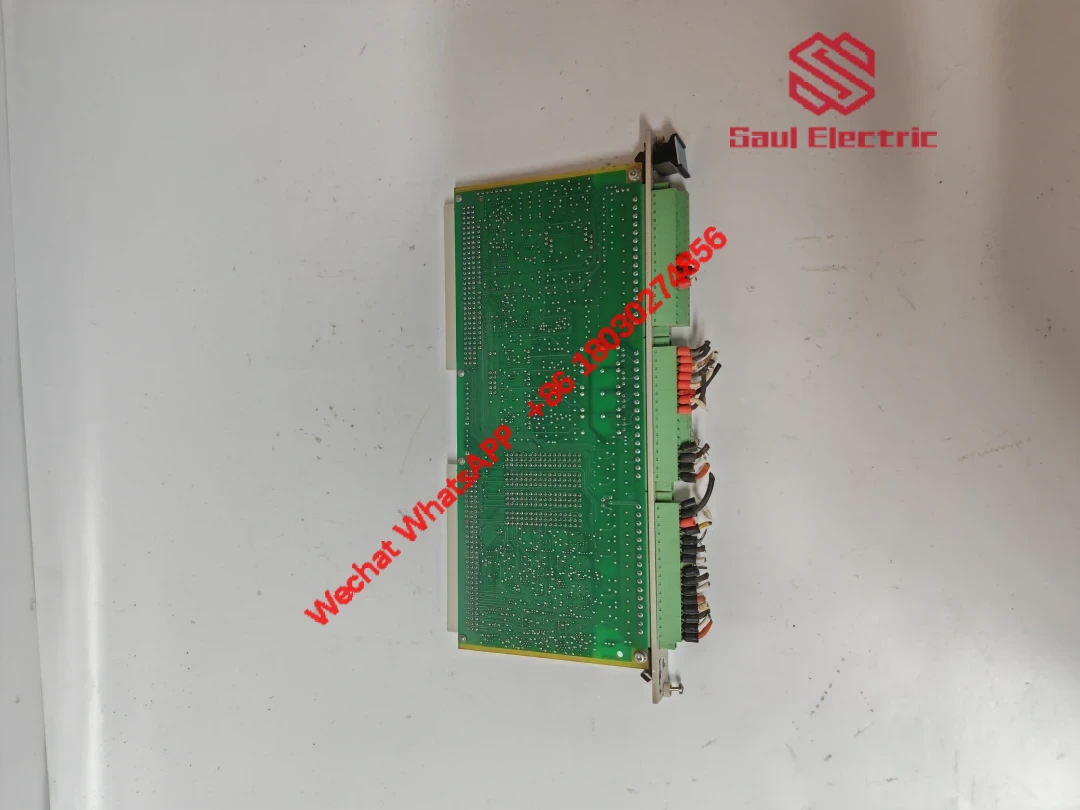

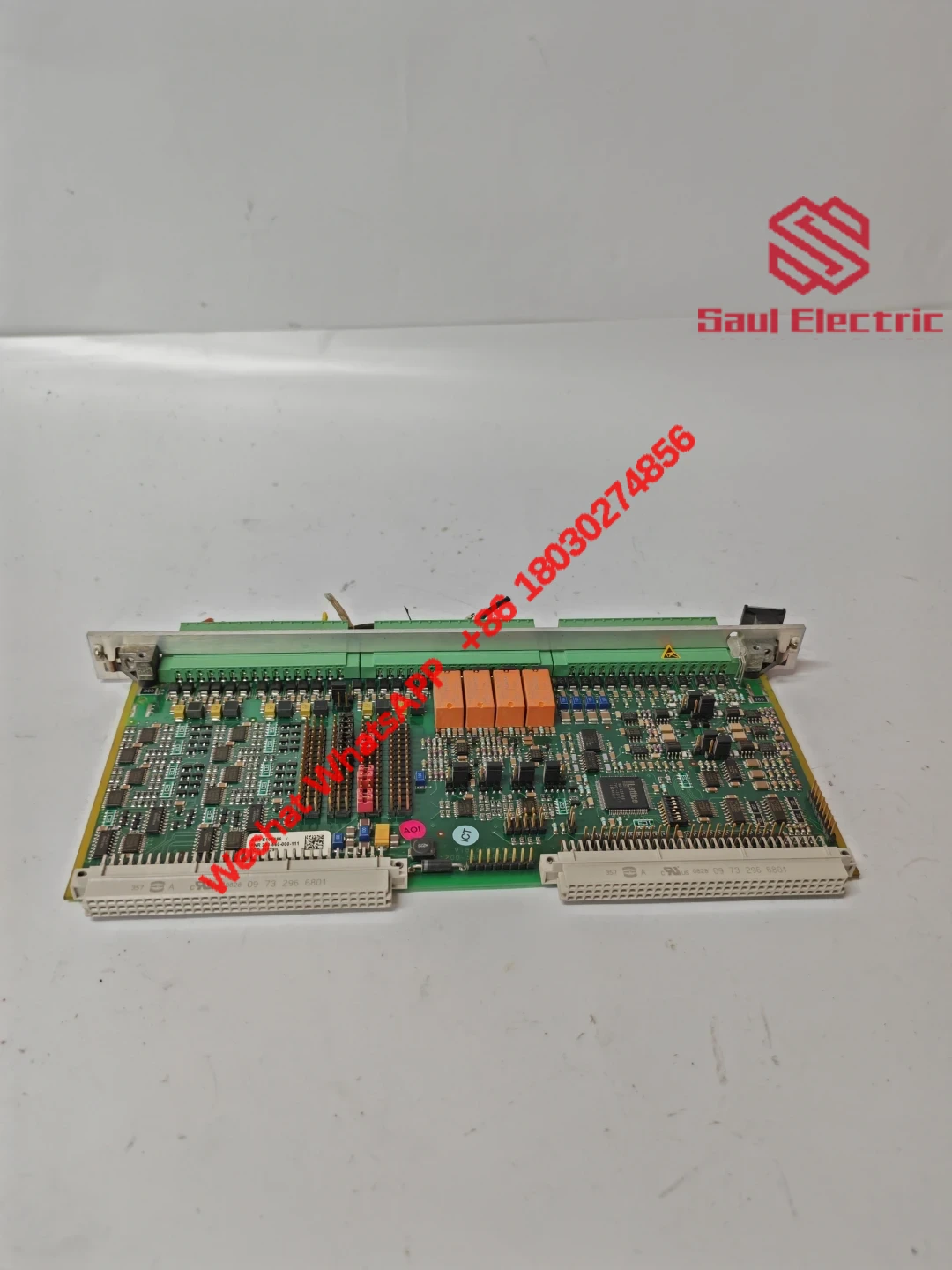

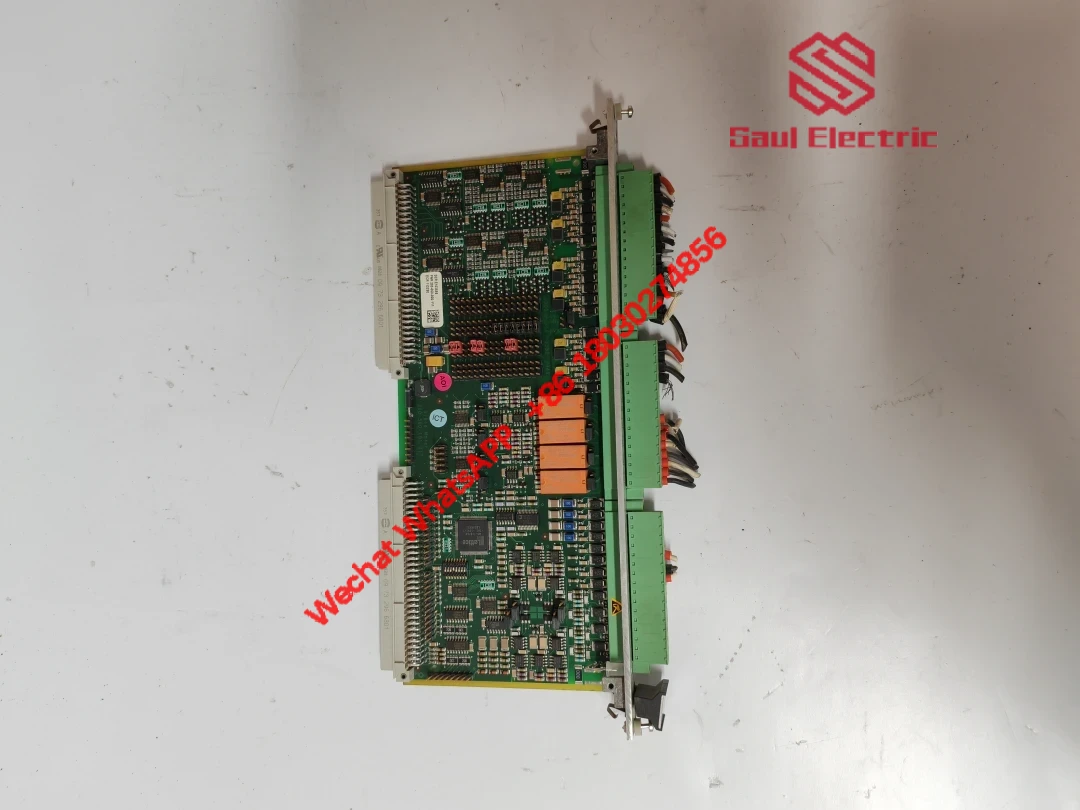

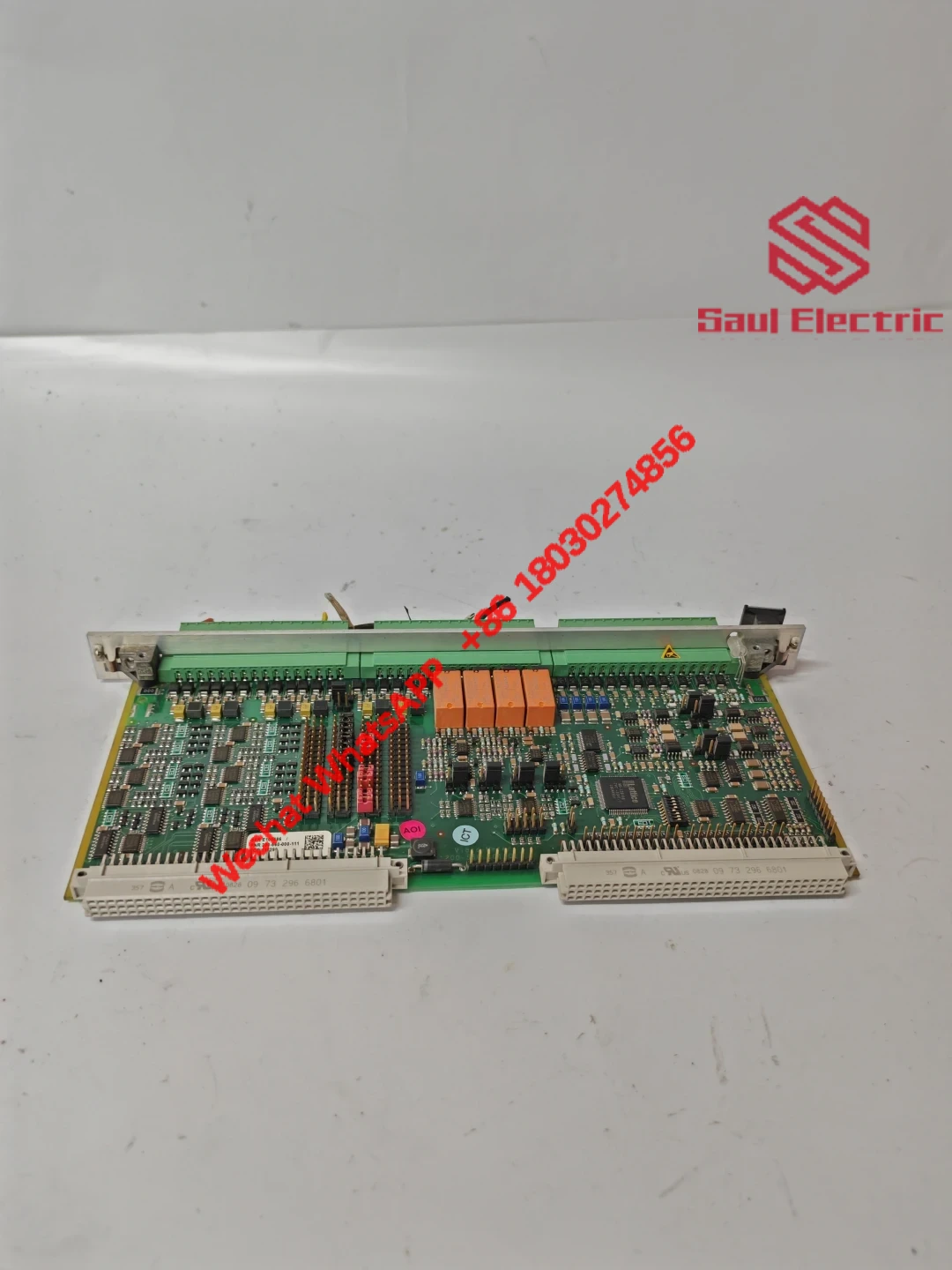

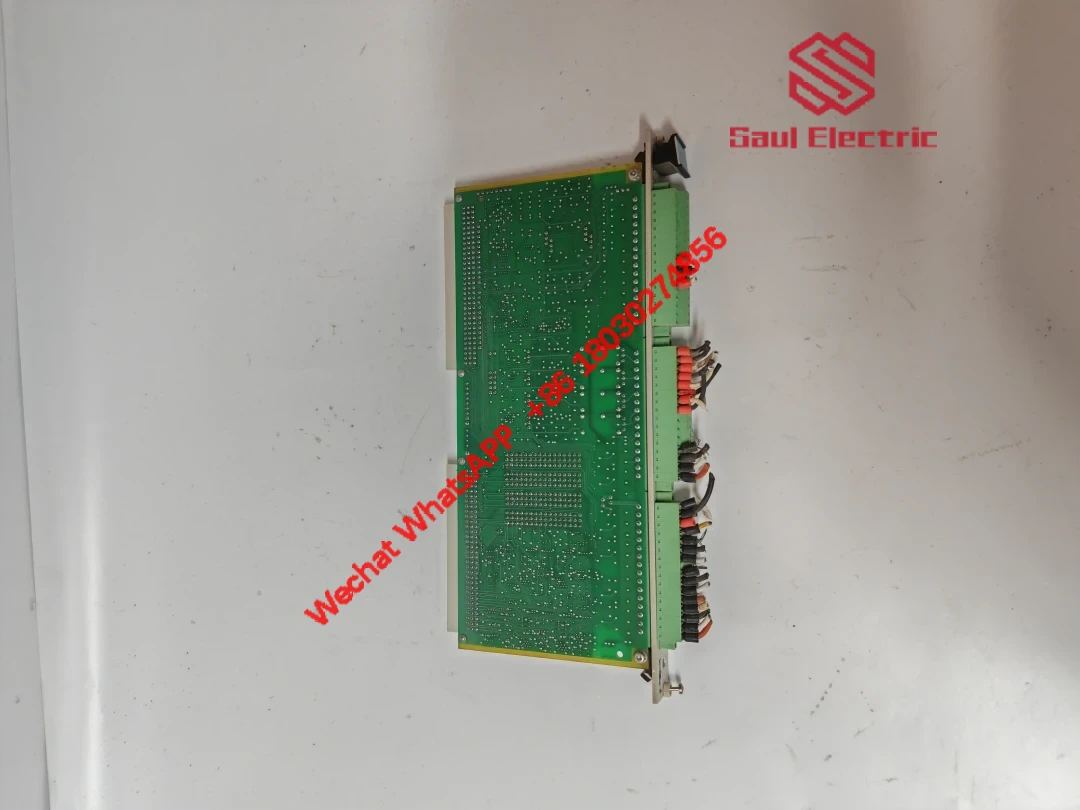

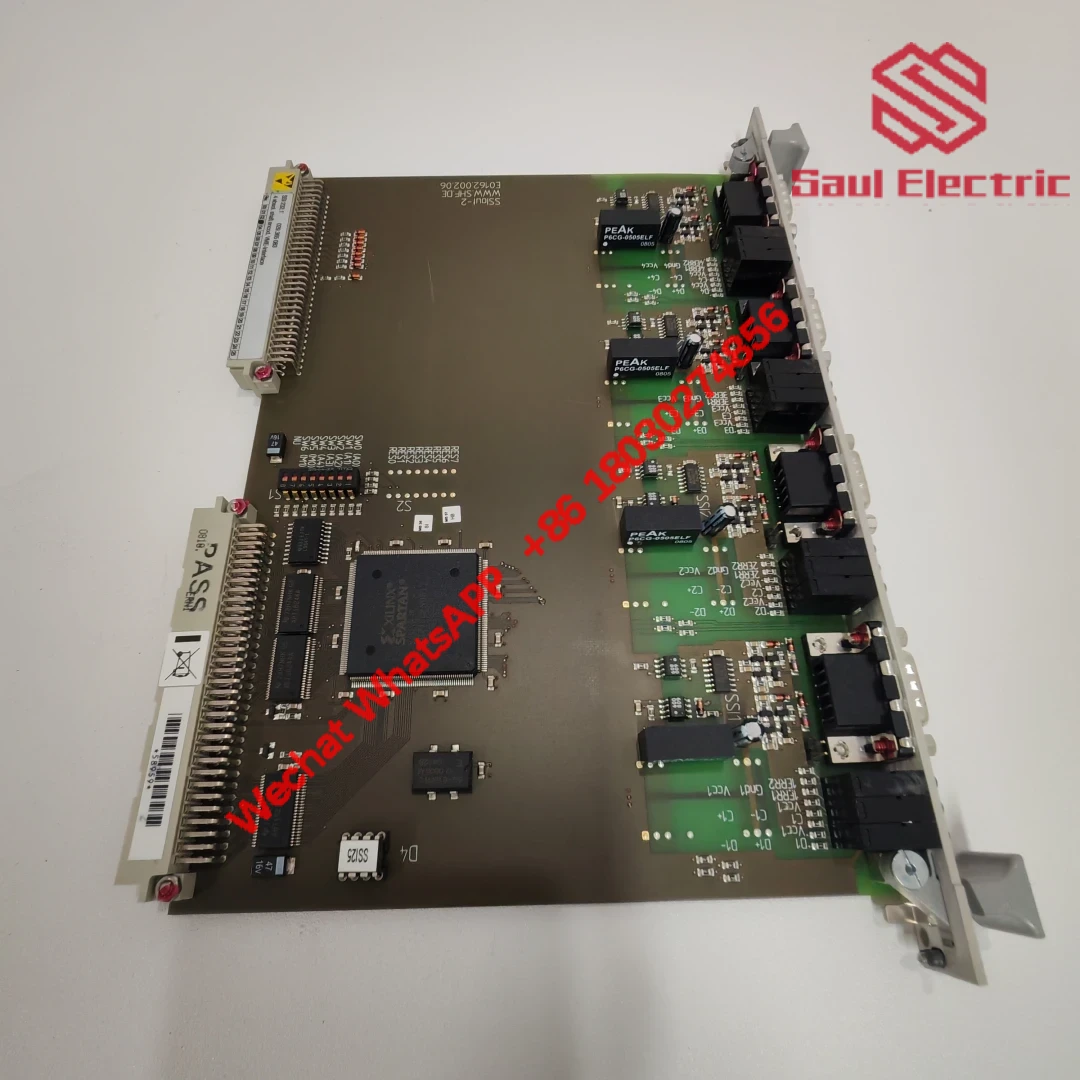

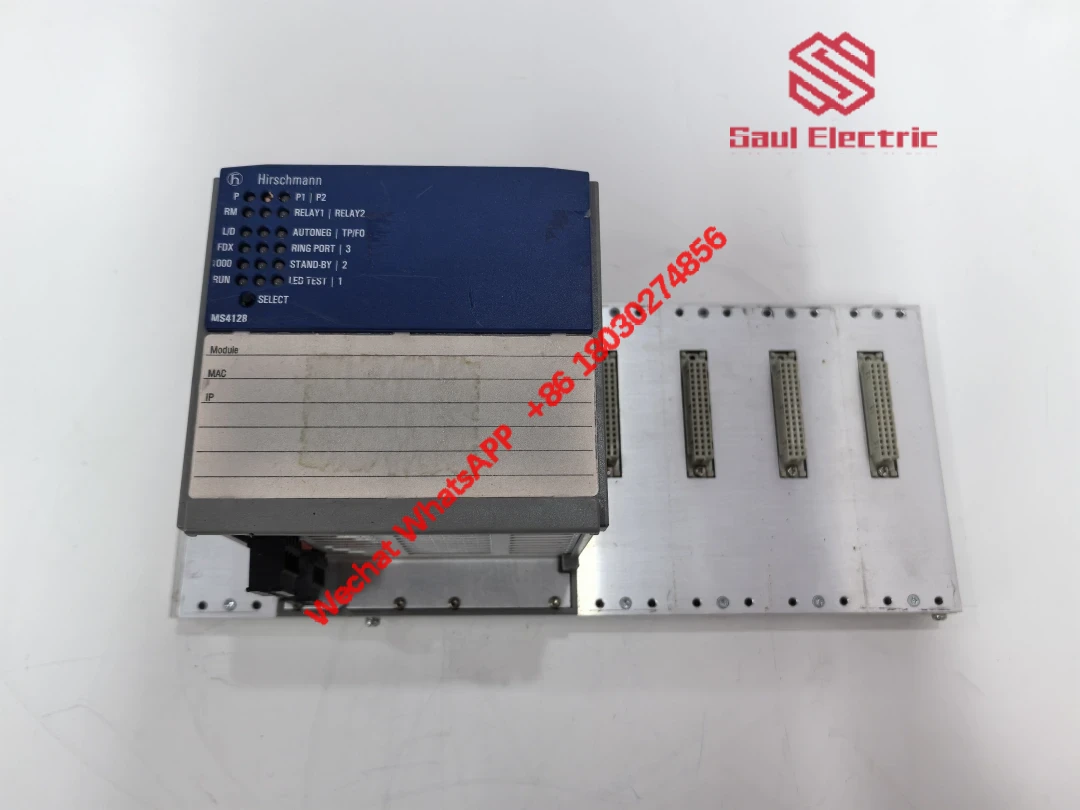

VIBRO-METER VM600 IOC4T Industrial Vibration Meter

