Description

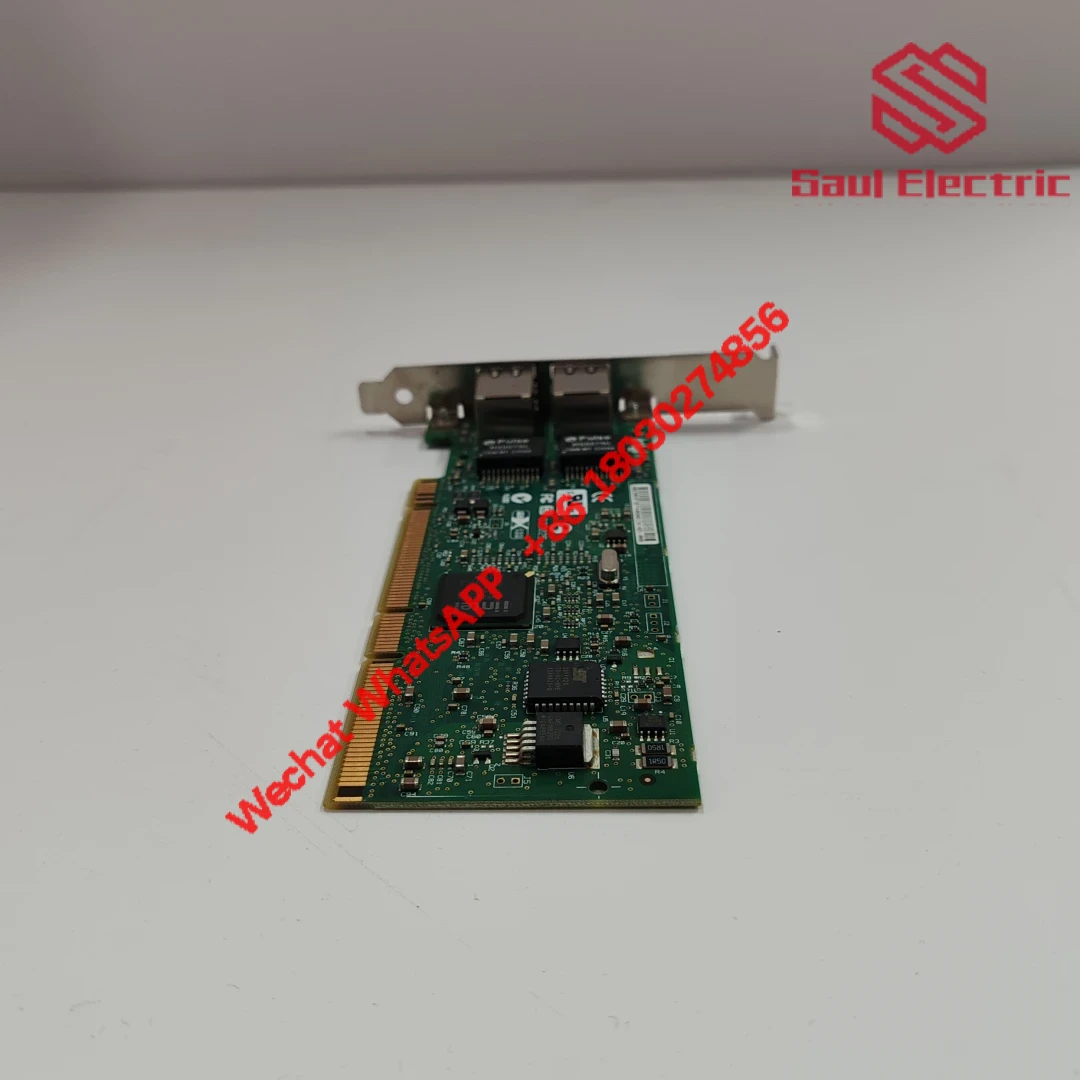

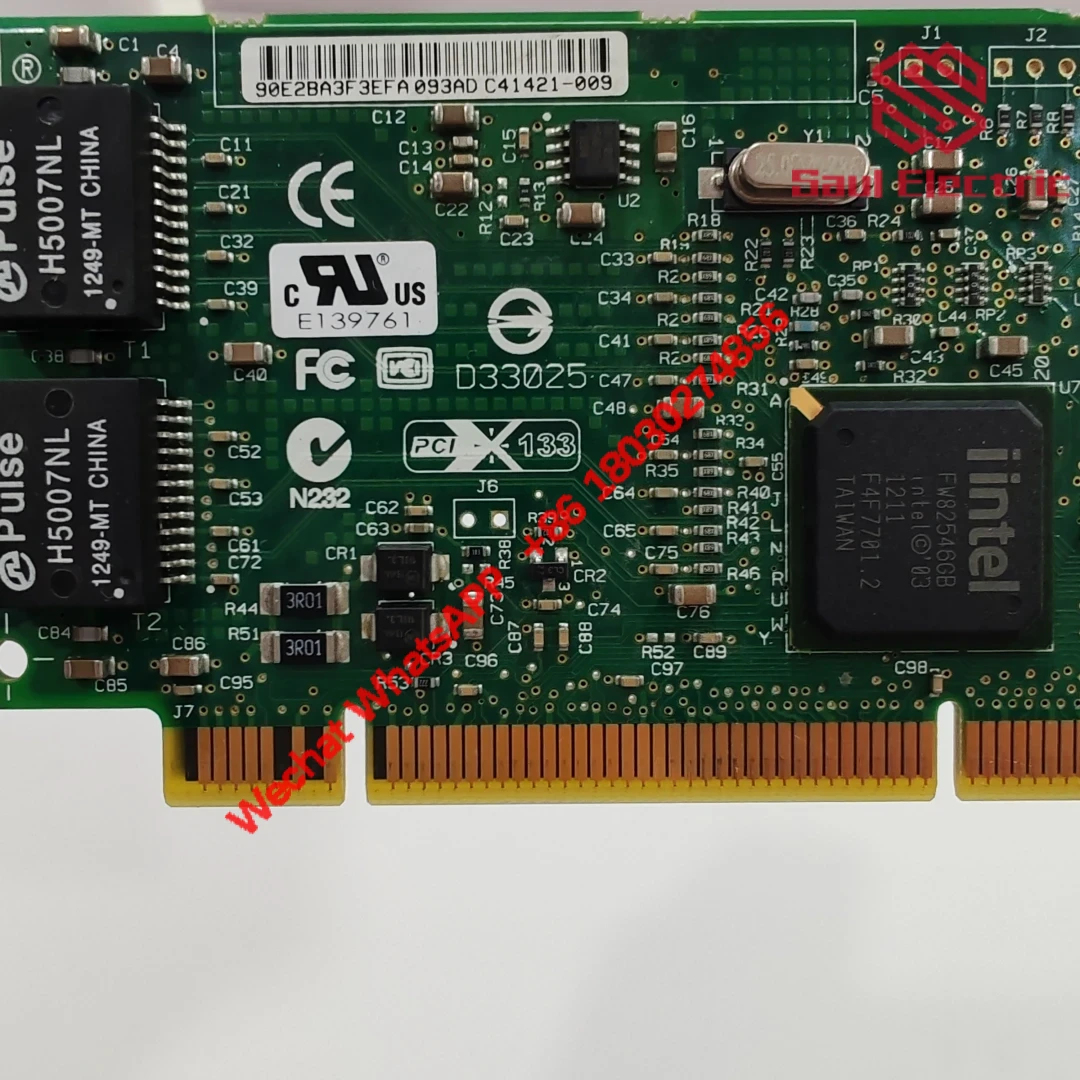

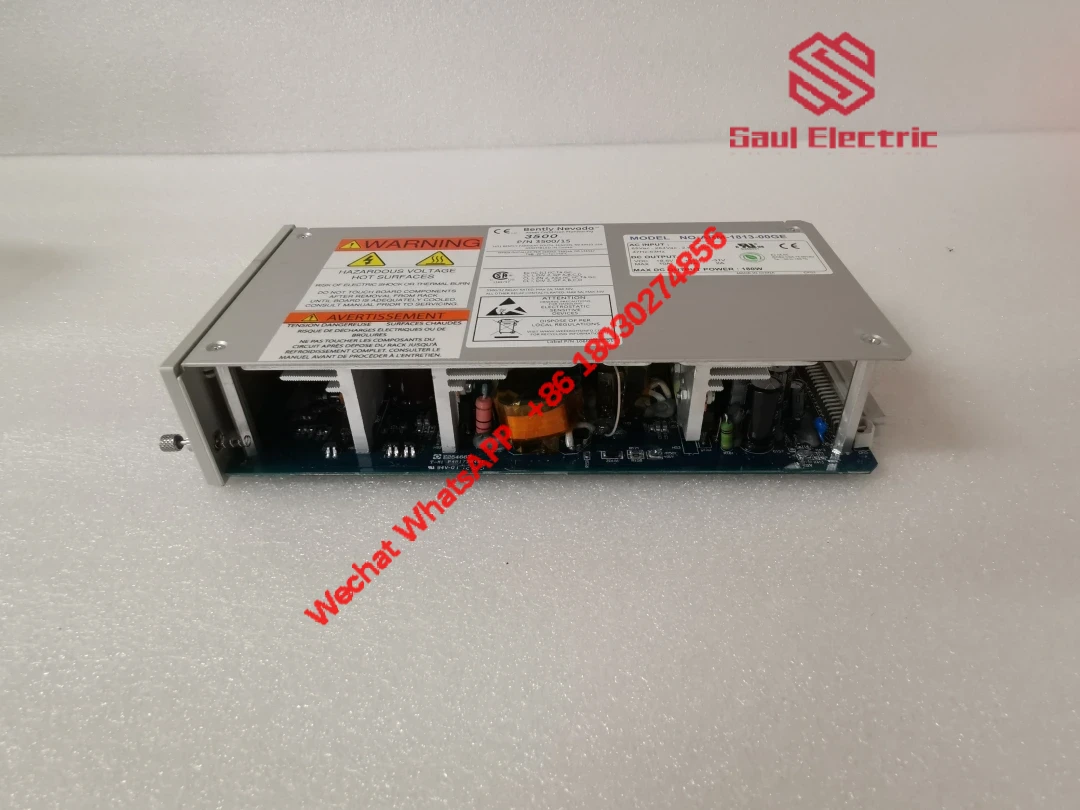

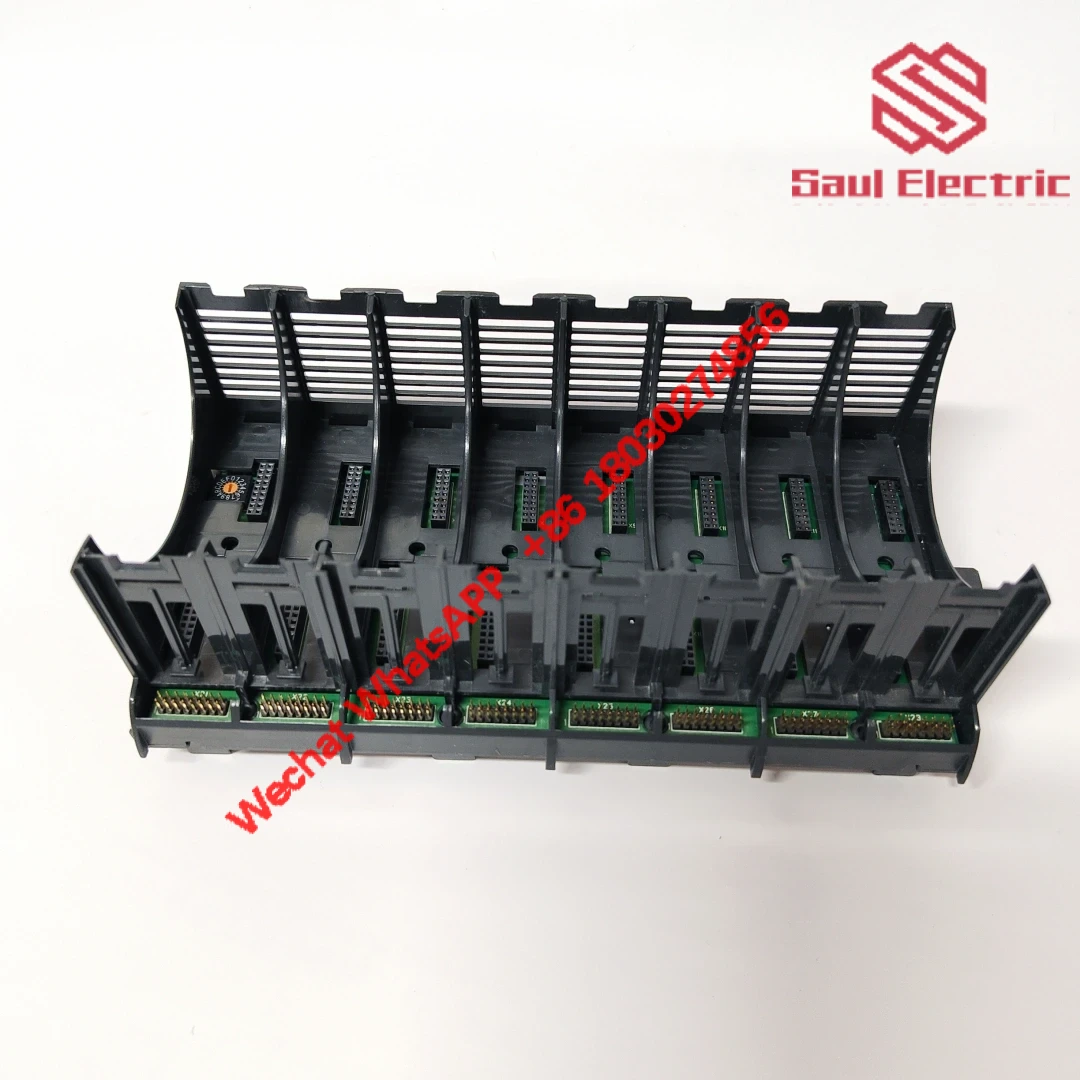

ABB D33025 Industrial Control Module

Engineered for demanding industrial environments, the ABB D33025 control module delivers precise automation management across manufacturing, energy systems, and process control applications. Its robust design handles complex tasks like motor control arrays or sensor data aggregation where reliability under pressure matters most.

| Specification | Details |

|---|---|

| Brand | ABB |

| I/O Channels | 16 in / 16 out |

| Voltage | 24 VDC |

| Protocols | Modbus, CANopen, Ethernet/IP |

| Operating Temp | -20°C to 70°C |

| Certifications | CE, UL, RoHS |

| Dimensions | 120 x 80 x 30 mm |

| Weight | 300g |

Common deployments include automotive assembly lines needing synchronized motion control, power grid monitoring systems tracking voltage fluctuations, and chemical processing plants managing reactor temperatures. We frequently pair this module with complementary ABB hardware like the PM866 controller for turbine management or PP865A communication interfaces in oil & gas operations. Its compact footprint suits retrofitting into legacy machinery while supporting modern Industry 4.0 connectivity standards.

Three communication protocols (Modbus for simple PLC linking, CANopen for motion control networks, and Ethernet/IP for enterprise integration) create versatile system compatibility. The -20°C cold start capability proved crucial for a Canadian mining client’s conveyor controls during winter power cycles. While not explicitly labeled “redundant,” users report configuring dual modules in parallel for critical applications like pharmaceutical sterilization processes requiring 99.999% uptime. CE certification covers electromagnetic compatibility, which helped a European semiconductor factory avoid signal interference issues near high-frequency welders.

Reviews

There are no reviews yet.