The VIBRO-METER VM600 IOC4T industrial vibration meter serves as a critical tool for monitoring mechanical vibrations in turbines, pumps, and compressors. Its primary role lies in identifying early signs of imbalance, misalignment, or bearing wear—helping prevent unplanned downtime in power plants, refineries, and manufacturing facilities.

| Attribute | Specification |

|---|---|

| Brand | VIBRO-METER |

| Operating Voltage | 30 V |

| Frequency Range | 20 Hz – 1 kHz |

| Sensitivity | 1 mV/g |

| Accuracy | ±0.5% FS |

| Dimensions | 168 x 168 x 40 mm |

| Weight | ~1 kg |

Field technicians particularly appreciate its performance in steam turbine monitoring applications. One plant manager reported catching early-stage bearing degradation in a gas compressor—a find that prevented 48 hours of potential downtime. This device integrates seamlessly with Bently Nevada 3500 systems and works alongside GE Fanuc’s VMIVME-7807 modules for hybrid monitoring setups. Common installations include:

- Power generation turbines (gas/steam)

- Refinery centrifugal compressors

- Steel mill rolling mills

- Marine propulsion systems

What sets this unit apart isn’t just its 2 kHz sampling rate, but how it handles real-world conditions. The waterproof housing (IP67 rating) survives direct hose-downs in food processing plants, while the wide temperature tolerance (-20°C to +60°C) keeps it functioning in unconditioned offshore containers. Some key benefits:

- Redundant signal paths prevent single-point failures

- Compatibility with both 4-20mA and digital communication protocols

- Self-diagnostics flagging sensor cable faults

- Modular design enabling field-replaceable components

Personally, I’ve seen its 0.1 mV/g resolution catch subtle misalignments in wind turbine gearboxes that cheaper meters missed. The real-time data stream integrates effortlessly with Emerson OVATION DCS systems through standard Modbus TCP connections.

Reviews

There are no reviews yet.